Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Nad Cafs HNG CH KLST

Caricato da

Rupesh Banait0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni2 pagineR4r

Titolo originale

Nad Cafs Hng Ch Klst

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoR4r

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni2 pagineNad Cafs HNG CH KLST

Caricato da

Rupesh BanaitR4r

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

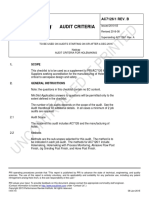

NADCA Commercial Practices

C-8-1-06

CHECKLIST

This checklist is for use

in consultation with your Casting Production Specifications

die caster prior to estimat-

ing production costs. Use

in combination with the To be used in consultation with your caster (Use in combination with Checklist C-8-2)*

Finishing Checklist C-8-2.

Also review Checklists

T-2-1A and T-2-1B, for Die Checklist for Die,Casting

SSM andProduction

Squeeze Part Purchasing

Casting Die Specification, in

Section 2. This Production Checklist provides a convenient method for assuring important factors

involved in purchasing cast parts are evaluated and clearly

communicated between the purchaser and the caster.

No. Cost Effect It should be used as a supplement to the essential dimensional

and alloy specifications detailed on part prints submitted for

1 Most economical basis for production

quotation, since the listed factors directly affect the basis on which

2 Involves additional work which may the casting quotation is made. The checklist may be reproduced

affect cost for this purpose. Your caster will clarify any item requiring further

3 Additional work which may increase cost explanation.

4 Special Requirements which may

This checklist provides a numbering system in which the lowest

increase cost numbered description for each requirement can be met at the lowest

production cost, as follows:

Casting 1 Some residue and chips not objectionable

Cleanliness 2 Shop run — blown reasonable free of chips but not degreased

A 3 Clean, dry and free of chips

4 Special requirements

Cast Surface 1 Mechanical quality — finish is not significant

B Finish 2 Painting quality — streaks and chill areas coverable with paint

3 Highest quality — for electroplating, decorative finishing, O-ring seats

Metal Extension 1 No die trimming — break off gates and overflows

(Flash) Removal 2 Die trimmed to within 0.0150” (0.38 mm) of die casting surface (See NADCA Guideline G-6-5)

C Parting Line 3 Hand filed or polished — flush with die casting’s surface

External Profile 4 Customer defined requirements

Metal Extension 1 Flash not removed

D (Flash) Removal 2 Flash trimmed to within 0.010” (0.25 mm) of die casting surface

Cored Holes 3 Flash to be machined

Metal Extension 1 Not removed (See NADCA Guidelines G-6-4)

E (Flash) Removal 2 Crushed or flattened (See NADCA Guidelines G-6-4)

Ejector Pins 3 Removed from specific locations

Pressure 1 No requirement

F Tightness 2 Pressure-tight to agreed-upon psi (kPa). Testing medium: ___________________

3 Other arrangements to be agreed upon

Flatness 1 No requirement

2 To NADCA “Standard” specification tolerances (S-4A-8)

G 3 Critical requirement — to NADCA “Precision” specification tolerances (P-4A-8)

4 Customer defined requirements

Dimensions 1 Normal: per NADCA “Standard” specification tolerances

H 2 Semi-critical: “Precision” tolerances on specified dimensions, others “Standard”

3 Critical: Special tolerances to be agreed upon

Customer’s 1 No unusual inspection requirements — no Statistical Quality Control

I Receiving Inspec- 2 Statistical quality control: Acceptable at Cpk 1.33 or higher (or AQL over _________________)

tion 3 Statistical quality control: Acceptable at Cpk 2.0 or higher (or AQL over __________________)

Packaging 1 Not critical — bulk packed

2 Layer packed, with separators, or weight restriction

J 3 Packed in cell-type separators or individually wrapped

4 Customer defined requirements

* The specification provisions and procedures listed in Section 7, “Quality Assurance,” should also be addressed.

Publisher grants permission to reproduce this checklist as part of a casting Request for Quotation or Production Specification.

8-14 NADCA Product Specification Standards for Die Castings / 2006

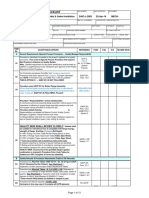

Commercial Practices NADCA

C-8-2-06

CHECKLIST

This checklist is for use

Casting Surface Finishing Specifications in consultation with your

die caster prior to estimat-

ing production costs. Use

To be used in consultation with your caster (Use in combination with Checklist C-8-1)* in combination with the

Finishing Checklist C-8-2.

Also review Checklists

Checklist for Finished Die,Casting

SSM andPart

Squeeze

Purchasing T-2-1A and T-2-1B, for Die

Casting Die Specification, in

This Finishing Checklist provides a convenient method for assuring that important factors Section 2.

involved in the surface finishing of cast parts are evaluated and

clearly communicated between the purchaser and the caster.

It should be used as a supplement to the essential dimensional No. Cost Effect

and alloy specifications detailed on part prints submitted for quota-

tion, since the listed factors directly affect the basis on which the 1 Most economical basis for production

casting quotation is made. The checklist may be reproduced for this 2 Involves additional work which may

purpose. Your caster will clarify any item requiring explanation. affect cost

This checklist provides a numbering system in which the lowest 3-4 Additional work which may increase cost

numbered description for each requirement can be met at the 5 Most difficult surface to cast on a produc-

lowest production cost, as follows: tion basis

Casting Insert 1 No insert used in cast part

K 2 Inserts required, to be supplied by customer at 10% overage

3 Inserts required, to be supplied by caster

Parting Lines 1 Polishing not required

L 2 Polish only where marked on drawing

3 Polish all parting lines (except as noted)

Surface 1 No buffing required

M Preparation 2 Mechanical (burnishing, tumbling, etc.)

3 Buff as indicated on drawing

Plating, 1 Protective Only — Specify: ______________________________________

Anodizing

N or Other

2 Decorative Paint — Specify: ______________________________________

Special Finish 3 Severe Exposure Protection — Specify: ______________________________________

Painting 1 Heavy Paint, Protective Only — Specify: ______________________________________

2 Decorative Paint — Specify: ______________________________________

O

3 Application requires base coat or special treatment: ___________________________________

Specify: ______________________________________

Environmental 1 Normal interior use only

P 2 Exposure to weather — Specify: ______________________________________

3 Exposure ot unusual chemistry — Specify: ______________________________________

As-Cast 1 Utility Grade — surface imperfections acceptable, nondecorative coatings

Surface 2 Functional Grade — slight, removable surface imperfections, heavier coatings

See NADCA 3 Commercial Grade — removable imperfections

Q Guidelines

4 Consumer Grade — no objectionable imperfections, as agreed upon, when viewed under

G-6-6

normal lighting conditions at ___________________ feet viewing distance

5 Superior Grade — specified average surface finish value of ___________________ micro-

inches, per print

Special For special flash removal requirements, see Checklist C-8-1, items C & E

R Requirements For special packaging/weight restrictions, see Checklist C-8-1, item J

* The specification provisions and procedures listed in Section 7, “Quality Assurance,” should also be addressed.

Publisher grants permission to reproduce this checklist as part of a casting Request for Quotation or Production Specification.

NADCA Product Specification Standards for Die Castings / 2006 8-15

Potrebbero piacerti anche

- Making Soap From WoodDocumento6 pagineMaking Soap From WoodmastabloidNessuna valutazione finora

- Design Guidelines for Surface Mount TechnologyDa EverandDesign Guidelines for Surface Mount TechnologyValutazione: 5 su 5 stelle5/5 (1)

- 220 & 132 KV SF6 CB - GetcoDocumento36 pagine220 & 132 KV SF6 CB - GetcoVenkatNessuna valutazione finora

- AN912 Rev10Documento7 pagineAN912 Rev10MAI_QualityNessuna valutazione finora

- T E F A: HE Uropean Oundry SsociationDocumento0 pagineT E F A: HE Uropean Oundry SsociationpkjenaleoNessuna valutazione finora

- SSPC SP3Documento2 pagineSSPC SP3hidromecanico78% (9)

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Documento48 paginePsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- SSPC SP3Documento2 pagineSSPC SP3Jose AngelNessuna valutazione finora

- Saes J 200Documento6 pagineSaes J 200milton1987Nessuna valutazione finora

- Casting ChecklistDocumento4 pagineCasting Checklistmihai90Nessuna valutazione finora

- Aerospace Material Specification: Nickel Plating (Electrodeposited)Documento12 pagineAerospace Material Specification: Nickel Plating (Electrodeposited)BHUSHAN100% (2)

- BrochureDocumento28 pagineBrochurePapa100% (1)

- Vietnam & Angkor Wat (PDFDrive) PDFDocumento306 pagineVietnam & Angkor Wat (PDFDrive) PDFChristine TranNessuna valutazione finora

- Split Tee Specifications and Drawings - 20130906 - 191217Documento17 pagineSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLINessuna valutazione finora

- GMW 14057Documento10 pagineGMW 14057JOECOOL67Nessuna valutazione finora

- Everything You Need to Know About Centrifugal FansDocumento65 pagineEverything You Need to Know About Centrifugal Fansahmed100% (1)

- Guide to Separator Inspection and OptimisationDocumento25 pagineGuide to Separator Inspection and OptimisationRawat67% (3)

- Houston Impact of J-STD-001F and IPC-A-610F ChangesDocumento36 pagineHouston Impact of J-STD-001F and IPC-A-610F Changeswayneseal1Nessuna valutazione finora

- ASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphDocumento3 pagineASME BPVC Section VIII Division 2: Responsibilities and Duties ParagraphSubrata PatraNessuna valutazione finora

- Updated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsDocumento7 pagineUpdated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsLinnie McleodNessuna valutazione finora

- Canadian Wood Council Publications and Tools For Wood Design Robertson RocchiDocumento62 pagineCanadian Wood Council Publications and Tools For Wood Design Robertson RocchiDj MacNessuna valutazione finora

- 50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsDocumento6 pagine50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsJKKNessuna valutazione finora

- Aux Prds Techincal SpecificationDocumento30 pagineAux Prds Techincal SpecificationSwaraj BiswasNessuna valutazione finora

- Blueprint for Project Recovery--A Project Management GuideDa EverandBlueprint for Project Recovery--A Project Management GuideNessuna valutazione finora

- Approved By:: Calibration Procedure For Pressure Chart RecorderDocumento7 pagineApproved By:: Calibration Procedure For Pressure Chart Recordervinsensius rasaNessuna valutazione finora

- GMW 14057-2012Documento11 pagineGMW 14057-2012JUAN CARLOS MURILLO LARROTANessuna valutazione finora

- Service and Repair Instructions: Water & WastewaterDocumento72 pagineService and Repair Instructions: Water & WastewaterLa Marina Mantenimiento100% (1)

- Swami Brahmananda - The Spiritual Son of Sri RamakrishnaDocumento7 pagineSwami Brahmananda - The Spiritual Son of Sri RamakrishnaEstudante da Vedanta100% (2)

- C 8 1 09Documento1 paginaC 8 1 09Sandino TorresNessuna valutazione finora

- C 8 2 09Documento1 paginaC 8 2 09Sandino TorresNessuna valutazione finora

- 2021 NADCA ToolingDocumento3 pagine2021 NADCA ToolingMarcosNessuna valutazione finora

- QSQR+S7 48 2020 1Documento8 pagineQSQR+S7 48 2020 1مرکز پژوهش متالورژی رازی RMRCNessuna valutazione finora

- Technical Specification for Heavy Duty DampersDocumento6 pagineTechnical Specification for Heavy Duty Dampersprth valveNessuna valutazione finora

- Working Together For A Safer World ASMEDocumento63 pagineWorking Together For A Safer World ASMETin Aung KyiNessuna valutazione finora

- Material Specification: Safety And/Or Government Regulated PartDocumento21 pagineMaterial Specification: Safety And/Or Government Regulated PartAbhishek ChauhanNessuna valutazione finora

- A-A 59503A (Nitrogen)Documento6 pagineA-A 59503A (Nitrogen)mtcengineeringNessuna valutazione finora

- Evaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque ConditionsDocumento18 pagineEvaluation of Load-Carrying Capacity of Lubricants Used in Hypoid Final-Drive Axles Operated Under Low-Speed and High-Torque Conditionsomar TahaNessuna valutazione finora

- Jars Accelerators Hydraulic NS 1 A4 2watermarkedDocumento15 pagineJars Accelerators Hydraulic NS 1 A4 2watermarkedislam atifNessuna valutazione finora

- Mechanical Tank Gauging System (D 29)Documento3 pagineMechanical Tank Gauging System (D 29)Elias EliasNessuna valutazione finora

- KOC Standard for Generator SetsDocumento58 pagineKOC Standard for Generator SetsinbNessuna valutazione finora

- Fabrication of Process Analyzer Packages-MSDocumento24 pagineFabrication of Process Analyzer Packages-MSAhmed ElghmatiNessuna valutazione finora

- AC7126-1 Rev B 23-AUG-2016Documento26 pagineAC7126-1 Rev B 23-AUG-2016unknown1711Nessuna valutazione finora

- 36-00-012C Design Review - ReliabilityDocumento184 pagine36-00-012C Design Review - ReliabilityDavid KeilNessuna valutazione finora

- Fuel System Standpipe InspectionDocumento6 pagineFuel System Standpipe Inspectionmohammed kareemNessuna valutazione finora

- Mss sp952006 Swaged Nipples and Bull PlugsDocumento16 pagineMss sp952006 Swaged Nipples and Bull PlugsDaryna KupriianovaNessuna valutazione finora

- In Word, USE TOOLS-OPTIONS-VIEW-HIDDEN TEXT TO SEE Blue Authors NotesDocumento6 pagineIn Word, USE TOOLS-OPTIONS-VIEW-HIDDEN TEXT TO SEE Blue Authors Notes081382991318Nessuna valutazione finora

- Mil STD 1498BDocumento40 pagineMil STD 1498BarielaparicioNessuna valutazione finora

- 212 Asb 08 130Documento7 pagine212 Asb 08 130Walberto PachecoNessuna valutazione finora

- TMS6900Documento14 pagineTMS6900Josue Garcia QuiniNessuna valutazione finora

- QAP WD-71-BD-15 Compliance To STRDocumento19 pagineQAP WD-71-BD-15 Compliance To STRAnonymous kQUFSJuW4uNessuna valutazione finora

- 45 Samss 013Documento23 pagine45 Samss 013Waleed MedhatNessuna valutazione finora

- Saic L 2002Documento13 pagineSaic L 2002chidambaramNessuna valutazione finora

- GMN7152 2002Documento16 pagineGMN7152 2002odiosmio8282201Nessuna valutazione finora

- GMW14057Documento19 pagineGMW14057Felipe De la cruzNessuna valutazione finora

- Calibration Procedure for Torque WrenchesDocumento7 pagineCalibration Procedure for Torque Wrenchesvinsensius rasaNessuna valutazione finora

- CAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsDocumento7 pagineCAIRN-TSG-L-TN-0006-B1-Technical Notes For Flanges, Spectacle Blinds and Drip RingsGOPINATH KRISHNAN NAIRNessuna valutazione finora

- Quality Assurance and Process Capabilities for Die CastingsDocumento12 pagineQuality Assurance and Process Capabilities for Die CastingsFederico MoranNessuna valutazione finora

- AC7102.5 Rev. EDocumento15 pagineAC7102.5 Rev. Eamit gajbhiyeNessuna valutazione finora

- Technical Specification for Dual Plate Check ValvesDocumento12 pagineTechnical Specification for Dual Plate Check ValvesShivashankar Durga MedisettiNessuna valutazione finora

- Air&gas-Design Pr.29576Documento18 pagineAir&gas-Design Pr.29576JKKNessuna valutazione finora

- UntitledDocumento11 pagineUntitledRodrigo LeanosNessuna valutazione finora

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachDa EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNessuna valutazione finora

- Codification of Statements on Standards for Attestation Engagements, January 2018Da EverandCodification of Statements on Standards for Attestation Engagements, January 2018Nessuna valutazione finora

- Discrete Variable Probability Distribution FunctionsDocumento47 pagineDiscrete Variable Probability Distribution FunctionsJanine CayabyabNessuna valutazione finora

- Vectors FoundationDocumento8 pagineVectors FoundationNaning RarasNessuna valutazione finora

- March 17, 2016 Strathmore TimesDocumento24 pagineMarch 17, 2016 Strathmore TimesStrathmore TimesNessuna valutazione finora

- Shiva Home - DCFDocumento2 pagineShiva Home - DCFshyamsundar_ceNessuna valutazione finora

- JSA .Hendra Pouring Congcrete by Mixer TruckDocumento2 pagineJSA .Hendra Pouring Congcrete by Mixer TruckMuhamad Rizki AzisNessuna valutazione finora

- Sdre14-5 Ral 1-2-Rev17Documento3 pagineSdre14-5 Ral 1-2-Rev17lwin_oo2435Nessuna valutazione finora

- Prob Stats Module 4 2Documento80 pagineProb Stats Module 4 2AMRIT RANJANNessuna valutazione finora

- Psychoacoustics: Art Medium SoundDocumento3 paginePsychoacoustics: Art Medium SoundTheodora CristinaNessuna valutazione finora

- Ichroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemDocumento6 pagineIchroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemGopinath AgnihotramNessuna valutazione finora

- Improving Students' Science Process SkillsDocumento9 pagineImproving Students' Science Process SkillsNovia RahmawatiNessuna valutazione finora

- Misamis Occidental Plans to Protect Aquamarine ResourceDocumento8 pagineMisamis Occidental Plans to Protect Aquamarine ResourcejelosalisaliNessuna valutazione finora

- Kinematics Problem SetDocumento1 paginaKinematics Problem SetMohammad JubranNessuna valutazione finora

- Basicline BL 21t9stDocumento28 pagineBasicline BL 21t9stgabriel6276Nessuna valutazione finora

- Spcr-TagbayaganDocumento76 pagineSpcr-TagbayaganReycia Vic QuintanaNessuna valutazione finora

- Engineering Aspects of Food Emulsification and HomogenizationDocumento325 pagineEngineering Aspects of Food Emulsification and Homogenizationfurkanturker61Nessuna valutazione finora

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDocumento48 pagineMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaNessuna valutazione finora

- Sherco 450 Se R Workshop Manual 1Documento79 pagineSherco 450 Se R Workshop Manual 1miguelNessuna valutazione finora

- BS 7941-1-2006Documento20 pagineBS 7941-1-2006Willy AryansahNessuna valutazione finora

- General Biology 2: Quarter 3, Module 1 Genetic EngineeringDocumento20 pagineGeneral Biology 2: Quarter 3, Module 1 Genetic EngineeringRonalyn AndaganNessuna valutazione finora

- Painting, DrawingDocumento22 paginePainting, DrawingMithilesh_Kuma_7083Nessuna valutazione finora

- Ben Wilkins PRISON MADNESS and LOVE LETTERS: THE LOST ARTDocumento5 pagineBen Wilkins PRISON MADNESS and LOVE LETTERS: THE LOST ARTBarbara BergmannNessuna valutazione finora

- Answer Sheet FINAL LipidDocumento3 pagineAnswer Sheet FINAL LipidFaridah MagumparaNessuna valutazione finora

- SEFT Islamic care effect on hypertension patients' blood pressureDocumento12 pagineSEFT Islamic care effect on hypertension patients' blood pressureSopian HadiNessuna valutazione finora