Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bolted and Riveted Connections Strength Calculation

Caricato da

Joshua TesoroTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bolted and Riveted Connections Strength Calculation

Caricato da

Joshua TesoroCopyright:

Formati disponibili

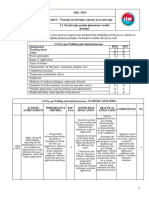

BOLTED AND RIVETED CONNECTIONS b.

Bolted flange of W-section

Most connections in modern steel building

construction are made with bolts or welds or combinations of

both.

• Assumptions involved in bolted connections:

c. Bolted connection

1. The frictions between the joined plates is ignored.

2. The stress transferred from one plate to another is

equally distributed to all bolts in the joint.

3. The tensile stress in the net sections of the plates is

uniform for each unit area of the cross-section.

4. The bending stress in the bolts are ignored.

𝑠𝑡𝑟𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑗𝑜𝑖𝑛𝑡

𝐸𝑓𝑓𝑖𝑐𝑖𝑒𝑛𝑐𝑦 𝑜𝑓 𝑎 𝑗𝑜𝑖𝑛𝑡 (%) = 𝑥 100

𝑠𝑡𝑟𝑒𝑛𝑔𝑡ℎ 𝑜𝑓 𝑝𝑙𝑎𝑡𝑒

• Examples.

4. Determine the allowable tensile force P which can be

applied to the plates shown. The AISC specification

A36 steel and 20 mm diameter A325 bolts placed in • Examples.

standard holes with threads excluded from the shear 1. Two plates each with thickness t=16mm and bolted

failure are used in a bearing type connection. Fy=248 together with 6-22 mm bolts forming a lap

MPa, Fu=400 MPa, Fv=206.9 MPa and Fp=1.5Fu. connection. Use bolt hole diameter = 25mm. Use

Use NSCP 2001. Fu=400MPa. Calculate the permissible tensile load P

under the following conditions. Fv=120MPa;

Fp=1.2Fu

a. Shear capacity of bolts

b. Bearing capacity of bolts

c. Block shear strength

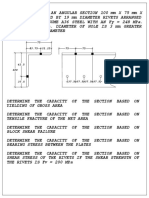

5. The riveted connection shown is a double riveted butt

joint where the upper cover plate extends over only the

inner rows of rivets, and the lower cover plate extends

over all rows. Diameter of rivet and hole is 23.5 mm,

thickness of main plate is 12mm, the thickness of each

cover plate is 10 mm. Determine the capacity of the 2. A single angle tension member in a roof truss is

section and its efficiency. Allowable stresses are as attached to a 9.5 mm thick gusset plate with A325

follows: 19mm high tensile strength bolts in standard holes.

Tension of plates = 76 MPa The gusset plate and the angle are A36 steel with

Fy=250MPa, Fu=400MPa. Area of one angle

Shearing stress = 60 MPa

125x75x8mm is 1540mm2. Compute the capacity of

Bearing stress = 130 MPa

the connection due to block shear strength of the angle.

3. Given a W12x30 (Fy=50ksi, Fu=65ksi), 7/8-in bolts

are used in the connection. Determine the block shear

BLOCK SHEAR strength.

Allowable strengths of tension members are not

always controlled by tension yielding, tension rupture or by the

strengths of bolts or welds which they are connected.

Block shear strength is the failure of a member along

a path involving tension on one plane and shear on a

perpendicular plane.

𝑻𝑩𝑺 = 𝟎. 𝟑𝑭𝒖 𝑨𝒗 + 𝟎. 𝟓𝑭𝒖 𝑨𝒕

• Critical sections for block shear

a. Bolted angle

Potrebbero piacerti anche

- Sample Concept PapersDocumento30 pagineSample Concept PapersEmily Dueñas SingbencoNessuna valutazione finora

- Review Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsDocumento2 pagineReview Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsJoseph LantoNessuna valutazione finora

- AP Chemistry: Free-Response QuestionsDocumento22 pagineAP Chemistry: Free-Response QuestionsAnita100% (1)

- For The Various Engine Oils Approved by Pratt and Whitney, Refer To The Pratt and Whitney Service Bulletin No. 13001Documento36 pagineFor The Various Engine Oils Approved by Pratt and Whitney, Refer To The Pratt and Whitney Service Bulletin No. 13001arunNessuna valutazione finora

- Modes of Failure of A Bolted/ Riveted ConnectionDocumento4 pagineModes of Failure of A Bolted/ Riveted ConnectionNajib A. CasanNessuna valutazione finora

- What Upward Force (KN) Is To Be Applied at The Free End To Prevent The Beam From Deflecting?Documento15 pagineWhat Upward Force (KN) Is To Be Applied at The Free End To Prevent The Beam From Deflecting?Jhoriz QuilloNessuna valutazione finora

- NSCP 2010 Deadload and Live Load Specifications for Steel StructuresDocumento7 pagineNSCP 2010 Deadload and Live Load Specifications for Steel StructuresIan Dave AdvinculaNessuna valutazione finora

- Insulated Pipe - Temperature Loss CalculationDocumento5 pagineInsulated Pipe - Temperature Loss CalculationnopNessuna valutazione finora

- Steel Design Part 1Documento4 pagineSteel Design Part 1Lenielle AmatosaNessuna valutazione finora

- Sans 1200 LeDocumento9 pagineSans 1200 Lefilipe100% (1)

- Culvert Estimate 600mm PipeDocumento6 pagineCulvert Estimate 600mm Pipedhiraj KumarNessuna valutazione finora

- Bolted ConnectionsDocumento16 pagineBolted ConnectionsCharizza Montarin CENessuna valutazione finora

- CE Board Nov 2020 Strength of Materials Set 1Documento2 pagineCE Board Nov 2020 Strength of Materials Set 1Eugenio Genesis AbadNessuna valutazione finora

- StrengthDocumento101 pagineStrengthSigue Ramel Hinayas0% (1)

- GER3620L 1 Oct 19 2010 1Documento60 pagineGER3620L 1 Oct 19 2010 1carlitos8022Nessuna valutazione finora

- Prepared By: Engr. Jeffrey P. LandichoDocumento10 paginePrepared By: Engr. Jeffrey P. LandichoNoel So jrNessuna valutazione finora

- Et 0000 0 000 04 750Documento83 pagineEt 0000 0 000 04 750RenatoNessuna valutazione finora

- CE Module 29 - StaticsDocumento13 pagineCE Module 29 - StaticsAngelice Alliah De la CruzNessuna valutazione finora

- 8 - Analysis of Doubly Reinforced BeamDocumento13 pagine8 - Analysis of Doubly Reinforced BeamgarhgelhNessuna valutazione finora

- Steel Design 6 April 2023 PDFDocumento2 pagineSteel Design 6 April 2023 PDFTristan CatapangNessuna valutazione finora

- SheetDocumento2 pagineSheetRoma Raquepo RingorNessuna valutazione finora

- 2160607-Elementary Structural Design 09012017 040945AMDocumento16 pagine2160607-Elementary Structural Design 09012017 040945AMAydinAkhtarpour100% (1)

- Approximate Analysis of Statically Indeterminate StructuresDocumento36 pagineApproximate Analysis of Statically Indeterminate StructuresRommel BaesaNessuna valutazione finora

- REFRESHER COURSE MODULE ON STRUCTURAL ENGINEERINGDocumento1 paginaREFRESHER COURSE MODULE ON STRUCTURAL ENGINEERINGMohammad Hussein Masiu BacaramanNessuna valutazione finora

- Design and Const2Documento101 pagineDesign and Const2Sigue Ramel HinayasNessuna valutazione finora

- Design of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerDocumento5 pagineDesign of Purlins: With Engr. Mark Lehi P. Palmes Faculty-RMMC Civil Engineering Program Review LecturerMohammad Taha PumbayaNessuna valutazione finora

- Strength of MaterialsDocumento1 paginaStrength of MaterialsAnonymous P1iMibNessuna valutazione finora

- Co78 QuizDocumento3 pagineCo78 QuizEjitNessuna valutazione finora

- BrasdaDocumento3 pagineBrasdaJayson Brylle MojaresNessuna valutazione finora

- Reinforced Concrete - Shear StrengthDocumento7 pagineReinforced Concrete - Shear StrengthDenice CastroNessuna valutazione finora

- Forces, moments, shear and stresses in beams and columnsDocumento9 pagineForces, moments, shear and stresses in beams and columnsRowena Remorosa GalayNessuna valutazione finora

- Final ExamDocumento4 pagineFinal ExamEzekiel SantosNessuna valutazione finora

- 3331 ST7008 Prestressed Concrete QBDocumento11 pagine3331 ST7008 Prestressed Concrete QBsundar100% (1)

- Ce Reviewer DesignDocumento18 pagineCe Reviewer Designeleonor0% (1)

- Statics of Rigid BodiesDocumento11 pagineStatics of Rigid Bodiesdonald escalanteNessuna valutazione finora

- Principles of Reinforced Concrete Design: Arlegui, Quiapo, ManilaDocumento10 paginePrinciples of Reinforced Concrete Design: Arlegui, Quiapo, ManilaMary Scarlette CenaNessuna valutazione finora

- Reinforced Concrete Beam Design ProblemsDocumento4 pagineReinforced Concrete Beam Design ProblemsRaine ZaficoNessuna valutazione finora

- Plate No.6 - Autor, Joy LauriaDocumento12 paginePlate No.6 - Autor, Joy LauriaJoy lauriaNessuna valutazione finora

- CE Review - Steel Design Problems SolvedDocumento3 pagineCE Review - Steel Design Problems SolvedLemuel TeopeNessuna valutazione finora

- Prc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDocumento51 paginePrc-I Lec 7 - 18th March 014 - Flexural Analysis of BeamsDavidm AndosNessuna valutazione finora

- Steel Module 7Documento5 pagineSteel Module 7dash1991Nessuna valutazione finora

- "Gtfiuctural Steel Dkign: Yletd Stress, Fy - Is That Unit Tensile Stress atDocumento13 pagine"Gtfiuctural Steel Dkign: Yletd Stress, Fy - Is That Unit Tensile Stress atMhiaBuenafeNessuna valutazione finora

- Civil-Engineering-Reviewer-NOV 2011Documento83 pagineCivil-Engineering-Reviewer-NOV 2011aomine100% (1)

- Refresher (Probability Discussion)Documento33 pagineRefresher (Probability Discussion)sadonNessuna valutazione finora

- ES 13 1920A Problem Set 2Documento5 pagineES 13 1920A Problem Set 2Charmaine ColetaNessuna valutazione finora

- Assignment 3 Part 1Documento1 paginaAssignment 3 Part 1Student555Nessuna valutazione finora

- Republic of The Philippines: Battery - 1Documento8 pagineRepublic of The Philippines: Battery - 1Aileen AntipoloNessuna valutazione finora

- Engineers: My Notes StructuralDocumento14 pagineEngineers: My Notes StructuralGladies Mhay Binay SandovalNessuna valutazione finora

- DIFFERENTIAL CALCULUS AND APPLICATIONSDocumento2 pagineDIFFERENTIAL CALCULUS AND APPLICATIONSEricson CapuaNessuna valutazione finora

- Steel Design 3 April 2024Documento3 pagineSteel Design 3 April 2024Craeven AranillaNessuna valutazione finora

- Steel Design Problem Set and Quizzes Model PDFDocumento1 paginaSteel Design Problem Set and Quizzes Model PDFTaki Tachibana0% (2)

- Answer: Put It Diagonally in A Cubical Box 1 Yard On A SideDocumento6 pagineAnswer: Put It Diagonally in A Cubical Box 1 Yard On A Sideiamcerbzjr100% (1)

- Midterm 20210405 SolutionDocumento12 pagineMidterm 20210405 SolutionSelf SevNessuna valutazione finora

- Design of Beams Miscellaneous Topics (Shear, Deflection, Etc.)Documento37 pagineDesign of Beams Miscellaneous Topics (Shear, Deflection, Etc.)Morad AJNessuna valutazione finora

- April 2024 - PSAD 2Documento2 pagineApril 2024 - PSAD 2rando12345Nessuna valutazione finora

- LECTURE 5 - T-Beams and Doubly ReinforcementDocumento34 pagineLECTURE 5 - T-Beams and Doubly ReinforcementHowell TungolNessuna valutazione finora

- Falcon RCD ColumnsDocumento4 pagineFalcon RCD ColumnsJerome Adduru100% (1)

- RCDocumento14 pagineRClexterNessuna valutazione finora

- 4.) RCD - Midterm Library Work Quiz - Concept and Solutions (1-Way Slab)Documento8 pagine4.) RCD - Midterm Library Work Quiz - Concept and Solutions (1-Way Slab)Penuel G. Bantog100% (1)

- Quiz No 1Documento2 pagineQuiz No 1Tris ZackNessuna valutazione finora

- Strain and Stress-Strain DiagramDocumento12 pagineStrain and Stress-Strain DiagramChristine Mae TinapayNessuna valutazione finora

- CS Apr22Documento8 pagineCS Apr22John Taylor BernasNessuna valutazione finora

- RC 3Documento4 pagineRC 3Jade David FranciscoNessuna valutazione finora

- LOCAL BUCKLING2 VisualBeeDocumento24 pagineLOCAL BUCKLING2 VisualBeeMart Brevin BitonNessuna valutazione finora

- Beam ExampleProblemsDocumento10 pagineBeam ExampleProblemsApril IngramNessuna valutazione finora

- Simple BendingDocumento41 pagineSimple BendingrpsirNessuna valutazione finora

- "Transportation Engineering" Is The Application of Principles of Engineering, PlanningDocumento17 pagine"Transportation Engineering" Is The Application of Principles of Engineering, PlanningJoshua TesoroNessuna valutazione finora

- FlowchartDocumento2 pagineFlowchartJoshua TesoroNessuna valutazione finora

- University of The East - Manila: BS Civil Engineering On-the-Job Training On-The-Job Training / Practicum Weekly ReportDocumento4 pagineUniversity of The East - Manila: BS Civil Engineering On-the-Job Training On-The-Job Training / Practicum Weekly ReportJoshua TesoroNessuna valutazione finora

- Lecture 3 (Bernoulli's Energy Equation) PDFDocumento2 pagineLecture 3 (Bernoulli's Energy Equation) PDFJoshua TesoroNessuna valutazione finora

- Lecture 2 (Continuity Equation)Documento1 paginaLecture 2 (Continuity Equation)Joshua TesoroNessuna valutazione finora

- Nicolas DSPDocumento13 pagineNicolas DSPJoshua TesoroNessuna valutazione finora

- Instrumental 3.2Documento4 pagineInstrumental 3.2deon kumukwayaNessuna valutazione finora

- Welding Non-Code Specialty Equipment: NIOEC-SP-90-11Documento8 pagineWelding Non-Code Specialty Equipment: NIOEC-SP-90-11aminNessuna valutazione finora

- Peelman 2013Documento32 paginePeelman 2013Jennilou CortesNessuna valutazione finora

- 2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciDocumento25 pagine2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciticmaNessuna valutazione finora

- What Are The Advantages of Water As A Solvent?: Weathering of Rocks MedicinesDocumento1 paginaWhat Are The Advantages of Water As A Solvent?: Weathering of Rocks MedicinesBernardo Milleniu De VeraNessuna valutazione finora

- Silk Data SheetDocumento2 pagineSilk Data SheetJoey DunnNessuna valutazione finora

- 02 WholeDocumento121 pagine02 WholeBarohNessuna valutazione finora

- Visco Elastic DamperDocumento4 pagineVisco Elastic DampergauravNessuna valutazione finora

- 2 - (Biochem) Oxidizing and ReducingDocumento3 pagine2 - (Biochem) Oxidizing and ReducingKaireen OzNessuna valutazione finora

- Green Catalogue PDFDocumento12 pagineGreen Catalogue PDFSumita JaiswalNessuna valutazione finora

- Dalian Hivolt Power System Co. Glass Insulator Test ReportDocumento5 pagineDalian Hivolt Power System Co. Glass Insulator Test ReportdiegoyyNessuna valutazione finora

- 7 Skema Kimia K1 & K2 Trial SPM Terengganu MPP3 2019Documento14 pagine7 Skema Kimia K1 & K2 Trial SPM Terengganu MPP3 2019Ain MiorNessuna valutazione finora

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDocumento5 pagineExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolNessuna valutazione finora

- Klubermatic FLEXDocumento24 pagineKlubermatic FLEXVelibor KaranovicNessuna valutazione finora

- Aalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112Documento2 pagineAalco Metals LTD Copper Brass Bronze CW712R Naval Brass CZ112kriskee13Nessuna valutazione finora

- A Course in General ChemistryDocumento590 pagineA Course in General Chemistryd010060002Nessuna valutazione finora

- Answers & Solutions: For For For For ForDocumento22 pagineAnswers & Solutions: For For For For ForYashNessuna valutazione finora

- Relative Permittivity - WikipediaDocumento7 pagineRelative Permittivity - WikipediakamaalNessuna valutazione finora

- Clark1984 PDFDocumento29 pagineClark1984 PDFMiguel HerreraNessuna valutazione finora

- AITECH Accredited October 2015Documento17 pagineAITECH Accredited October 2015Jiane NavalNessuna valutazione finora

- Melles Griot - Diode Laser Optics - Broadband Hybrid Dielectric Cube BeamsplittersDocumento2 pagineMelles Griot - Diode Laser Optics - Broadband Hybrid Dielectric Cube BeamsplittersnorbertscribdNessuna valutazione finora

- Application Ultratrace Ree Icp-Qqq-5994-1785en Us AgilentDocumento5 pagineApplication Ultratrace Ree Icp-Qqq-5994-1785en Us AgilentGuillermo Acosta OchoaNessuna valutazione finora