Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Exxon IP 7-3-1 Sootblowers For Fired Equipment

Caricato da

Gilvan SilvaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Exxon IP 7-3-1 Sootblowers For Fired Equipment

Caricato da

Gilvan SilvaCopyright:

Formati disponibili

Sootblowers for Fired Equipment IP 7-3-1

INTERNATIONAL Page 1 of 3

PRACTICE (This practice is appropriate for attachment to Inquiry or Purchase Document) Rev. 1 March 1998

Changes shown by

SCOPE

I 1.1 This practice covers the design, fabrication, and installation of sootblowers for fired heaters, boilers, and

other fired equipment.

I 1.2 An asterisk () indicates that a decision by the Purchaser is required, or that additional information is

furnished by the Purchaser.

SUMMARY OF ADDITIONAL REQUIREMENTS

I 2.1 Table 1 lists the practices which shall be used with this standard.

TABLE 1

PRACTICES

IP 3-4-1 Piping for Fired Equipment

IP 15-11-1 Instrument Control Panels

IP 16-9-1 Low Voltage A-C Motors Up to 200 HP (150 kW)

DOCUMENTATION

PROPOSAL INFORMATION

I 3.1 The vendor shall submit as a minimum the following information with his proposal:

a. Complete description of sootblower including model number and type.

b. Outline drawing of unit showing mounting (including wall box and wall support bearing/bracket).

c. Materials of construction of lance, feed tube, nozzle, and valve components.

d. Lance travel speed and steam consumption rate at sootblower valve inlet flange pressure.

e. Proposed method and utility requirements for purge, sealing, and aspirating air, when specified.

f. Maximum pressure/temperature rating of valve and other pressure-containing components.

g. Specification for drive motors, motor starters, and switchgear including NEMA rating and area

electrical classification.

h. Proposed sootblower control scheme.

i. Details of control panel, including electrical classification.

REVIEW INFORMATION

I 3.2 The vendor shall submit, as a minimum, the following information for review by the Owner's Engineer:

a. Updated proposal information.

b. Details of vendor-supplied instruments and control valves.

c. Control panel and motor starter console arrangement drawings, wiring diagrams, and interconnecting

wiring diagrams.

d. Installation, operating, and maintenance manuals.

e. Thrust calculation.

FINAL RECORDS

I 3.3 The following information shall be submitted for final records:

a. Complete “as-built" documentation issued for review.

b. Spare parts lists.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

IP 7-3-1 Sootblowers for Fired Equipment

Page 2 of 3 INTERNATIONAL

PRACTICE

Rev. 1 March 1998 (This practice is appropriate for attachment to Inquiry or Purchase Document)

DESIGN

GENERAL DESIGN

O,R 4.1 Sootblowers shall be of automatic retractable design with electric motor drive, automatic warm-up and

condensate draining facilities unless otherwise specified, such as for steam generating boilers, etc.

O,R 4.2 Types of sootblowers which are acceptable include: Clyde Mark F. H. or 400 series; Diamond Power

Model 4M or IK Series, and Vulcan T Series. Use of other makes of sootblowers must be approved by the

Owner's Engineer.

O 4.3 Blowing medium shall be steam unless otherwise specified

O 4.4 Sootblower shall be selected to achieve a minimum thrust of 130 lbf (580 N) with the specified media

pressure and temperature at the sootblower valve inlet flange. Thrust shall be calculated from the

following equation:

T = C W hi - he

where: C = 6.95 English units (70.9 metric units)

W = mass flow rate through nozzle, lb/sec (kg/sec)

hi = inlet enthalpy, Btu/lb (MJ/kg)

he = exit enthalpy, Btu/lb (MJ/kg) - determined from steam tables assuming isentropic

expansion through the nozzle with pressure equal to atmospheric

O 4.5 Sootblowers shall not be supplied with integral blowing steam pressure-reducing disc, linkage, or other

device unless specified by the Purchaser.

R,M 4.6 Packing used for the joint between the steam feed tube and steam lance, and for the sootblower valve

itself, shall be graphite with corrosion inhibitors unless otherwise specified.

O,R 4.7 Sootblower lance tube shall be provided with holes near the tip for drainage of condensate.

R 4.8 All sootblower valves shall be provided with an air purge connection equipped with a check valve.

R 4.9 Wall box design shall minimize leakage of air and flue gas between the fired equipment and atmosphere.

O,R 4.10 Sootblower mounting shall allow for elevation adjustments to maintain the required slope.

S 4.11 Removable guards or other means of protection shall be provided, which fully enclose all gears,

chains, and moving pinch points.

O,R 4.12 Fixed position rotary sootblowers shall:

a. Be supported at both ends and within the flue gas stream by brackets attached to the tubes.

b. Provide one nozzle per space between tube rows.

DESIGN OF ELECTRICAL COMPONENTS

R,M 4.13 Sootblower motor shall be of TEFC/TENV type.

O,R 4.14 A Control panel shall be provided for each set of sootblowers which provides the following functions:

a. Ability to operate all or individually selected sootblowers in automatic sequence as determined by

selector switches.

b. Manual operation of any sootblower.

c. Indication of forward and reverse travel, along with sequence finish, for each sootblower.

d. Indication of any fault which stops the sequence.

e. Ability to test integrity of all lamps on or off line.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

Sootblowers for Fired Equipment IP 7-3-1

INTERNATIONAL Page 3 of 3

PRACTICE (This practice is appropriate for attachment to Inquiry or Purchase Document) Rev. 1 March 1998

O,R 4.15 The following minimum interlocks and alarms, with adjustable setpoint/time delay shall be incorporated

into the control logic.

a. Warm-up time interlock (for entire system).

b. Automatic condensate drain at end of sequence.

c. Magnetic overload and motor stall interlock (retract).

d. Excessive elapsed time interlock (retract).

e. Loss of control voltage interlock (retract).

f. Loss of blowing medium interlock (retract).

g. Low blowing pressure (alarm only unless otherwise specified).

O 4.16 Each sootblower shall have a local push-button or lever actuator, subject to the same interlocks and

safeguards as the primary control system.

Revision Memo

6/96 Revision 0

3/98 Revision 1

Complete editorial revision to rationalize this practice with referenced IPs. Significant changes include:

Old Pars. 1.3 & 1.4, Table of Contents, deleted. Old Pars. 3.1 thru 3.7, Definitions, deleted. Par. 3.1, deleted details

of valve/seat requirements. Par. 4.1, Modified to allow provision for non-retractable blowers. Par. 4.2, Added Diamond

Model 4M. Par. 4.3, Deleted allowance for other than steam as blowing media. New Par. 4.5, Added restriction

against use of pressure-reducing devices. Pars. 4.7 & 4.8, Editorial change. Old Par. 5.8, Deleted , since standard

practice. Par. 4.11, Added requirement for guards to be removable. Old Pars. 5.13 & 5.15, Deleted since no added

technical value.

Paragraph renumbering:

Old Par. No. New Par. No.

4.1 thru 4.3 3.1 thru 3.3

5.1 thru 5.4 4.1 thru 4.4

5.5 & 5.6 4.6 & 4.7

5.9 thru 5.12 4.8 thru 4.11

5.14 4.12

5.16 thru 5.19 4.13 thru 4.16

Exxon Research and Engineering Company, 1996, 1998

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY — FLORHAM PARK, N.J.

Potrebbero piacerti anche

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Da EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNessuna valutazione finora

- Exxon IP 10-10-2 General Purpose Gear UnitsDocumento3 pagineExxon IP 10-10-2 General Purpose Gear UnitsGilvan SilvaNessuna valutazione finora

- IP 7-1-1 Fired HeatersDocumento9 pagineIP 7-1-1 Fired HeatersArnold Jose Batista RodriguezNessuna valutazione finora

- Exxon IP 7-5-1 Coils For Fired Heaters and BoilersDocumento5 pagineExxon IP 7-5-1 Coils For Fired Heaters and BoilersGilvan SilvaNessuna valutazione finora

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocumento14 pagineInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezNessuna valutazione finora

- Dampers and Guillotines For Fired Equipment: ScopeDocumento8 pagineDampers and Guillotines For Fired Equipment: ScopeAna Bella RosarioNessuna valutazione finora

- Double Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - GeneralDocumento7 pagineDouble Pipe and Multitube IP 6-2-1 Hairpin Heat Exchangers: Section 1 - Generalhcsharma1967Nessuna valutazione finora

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Documento14 pagineA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNessuna valutazione finora

- Standard Specification 3-26-4 Vessel Internals Low Chrome and Stainless SteelDocumento2 pagineStandard Specification 3-26-4 Vessel Internals Low Chrome and Stainless SteelSenthil KumarNessuna valutazione finora

- Exxon IP 10-3-4 Axial Compressors For Air ServiceDocumento7 pagineExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaNessuna valutazione finora

- 193-202 ThyssenKrupp Industrial Solutions AG - Klaus NoelkerDocumento10 pagine193-202 ThyssenKrupp Industrial Solutions AG - Klaus Noelkermmlatif4Nessuna valutazione finora

- 12c-Inspection Refractory UOPDocumento7 pagine12c-Inspection Refractory UOPFranco Angelo RegenciaNessuna valutazione finora

- Exxon IP 6-4-1 Air-Cooled Heat ExchangersDocumento6 pagineExxon IP 6-4-1 Air-Cooled Heat Exchangershcsharma1967Nessuna valutazione finora

- G3ir 1000 25 SP 9001 - R1Documento72 pagineG3ir 1000 25 SP 9001 - R1Ramu NallathambiNessuna valutazione finora

- Burners For Fired Heaters: ScopeDocumento12 pagineBurners For Fired Heaters: ScopeAna Bella RosarioNessuna valutazione finora

- 50a99 ReadingDocumento15 pagine50a99 Readingishu vohraNessuna valutazione finora

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsDocumento22 pagineIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianNessuna valutazione finora

- Type PR Online Assurance Program: Success StoryDocumento2 pagineType PR Online Assurance Program: Success Storyvarun sharmaNessuna valutazione finora

- FW Utility Boiler PDFDocumento12 pagineFW Utility Boiler PDFChandan AulakhNessuna valutazione finora

- UOP-Proposed Layout Critical Piping Rev 00Documento6 pagineUOP-Proposed Layout Critical Piping Rev 00ermusatNessuna valutazione finora

- Exxon IP 9 2 1 Additional RequirementsDocumento8 pagineExxon IP 9 2 1 Additional RequirementsGilvan SilvaNessuna valutazione finora

- Fired Heaters - Fired Capital Equipment Key Plant ComponentsDocumento4 pagineFired Heaters - Fired Capital Equipment Key Plant ComponentsReyes SanchezNessuna valutazione finora

- Interplant Standard - Steel Industry: Code of Practice For Oxygen Gas Pipeline IPSS:1-06-034-17 (First Revision)Documento17 pagineInterplant Standard - Steel Industry: Code of Practice For Oxygen Gas Pipeline IPSS:1-06-034-17 (First Revision)siddhesh_guessNessuna valutazione finora

- Packed Tower InternalsDocumento1 paginaPacked Tower Internalspalto1Nessuna valutazione finora

- Selection of Gasket MaterialsDocumento6 pagineSelection of Gasket MaterialsswatkoolNessuna valutazione finora

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Documento22 pagine15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNessuna valutazione finora

- Training - Reforming SectionDocumento69 pagineTraining - Reforming SectionsahrilbayunirosidikNessuna valutazione finora

- Steam DumpingDocumento9 pagineSteam DumpingsrinivasanNessuna valutazione finora

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringDocumento5 pagineInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLANessuna valutazione finora

- Storage Tanks DSDocumento18 pagineStorage Tanks DSNatarajan RavisankarNessuna valutazione finora

- Standard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USADocumento9 pagineStandard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAhlagos123Nessuna valutazione finora

- 3PS PL 006Documento22 pagine3PS PL 006ravi00098Nessuna valutazione finora

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Documento5 pagine18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNessuna valutazione finora

- NL-WI-236-04 Nozzle Loads EquipmentDocumento3 pagineNL-WI-236-04 Nozzle Loads EquipmentChirag ShahNessuna valutazione finora

- Engineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardDocumento9 pagineEngineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardGabbar SinghNessuna valutazione finora

- Air Coolers Excerpt From Rules of Thumb For Chemical EngineersDocumento3 pagineAir Coolers Excerpt From Rules of Thumb For Chemical Engineershalder_kalyan9216Nessuna valutazione finora

- EGE13B11Documento18 pagineEGE13B11Jhonny Rafael Blanco CauraNessuna valutazione finora

- 32 Samss 029Documento25 pagine32 Samss 029biplabpal2009Nessuna valutazione finora

- Mobil Egs 260 (1995) Tank Heating and Heat LossDocumento40 pagineMobil Egs 260 (1995) Tank Heating and Heat LossPilar Ruiz RamirezNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento14 pagineNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNessuna valutazione finora

- Compressor Station Optimization Using Simulation-Based OptimizationDocumento10 pagineCompressor Station Optimization Using Simulation-Based OptimizationAmbrish SinghNessuna valutazione finora

- Progress of Modern Pyrolysis Furnace TechnologyDocumento4 pagineProgress of Modern Pyrolysis Furnace TechnologyDavid Rodrigues100% (1)

- Stack Damper FATDocumento13 pagineStack Damper FATSureandran SabadiNessuna valutazione finora

- Distillation Tower Internals InstallationDocumento10 pagineDistillation Tower Internals Installationrvkumar61Nessuna valutazione finora

- O&Msec2 Heat & Material BalanceDocumento8 pagineO&Msec2 Heat & Material Balanceugun87Nessuna valutazione finora

- Incinerators: SectionDocumento18 pagineIncinerators: SectionFRANKLIN REVILLANessuna valutazione finora

- Makalah Convection Section Cleaning 4Documento7 pagineMakalah Convection Section Cleaning 4akjayaNessuna valutazione finora

- Standard Specification 3-26-2: 1. GeneralDocumento2 pagineStandard Specification 3-26-2: 1. Generalhlagos123Nessuna valutazione finora

- 9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedDocumento23 pagine9686-6130-MS-000-0002 - B2 - MS Tank Construction. - ApprovedANIL PLAMOOTTIL100% (1)

- D 103eDocumento19 pagineD 103eCivil FriendNessuna valutazione finora

- Foster Wheeler - Design Rundown TemperatureDocumento1 paginaFoster Wheeler - Design Rundown TemperatureAsad RazaNessuna valutazione finora

- Piping For Hydrocarbon and Chemical Processing Facilities (ODocumento14 paginePiping For Hydrocarbon and Chemical Processing Facilities (OswatkoolNessuna valutazione finora

- A Complete Analysis of Your Reformer: Bill Cotton and Barry FisherDocumento9 pagineA Complete Analysis of Your Reformer: Bill Cotton and Barry Fishersalvatore raffaNessuna valutazione finora

- Vol 1 HeaterDocumento252 pagineVol 1 HeaterShabir MansuriNessuna valutazione finora

- 6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01Documento9 pagine6700-EQS-2800-EC-0004 - EC 2802 - Flash Cooler Condenser - R01balajiNessuna valutazione finora

- Reciprocating CompressorsDocumento5 pagineReciprocating CompressorsthirumalaiNessuna valutazione finora

- EGE15B2Documento14 pagineEGE15B2Jhonny Rafael Blanco CauraNessuna valutazione finora

- Hydrogen Reformer Furnace Failure PDFDocumento10 pagineHydrogen Reformer Furnace Failure PDFJacekNessuna valutazione finora

- PP Aaa PP1 144Documento39 paginePP Aaa PP1 144Rabah AmidiNessuna valutazione finora

- EXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningDocumento6 pagineEXXON IP-03-19-01 Piping Erection, Testing, Flushing and CleaningJJ WeldingNessuna valutazione finora

- Practical Guide To Rubber Injection Molding PDFDocumento130 paginePractical Guide To Rubber Injection Molding PDFGilvan Silva100% (3)

- Exxon IP 10-3-4 Axial Compressors For Air ServiceDocumento7 pagineExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaNessuna valutazione finora

- X-Ray Film SeminarDocumento40 pagineX-Ray Film SeminarGilvan SilvaNessuna valutazione finora

- Packaged, Integrally Geared Centrifugal IP 10-3-2 Air CompressorsDocumento5 paginePackaged, Integrally Geared Centrifugal IP 10-3-2 Air CompressorsGilvan SilvaNessuna valutazione finora

- Exxon IP 10-9-1 Mechanical AgitatorsDocumento7 pagineExxon IP 10-9-1 Mechanical AgitatorsGilvan SilvaNessuna valutazione finora

- Vents For Fixed Roof Atmospheric IP 9-7-3 Storage Tanks: ScopeDocumento1 paginaVents For Fixed Roof Atmospheric IP 9-7-3 Storage Tanks: ScopeGilvan SilvaNessuna valutazione finora

- Exxon IP 9 2 1 Additional RequirementsDocumento8 pagineExxon IP 9 2 1 Additional RequirementsGilvan SilvaNessuna valutazione finora

- Exxon IP 10-12-1 Vibration, AxialDocumento3 pagineExxon IP 10-12-1 Vibration, AxialGilvan SilvaNessuna valutazione finora

- Quiz1 - CIP 2Documento4 pagineQuiz1 - CIP 2Gilvan Silva100% (1)

- Corrugated Steel Manhole Assemblies: Standard Specification ForDocumento8 pagineCorrugated Steel Manhole Assemblies: Standard Specification ForGilvan SilvaNessuna valutazione finora

- GP 43-50 31 January 2009 PDFDocumento52 pagineGP 43-50 31 January 2009 PDFGilvan SilvaNessuna valutazione finora

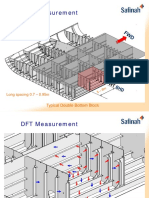

- DFT Measurement: Typical Double Bottom BlockDocumento4 pagineDFT Measurement: Typical Double Bottom BlockGilvan SilvaNessuna valutazione finora

- Fiber Glass Reinforced HDDDocumento8 pagineFiber Glass Reinforced HDDGilvan SilvaNessuna valutazione finora

- Aspersão Termica - FundamentosDocumento1 paginaAspersão Termica - FundamentosGilvan SilvaNessuna valutazione finora

- Quiz4 PDFDocumento6 pagineQuiz4 PDFGilvan Silva100% (4)

- Quiz1 - CIP 2Documento4 pagineQuiz1 - CIP 2Gilvan Silva100% (1)

- Hydroblasting and Coating Procedure of FpsoDocumento33 pagineHydroblasting and Coating Procedure of FpsoGilvan Silva100% (2)

- How To TenderDocumento17 pagineHow To TenderSimba NcubeNessuna valutazione finora

- Andrew Allen: 454 CR 3504 Quinlan, TX 75474 (903) 269-7874Documento3 pagineAndrew Allen: 454 CR 3504 Quinlan, TX 75474 (903) 269-7874api-250314960Nessuna valutazione finora

- Pearl and Dean (Phil.) Inc. v. Shoemart, Inc. and North Edsa Marketing Inc GR 148222, August 15, 2003Documento13 paginePearl and Dean (Phil.) Inc. v. Shoemart, Inc. and North Edsa Marketing Inc GR 148222, August 15, 2003Jeng Pion100% (1)

- Bugreport 2022 01 04 15 15 29 Dumpstate - Log 29625Documento3 pagineBugreport 2022 01 04 15 15 29 Dumpstate - Log 29625Yorman Ruiz AcstaNessuna valutazione finora

- DH-IPC-HFW5431E-Z5E: 4MP WDR IR Bullet Network CameraDocumento3 pagineDH-IPC-HFW5431E-Z5E: 4MP WDR IR Bullet Network CameraAri Yulianto NugrohoNessuna valutazione finora

- BCG Most Innovative Companies Mar 2019 R2 - tcm38 215836 PDFDocumento22 pagineBCG Most Innovative Companies Mar 2019 R2 - tcm38 215836 PDFAbhinav SrivastavaNessuna valutazione finora

- Hand Powered Drilling Tools and MachinesDocumento70 pagineHand Powered Drilling Tools and Machinessmole79Nessuna valutazione finora

- FaDocumento20 pagineFaVishwanath ShervegarNessuna valutazione finora

- 2-CFOT Handout 23Documento113 pagine2-CFOT Handout 23SumitNessuna valutazione finora

- Easy Soft Education Loans For SRM StudentsDocumento13 pagineEasy Soft Education Loans For SRM StudentsSankarNessuna valutazione finora

- 2020 Media Strategy Report: Insights From The WARC Media AwardsDocumento53 pagine2020 Media Strategy Report: Insights From The WARC Media AwardsShachin ShibiNessuna valutazione finora

- AgrrrraaDocumento31 pagineAgrrrraaAnonymous apYVFHnCYNessuna valutazione finora

- Financial PDFDocumento111 pagineFinancial PDFKarteek Reddy GuntakaNessuna valutazione finora

- Rubber Loc Cleaner A Methyl Ethyl Ketone M.E.K. Conveyor Belt Repair Kit V1 PDFDocumento8 pagineRubber Loc Cleaner A Methyl Ethyl Ketone M.E.K. Conveyor Belt Repair Kit V1 PDFOscar Giovani SosaNessuna valutazione finora

- Little ASP Net Core BookDocumento124 pagineLittle ASP Net Core Booklauhom130% (1)

- Formatting TextsDocumento3 pagineFormatting TextsCelestineNessuna valutazione finora

- Numerical Computing Lab 3Documento8 pagineNumerical Computing Lab 3Aamna ImranNessuna valutazione finora

- Ministry of PowerDocumento4 pagineMinistry of PowerVivek KumarNessuna valutazione finora

- PSTC-Appendix C - Cleaning Test SurfacesDocumento4 paginePSTC-Appendix C - Cleaning Test SurfacesChung LeNessuna valutazione finora

- Asset Management Council 1205 TheAsset0602 PDFDocumento48 pagineAsset Management Council 1205 TheAsset0602 PDFSushmit SharmaNessuna valutazione finora

- Louis Vuitton Out Let On Lines LVDocumento24 pagineLouis Vuitton Out Let On Lines LVLiu DehuaNessuna valutazione finora

- C Program StructureDocumento3 pagineC Program StructureAnik MukherjeeNessuna valutazione finora

- Wireless-N ADSL2+ Gateway: User GuideDocumento41 pagineWireless-N ADSL2+ Gateway: User GuidenaweedqadirNessuna valutazione finora

- Steel Quantity by Thumb RuleDocumento15 pagineSteel Quantity by Thumb RuleSheikh Nouman Mohsin RamziNessuna valutazione finora

- Literary CriticismDocumento3 pagineLiterary CriticismAnnabelle LerioNessuna valutazione finora

- Temperature Performance Study-SilviaDocumento11 pagineTemperature Performance Study-SilviadalheimerNessuna valutazione finora

- UNIT1 Question Bank EDDocumento7 pagineUNIT1 Question Bank EDsuganya1190Nessuna valutazione finora

- Soal Bahasa Inggris Semerter VI (Genap) 2020Documento5 pagineSoal Bahasa Inggris Semerter VI (Genap) 2020FabiolaIvonyNessuna valutazione finora

- Javascript For Abap Programmers: Chapter 3.5 - ArraysDocumento26 pagineJavascript For Abap Programmers: Chapter 3.5 - ArraysvenubhaskarNessuna valutazione finora

- Hofstede's Cultural DimensionsDocumento19 pagineHofstede's Cultural DimensionsbublusNessuna valutazione finora

- Well Integrity for Workovers and RecompletionsDa EverandWell Integrity for Workovers and RecompletionsValutazione: 5 su 5 stelle5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Oil: An Overview of the Petroleum IndustryDa EverandOil: An Overview of the Petroleum IndustryValutazione: 4.5 su 5 stelle4.5/5 (3)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Hybrid Enhanced Oil Recovery Using Smart WaterfloodingDa EverandHybrid Enhanced Oil Recovery Using Smart WaterfloodingNessuna valutazione finora

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesDa EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNessuna valutazione finora

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeDa EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNessuna valutazione finora

- Advanced Production Decline Analysis and ApplicationDa EverandAdvanced Production Decline Analysis and ApplicationValutazione: 3.5 su 5 stelle3.5/5 (4)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsDa EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNessuna valutazione finora

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsDa EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNessuna valutazione finora

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsDa EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNessuna valutazione finora

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationDa EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbDa EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbValutazione: 4.5 su 5 stelle4.5/5 (11)

- Oil and Gas Artificial Fluid Lifting TechniquesDa EverandOil and Gas Artificial Fluid Lifting TechniquesValutazione: 5 su 5 stelle5/5 (1)

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonDa Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNessuna valutazione finora

- Ship and Mobile Offshore Unit Automation: A Practical GuideDa EverandShip and Mobile Offshore Unit Automation: A Practical GuideNessuna valutazione finora

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)