Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Boston Eng Info - SpurGears

Caricato da

Mauro TognocchiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Boston Eng Info - SpurGears

Caricato da

Mauro TognocchiCopyright:

Formati disponibili

Engineering Information

Spur Gears

Gear Nomenclature (Continued)

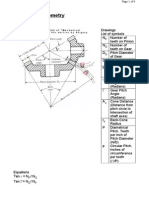

PITCH CIRCLE is the circle derived from a number of teeth ROOT DIAMETER (Dr) is the diameter at the base of the tooth

and a specified diametral or circular pitch. Circle on which space.

spacing or tooth profiles is established and from which the

tooth proportions are constructed. PRESSURE ANGLE—OPERATING (ør) is determined by the

center distance at which the gears operate. It is the pressure

PITCH CYLINDER is the cylinder of diameter equal to the angle at the operating pitch diameter.

pitch circle.

TIP RELIEF is an arbitrary modification of a tooth profile

PINION is a machine part with gear teeth. When two gears whereby a small amount of material is removed near the tip of

run together, the one with the smaller number of teeth is the gear tooth.

called the pinion.

UNDERCUT is a condition in generated gear teeth when any

PITCH DIAMETER (D) is the diameter of the pitch circle. In part of the fillet curve lies inside a line drawn tangent to the

parallel shaft gears, the pitch diameters can be determined working profile at its point of juncture with the fillet.

directly from the center distance and the number of teeth.

WHOLE DEPTH (ht) is the total depth of a tooth space, equal

PRESSURE ANGLE (ø) is the angle at a pitch point between to addendum plus dedendum, equal to the working depth

the line of pressure which is normal to the tooth surface, and plus variance.

the plane tangent to the pitch surface. In involute teeth,

pressure angle is often described also as the angle between WORKING DEPTH (hk) is the depth of engagement of two

the line of action and the line tangent to the pitch circle. gears; that is, the sum of their addendums.

Standard pressure angles are established in connection with

standard gear-tooth proportions.

Tooth Parts

PINION

GEAR

P-1930-BG 7/12 Boston Gear 800-825-6544 299

Engineering Information

Spur Gears

Involute Form

Gear teeth could be manufactured with a wide variety of An involute drawn from a larger base circle will be less curved

shapes and profiles. The involute profile is the most (straighter) than one drawn from a smaller base circle.

commonly used system for gearing today, and all Boston spur Similarly, the involute tooth profile of smaller gears is

and helical gears are of involute form. considerably curved, on larger gears is less curved

(straighter), and is straight on a rack, which is essentially an

An involute is a curve that is traced by a point on a taut cord infinitely large gear.

unwinding from a circle, which is called a BASE CIRCLE. The

involute is a form of spiral, the curvature of which becomes

straighter as it is drawn from a base circle and eventually

would become a straight line if drawn far enough.

Involute gear tooth forms and standard tooth proportions are

specified in terms of a basic rack which has straight-sided

teeth, for involute systems.

20 TEETH 48 TEETH RACK

300 Boston Gear 800-825-6544 P-1930-BG 7/12

Engineering Information

Spur Gears

Diametral Pitch System

All stock gears are made in accordance with the diametral

pitch system. The diametral pitch of a gear is the number of

teeth in the gear for each inch of pitch diameter. Therefore,

the diametral pitch determines the size of the gear tooth.

Pressure Angle

Pressure angle is the angle at a pitch point between the line of

pressure which is normal to the tooth surface, and the plane

tangent to the pitch surface. The pressure angle, as defined in

this catalog, refers to the angle when the gears are mounted on

their standard center distances.

Boston Gear manufactures both 14-1/2° and 20° PA, involute,

full depth system gears. While 20°PA is generally recognized

as having higher load carrying capacity, 14-1/2°PA gears

have extensive use. The lower pressure angle results in less

change in backlash due to center distance variation and

concentricity errors. It also provides a higher contact ratio and

consequent smoother, quieter operation provided that

undercut of teeth is not present.

Tooth dimensions

I

For convenience, Tooth Proportions of various standard

diametral pitches of Spur Gears are given below.

Thickness

of Tooth Depth to be

Circular on Pitch Cut in Gear

Diametral Pitch Line (Inches) Addendum

Pitch (Inches) (Inches) (Hobbed Gears) (Inches)

3 1.0472 .5236 .7190 .3333

4 .7854 .3927 .5393 .2500

5 .6283 .3142 .4314 .2000

6 .5236 .2618 .3565 .1667

8 .3927 .1963 .2696 .1250

10 .3142 .1571 .2157 .1000

12 .2618 .1309 .1798 .0833

16 .1963 .0982 .1348 .0625

20 .1571 .0785 .1120 .0500

24 .1309 .0654 .0937 .0417

32 .0982 .0491 .0708 .0312

48 .0654 .0327 .0478 .0208

64 .0491 .0245 .0364 .0156

P-1930-BG 7/12 Boston Gear 800-825-6544 301

Engineering Information

Spur Gears

Backlash Spur Gear Formulas

Stock spur gears are cut to operate at standard center FOR FULL DEPTH INVOLUTE TEETH

distances. The standard center distance being defined by:

Standard Center Distance = Pinion PD + Gear PD

2

When mounted at this center distance, stock spur gears will To Obtain Having Formula

have the following average backlash: Circular Pitch (p) P = 3.1416

p

Diametral Backlash Diametral Backlash Diametral Pitch (P) Number of Teeth (N) & P = N

Pitch (Inches) Pitch (Inches) Pitch Diameter (D) D

Number of Teeth (N) & P = N + 2

3 .013 8-9 .005 (Approx.)

Outside Diameter (Do) Do

4 .010 10-13 .004

5 .008 14-32 .003 Circular Pitch (p) Diametral Pitch (P) p = 3.1416

P

6 .007 33-64 .0025 Number of Teeth (N) & D = N

7 .006 Pitch Diameter (D) Diametral Pitch (P) P

Outside Diameter (Do) &

An increase or decrease in center distance will cause an D = Do – 2

Diametral Pitch (P) P

increase or decrease in backlash. Pitch Diameter (D) and Db = Dcosø

Base Diameter (Db)

Since, in practice, some deviation from the theoretical Pressure Angle (ø)

standard center distance is inevitable and will alter the Diametral Pitch (P) &

Number of Teeth (N) N=PxD

backlash, such deviation should be as small as possible. For Pitch Diameter (D)

most applications, it would be acceptable to limit the Tooth Thickness (t) Diametral Pitch (P) t = 1.5708

deviation to an increase over the nominal center distance of @Pitch Diameter (D) P

one half the average backlash. Varying the center distance 1

Addendum (a) Diametral Pitch (P) a=

may afford a practical means of varying the backlash to a P

limited extent. Outside Pitch Diameter (D) & Do = D + 2a

The approximate relationship between center distance and Diameter (Do) Addendum (a)

backlash change of 14-1/2° and 20° pressure angle gears is Whole Depth (ht)

Diametral Pitch (P) ht = 2.2 + .002

shown below: (20P & Finer) P

Whole Depth (ht)

For 14-1/2°–Change in Center Distance = 1.933 x Change in Backlash Diametral Pitch (P) ht = 2.157

For 20° –Change in Center Distance = 1.374 x Change in Backlash (Courser than 20P) P

Working Depth (h k) Addendum (a) hk = 2(a)

From this, it is apparent that a given change in center

Whole Depth (ht)

distance, 14-1/2° gears will have a smaller change in Clearance (c) c = ht – 2a

Addendum (a)

backlash than 20° gears. This fact should be considered in

Whole Depth (ht) &

cases where backlash is critical. Dedendum (b) b = ht – a

Addendum (a)

Outside Radii, Base

Undercut Contact Ratio (Mc) Radii, Center Distance

and Pressure Angle+C.P.

When the number of teeth in a gear is small, the tip of the

I

mating gear tooth may interfere with the lower portion of the

tooth profile. To prevent this, the generating process removes

material at this point. This results in loss of a portion of the

involute adjacent to the tooth base, reducing tooth contact and Root Diameter (Dr) Pitch Diameter (D) Dr = D – 2b

tooth strength. and Dedendum (b)

On 14-1/2°PA gears undercutting occurs where a number of Pitch Diameter (D) or C = D1 + D2

Center Distance (C)

teeth is less than 32 and for 20°PA less than 18. Since this No. of Teeth and Pitch 2

condition becomes more severe as tooth numbers decrease, or N1 + N2

it is recommended that the minimum number of teeth be 16 2P

for 14-1/2°PA and 13 for 20°PA.

In a similar manner INTERNAL Spur Gear teeth may interfere *Ro = Outside Radius, Gear

when the pinion gear is too near the size of its mating internal ro = Outside Radius, Pinion

gear. The following may be used as a guide to assure proper Rb = Base Circle Radius, Gear

operation of the gear set. For 14-1/2°PA, the difference in rb = Base Circle Radius, Pinion

tooth numbers between the gear and pinion should not be

less than 15. For 20°PA the difference in tooth numbers

should not be less than 12.

302 Boston Gear 800-825-6544 P-1930-BG 7/12

Engineering Information

Spur Gears

Lewis Formula (Barth Revision) TABLE II–VALUES OF SAFE STATIC STRESS (s)

Gear failure can occur due to tooth breakage (tooth stress) or

Material (s) Lb. per Sq. In.

surface failure (surface durability) as a result of fatigue and

Plastic ........................................................................ 5000

wear. Strength is determined in terms of tooth-beam stresses

Bronze ........................................................................ 10000

for static and dynamic conditions, following well established

Cast Iron ..................................................................... 12000

{

formula and procedures. Satisfactory results may be obtained

.20 Carbon (Untreated) ................................... 20000

by the use of Barth’s Revision to the Lewis Formula, which

.20 Carbon (Case-hardened) .......................... 25000

considers beam strength but not wear. The formula is

Steel .40 Carbon (Untreated) ................................... 25000

satisfactory for commercial gears at Pitch Circle velocities of

.40 Carbon (Heat-treated)............................... 30000

up to 1500 FPM. It is this formula that is the basis for all Boston

.40 C. Alloy (Heat-treated) .............................. 40000

Spur Gear ratings.

METALLIC SPUR GEARS

Max. allowable torque (T) that should be imposed on a gear

will be the safe tooth load (W) multiplied by D or T = W x D

2 2

W = Tooth Load, Lbs. (along the Pitch Line) The safe horsepower capacity of the gear (at a given RPM) can

S = Safe Material Stress (static) Lbs. per Sq. In. (Table II)

F = Face Width, In. be calculated from HP = T x RPM or directly from (W) and (V);

63,025

Y = Tooth Form Factor (Table I) WV

P = Diametral Pitch HP =

33,000

D = Pitch Diameter

V = Pitch Line Velocity, Ft. per Min. = .262 x D x RPM For a known HP, T = 63025 x HP

RPM

For NON-METALLIC GEARS, the modified Lewis Formula

shown below may be used with (S) values of 6000 PSI for

Phenolic Laminated material.

TABLE I TOOTH FORM FACTOR (Y)

14-1/2° Full 20° Full

Number of Teeth Depth Involute Depth Involute

10 0.176 0.201

11 0.192 0.226

12 0.210 0.245

13 0.223 0.264

14 0.236 0.276

15 0.245 0.289

16 0.255 0.295

I

17 0.264 0.302

18 0.270 0.308

19 0.277 0.314

20 0.283 0.320

22 0.292 0.330

24 0.302 0.337

26 0.308 0.344

28 0.314 0.352

30 0.318 0.358

32 0.322 0.364

34 0.325 0.370

36 0.329 0.377

38 0.332 0.383

40 0.336 0.389

45 0.340 0.399

50 0.346 0.408

55 0.352 0.415

60 0.355 0.421

65 0.358 0.425

70 0.360 0.429

75 0.361 0.433

80 0.363 0.436

90 0.366 0.442

100 0.368 0.446

150 0.375 0.458

200 0.378 0.463

300 0.382 0.471

Rack 0.390 0.484

P-1930-BG 7/12 Boston Gear 800-825-6544 303

Potrebbero piacerti anche

- Engineering Information: Spur GearsDocumento6 pagineEngineering Information: Spur GearsLuis MarcosNessuna valutazione finora

- Chapter 05Documento15 pagineChapter 05Muhammad Nur IkhwanNessuna valutazione finora

- Gears, Splines, and Serrations: Unit 24Documento8 pagineGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- CH08 2Documento52 pagineCH08 2abdallah ghannamNessuna valutazione finora

- The ABCs of Gears - BDocumento49 pagineThe ABCs of Gears - BDavid Mejido0% (1)

- Parametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachDocumento5 pagineParametric Modelling of Straight Bevel Gearing System and Analyze The Forces and Stresses by Analytical ApproachseventhsensegroupNessuna valutazione finora

- Gear Notes - SlideDocumento19 pagineGear Notes - SlideNEF RIDERSNessuna valutazione finora

- Basic Gear Terminology and Calculation - KHK GearsDocumento8 pagineBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaNessuna valutazione finora

- Involute Gear ProfileDocumento8 pagineInvolute Gear ProfiledressfeetNessuna valutazione finora

- Basic Gear Terminology and Calculation - KHK GearsDocumento10 pagineBasic Gear Terminology and Calculation - KHK GearsJoab Max Apaza MartinezNessuna valutazione finora

- Inventor-Gears - Jeffery J Jensen Wiki PDFDocumento30 pagineInventor-Gears - Jeffery J Jensen Wiki PDFEndalkachew Abate100% (1)

- Kom Gear TerminologyDocumento3 pagineKom Gear Terminologydhilip_sacetNessuna valutazione finora

- Optimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoDocumento7 pagineOptimal Gear Design For Medical Applications: Alexander L. Kapelevich Akgears, LLC, Thomas M. Mcnamara Thermotech CoAvinash KumarNessuna valutazione finora

- Direct Gear DesignDocumento7 pagineDirect Gear DesignFranco Angelo RegenciaNessuna valutazione finora

- Gear Heel Pitch DiameterDocumento5 pagineGear Heel Pitch DiameterMadnutsNessuna valutazione finora

- Gear Tooth Thickness MeasurmentDocumento7 pagineGear Tooth Thickness MeasurmentYohannes Mengistu AbebeNessuna valutazione finora

- Gear Theory 1Documento164 pagineGear Theory 1suneel kumar rathoreNessuna valutazione finora

- Basic Gear Terminology and Calculation - KHK Gears PDFDocumento8 pagineBasic Gear Terminology and Calculation - KHK Gears PDFMinhas ArshadNessuna valutazione finora

- Project Report Manufacturing Process and Design of Machine Elements Gear BoxDocumento23 pagineProject Report Manufacturing Process and Design of Machine Elements Gear BoxNisarg PatelNessuna valutazione finora

- Design of Spur Gear - Fundamentals - 1Documento19 pagineDesign of Spur Gear - Fundamentals - 1Dhyan PatelNessuna valutazione finora

- Chain Drive and Conveyor Applications Roller Chain Drive DesignDocumento40 pagineChain Drive and Conveyor Applications Roller Chain Drive DesignHariNessuna valutazione finora

- Elements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasDocumento13 pagineElements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasRakeshvb10Nessuna valutazione finora

- Basic Gear Terminology and CalculationDocumento10 pagineBasic Gear Terminology and CalculationTesseract spyderNessuna valutazione finora

- Design of GearsDocumento64 pagineDesign of GearsFauiqe Yousaf100% (1)

- Gears - General: Shigley's Mechanical Engineering DesignDocumento229 pagineGears - General: Shigley's Mechanical Engineering DesignbasitNessuna valutazione finora

- Spur Gears Are The Most Common Type of GearsDocumento9 pagineSpur Gears Are The Most Common Type of GearsEngineering ProjectNessuna valutazione finora

- Definition of Spur Gear - A Gearwheel With Teeth Projecting Parallel To The Wheel's Axis. Nomenclature of Spur GearDocumento6 pagineDefinition of Spur Gear - A Gearwheel With Teeth Projecting Parallel To The Wheel's Axis. Nomenclature of Spur GearMichael Angelo ComediaNessuna valutazione finora

- DJJ 10033-Chapter 5Documento45 pagineDJJ 10033-Chapter 5Abbas SeuNessuna valutazione finora

- Design of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentDocumento37 pagineDesign of Machine Elements-II: Lecture By: - Engr Aakash Munsif Mechanical Engineering DepartmentMuhammad Mubashar FareedNessuna valutazione finora

- Toothed GearingDocumento33 pagineToothed GearingpvkkrNessuna valutazione finora

- Sprockets CatalogueDocumento164 pagineSprockets Cataloguemore cars , more passionNessuna valutazione finora

- Design of Spur GearsDocumento29 pagineDesign of Spur GearsAishwarya RameshNessuna valutazione finora

- Group 3 (Gears)Documento52 pagineGroup 3 (Gears)CherrydhelNessuna valutazione finora

- 2 - 3 Involute Spur Gear 1Documento13 pagine2 - 3 Involute Spur Gear 1jiteshpaul100% (1)

- How To Measure The Pressure Angle of A Physical Spur GearDocumento16 pagineHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- ME 308 Machine Elements Ii: 26.04.2012 Chapter 5 Spur Gears 1Documento31 pagineME 308 Machine Elements Ii: 26.04.2012 Chapter 5 Spur Gears 1Nihat YildirimNessuna valutazione finora

- Hypoid Gears With Involute Teeth: David B. DoonerDocumento6 pagineHypoid Gears With Involute Teeth: David B. DoonerLibardo Cardenas PNessuna valutazione finora

- Gear MillingDocumento54 pagineGear MillingMichael Castro AbuduNessuna valutazione finora

- Gear Measurements:-Mechanical Measurements and MetrologyDocumento4 pagineGear Measurements:-Mechanical Measurements and Metrologykathir drayNessuna valutazione finora

- Gear Drawing PDFDocumento12 pagineGear Drawing PDFpradeep315Nessuna valutazione finora

- Rack and PinionDocumento16 pagineRack and PinionjeronimoisraelNessuna valutazione finora

- GearsDocumento70 pagineGearsJayesh NayakantiNessuna valutazione finora

- Design II MDE 221 Mott CH 8 and CH 9 Spur GearsDocumento42 pagineDesign II MDE 221 Mott CH 8 and CH 9 Spur GearsThieroy PelendaNessuna valutazione finora

- 5.0 GearsDocumento9 pagine5.0 GearsMaggy IrunguNessuna valutazione finora

- M 275 ContentDocumento40 pagineM 275 ContentAnonymous DQ4wYUmNessuna valutazione finora

- GearDocumento31 pagineGearzaheer100% (2)

- Sprocket Blank Diameter Calculator (Version 02 - 09/09/2008) Author: Douglas AndersonDocumento5 pagineSprocket Blank Diameter Calculator (Version 02 - 09/09/2008) Author: Douglas AndersonAshokNessuna valutazione finora

- Gears Very BasicDocumento5 pagineGears Very BasicpetsatNessuna valutazione finora

- Design of Spur GearDocumento67 pagineDesign of Spur GearShubham DhurjadNessuna valutazione finora

- Spline DesignDocumento5 pagineSpline DesignRuchira Chanda Indu100% (2)

- Xtek Gear TerminologyDocumento4 pagineXtek Gear TerminologyMc AxNessuna valutazione finora

- Bevel ExplanationDocumento4 pagineBevel ExplanationVarun VaidyaNessuna valutazione finora

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDa EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsValutazione: 5 su 5 stelle5/5 (1)

- Speed Changers, Drives & Gears World Summary: Market Values & Financials by CountryDa EverandSpeed Changers, Drives & Gears World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDa EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNessuna valutazione finora

- DynapumpsDocumento2 pagineDynapumpsMauro TognocchiNessuna valutazione finora

- DOE Chilled Water System Analysis ToolDocumento2 pagineDOE Chilled Water System Analysis ToolMauro TognocchiNessuna valutazione finora

- DANFOSS Optimize Superheat ControlDocumento7 pagineDANFOSS Optimize Superheat ControlMauro TognocchiNessuna valutazione finora

- Measuring and Monitoring The Efficiency of Central Chiller PlantsDocumento14 pagineMeasuring and Monitoring The Efficiency of Central Chiller PlantsMauro TognocchiNessuna valutazione finora

- DANFOSS Electronic Expansion ValvesDocumento10 pagineDANFOSS Electronic Expansion ValvesMauro TognocchiNessuna valutazione finora

- Energy Efficiency Optimization of Coal Conveying SystemsDocumento9 pagineEnergy Efficiency Optimization of Coal Conveying SystemsMauro TognocchiNessuna valutazione finora

- Solufore Fitting System Material SelectionDocumento13 pagineSolufore Fitting System Material SelectionMauro TognocchiNessuna valutazione finora

- DNV 301Documento70 pagineDNV 301Mauro TognocchiNessuna valutazione finora

- Full Paper 341Documento11 pagineFull Paper 341Mauro TognocchiNessuna valutazione finora

- OSHA Standard 29 CFRDocumento4 pagineOSHA Standard 29 CFRMauro TognocchiNessuna valutazione finora

- Bin Activator Palamatic ProcessDocumento1 paginaBin Activator Palamatic ProcessMauro TognocchiNessuna valutazione finora

- SoluForce General Brochure 02 2020Documento15 pagineSoluForce General Brochure 02 2020Mauro TognocchiNessuna valutazione finora

- Factors PDFDocumento8 pagineFactors PDFMauro TognocchiNessuna valutazione finora

- Artificial Demand in PneumaticsDocumento6 pagineArtificial Demand in PneumaticsMauro TognocchiNessuna valutazione finora

- Demand Side Check 1Documento4 pagineDemand Side Check 1Mauro TognocchiNessuna valutazione finora

- Parker Pneumatic ATEX Components Catalogue PDE2584TCUKDocumento64 pagineParker Pneumatic ATEX Components Catalogue PDE2584TCUKMauro TognocchiNessuna valutazione finora

- p1v A p1v B Pneumatic Air Motors Catalogue PDFDocumento52 paginep1v A p1v B Pneumatic Air Motors Catalogue PDFMauro TognocchiNessuna valutazione finora

- Guide To The Types and Sizes of Dry Cargo and Tanker ShipsDocumento20 pagineGuide To The Types and Sizes of Dry Cargo and Tanker ShipsMauro TognocchiNessuna valutazione finora

- Python LAB Exercises: Sample OutputDocumento2 paginePython LAB Exercises: Sample OutputMadhu Priya Guthi100% (1)

- Fire Risk of Cold Room PanelDocumento6 pagineFire Risk of Cold Room Paneldarby1028Nessuna valutazione finora

- Uncoated SteelDocumento2 pagineUncoated SteelBui Chi TamNessuna valutazione finora

- ASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFDocumento2 pagineASSEMBLY AND PARTS ALBUM - Kipor Power Systems - KDE6700TA PDFracsoNessuna valutazione finora

- Alternative Sources of EnergyDocumento6 pagineAlternative Sources of EnergykageNessuna valutazione finora

- 02 February 1990Documento108 pagine02 February 1990Monitoring TimesNessuna valutazione finora

- Hangzhou Chenrui Air Separator Installation Manufacture CO., LTDDocumento10 pagineHangzhou Chenrui Air Separator Installation Manufacture CO., LTDTonyNessuna valutazione finora

- Is 13134Documento14 pagineIs 13134Sowjanya ChNessuna valutazione finora

- H 012200 Barame Sho Man 2Documento2 pagineH 012200 Barame Sho Man 2Obande OrinyaNessuna valutazione finora

- VSL 2024 Course List and Loan Caps (Students)Documento14 pagineVSL 2024 Course List and Loan Caps (Students)ashishkumar777Nessuna valutazione finora

- ELEG 270 Electronics: Dr. Ali BostaniDocumento25 pagineELEG 270 Electronics: Dr. Ali BostanigigiNessuna valutazione finora

- NSX Battle Card - FinalDocumento2 pagineNSX Battle Card - FinalElias Bezulle100% (1)

- Contoh Program Penjumlahan Dan PengurangDocumento5 pagineContoh Program Penjumlahan Dan Pengurangabdul hakimNessuna valutazione finora

- EXCEL To Tally LeggerImport-ok - 2Documento7 pagineEXCEL To Tally LeggerImport-ok - 2Mukesh MakadiaNessuna valutazione finora

- BUTLER 1924 PAPER Studies in Heterogeneous EquilibriaDocumento6 pagineBUTLER 1924 PAPER Studies in Heterogeneous Equilibriaglen19Nessuna valutazione finora

- LogcatDocumento3.139 pagineLogcatvatsavai swathiNessuna valutazione finora

- Transfer FunctionDocumento19 pagineTransfer FunctionVinay Kumar SmartyNessuna valutazione finora

- Aset WTP HarapanDocumento7 pagineAset WTP HarapanReinhard SimbolonNessuna valutazione finora

- AcetophenoneDocumento1 paginaAcetophenoneDinda Melissa ArdiNessuna valutazione finora

- Garrita National High SchoolDocumento5 pagineGarrita National High SchoolAxle Rose CastroNessuna valutazione finora

- Microsoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODDocumento75 pagineMicrosoft PowerPoint - ASEP - NSCP 2015 Chapter6 - WOODRay Ramilo67% (9)

- Health Care Facilities and Medical Gas and VacuumDocumento27 pagineHealth Care Facilities and Medical Gas and VacuumStephen TabiarNessuna valutazione finora

- YWNC Piranhas Individual Meet Results - Standard: TUSSDocumento12 pagineYWNC Piranhas Individual Meet Results - Standard: TUSSymcawncNessuna valutazione finora

- Is 13935 2009 PDFDocumento33 pagineIs 13935 2009 PDFManojKumawatRjNessuna valutazione finora

- Requirements For Pressure Vessel Basic Engineering DesignDocumento6 pagineRequirements For Pressure Vessel Basic Engineering DesignLDM Man. e Mont. Ind. EIRELINessuna valutazione finora

- Toshiba Satellite L650 12Q Laptop ManualDocumento229 pagineToshiba Satellite L650 12Q Laptop ManualTasos KachpanisNessuna valutazione finora

- Common Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Documento4 pagineCommon Examples and Applications of Copolymers. Acrylonitrile Butadiene Styrene (ABS)Yashi SrivastavaNessuna valutazione finora

- DWL-G120: Before You BeginDocumento12 pagineDWL-G120: Before You BeginMark TeaterNessuna valutazione finora

- BMW COMMON RAIL Injection Systems PDFDocumento22 pagineBMW COMMON RAIL Injection Systems PDFEnd1y1Nessuna valutazione finora

- PreponlineDocumento8 paginePreponlineGeeth SagarNessuna valutazione finora