Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Job Safety Analysis: How To Use This Form

Caricato da

jithin shankar100%(1)Il 100% ha trovato utile questo documento (1 voto)

213 visualizzazioni4 pagineDrs

Titolo originale

Jsa

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoDrs

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

213 visualizzazioni4 pagineJob Safety Analysis: How To Use This Form

Caricato da

jithin shankarDrs

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

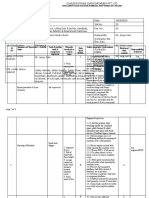

JOB SAFETY ANALYSIS

HOW TO USE THIS FORM : Installation/Facility EDG

1) Crew performing task reviews ALL generic JSA considerations. Location Local Control Panel

2) Review previous JSA update(s) for useful information which will help this task. Associated Work Permit Type

3) Create new JSA update with generic form and ALL considerations for this task. Associated Work Permit Number

4) Carry out task as per plan. If any conditions change ---STOP & RE-ASSESS. Electrical Isolation Certificate Number

5) File JSA update for future reference. Physical Isolation Certificate Number

WORK ACTIVITY Pneumatic Test For FM200 Pipe (using N2 Nitrogen) JHA Cross-Reference Number

Job Description of Potential Potential

L S R Control/Recovery Measures L S R Result

Step Job Step Hazards Impact

All personal to wear proper and suitable

Work and site 1.1 Protrusion to hand and hand protection glove.

1 preparation finger Minor injury 3 2 6 Eliminate or to make safe any 2 1 2 Acceptable

(housekeeping) protruding hazard.

First aid treatment.

All worker must wear proper PPE when

2.1 Manual lifting for nitrogen do manual lifting.

gas cylinder by

Provide glove to avoid pinch point.

manpower can cause

Do not lift the cylinder alone. Make sure

ergonomic hazards.

Back ache do it with buddy system.

Install of nitrogen gas 2.2 Cylinder can fall while

Body injury If possible use trolley or keep on

2 for leak test of FM200 manual lifting. 3 2 6 1 2 2 Acceptable

pipe 2.3 Workers hit by the Pinch point standing position and tightly bound to

strong structure.

cylinder.

2.4 Unsafe cylinder gas Do not locate cylinder gas in access &

position. egress pathway.

Safe handling of cylinder gas, do not

move cylinder by rolling it.

Make sure the cylinder is tighten to the

3.1 Cylinder fall from

wall or something that not easily move.

standing.

Blow the pipe to clean

Material damage Make sure all fittings is tighten properly

3.2 The pressure hose

iron dust inside pipe before blow the pressure for clean up

disconnected. Major

happen during cutting, the pipe.

3 3.3 N2 gas accumulate at injury/Fatality 3 3 9 1 2 2 Acceptable

drilling and welding Make sure all area that involve for this

using notrogen gas.

Local control panel room. Asphyxia

activity is already barricade and

(5 bar pressure)

3.4 Dust/debris from inside Respiratory acute

FM200 pipeline. provided with signage to avoid not

authorize person coming in or near at

the area.

JOB SAFETY ANALYSIS

OPEN ALL DOORS (ENTRY & EXIT)

in Local control panel for ventilation.

Cover area (panel) below blowout end

pipe.

Use Dust mask (PPE).

Provide training for working at height

for worker that involve to the work

activity.

4.1 Worker fall from ladder or Make sure the worker is a competent to

scaffolding while do the job.

installing the testing

Installation of testing Install toe board at scaffolding to avoid

device.

device (pressure Major falling material or tools from scaffolding.

4.2 Testing device fall from

4 gauge, flexible hose, injury/Fatality 3 3 9 Provide proper PPE for worker to avoid 1 2 2 Acceptable

height.

nitrogen gas, and pipe Material damage them from falling at height.

4.3 Tools falling from height.

fitting)

4.4 Unstandard connection Provided first aid kit box in place.

hose. Provide first aider and rescue plan

(refer to attached) in place.

Use standard hose that appropriate

with maximum pressure for pneumatic

test (27,5 bar).

Make sure all fittings is tighten properly

before blow the pressure for clean up

the pipe.

Provide standby person at any

entrance for the test location.

5.1 Cylinder fall from Make sure all area that involve for this

standing. activity is already barricade and

5.2 The pressure hose provided with signage to avoid not

disconnected. authorize person coming in or near at

5.3 Uncontrol filling pressure the area (access control

Pressure test pipe from cylinder gas. Material damage implementation).

5 FM200 (27-31 bar 5.4 Communcation problem Major 3 3 9 Make sure the activity is conducted with 1 2 2 Acceptable

pressure) between valve operator injury/Fatality competent person.

and tester due to Use regulator, pressure gauge and ball

separate room. valve to control pressure.

5.5 Leaking or cracking on Point blow out direction to safe

welding area or pipe atmosfer and outlet area

protected/barricade/warning sign

(Danger of nitrogen gas).

Use proper communication tools (HT).

Cover existing equipment with

bluesheet and playwood.

JOB SAFETY ANALYSIS

All personnel to wear proper and

suitable hand protection glove.

6.1 Protrusion to hand and Minor injury (first

6 Housekeeping 3 2 6 Eliminate or to make safe any 2 1 2 Acceptable

finger aid treatment)

protruding hazard.

First aid treatment.

L - LIKELIHOOD S - SEVERITY R- RATING RESULTS

CATEGORY DEFINITION CATEGORY DEFINITION H 3 6 9 6–9 UNACCEPTABLE

LOW 1 REMOTE LOW 1 No Injury No Damage No Pollution M 2 4 6 3–4 TOLERABLE

Minor Pollu-

MEDIUM 2 POSSIBLE MEDIUM 2 First Aid Injury Minor Damage

tion L 1 2 3 1-2 ACCEPTABLE

Lost Time In- Major Pollu-

HIGH 3 PROBABLE HIGH 3 jury

Major Damage

tion L M H

IS THERE A SAFER WAY TO COMPLETE THE JOB ? ARE THERE ALTERNATIVES WITH

L- LIKELIHOOD

LESS RISK ?

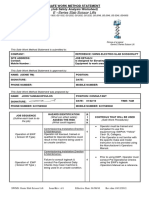

JOB SAFETY ANALYSIS

JSA Number: TASK SAFETY MANAGEMENT OUTLINE Date This JSA Created: 5-1-2015

Date JSA Last Revised : 7-1-2015

WORK ACTIVITY EQUIPMENT

Type of Equipment Manufacturer Tag. No. Precise Work Site

WORK ACTIVITY PARTICIPANTS THIS JSA CREATED BY

Performed

Name Discipline Position Name Discipline Position

Job Before?

JSA SUBMITTED BY PERFORMING

AUTHORITY JSA REVIEWED BY CONSORTIUM ENDORSED BY

WORK LEADER HSE DEPT RECEIVING AUTHORITY APPROVING AUTHORITY

Name: Name: Name: Name:

Signature: Signature: Signature: Signature:

Signature:

Date: Date: Date: Date:

Time: Time: Time: Time:

Potrebbero piacerti anche

- 4.cutting Grinding WeldingDocumento5 pagine4.cutting Grinding WeldingMohammad Fazal KhanNessuna valutazione finora

- PTW JHA Prayer Garment Hanging Rack InstallationDocumento2 paginePTW JHA Prayer Garment Hanging Rack InstallationPHH9834Nessuna valutazione finora

- Rock Breaker Self ChecklistDocumento1 paginaRock Breaker Self ChecklistNair R RakeshNessuna valutazione finora

- Jsa Ground Grid MocksvilleDocumento2 pagineJsa Ground Grid MocksvilleChristopher NewbyNessuna valutazione finora

- JHA For Installation 2 Inch Nozzle..Documento6 pagineJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Jsa - Cable Termination PDFDocumento4 pagineJsa - Cable Termination PDFD FiransyahNessuna valutazione finora

- JSA Working in Live AreasDocumento1 paginaJSA Working in Live Areasyc safetyNessuna valutazione finora

- SOP Grinding & CuttingDocumento3 pagineSOP Grinding & CuttingIMRANNessuna valutazione finora

- Jsa For The Installation of I EamDocumento5 pagineJsa For The Installation of I EamMohammed MinhajNessuna valutazione finora

- Job Safety Analysis (Jsa) : Title of Activity / Work: DG OperationDocumento2 pagineJob Safety Analysis (Jsa) : Title of Activity / Work: DG Operationba ratnaparkheNessuna valutazione finora

- Hot Works: Risk Assesment Form For Rolling ShutterDocumento1 paginaHot Works: Risk Assesment Form For Rolling Shutterchandanprakash30Nessuna valutazione finora

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocumento1 paginaJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNessuna valutazione finora

- JSA Formet New Hot WorkDocumento6 pagineJSA Formet New Hot Worksakthi venkat100% (1)

- Job Safety Analysis Erection SiloDocumento3 pagineJob Safety Analysis Erection SiloDanangNessuna valutazione finora

- Job Safety Analysis Report: DG Lifting & InstallationDocumento2 pagineJob Safety Analysis Report: DG Lifting & Installationvijay kumar singh100% (1)

- Jsa Ducting Rev 00Documento1 paginaJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Nessuna valutazione finora

- PDF Gi 0002721 2016 Arc Flash CompressDocumento23 paginePDF Gi 0002721 2016 Arc Flash CompressMark DingalNessuna valutazione finora

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocumento2 pagineJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinNessuna valutazione finora

- Job Safety Analysis - Overhead Power LinesDocumento2 pagineJob Safety Analysis - Overhead Power Linesrenee100% (2)

- Operating A Telescoping Aerial Boom LiftDocumento1 paginaOperating A Telescoping Aerial Boom LiftTFattahNessuna valutazione finora

- Job HazardDocumento2 pagineJob HazardBre WirabumiNessuna valutazione finora

- 3216 JSA Roof PlumbingDocumento14 pagine3216 JSA Roof Plumbingmalimsaidi_160040895100% (2)

- 2014 Energized Electrical Work Permit - ByU-IdahoDocumento2 pagine2014 Energized Electrical Work Permit - ByU-Idahocarrot123456Nessuna valutazione finora

- Job Safety Analysis Risk Assess Restricted Spaces v1 290311Documento9 pagineJob Safety Analysis Risk Assess Restricted Spaces v1 290311Anto MaryadiNessuna valutazione finora

- 0 JsaDocumento54 pagine0 JsaRavi AmarlapudiNessuna valutazione finora

- Scaffold TowerDocumento20 pagineScaffold TowerAndhika HerdiawanNessuna valutazione finora

- JSA Format Erection of Column 901-C-01Documento9 pagineJSA Format Erection of Column 901-C-01sakthi venkatNessuna valutazione finora

- JSA For Flue Gas Duct Height WorkDocumento4 pagineJSA For Flue Gas Duct Height Worksubhadipmanna8Nessuna valutazione finora

- Jsa Cable LayingDocumento2 pagineJsa Cable LayingAbcd efgh100% (1)

- JSA For Scissor Lift, Rev-6Documento2 pagineJSA For Scissor Lift, Rev-6Mahamudul HasanNessuna valutazione finora

- Jsa Fan Coil Unites MaintenanceDocumento5 pagineJsa Fan Coil Unites MaintenanceASLAM MULANINessuna valutazione finora

- JHA M&F ToiletDocumento3 pagineJHA M&F ToiletBala Subra ManiamNessuna valutazione finora

- Jsa - Cable TerminationDocumento4 pagineJsa - Cable TerminationD FiransyahNessuna valutazione finora

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDocumento11 pagine2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarNessuna valutazione finora

- SS JSP - 007 Excavation Work Using EquipmentDocumento6 pagineSS JSP - 007 Excavation Work Using EquipmentFarhat SetharNessuna valutazione finora

- Jsa Bearing Replacement-OverhaulingDocumento2 pagineJsa Bearing Replacement-Overhaulingashish engineeringNessuna valutazione finora

- Confine Space at Water TankDocumento7 pagineConfine Space at Water TanknaraNessuna valutazione finora

- Job Safety & Environment Analysis: Revision NoDocumento3 pagineJob Safety & Environment Analysis: Revision NonishanthNessuna valutazione finora

- Excavation (Company Name) : Phase Hazard AnalysisDocumento11 pagineExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNessuna valutazione finora

- 03 DG Checklist DailyDocumento1 pagina03 DG Checklist Dailyjohn rajNessuna valutazione finora

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Documento5 pagineJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNessuna valutazione finora

- JSA Excavation PDFDocumento6 pagineJSA Excavation PDFmohamedamine.zemouriNessuna valutazione finora

- Genie E Series Slab Scissor Lift Operation PDFDocumento11 pagineGenie E Series Slab Scissor Lift Operation PDFRajesh gpNessuna valutazione finora

- DOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerDocumento4 pagineDOD-MST-AKG-2-E-012 (Rev-A) Installation of TransformerProfessional TrustNessuna valutazione finora

- JSA - Low Voltage PanelDocumento19 pagineJSA - Low Voltage PanelASLAM MULANINessuna valutazione finora

- JSA Erection StructureDocumento11 pagineJSA Erection StructureJAYESH JOSHINessuna valutazione finora

- Updated JSA For SAPMTofficeDocumento30 pagineUpdated JSA For SAPMTofficeShaikh Abu bakarNessuna valutazione finora

- 28.1.1 Mobile Equipment Inspection ChecklistDocumento1 pagina28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNessuna valutazione finora

- ENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous AreaDocumento4 pagineENO JHA SHELL 001 - Cutting and Excavation Work at None - Hazardous Areamyn maliQue0% (1)

- RiggingDocumento2 pagineRiggingpruncu.alianmNessuna valutazione finora

- CTRA TK 64 003 Scaffolding Inside OutsideDocumento6 pagineCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNessuna valutazione finora

- Aj Infratech: Job Hazard AnalysisDocumento5 pagineAj Infratech: Job Hazard AnalysisDwitikrushna RoutNessuna valutazione finora

- Rigging JSA RiggerDocumento12 pagineRigging JSA RiggeraQiLGunawanNessuna valutazione finora

- Job Hazard Analysis - Granite Surface PlateDocumento2 pagineJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNessuna valutazione finora

- JSA #28 - Use of Hand ToolsDocumento1 paginaJSA #28 - Use of Hand ToolsSubham SohalNessuna valutazione finora

- JSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesDocumento10 pagineJSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesNazreen AzriNessuna valutazione finora

- Akk Jha Installation of Diesel TankDocumento3 pagineAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Stand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Documento3 pagineStand Operating For Maintenance of HOUSE KEEPING AND CLEANING Sop No.-Kpo / BND / Sinter Plant / Sop - 00Dwitikrushna Rout100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDocumento6 pagine4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNessuna valutazione finora

- Stas Ctic IsDocumento1 paginaStas Ctic Isjithin shankarNessuna valutazione finora

- Price Quotation Without Tax1Documento1 paginaPrice Quotation Without Tax1jithin shankarNessuna valutazione finora

- JournalDocumento24 pagineJournaljithin shankarNessuna valutazione finora

- FMEA FMECA The WorkhorseDocumento33 pagineFMEA FMECA The Workhorsejithin shankarNessuna valutazione finora

- Alcohol Drug PolicyDocumento2 pagineAlcohol Drug Policyjithin shankarNessuna valutazione finora

- Defensive Driving TrainingDocumento14 pagineDefensive Driving Trainingjithin shankarNessuna valutazione finora

- Organization ChartDocumento1 paginaOrganization Chartjithin shankarNessuna valutazione finora

- Road Safety StandardDocumento2 pagineRoad Safety Standardjithin shankarNessuna valutazione finora

- IG1 0029 ENG OBE Answer Sheet V1Documento8 pagineIG1 0029 ENG OBE Answer Sheet V1jithin shankar100% (3)

- Accidenn Incident PolicyDocumento2 pagineAccidenn Incident Policyjithin shankarNessuna valutazione finora

- Legal RegisterDocumento3 pagineLegal Registerjithin shankarNessuna valutazione finora

- RVK CVDocumento7 pagineRVK CVjithin shankarNessuna valutazione finora

- Unit IG2 Tony BabuDocumento14 pagineUnit IG2 Tony Babujithin shankar100% (3)

- Legal Register 01Documento7 pagineLegal Register 01jithin shankarNessuna valutazione finora

- Updated Corporate Training SessionDocumento4 pagineUpdated Corporate Training Sessionjithin shankarNessuna valutazione finora

- Ehs Hse PlanDocumento50 pagineEhs Hse Planjithin shankarNessuna valutazione finora

- Attendeence SheetDocumento2 pagineAttendeence Sheetjithin shankarNessuna valutazione finora

- Accident ReportDocumento6 pagineAccident Reportjithin shankarNessuna valutazione finora

- Hazard Identification Risk AssessmentDocumento5 pagineHazard Identification Risk Assessmentjithin shankarNessuna valutazione finora

- Organisation Chart Need To UpgradeDocumento1 paginaOrganisation Chart Need To Upgradejithin shankarNessuna valutazione finora

- TS June MonthDocumento7 pagineTS June Monthjithin shankarNessuna valutazione finora

- S.No Date Type of Work Depth (MTS) Grade QTY Cum - Qty: Ogt, Ongc, MallavaramDocumento2 pagineS.No Date Type of Work Depth (MTS) Grade QTY Cum - Qty: Ogt, Ongc, Mallavaramjithin shankarNessuna valutazione finora

- Daily Man Power MallavaramDocumento2 pagineDaily Man Power Mallavaramjithin shankarNessuna valutazione finora

- RTW Communication PlanDocumento1 paginaRTW Communication Planjithin shankarNessuna valutazione finora

- Legal RegisterDocumento3 pagineLegal Registerjithin shankarNessuna valutazione finora

- SL No Date Permit No Permit Type Activity Permit Receiver Permit Under ReniwalDocumento2 pagineSL No Date Permit No Permit Type Activity Permit Receiver Permit Under Reniwaljithin shankarNessuna valutazione finora

- Manpower For The Month: SEPT-2020: On Shore Terminal KG DWN 98/2 Development ProjectDocumento2 pagineManpower For The Month: SEPT-2020: On Shore Terminal KG DWN 98/2 Development Projectjithin shankarNessuna valutazione finora

- New Final Requirement-26.05.2017Documento4 pagineNew Final Requirement-26.05.2017jithin shankarNessuna valutazione finora

- Activity Potential Hazard Safe Work Practice & Control MeasuresDocumento1 paginaActivity Potential Hazard Safe Work Practice & Control Measuresjithin shankarNessuna valutazione finora

- NoDocumento1 paginaNojithin shankarNessuna valutazione finora

- Tinh Toan Tang AP Cau Thang - CT Qui LongDocumento20 pagineTinh Toan Tang AP Cau Thang - CT Qui Longntt_121987Nessuna valutazione finora

- This Study Resource WasDocumento3 pagineThis Study Resource WasNayre JunmarNessuna valutazione finora

- MLT IMLT Content Guideline 6-14Documento4 pagineMLT IMLT Content Guideline 6-14Arif ShaikhNessuna valutazione finora

- So 2nd Ed Adv Read Extra U4Documento2 pagineSo 2nd Ed Adv Read Extra U4hector1817Nessuna valutazione finora

- JAR Part 66 Examination Mod 03Documento126 pagineJAR Part 66 Examination Mod 03Shreyas PingeNessuna valutazione finora

- JOHARI Window WorksheetDocumento2 pagineJOHARI Window WorksheetAnonymous j9lsM2RBaINessuna valutazione finora

- Government of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Documento30 pagineGovernment of Tamilnadu Directorate of Legal Studies: Inter-Collegeiate State Level Moot Court Competition-2022Divya SrinimmiNessuna valutazione finora

- Hotel Transportation and Discount Information Chart - February 2013Documento29 pagineHotel Transportation and Discount Information Chart - February 2013scfp4091Nessuna valutazione finora

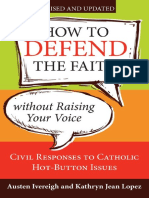

- How To Defend The Faith Without Raising Your VoiceDocumento139 pagineHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- Week 2 - ValEdDocumento30 pagineWeek 2 - ValEdBernadette MacalindongNessuna valutazione finora

- Piaget Stages of Cognitive DevelopmentDocumento2 paginePiaget Stages of Cognitive DevelopmentSeph TorresNessuna valutazione finora

- Director's Update Our StudentsDocumento23 pagineDirector's Update Our StudentsAdrian MojicaNessuna valutazione finora

- Deductions From Gross IncomeDocumento2 pagineDeductions From Gross Incomericamae saladagaNessuna valutazione finora

- Ahsan Menu KolachiDocumento12 pagineAhsan Menu Kolachisalman GtrNessuna valutazione finora

- All About Hemp Plant HempInc-eBookDocumento17 pagineAll About Hemp Plant HempInc-eBookFelix MartinezNessuna valutazione finora

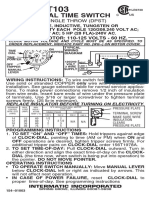

- T103 InstructionsDocumento1 paginaT103 Instructionsjtcool74Nessuna valutazione finora

- Maternal and Child Health Nursing 7 BulletsDocumento4 pagineMaternal and Child Health Nursing 7 BulletsHoneylie PatricioNessuna valutazione finora

- Process of Reinstatement Value Fire PoliciesDocumento1 paginaProcess of Reinstatement Value Fire PoliciesvinaysekharNessuna valutazione finora

- Physio Essay #4Documento2 paginePhysio Essay #4Maria Margarita Chon100% (1)

- IS 11255 - 7 - 2005 - Reff2022 Methods For Measurement of Emission From Stationary Sources Part 7 Oxides of NitrogenDocumento10 pagineIS 11255 - 7 - 2005 - Reff2022 Methods For Measurement of Emission From Stationary Sources Part 7 Oxides of NitrogenPawan SharmaNessuna valutazione finora

- Kmart PDFDocumento105 pagineKmart PDFkaranbhayaNessuna valutazione finora

- Full Download Small Animal Care and Management 4th Edition Warren Test BankDocumento35 pagineFull Download Small Animal Care and Management 4th Edition Warren Test Bankkrzyszhugvik6100% (20)

- Building Technology (CE1303) : Window: Lecturer: Madam FatinDocumento19 pagineBuilding Technology (CE1303) : Window: Lecturer: Madam FatinRazif AjibNessuna valutazione finora

- 2-Phase Synchronous-Rectified Buck Controller For Mobile GPU PowerDocumento18 pagine2-Phase Synchronous-Rectified Buck Controller For Mobile GPU PowerMax Assistência TécnicaNessuna valutazione finora

- Emergency War Surgery Nato HandbookDocumento384 pagineEmergency War Surgery Nato Handbookboubiyou100% (1)

- Anatomy, Physiology & Health EducationDocumento2 pagineAnatomy, Physiology & Health Educationsantosh vaishnaviNessuna valutazione finora

- Practice Test: Ielts UsaDocumento11 paginePractice Test: Ielts UsajoseNessuna valutazione finora

- Digital Habits Across Generations: Before ReadingDocumento3 pagineDigital Habits Across Generations: Before ReadingSharina RamallahNessuna valutazione finora

- App Guide EntelliGuard - G 09 - 2020 AplicacionDocumento100 pagineApp Guide EntelliGuard - G 09 - 2020 AplicacionjeorginagNessuna valutazione finora

- NIST Standard Reference Materials® 2023 CatalogDocumento128 pagineNIST Standard Reference Materials® 2023 CatalogAbdul HaseebNessuna valutazione finora