Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Canon IR9070 Error Codes

Caricato da

nafees0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

221 visualizzazioni19 pagineCanon IR9070 Error Codes

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCanon IR9070 Error Codes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

221 visualizzazioni19 pagineCanon IR9070 Error Codes

Caricato da

nafeesCanon IR9070 Error Codes

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 19

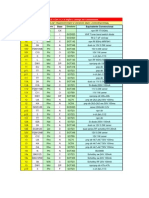

Canon iR9070 Error Codes List page 1 (from 8)

Code Description Remedy

The temperature of

the fixing assembly

is abnormally high.

- Check if the main thermistor is mounted properly and

When the main

also check if there is no contamination. - Replace the

E000- power switch is

main thermistor. - Replace the AC driver PCB. - Replace

0000 turned on, the

the DC controller PCB. Caution You must clear the error

reading of the main

in service mode (COPIER>FUNCTION>CLEAR>ERR).

thermistor does not

reach 70 deg C

within 3 min 30 sec.

The temperature of

the fixing assembly

is abnormally high.

E000- - Clear the error in service

The power is turned

0010 mode (COPIER>FUNCTION>CLEAR>ERR).

off and then on

without clearing the

error.

The over-rising in

temperature of the

- Replace the AC driver PCB. - Replace the DC

E001- fixing assembly is

controller PCB. Caution You must clear the error

0001 detected.

in service mode(COPIER>FUNCTION>CLEAR>ERR).

The hardware port

detects a fault.

The over-rising in

temperature of the

fixing assembly is - Check if the main thermistor and the sub thermistor are

detected. mounted properly. - Replace the main thermistor or the

E001-

Either the main sub thermistor. - Replace the AC driver PCB. - Replace

0002

thermistor or the the DC controller PCB. Caution You must clear the error

sub thermistor in service mode (COPIER>FUNCTION>CLEAR>ERR).

detects 230 deg C

or higher for 2 sec.

The over-rising in

temperature of the

fixing assembly is

Check if the main thermistor and the sub thermistor are

detected.

mounted properly. - Replace the main thermistor. -

E001- The reading of the

Replace the AC driver PCB. - Replace the DC controller

0003 main thermistor is

PCB. Caution You must clear the error in service

higher than that of

mode (COPIER>FUNCTION>CLEAR>ERR).

the sub thermistor

by 50 deg C or

more for 1 sec.

The over-rising in

temperature of the

fixing assembly is

- Check if the main thermistor is mounted properly. -

detected.

Replace the main thermistor. - Replace the AC driver

E001- The reading of the

PCB. - Replace the DC controller PCB. Caution You

0004 main thermistor is

must clear the error in service

lower than that of

mode (COPIER>FUNCTION>CLEAR>ERR).

the sub thermistor

by 50 deg C or

more for 1 sec.

The over-rising in

temperature of the

fixing assembly is

E001- detected. - Clear the error in service

0010 The power is turned mode (COPIER>FUNCTION>CLEAR>ERR).

off and then on

without clearing the

error.

The rise in

- Check if the connector (J505) of the DC controller PCB

temperature of the

is mounted properly and also check if the connector of

fixing assembly is

the fixing assembly is mounted properly. - Check the

faulty.

wiring between the thermistor and the DC controller. -

The reading of the

E002- Check if the main thermistor is mounted properly and

main thermistor

0000 also check if there is no contamination. - Replace the

(TH1) does not

main thermistor. - Replace the fixing heater. - Replace

reach 100 deg C 2

the AC driver PCB. - Replace the DC controller PCB.

min 30 sec after it

Caution You must clear the error in service

has exceeded 70

mode (COPIER>FUNCTION>CLEAR>ERR).

deg C.

The rise in

- Check if the connector (J505) of the DC controller PCB

temperature of the

is mounted properly and also check if the connector of

fixing assembly is

the fixing assembly is mounted properly. - Check the

faulty.

wiring between the thermistor and the DC controller. -

The reading of the

E002- Check if the main thermistor is mounted properly and

main thermistor

0001 also check if there is no contamination. - Replace the

does not reach 150

main thermistor. - Replace the fixing heater. - Replace

deg C within 2 min

the AC driver PCB. - Replace the DC controller PCB.

30 sec after it has

Caution You must clear the error in service

exceeded 100 deg

mode (COPIER>FUNCTION>CLEAR>ERR).

C.

The rise in

E002- temperature of the - Clear the error in service

0010 fixing assembly is mode (COPIER>FUNCTION>CLEAR>ERR).

faulty.

The power has

been turned off and

then on without

clearing the error.

The fixing - Check if the connector (J505) of the DC controller PCB

temperature is too is mounted properly and also check if the connector of

low after a standby the fixing assembly is mounted properly. - Check the

state. wiring between the thermistor and the DC controller. -

E003- The reading of the Check if the main thermistor is mounted properly and

0000 main thermistor is also check if there is no contamination. - Replace the

70 deg C or lower main thermistor. - Replace the fixing heater. - Replace

for 2 sec or more the AC driver PCB. - Replace the DC controller PCB.

after it has reached Caution You must clear the error in service

100 deg C. mode (COPIER>FUNCTION>CLEAR>ERR).

The fixing

temperature is too

low after a standby

E003- state. - Clear the error in service

0010 The power has mode (COPIER>FUNCTION>CLEAR>ERR).

been turned off and

then on without

clearing the error.

The fixing assembly

is faulty.

The SSR used to - Replace the AC driver PCB. - Replace the DC

E004-

drive the fixing controller PCB. Caution You will have to clear the error

0000

heater has a short in service mode(COPIER>FUNCTION>CLEAR>ERR).

circuit (detection by

hardware circuitry).

The absence of the

fixing web is

detected.

The length of the - Check the position of the fixing web detection lever. -

fixing web that has Replace the fixing web. - Replace the fixing web length

been taken up is sensor. - Replace the DC controller PCB. Caution After

E005-

more than a replacing the fixing web, you will have to clear the two

0000

specific value and web counters in service

the fixing web mode (COPIER>COUNTER>MISC>FIX-WEB and

length sensor (PS7) COPIER>COUNTER>DRBL-1>FIX-WEB).

has detected the

absence of the web

for 5 sec or more.

E005- The absence of the - Reset the counters of the two webs to zero in service

0010 fixing web is mode (COPIER>COUNTER>MISC>FIX-WEB,

detected. COPIER>COUNTER>DRBL-1>FIX-WEB)

The power is turned

off and then on

without clearing the

error.

Code Description Remedy

The rotation of the

main motor is faulty. - Check if the connecter (J611, J612) of the main motor

No clock pulse arrive is mounted properly. - Check if the connector (J1720) of

E010-

for 2 sec or more after the relay PCB is mounted properly. - Replace the main

0000

the main motor drive motor. - Replace the relay PCB. - Replace the DC

signal (MMFG) has controller PCB.

been generated.

The rotation of the

- Check if the connector (J1720) of the relay PCB is

drum motor is faulty.

mounted properly. - Check if the connector (J512) of the

No clock pulse arrives

E012- DC controller PCB is mounted properly. - Check if the

for 2 sec or more after

0000 connecter (J601, J602) of the drum motor is mounted

the drum motor drive

properly. - Replace the drum motor. - Replace the DC

signal (DMFG) has

controller PCB.

been generated.

The lock of the waste

toner feed screw is

detected.

- Re-mount the waste toner pipe. - Replace the waste

The waste toner feed

toner pipe. - Replace the waste toner clog detecting

E013- screw fails to rotate

switch. - Replace the DC controller PCB. Caution You

0000 normally, and the

will have to clear the error in service

switch MSW2 is

mode(COPIER>FUNCTION>CLEAR>ERR).

pressed multiple times

within a specific period

of time.

The lock of the waste

toner feed screw is

E013- detected. - Clear the error in service

0010 The power is tuned off mode (COPIER>FUNCTION>CLEAR>ERR).

and then on without

clearing the error.

The rotation of the - Check if the connecter (J651, J652) of the fixing motor

E014- fixing motor is faulty. is mounted properly. - Replace the fixing motor. -

0000 The motor clock signal Replace the relay PCB. - Replace the DC controller

is not detected for 2 PCB.

sec or more after the

fixing motor drive

signal has been

generated.

The rotation of the

pickup motor is faulty.

The motor lock signal - Check if the connecter (J621, J622) of the pickup

E015- is not detected for 2 motor is mounted properly. - Replace the pickup motor. -

0000 sec or more after the Replace the relay PCB. - Replace the DC controller

pickup motor drive PCB.

signal has been

generated.

The waste toner case

is full, or the waste

toner case full sensor

is faulty. - Dispose the waste toner in the case. - Check the

More than a specific operation of the base plate of waste toner case. - Check

E019-

number of pages are if the connector (J514) of the DC controller PCB is

0000

printed without mounted properly. - Replace the waste toner full sensor.

disposing of the waste - Replace the DC controller PCB.

toner after the waste

toner case has been

found to be full.

The difficulty providing

toner inside the hopper

developing assemblies

is detected. - Replace the magnet roller drive clutch. - Replace the

E020- Although the toner feed motor (M18). - Replace the toner sensor.

0000 developing assembly Caution You will have to clear the error in service

is supplied with toner, mode (COPIER>FUNCTION>CLEAR>ERR).

the absence of toner

inside it is detected for

3 sec or more.

The difficulty providing

toner inside the hopper

developing assemblies

E020- - Clear the error in service

is detected.

0010 mode (COPIER>FUNCTION>CLEAR>ERR).

The power is turned off

and then on without

clearing the error.

The toner feed motor

- Check if the connector (J512) of the DC controller PCB

E025- inside the hopper is

is mounted properly. - Replace the toner feed motor

0000 faulty.

(M6).

The DC controller PCB

detects an overcurrent

flowing to the toner

feed motor (M6) inside

the cartridge for 10 sec

or more twice. (In

response to the first

detection, it indicates

the message "Shake

the Toner Case, and

Set.")

The counter of the

copy data controller or

the NE controller is

faulty.

- Check if the connecter of the main controller PCB is

E032- The copy data

mounted properly. - Replace the main controller PCB. -

0000 controller or the NE

Replace the copy data controller or the NE controller.

controller are

disconnected after

they have once been

connected.

The rotation of the side

paper deck main motor

is faulty.

The PLL lock signal - Check if the connecter (J101, J106) of the side deck

E043- (DMPLK) does not driver PCB is mounted properly. - Replace the side deck

0000 arrive for 2 sec or main motor. - Replace the side deck driver PCB. -

more after the side Replace the DC controller PCB.

paper deck main motor

drive signal has been

generated.

There is an error in the

detection of the

horizontal registration - Replace the horizontal registration sensor. - Replace

home position. the horizontal registration motor. - Check if the manual

E051-

Departure from home feed tray open/closed detecting switch is mounted

0001

position is not detected properly. - Replace the stackless feed driver PCB. -

within 5 sec during a Replace the DC controller PCB.

horizontal registration

home position search.

There is an error in the - Replace the horizontal registration sensor. - Replace

detection of the the horizontal registration motor. - Check if the manual

E051-

horizontal registration feed tray open/closed detecting switch is mounted

0002

home position. properly. - Replace the stackless feed driver PCB. -

Home position is not Replace the DC controller PCB.

detected within 5 sec

during a horizontal

registration home

position search.

There is an error in the

detection of the

horizontal registration

home position.

- Replace the horizontal registration sensor. - Replace

The horizontal

the horizontal registration motor. - Check if the manual

E051- registration detection

feed tray open/closed detecting switch is mounted

0003 movement for the

properly. - Replace the stackless feed driver PCB. -

preceding sheet does

Replace the DC controller PCB.˜

not end within 5 sec at

the start of a horizontal

registration search

during printing.

Code Description Remedy

There is an error in the high- - Check if the primary charging assembly is

voltage output to the transfer mounted properly and also check if there is no

E065- charging assembly. contamination. - Check if the connector (T601,

0000 An error (leakage) is detected J723, J730) of the HV-DC PCB is mounted

in the high-voltage output to properly and also check the wiring. - Replace

the primary charging assembly. the HV-DC PCB.

There is an error in the high-

voltage output.

An error is detected in two or - Check if the primary charging assembly,

more of the following at the pretransfer charging assembly, transfer

same time: the primary high charging assembly and separation charging

E067- voltage, pre-transfer high assembly are mounted properly. - Check if the

0000 voltage, transfer high voltage, connector (J722, J723, J730) of the HV-DC

and separation high voltage. PCB is mounted properly and also check the

Or, an error (leakage) in the wiring. - Replace the HV-DC PCB. - Replace

high-voltage output to the the HV-AC PCB.

separation charging assembly

is detected.

There is an error in the high- - Check if the transfer charging assembly and

voltage output to the separation charging assembly are mounted

E068- separation charging assembly. properly. - Check if the connector (J722, J723,

0000 An error (leakage) to the high- J730, J734) of the HV-DC PCB and the

voltage output to the connector (J741, J742) of the HV-AC PCB are

separation charging assembly mounted properly. - Replace the HV-AC PCB. -

is detected. Replace the separation charging assembly. -

Replace the pre-transfer charging assembly.

- Check if the transfer charging assembly and

There is an error in the high-

separation charging assembly are mounted

voltage output to the transfer

properly. - Check if the connector (T701, J723,

E069- charging assembly.

J730) of the HV-DC PCB is mounted properly

0000 An error (leakage) is detected

and also check the wiring. - Replace the HV-DC

in the high-voltage output to

PCB. - Replace the pre-transfer charging

the transfer charging assembly.

assembly.

The BD PCB is faulty.

The BD signal does not arrive

within 1 sec after the laser - Check if the BD PCB, laser driver PCB and

E100- drive signal has been DC controller are connected properly. - Replace

0000 generated. Or, the BD signal the BD PCB. - Replace the laser scanner unit. -

does not arrive for 1 sec or Replace the DC controller PCB.

more while the laser remains

ON.

The rotation of the laser

scanner motor is faulty. - Check if the connector (J762) of the laser

The constant speed rotation scanner motor driver PCB is mounted properly.

E110- signal (LM-RDY) does not - Check if the connector (J503) of the DC

0000 arrive for 20 sec or more after controller PCB is mounted properly. - Replace

the laser scanner motor (M4) the laser scanner unit. - Replace the DC

drive signal has been controller PCB.

generated.

The rotation of the laser motor

- Check if there is no foreign material in the

cooling fan is faulty.

rotation assembly of the laser motor cooling fan.

E111- The lock signal arrives for 5

- Check if the connector (J503) of the relay PCB

0000 sec or more although the laser

is mounted properly. - Replace the laser motor

motor cooling fan (FM1) is

cooling fan. - Replace the DC controller PCB.

being driven.

The rotation of the laser

- Check if there is no foreign material in the

cooling fan (1/2) is faulty.

rotation assembly of the laser cooling fan 1. -

E121- The lock signal arrives for 5

Check if the connector (J503) of the relay PCB

0001 sec or more although the laser

is mounted properly. - Replace the laser cooling

cooling fan 1 (FM3) is being

fan 1. - Replace the DC controller PCB.

driven.

The rotation of the laser

- Check if there is no foreign material in the

cooling fan (1/2) is faulty.

rotation assembly of the laser cooling fan 2. -

E121- The lock signal arrives for 5

Check if the connector (J503) of the relay PCB

0002 sec or more although the laser

is mounted properly. - Replace the laser cooling

cooling fan 2 (FM5) is being

fan 2. - Replace the DC controller PCB.

driven.

Caution No code will be indicated. The keys will

There is an error in the

be locked. You can check the code in service

detection of the scanner home

mode (COPIER>DISPLAY>ERR). - Check if the

position.

scanner motor is connected properly, and

E202- Scanner home position cannot

replace the scanner motor if necessary. - Check

0000 be detected within a specific

if the connector (J1720) of the relay PCB is

period of time after the power

mounted properly. - Replace the scanner home

switch is turned on or the Start

position sensor. - Replace the reader controller

key is pressed.

PCB.

There is an error in the

detection of the image leading

edge signal. Caution No code will be indicated. The keys will

During forward movement in be locked. You can check the code in service

fixed reading mode or during a mode (COPIER>DISPLAY>ERR). - Check if the

E204-

home position search, the scanner motor is connected properly, and

0000

image leading signal does not replace the scanner motor if necessary. -

occur; or, in stream reading Replace the scanner image leading edge

mode, the image leading edge sensor. - Replace the reader controller PCB.

signal does not arrive from the

ADF controller PCB.

The rise in temperature of the

scanning lamp heater is faulty.

While the power is ON, the

ambient temperature of the

- Check if the connecter (J852, J853) of the light

scanning lamp does not

control PCB is mounted properly. - Replace the

E211- exceed 10 deg C 2 min after

scanning lamp heater. - Replace the light

0000 the florescent heater has gone

control PCB. - Replace the reader controller

ON; or, after the power is

PCB.

turned on, the reading of the

ambient temperature of the

scanning lamp is 0 deg C or

lower.

The rise in temperature of the

- Check if the connecter (J852, J853) of the light

scanning lamp heater is faulty.

control PCB is mounted properly. - Replace the

E215- While the scanning lamp is

scanning lamp heater. - Replace the light

0000 OFF, the reading of the

control PCB. - Replace the reader controller

ambient temperature is 170

PCB.

deg C or higher.

- Check if the scannning lamp is mounted

The scanning lamp is not

properly. - Check if the connecter (J1002,

mounted properly.

E218- J1003) of the inverter PCB is mounted properly.

When the power is turned on,

0000 - Check if the connector (J1720) of the relay

the absence of the scanning

PCB is mounted properly. - Replace the

lamp is detected.

scanning lamp. - Replace the reader controller

PCB.

The scanning lamp life - Check if the connecter (J852, J853) of the light

While the scanning lamp is ON, control PCB is mounted properly. - Replace the

E219-

the reading of the ambient scanning lamp heater. - Replace the light

0000

temperature is 170 deg C or control PCB. - Replace the reader controller

higher. PCB.

Code Description Remedy

The lighting of the scanning lamp is

faulty.

The scanning lamp does not reach a

specific intensity within 10 sec after it is - Check if the connecter (J852, J853)

tuned on (if the room temperature is 10 of the light control PCB is mounted

E220- deg C or lower, within 60 sec). Or, the ON properly. - Replace the scanning

0000 detection signal (FL-DTCT) does not go lamp heater. - Replace the light

OFF within 5 sec after the scanning lamp control PCB. - Replace the reader

is turned off; during shading adjustment, controller PCB.

the ON detection signal (FL-DTCT) does

not go ON within 60 sec after the

scanning lamp is turned on.

The rise in temperature of the scanning

lamp heater is faulty. - Check if the connecter (J852, J853)

During the initial activation after power- of the light control PCB is mounted

E222- on, the reading does not reach 70 deg C properly. - Replace the scanning

0000 within 5 min after the heater is turned on. lamp heater. - Replace the light

Or, during standby or reading operation, control PCB. - Replace the reader

the reading does not reach 75 deg C controller PCB.

within 3 min after the heater is tuned on.

The communication between the MCON - Check the wiring between the DC

and DCON is faulty. controller PCB and the main

E240-

A communication fault exists between the controller PCB. - Replace the DC

0000

CPUs of the main controller PCB and the controller PCB. - Replace the main

DC controller PCB. controller PCB.

The communication between the original

orientation detection PCB and RCON is

- Replace the original orientation

E241- faulty.

PCB. - Replace the reader controller

0000 The initial communication between the

PCB.

CPUs of the original orientation detection

PCB and the reader controller PCB fails.

The communication between the original - Replace the original orientation

E241-

orientation detection PCB and RCON is PCB. - Replace the reader controller

0001

faulty. PCB.

When the orientation of an original is

detected, the result of detection is not

communicated by the original orientation

detection PCB until the next original is

read.

The communication between the original

orientation detection PCB and RCON is

- Replace the original orientation

E241- faulty.

PCB. - Replace the reader controller

0002 The result of detection of the last original

PCB.

is not communicated 5 sec after the end

of reading the last original.

The communication between the control

panel PCB and MCON is faulty.

E243- - Replace the control panel PCB. -

A communication fault exists between the

0000 Replace the main controller PCB.

CPUs of the control panel PCB and the

main controller PCB.

- Check if there is no foreign material

The rotation of the inverter cooling fan is in the rotation assembly of the

faulty. inverter cooling fan. - Check if the

E251-

The lock signal (FM9LCK) arrives for 5 connecter (J1110) of the reader

0000

sec or more although the inverter cooling control PCB is mounted properly. -

fan (FM9) is being driven. Replace the inverter cooling fan. -

Replace the reader controller PCB.

- Check if the connecter (J1502,

J1503) of the CCD PCB is mounted

Shading error

properly. - Check if the connecter

E302- During shading operation, the reader

(J1107, J1108) of the reader control

0000 controller PCB fails to end shading

PCB is mounted properly. - Replace

processing.

the CCD PCB. - Replace the reader

controller PCB.

There is an error in image data. The

reader controller PCB is faulty. The main

E315- - Replace the reader controller PCB.

controller PCB is faulty.

0000 - Replace the main controller PCB.

During image rotation, the encoding/

decoding has a fault.

- Check if the connecter (J1502,

There is a time out error in the image

J1503) of the CCD PCB is mounted

reading processing.

properly. - Check if the connecter

E320- While an image is being read, the image

(J1107, J1108) of the reader control

0000 read end notice does not arrive at the

PCB is mounted properly. - Replace

reader controller PCB within 60 sec from

the CCD PCB. - Replace the reader

the CCD/AP PCB.

controller PCB.

E400- Communication error with the ADF - Check if the communication cable

0000 While the ADF is in standby, the between the ADF and copier is

communication between ADF and copier connected properly. - Replace the

is interrupted for 5 sec or more. Or, when ADF controller PCB.

the ADF is in operation, the

communication between ADF and copier

is disrupted for 0.5 sec or more.

- Check if the cable between the ADF

belt motor drive PCB and ADF

The rotation of the ADF belt motor is

controller PCB is connected properly.

faulty.

E402- - Replace the ADF belt motor clock

The clock signal does not occur for 100

0000 sensor. - Replace the ADF belt

msec when the belt motor drive signal is

motor. - Replace the ADF belt motor

generated.

drive PCB. - Replace the ADF

controller PCB.

The rotation of the ADF delivery motor is

- Replace the ADF delivery motor. -

faulty.

E404- Replace the ADF delivery motor

The clock signal does not occur for 200

0000 clock sensor. - Replace the ADF

msec when the delivery motor drive

controller PCB.

signal is generated.

The rotation of the ADF separation motor

- Replace the ADF separation motor.

is faulty.

E405- - Replace the ADF separation motor

The clock signal does not occur for 200

0000 clock sensor. - Replace the ADF

msec when the separation motor drive

controller PCB.

signal is generated.

Code Description Remedy

The rotation of the ADF pickup motor is

faulty. - Replace the ADF pickup motor. -

The pickup roller height sensor 1 (PI8) or Replace the ADF pickup roller height

2 (PI9) does not generate a signal within sensor 1. - Replace the ADF pickup

E410-

2 sec after the pickup motor is driven. roller height sensor 2. - Replace the

0000

Or, the pickup roller home position ADF pickup roller home position

sensor (PI7) does not generate a signal sensor. - Replace the ADF controller

within 2 sec after the pickup motor is PCB.

driven.

The rotation of the ADF cooling fan is

faulty.

E412- - Replace the ADF cooling fan. -

The lock signal arrives for 100 msec or

0000 Replace the ADF controller PCB.

more although the cooling fan is being

driven.

E420- The EEPROM is faulty. The ADF

- Replace the ADF controller PCB.

0000 controller PCB is faulty.

The backup data of the EEPROM cannot

be read when the connected device is

tuned on. Or, the data that has been

read has a fault.

E602 There is an error on the hard disk.

The image memory is faulty or is

E604- inadequate.

- Increase the memory.

0000 The memory size does not match the

model.

There is an error on the HDD.

E609- At startup, the HDD fails to reach a - Replace the HDD. - Replace the DC

0008 specific temperature level within a controller PCB.

specific period of time.

There is an error on the HDD.

E609- At time of sleep recovery, the - Replace the HDD. - Replace the DC

0009 temperature fails to reach a specific controller PCB.

level.

The HDD coding key is faulty. - Turn off and then back on the power

The SRAM/PCB is faulty. The battery switch to generate the key once

E610

has become exhausted, leading to loss again. - Replace the main controller

of SRAM contents. PCB.

There is an error in the initialization of

the IPC.

E710- - Check the cable. - Replace the

The IPC (IC5) on the reader controller

0001 reader controller PCB.

PCB cannot be initialized when the main

power supply is turned on.

There is an error in the initialization of

the IPC.

E710- - Check the cable. - Replace the DC

The IPC (IC40) on the DC controller PCB

0002 controller PCB.

cannot be initialized when the main

power supply is turned on.

There is an error in the initialization of

the IPC.

E710- - Check the cable. - Replace the main

The IPC (IC1003) on the machine

0003 controller PCB.

controller PCB cannot be initialized when

the main power is turned on.

There is an error in the IPC

communication.

E711- Data has been written to the error - Check the cable. - Replace the

0001 register of the IPC (IC5) on the reader reader controller PCB.

controller PCB 4 times or more within 1.5

sec.

There is an error in the IPC

communication.

E711- Data has been written to the error - Check the cable. - Replace the DC

0002 register of the IPC (IC40) on the DC controller PCB.

controller PCB 4 times or more within 2

sec.

There is an error in the IPC

communication.

E711- Data has been written to the error - Check the cable. - Replace the main

0003 register of the IPC (IC1003) on the main controller PCB.

controller PCB 4 times or more within 2

sec.

- Check if the communication cable

Communication error with the ADF

E712- between the ADF and copier is

The communication IC (IPC) on the ADF

0000 connected properly. - Replace the

controller PCB goes out of order.

ADF controller PCB.

Code Description Remedy

There is an error in the

- Check if the communication cable between

communication with the finisher.

E713- the finisher and copier is connected properly. -

The communications IC (IPC) on

0000 Replace the finisher controller PCB. - Replace

the finisher controller PCB goes

the DC controller PCB.

out of order.

There is an error in the

communication with the NE

controller.

Check the cable; thereafter, reset the

E717- The NE controller is not

condition in service mode:

0001 connected at power on, although

COPIER>FUNCTION>CLEAR>ERR.

it was connected before the

power was turned off because of

an error.

There is an error in the

communication with the NE

controller.

An IPC error has occurred while Check the cable; thereafter, reset the

E717-

the NE controller is in operation. condition in service mode:

0002

There is an open circuit for the COPIER>FUNCTION>CLEAR>ERR.

IPC. An error has occurred, and

the IPC communication remains

disabled.

E719- There is a coin vendor error. Check the cable; thereafter, reset the

0001 The coin vendor is not condition in service mode:

connected when the power is COPIER>FUNCTION>CLEAR>ERR.

turned on, although it was

connected before the power was

turned off because of an error.

There is a coin vendor error.

While the coin vendor is in

operation, an IPC error has

occurred, IPC has developed an

open circuit, or an error Check the cable; thereafter, reset the

E719-

preventing recovery of IPC condition in service mode:

0002

communication has occurred. An COPIER>FUNCTION>CLEAR>ERR.

open circuit ha been detected in

the line for the pickup/delivery

signal. An illegal signal has been

detected.

There is a coin vendor error.

While the unit price is being Check the cable; thereafter, reset the

E719-

checked at startup, an error condition in service mode:

0003

occurs in the communication COPIER>FUNCTION>CLEAR>ERR.

with the coin vendor.

There is a coin vendor error.

An error has occurred at new

card reader startup. The new Check the cable; thereafter, reset the

E719-

card reader is not connected condition in service mode:

0011

when the power is turned off, COPIER>FUNCTION>CLEAR>ERR.

although it was connected when

the power was turned off.

There is a coin vendor error.

An IPC error has occurred at

Check the cable; thereafter, reset the

E719- new card reader startup. There

condition in service mode:

0012 is an IPC open circuit. An error

COPIER>FUNCTION>CLEAR>ERR.

has occurred that prevents

recovery of IPC communication.

There is a PDL software error.

E730- - Execute PDL resetting. - Turn on the power

An initialization error has

1001 once again.

occurred.

There is a PDL software error.

E730- An error that may be critical to - Execute PDL resetting. - Turn on the power

100A the system (e.g., failed once again.

initialization) has occurred.

There is a PDL software error. - Turn on the power once main. - Check the

E730-

There is an error in the connection of the open I/F board and the

9004

communication (PAI) with an cable. - Replace the board for the external

external controller. controller open I/F. - Replace the main

controller PCB.

- Turn on the power once main. - Check the

There is a PDL software error. connection of the open I/F board and the

E730-

Fault in the connector of the vide cable. - Replace the board for the external

9005

cable to the external controller controller open I/F. - Replace the main

controller PCB.

There is a PDL software error. - Execute PDL resetting. - Turn on the power

E730- The PDL board does not once again. - Check the connection of the

A006 respond. A subbootable is faulty UFR board. - Re-install the firmware. -

or absent. Replace the main controller PCB.

There is a PDL software error.

There is a mismatch between - Execute PDL resetting. - Turn on the power

E730-

the control software of the once again. - Execute system formatting (all),

A007

machine and the PDL control and reinstall the system.

software in regard to version.

- Turn on the power once again. - Re-install

E730- There is a PDL software error.

the Software. - Execute system formatting

B013 Corruption in the font data

(all), and reinstall the system.

Code Description Remedy

There is an error in the - Check the connector used to connected the

communication with the scanner. - Check the power supply of the scanner

E732-

scanner. (to see if initialization takes place at startup). -

0001

There is a DDI-S Replace the reader controller, scanner board, or

communication error. main controller PCB as necessary.

There is an error in the - Check the connector used to connect to

communication with the printer. - Check the power supply of

E733-

theprinter. the printer (to see if initialization takes place at

0000

At startup, communication startup). - Replace the DC controller or the main

with the printer fails. controller PCB.

There is an error in the

- Check the connection with the printer. - Check the

communication with

E733- power supply of the printer (to see if initialization

theprinter.

0001 takes place at startup). - Replace the DC controller

There is a DDI-P

or the main controller PCB.

communication error.

There is an error on the

E740-

Ethernet board. - Replace the main controller PCB.

0002

The MAC address is illegal.

E744 There is an error in the - Download a language file of the correct version.

language file/boot ROM.

There is a fault on the - Disconnect and then connect the TokenRing

E745

TokenRing board board. - Replace the TokenRing board.

The accessories board is of

the wrong type.

E746- - Replace the UFR board of the correct type

˜At startup, a board for a

0003 (model).

different model has been

detected.

Mismatch in controller

board and SDRAM size˜

E748- - Check the correct combination between main

There is a mismatch

1001 controller PCB and SDRAM.

between the control board

and the SDRAM.

There is an error in the auto - Turn on the power once again. - Check if the

power-off circuit. connector (J505) of theDC controller PCB is

E800-

An open circuit is detected mounted properly. - Check if the connector (J1719)

0000

in the auto power-off circuit of the relay PCB is mounted properly. - Replace

for 3 sec or more. the relay PCB. - Replace the DC controller PCB.

There is an error in the

system fan/the power

- Check if there is no foreign material in the rotation

supply cooling fan (1 and

assembly of the power supply cooling fan (1 and 2)

2).

E804- fan. - Check if the connector (J505) of the DC

The lock signal is detected

0000 controller PCB is mounted properly. - Replace the

for 5 sec or more although

power supply cooling fan (1/2). - Replace the DC

the power supply cooling

controller PCB.

fan (1 and 2) is being

driven.

There is an error in the - Check if there is no foreign material in the rotation

system fan/the power assembly of the system fan. - Check if the

supply cooling fan (1 and connector (J1028) of the main controller PCB is

E804- 2). mounted properly. - Replace the sysytem fan. -

0004 The reading of the ambient Replace the main controller PCB. Caution In the

temperature of the main case of a fault in the system fan, the data will be

controller is 80 degrees or indicated in the form of an alarm (0008040004;

higher. ALARM-2).

The rotation of the fixing

assembly heat discharging - Check if there is no foreign material in the rotation

fan and separation heat assembly of the fixing assembly heat discharging

E805- discharging fan is faulty. fan. - Check if the connector (J503) of the DC

0001 The lock signal is detected controller PCB is mounted properly. - Replace the

for 5 sec or more although fixing assembly heat discharging fan. - Replace the

the fixing assembly heat DC controller PCB.

discharging fan is being

driven.

The rotation of the fixing

assembly heat discharging

- Check if there is no foreign material in the rotation

fan and separation heat

assembly of the separation heat discharging fan. -

discharging fan is faulty.

E805- Check if the connector (J1112) of the reader

The lock signal is detected

0002 controller PCB is mounted properly. - Replace the

for 5 sec or more although

separation heat discharging fan. - Replace the

the separation heat

reader controller PCB.

discharging fan is being

driven.

The rotation of the drum fan

- Check if there is no foreign material in the rotation

is faulty.

assembly of the drum fan. - Check if the connector

E820- The lock signal is detected

(J512) of the DC controller PCB is mounted

0000 for 5 sec or more although

properly. - Replace the drum fan. - Replace the DC

the drum fan is being

controller PCB.

driven.

The rotation of the pre-

transfer charging assembly - Check if there is no foreign material in the rotation

fan is faulty. assembly of the pre-transfer charging assembly

E823- The lock signal is detected fan. - Check if the connector (J504) of the DC

0000 for 5 sec or more although controller PCB is mounted properly. - Replace the

the pre-transfer charging pre-transfer charging assembly fan. - Replace the

assembly fan is being DC controller PCB.

driven.

Code Description Remedy

The rotation of the

- Check if there is no foreign material in the rotation

separation fan is faulty.

assembly of the separation cooling fan. - Check if

E830- The lock signal is detected

the connector (J509) of the DC controller PCB is

0000 for 5 sec or more although

mounted properly. - Replace the separation cooling

the separation cooling fan

fan. - Replace the DC controller PCB.

is being driven.

Potrebbero piacerti anche

- Canon IR105 Trouble Error CodesDocumento32 pagineCanon IR105 Trouble Error Codesnafees0% (2)

- Canon Ir8070 Error Codes List PDFDocumento18 pagineCanon Ir8070 Error Codes List PDFGirish KumarNessuna valutazione finora

- Canon iR8070 Error Codes ListDocumento18 pagineCanon iR8070 Error Codes ListGirish Kumar100% (1)

- Canon IR7095 Error CodesDocumento21 pagineCanon IR7095 Error CodesnafeesNessuna valutazione finora

- Ir 6570 Code ListDocumento22 pagineIr 6570 Code ListAashish Chaudhari90% (10)

- Error Code Ir5000Documento22 pagineError Code Ir5000Didi ConanNessuna valutazione finora

- Err CodeDocumento21 pagineErr CodeDidi ConanNessuna valutazione finora

- Canon IR4570 Trouble Error CodesDocumento22 pagineCanon IR4570 Trouble Error Codesnafees100% (3)

- IR Detail E602Documento9 pagineIR Detail E602Abah Yazien DjoenaedyNessuna valutazione finora

- Canon IR3245 Error CodesDocumento31 pagineCanon IR3245 Error Codesnafees80% (10)

- Error CodeDocumento99 pagineError CodeRDN Artha SentosaNessuna valutazione finora

- Error Code Ir3245 - Series-SmDocumento22 pagineError Code Ir3245 - Series-SmvikramNessuna valutazione finora

- Fix Heater Error Codes IR 5075 SeriesDocumento9 pagineFix Heater Error Codes IR 5075 Seriesslavko688% (8)

- Canon IR Advance 6075 Error Codes ListDocumento63 pagineCanon IR Advance 6075 Error Codes ListZhonny Rongsok Kendal60% (5)

- Error Code For Canon IR4045 AdvanceDocumento30 pagineError Code For Canon IR4045 AdvanceRopsonNessuna valutazione finora

- Imagerunner - 3045 Corona TechnicalDocumento23 pagineImagerunner - 3045 Corona TechnicalSilk Karim OussamaNessuna valutazione finora

- Canon IR2422 Error CodesDocumento7 pagineCanon IR2422 Error CodesnafeesNessuna valutazione finora

- Canon IR2530 Error CodesDocumento10 pagineCanon IR2530 Error CodesnafeesNessuna valutazione finora

- Canon IR Advance 4045 Trouble Error CodesDocumento94 pagineCanon IR Advance 4045 Trouble Error CodesnafeesNessuna valutazione finora

- Canon IR3225 Trouble Error CodesDocumento30 pagineCanon IR3225 Trouble Error Codesnafees80% (10)

- Canon IR2016 Error CodesDocumento7 pagineCanon IR2016 Error CodesnafeesNessuna valutazione finora

- Canon iR2318 error codesDocumento7 pagineCanon iR2318 error codesMabrouk Salem IssaNessuna valutazione finora

- Ir3235 Service ManualDocumento33 pagineIr3235 Service ManualGirish KumarNessuna valutazione finora

- Canon IR Advance 6055 Trouble Error CodesDocumento57 pagineCanon IR Advance 6055 Trouble Error Codesnafees100% (2)

- Kode Eror Mesin Canon 5075Documento16 pagineKode Eror Mesin Canon 5075donirahmat100% (2)

- Error Code: CANON Ir105 REV.0 JULY 2001Documento30 pagineError Code: CANON Ir105 REV.0 JULY 2001Willian S.Nessuna valutazione finora

- Canon IR Advance C5030 Trouble Error CodesDocumento73 pagineCanon IR Advance C5030 Trouble Error Codesnafees100% (8)

- Canon Ir Advance C5030 Trouble Error Codes PDFDocumento73 pagineCanon Ir Advance C5030 Trouble Error Codes PDFNafeesAhmad100% (1)

- Canon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineDocumento94 pagineCanon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineTengkuNessuna valutazione finora

- Imagerunner 2420Documento30 pagineImagerunner 2420Goodluck GundaNessuna valutazione finora

- Errorc Ir Advance 6055 6065 6075Documento77 pagineErrorc Ir Advance 6055 6065 6075nafeesNessuna valutazione finora

- Canon IR Advance 500 Trouble Error CodesDocumento30 pagineCanon IR Advance 500 Trouble Error CodesnafeesNessuna valutazione finora

- Ir 6000 Code ListDocumento21 pagineIr 6000 Code ListAashish Chaudhari83% (12)

- Ir7095 Error CodesDocumento15 pagineIr7095 Error Codesnag85100% (5)

- Canon IR Advance 6265 Error CodesDocumento56 pagineCanon IR Advance 6265 Error CodesnafeesNessuna valutazione finora

- Canon IR Advance 6065 Trouble Error CodesDocumento57 pagineCanon IR Advance 6065 Trouble Error Codesnafees100% (1)

- Canon IR2200 Trouble Error CodesDocumento29 pagineCanon IR2200 Trouble Error CodesnafeesNessuna valutazione finora

- Canon IR2535 Trouble Error CodesDocumento36 pagineCanon IR2535 Trouble Error Codesnafees100% (4)

- Canon IR Advance C2020 Trouble Error CodesDocumento62 pagineCanon IR Advance C2020 Trouble Error Codesnafees80% (5)

- Canon Ir2525 Trouble Error Codes PDFDocumento11 pagineCanon Ir2525 Trouble Error Codes PDFnafees80% (10)

- TMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151Documento3 pagineTMP - 11281-Error Codes - Canon - Ir3300 - Page 11424020151nichoNessuna valutazione finora

- Canon IRC2380i Error CodesDocumento24 pagineCanon IRC2380i Error Codesnafees100% (1)

- Canon IR Advance C2025 Trouble Error Codes - 1Documento73 pagineCanon IR Advance C2025 Trouble Error Codes - 1nafeesNessuna valutazione finora

- Error Code ListDocumento29 pagineError Code ListBipin SinghNessuna valutazione finora

- Daftar Kode Kesalahan Canon IR5000 IR6000Documento14 pagineDaftar Kode Kesalahan Canon IR5000 IR6000M MiftakhNessuna valutazione finora

- Canon IR Advance 500 Trouble Error CodesDocumento30 pagineCanon IR Advance 500 Trouble Error CodesnafeesNessuna valutazione finora

- Advance Image Runner 6075Documento96 pagineAdvance Image Runner 6075vishwajitNessuna valutazione finora

- Canon IR Advance C2025 Trouble Error Codes - 1Documento73 pagineCanon IR Advance C2025 Trouble Error Codes - 1nafeesNessuna valutazione finora

- Canon iR Advance C2025 Error Codes ListDocumento73 pagineCanon iR Advance C2025 Error Codes ListNafeesAhmadNessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Valutazione: 2.5 su 5 stelle2.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDa EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- How Vision WorksDocumento11 pagineHow Vision WorksNafeesAhmadNessuna valutazione finora

- How Diamonds WorkDocumento17 pagineHow Diamonds WorknafeesNessuna valutazione finora

- How You'Re Lungs WorkDocumento8 pagineHow You'Re Lungs WorknafeesNessuna valutazione finora

- How To Lose Weight On A LowDocumento5 pagineHow To Lose Weight On A LowNafeesAhmadNessuna valutazione finora

- Ricoh Aficio MP7000 Trouble Error CodesDocumento35 pagineRicoh Aficio MP7000 Trouble Error CodesnafeesNessuna valutazione finora

- How The Digestive System WorksDocumento9 pagineHow The Digestive System WorksnafeesNessuna valutazione finora

- How You're Kidneys WorkDocumento20 pagineHow You're Kidneys WorkNafeesAhmadNessuna valutazione finora

- How Airplanes WorkDocumento13 pagineHow Airplanes WorkNafeesAhmadNessuna valutazione finora

- How The Digestive System WorksDocumento9 pagineHow The Digestive System WorksnafeesNessuna valutazione finora

- How Helicopters WorkDocumento11 pagineHow Helicopters WorknafeesNessuna valutazione finora

- How To Lose Weight On A LowDocumento5 pagineHow To Lose Weight On A LowNafeesAhmadNessuna valutazione finora

- Ricoh Aficio MPC4000 Trouble Error CodesDocumento25 pagineRicoh Aficio MPC4000 Trouble Error CodesnafeesNessuna valutazione finora

- How Fat Cells WorkDocumento5 pagineHow Fat Cells WorknafeesNessuna valutazione finora

- How To Lose Weight On A LowDocumento5 pagineHow To Lose Weight On A LowNafeesAhmadNessuna valutazione finora

- How Fat Cells WorkDocumento5 pagineHow Fat Cells WorknafeesNessuna valutazione finora

- How Airplanes WorkDocumento13 pagineHow Airplanes WorkNafeesAhmadNessuna valutazione finora

- How Web Servers Work by NafeesDocumento9 pagineHow Web Servers Work by NafeesnafeesNessuna valutazione finora

- How The Sun WorksDocumento27 pagineHow The Sun WorksnafeesNessuna valutazione finora

- CanonDocumento747 pagineCanonnafeesNessuna valutazione finora

- Canon IR4570 Trouble Error CodesDocumento22 pagineCanon IR4570 Trouble Error Codesnafees100% (3)

- Ricoh Alicia MPC3503SP Trouble Error CodesDocumento46 pagineRicoh Alicia MPC3503SP Trouble Error CodesnafeesNessuna valutazione finora

- Ricoh Aficio MP4500 Trouble Error CodesDocumento19 pagineRicoh Aficio MP4500 Trouble Error Codesnafees100% (1)

- How Circuit Breakers Work 9Documento4 pagineHow Circuit Breakers Work 9nafeesNessuna valutazione finora

- How Food WorksDocumento19 pagineHow Food WorksnafeesNessuna valutazione finora

- How To Install Android 4Documento39 pagineHow To Install Android 4nafeesNessuna valutazione finora

- How BIOS Works 4Documento7 pagineHow BIOS Works 4nafeesNessuna valutazione finora

- Charging FaultsDocumento1 paginaCharging FaultsnafeesNessuna valutazione finora

- Konica-Minolta Bizhub 250 Trouble Error CodesDocumento11 pagineKonica-Minolta Bizhub 250 Trouble Error Codesnafees100% (1)

- Konica-Minolta Bizhub 423 Error CodesDocumento26 pagineKonica-Minolta Bizhub 423 Error Codesnafees0% (1)

- Ricoh Aficio MPC6501 Trouble Error CodesDocumento55 pagineRicoh Aficio MPC6501 Trouble Error Codesnafees100% (1)

- StacoAVR2 PDFDocumento20 pagineStacoAVR2 PDFmaungNessuna valutazione finora

- Magnetic Resonant Coupling Based Wireless PowerDocumento7 pagineMagnetic Resonant Coupling Based Wireless PowerHartantoNessuna valutazione finora

- Sta Ate Iwpriv UsageDocumento9 pagineSta Ate Iwpriv UsageskeyverNessuna valutazione finora

- Automatic Power Factor Detection and CorDocumento53 pagineAutomatic Power Factor Detection and CorAshritaNessuna valutazione finora

- Mixed Signal Microcontroller: FeaturesDocumento69 pagineMixed Signal Microcontroller: FeaturesAlfonso CorderoNessuna valutazione finora

- Trueview 5725Documento45 pagineTrueview 5725Hung Nguyenvan0% (1)

- Cisco 2900 & 3900 Series Routers OverviewDocumento46 pagineCisco 2900 & 3900 Series Routers OverviewPterocarpousNessuna valutazione finora

- Avh-288bt CRT5883Documento3 pagineAvh-288bt CRT5883marcio.balistaNessuna valutazione finora

- MTech ECE Syllabus of Singhania UniversityDocumento18 pagineMTech ECE Syllabus of Singhania UniversityPrashant SinhaNessuna valutazione finora

- Altec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFDocumento31 pagineAltec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFRaju100% (1)

- Vented. Box Loudspeaker Systems Part I1: Large-Signal AnalysisDocumento7 pagineVented. Box Loudspeaker Systems Part I1: Large-Signal AnalysisEclys MontenegroNessuna valutazione finora

- Equivalentes SMD X ConvencionalDocumento126 pagineEquivalentes SMD X Convencionaledaoeletronica100% (1)

- Remotek Pico ICS Repeater Introduction and Case StudyDocumento21 pagineRemotek Pico ICS Repeater Introduction and Case StudyKobby OwusuNessuna valutazione finora

- AAMCS S-Band AmplifierDocumento14 pagineAAMCS S-Band AmplifierMazlum ÜnalNessuna valutazione finora

- DatasheetDocumento17 pagineDatasheetErnesto SuarezNessuna valutazione finora

- Mimosa B5Lite DatasheetDocumento2 pagineMimosa B5Lite DatasheetMarcelo AraujoNessuna valutazione finora

- Ft-Oct 22 FinalDocumento79 pagineFt-Oct 22 FinalOmkar Balasaheb MetkariNessuna valutazione finora

- ANANTH SHETTY K R Resume - Full Custom Layout Design EngineerDocumento2 pagineANANTH SHETTY K R Resume - Full Custom Layout Design EngineerKrishna ShettyNessuna valutazione finora

- Speech About TouchscreenDocumento2 pagineSpeech About TouchscreenMarcelin RobuNessuna valutazione finora

- TMC THC301 Quick StartDocumento28 pagineTMC THC301 Quick StartM. Rizki SahrudiNessuna valutazione finora

- Tracker TeamDocumento1.707 pagineTracker TeamAbu Abdullah YaserNessuna valutazione finora

- 8085 Microrprocessor Lecture NoteDocumento119 pagine8085 Microrprocessor Lecture NoteGoitom Haile100% (1)

- Broadband Dual Circularly Polarized Square Slot AntennaDocumento4 pagineBroadband Dual Circularly Polarized Square Slot AntennaDr-Gurpreet KumarNessuna valutazione finora

- Blade Center S - Battery Unit ReplacementDocumento3 pagineBlade Center S - Battery Unit ReplacementJorge Duran HerasNessuna valutazione finora

- Conductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForDocumento6 pagineConductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForRob GridleyNessuna valutazione finora

- Service Manual: Micro-Tech - 600Documento43 pagineService Manual: Micro-Tech - 600Ivan mirandaNessuna valutazione finora

- Weekly Report JABO3 W42Documento32 pagineWeekly Report JABO3 W42Sehat MaruliNessuna valutazione finora

- Single line diagram 132/33 kV GSS ChapraDocumento1 paginaSingle line diagram 132/33 kV GSS ChapraAyaz Ahmad KhanNessuna valutazione finora

- Indiabix ELECS MCQ COMPILED Part 1Documento205 pagineIndiabix ELECS MCQ COMPILED Part 1Andreana Amor100% (1)

- History of Electronics & SemiconductorsDocumento3 pagineHistory of Electronics & SemiconductorsBill Joseph SuguitanNessuna valutazione finora