Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

DM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDF

Caricato da

demie figueroaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

DM-PH&SD-P4-TG23 - (Guidelines For Safety Procedures in Metal Finishing Industries) PDF

Caricato da

demie figueroaCopyright:

Formati disponibili

Organization Unit Public Health & Safety Department

Technical Guidelines for Safety Procedures in

Form sheet title:

Metal Finishing Industries

Doc Ref. DM-PH&SD-P4-TG23

Background: Metal finishing activities produce large quantities of waste

water and spent chemicals. Waste produced, if carelessly

handled or disposed of, may cause a significant threat to

people health and society. Ground and surface water

contamination would occur due to spills and careless dumping

of residues. Liquid waste generated is not safe for land,

marine, or sewer disposal. Pre-treatment of waste is required

to bring down the concentration of contaminants to the safe

levels before off-site disposal. The goal of this guideline is to

make the metal finishing industries safer for workers and

general public,

Safe Handling and Health Precautions of Chemicals

The following guidelines are meant to cover the general aspects of

safe handling of metal finishing chemicals. It is required that every

product has to be supplied with a safety data sheet containing detailed

information covering each one of the items mentioned below. Should

these statements differ from the ones reported in the safety card

provided by the supplier, THE DATA SPECIFIED IN THE MATERIAL

SAFETY DATA SHEET OF THE PRODUCT SHALL ALWAYS

PREVAIL.

1. Safe Handling

Most of the chemicals used in metal finishing industries are

considered hazardous to humans. While some of these

chemicals have acute health effects, many other persistent

chemicals cause chronic illnesses. Exposure routes vary from

inhalation, which is the most significant route in this case, to

ingestion, absorption through skin. Thus, all the employees

must be informed of the hazards from the exposure to the

contaminant and the precaution necessary to prevent damage

to their health.

2. Personal Protective Equipment:

a. The occupier shall provide the following personal

protective equipment

- Goggles or face shields

- Appropriate respirator, where mists and hazardous

3/1:الصفحة 2010 أبريل:تاريخ اإلصدار 2: رقم اإلصدار

Organization Unit Public Health & Safety Department

Technical Guidelines for Safety Procedures in

Form sheet title:

Metal Finishing Industries

Doc Ref. DM-PH&SD-P4-TG23

gases are generated.

- Gloves- Rubber or PVC

- Protective clothing, helmets, and boots.

The usage of PPE shall be ensured by adequate

supervision

b. An eyewash fountain and shower shall be provided.

c. The washing facilities with soap and nail brush shall be

provided.

3. Storage

- chemicals used should be stored properly as specified in the

material safety data sheet to each individual chemical.

- Label all tanks, valves, and pipelines clearly in a language that

is understood by all workers.

4. Fires

- Should be extinguished by the use of chemical powder, foam

or carbon dioxide extinguishers.

5. Leaks

- Must be stopped immediately.

- Spilled material should be contained by means of sand, soil or

other absorbent inert materials and then collected in special

containers and treated as hazardous waste.

- Necessary equipment should always be available for the

management of the unexpected spillage and leakage of

chemicals.

6. First Aid

i. Inhalation

- The injured person shall be immediately removed from

the contaminated area and transferred to a clean and

ventilated location.

- If breathing stops, artificial respiration will be necessary

- Consult a physician immediately.

ii. Contact with skin

- Wash with plenty of water

- Remove contaminated clothing

3/2:الصفحة 2010 أبريل:تاريخ اإلصدار 2: رقم اإلصدار

Organization Unit Public Health & Safety Department

Technical Guidelines for Safety Procedures in

Form sheet title:

Metal Finishing Industries

Doc Ref. DM-PH&SD-P4-TG23

- Consult a physician

iii. Contact with eyes

- Wash with plenty of water for at least 20 minutes.

- Do not apply anything into the eyes unless prescribed

by a physician.

- Seek medical attention.

iv. Ingestion

- Do not induce vomiting

- Do not give any milk, or fatty food.

- Nothing shall be given orally to an unconscious person

- Have the injured person attended by a physician

immediately

7. No person shall be allowed to smoke, eat food or drink in the

process area.

8. Medical Examination

All the employees engaged in metal finishing operations

including buffing and polishing operations shall undergo medical

examination at the expense of the employer, at Dubai

Municipality, Public Health Clinic, Dubai

i. Initial examination immediately within 30 days of

employment

ii. Annual examination every 12 months.

FOR FURTHER INFORMATION CONTACT

PUBLIC HEALTH AND SAFETY DEPARTMENT

TEL: 2064244/ FAX: 2270160

3/3:الصفحة 2010 أبريل:تاريخ اإلصدار 2: رقم اإلصدار

Potrebbero piacerti anche

- Nebosh Igc 1 Questions and AnswersDocumento11 pagineNebosh Igc 1 Questions and AnswersSenthil Kumar69% (16)

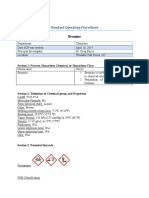

- Caustic Soda e CHB 014Documento1 paginaCaustic Soda e CHB 014Wasif KarimNessuna valutazione finora

- DM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFDocumento10 pagineDM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFdemie figueroaNessuna valutazione finora

- JHA - Manual TorquingDocumento6 pagineJHA - Manual TorquingMohamadSyahmiNessuna valutazione finora

- DM-PH&SD-P4-TG21 - (Guidelines For Examination and Certification of Cranes, Hoists, Lifts and Other Lifting Appliances) PDFDocumento2 pagineDM-PH&SD-P4-TG21 - (Guidelines For Examination and Certification of Cranes, Hoists, Lifts and Other Lifting Appliances) PDFdemie figueroaNessuna valutazione finora

- DM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFDocumento10 pagineDM PHSD P7 TG6 Emergency+Preparedness+GuidelineEN1 PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFDocumento3 pagineDM-PH&SD-P4-TG04 - (Guidelines For Entry Into Confined Spaces) PDFdemie figueroa100% (1)

- DM-PH&SD-P4-TG03 - (Guidelines For Heat Stress at Work)Documento3 pagineDM-PH&SD-P4-TG03 - (Guidelines For Heat Stress at Work)kevin100% (1)

- 10 PDFDocumento90 pagine10 PDFaniprk.995100% (3)

- OPITO BOSIET and FOET Standards PDFDocumento37 pagineOPITO BOSIET and FOET Standards PDFPengku Aji SadewaNessuna valutazione finora

- DM-PH&SD-P4-TG18 - (Guidelines For Safety in Vehicle Repair and Servicing Shops) PDFDocumento6 pagineDM-PH&SD-P4-TG18 - (Guidelines For Safety in Vehicle Repair and Servicing Shops) PDFdemie figueroaNessuna valutazione finora

- 0400E-CHB - Sulfuric AcidDocumento1 pagina0400E-CHB - Sulfuric AcidVeralord De VeraNessuna valutazione finora

- Development of Emergency Response Procedure For Accidents Involving Dangerous GoodsDocumento5 pagineDevelopment of Emergency Response Procedure For Accidents Involving Dangerous GoodsMuhammad Faheem100% (1)

- ENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFDocumento7 pagineENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFdemie figueroaNessuna valutazione finora

- Safety SpeechDocumento1 paginaSafety SpeechSaurabh BhartiyaNessuna valutazione finora

- DM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFDocumento3 pagineDM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFdemie figueroaNessuna valutazione finora

- Technical Guideline For Accident Investigation and ReportingDocumento9 pagineTechnical Guideline For Accident Investigation and ReportingChai Mandocdoc100% (2)

- ENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFDocumento7 pagineENG - DM-PHSD-P6-WI-02 Health Requirements For Labor Accommodation PDFdemie figueroaNessuna valutazione finora

- DM PH&SD P4 TG17 (Guidelines+for+First Aid+Requirement) PDFDocumento4 pagineDM PH&SD P4 TG17 (Guidelines+for+First Aid+Requirement) PDFAbdul HaneefNessuna valutazione finora

- DM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFDocumento3 pagineDM-PH&SD-P4-TG14 - (Guidelines For Personal Protective Equipment-Fall Protection-Safety Lines) PDFdemie figueroaNessuna valutazione finora

- DM Guidelines For Electrical Safety PDFDocumento4 pagineDM Guidelines For Electrical Safety PDFHaja FaizunnoorNessuna valutazione finora

- DM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)Documento6 pagineDM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)kevinNessuna valutazione finora

- DM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)Documento6 pagineDM-PH&SD-P4-TG01 - (Technical Guidelines For Industrial Compressed Gas Cylinders)kevinNessuna valutazione finora

- Reliability Engineering and System SafetyDocumento8 pagineReliability Engineering and System SafetyEjaj SiddiquiNessuna valutazione finora

- DM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)Documento3 pagineDM-PH&SD-P4-TG08 - (Guidelines For Personal Protective Equipment-Head Protection)narma143Nessuna valutazione finora

- DM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFDocumento4 pagineDM-PH&SD-P4-TG11 - (Guidelines For Personal Protective Equipment-Protective Clothing) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery)Documento7 pagineDM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery)kevinNessuna valutazione finora

- DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDFDocumento7 pagineDM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDFdemie figueroaNessuna valutazione finora

- 22 Hand Tool SafetyDocumento8 pagine22 Hand Tool SafetyAlma Tomas-CafeNessuna valutazione finora

- DM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFDocumento3 pagineDM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFdemie figueroaNessuna valutazione finora

- DM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFDocumento2 pagineDM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocumento5 pagineDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNessuna valutazione finora

- Chemical Hazard Bulletin: Chemtronics Pow-R-Wash VZDocumento1 paginaChemical Hazard Bulletin: Chemtronics Pow-R-Wash VZHaleemUrRashidBangashNessuna valutazione finora

- PPE Matrix ExampleDocumento2 paginePPE Matrix ExampleVarun SharmaNessuna valutazione finora

- SOP For Use of Grinder Machines in WorkshopDocumento8 pagineSOP For Use of Grinder Machines in WorkshopFaisal RajaNessuna valutazione finora

- Fire Policy 1Documento2 pagineFire Policy 1caleb99Nessuna valutazione finora

- Example-Self Safety Inspection Checklist - QADocumento3 pagineExample-Self Safety Inspection Checklist - QAHehok Hehe100% (1)

- Hse Audit Checklist PDFDocumento6 pagineHse Audit Checklist PDFnorlieNessuna valutazione finora

- 185 Eng PDFDocumento1 pagina185 Eng PDFHaleem Ur Rashid BangashNessuna valutazione finora

- TNSM Project Monthly Safety Meeting MinutesDocumento10 pagineTNSM Project Monthly Safety Meeting Minutesတိုး ေဝ ေအာင္Nessuna valutazione finora

- DM-PH&SD-P7-TG02 - (Guidelines For Approval of Swimming Pool Plans) PDFDocumento5 pagineDM-PH&SD-P7-TG02 - (Guidelines For Approval of Swimming Pool Plans) PDFNiel Brian VillarazoNessuna valutazione finora

- Health, Environment and Safety HandbookDocumento50 pagineHealth, Environment and Safety HandbooklordlucasenNessuna valutazione finora

- Hse Poster PDFDocumento4 pagineHse Poster PDFfani k3Nessuna valutazione finora

- Msds of Argon GasDocumento6 pagineMsds of Argon GasQilah KamarudinNessuna valutazione finora

- FormsDocumento134 pagineFormstaisiermed.safety100% (1)

- Ras Abu Aboud Stadium & Precinct Project: Chemical Name Coshh MsdsDocumento1 paginaRas Abu Aboud Stadium & Precinct Project: Chemical Name Coshh Msdssharon Aisha malroyNessuna valutazione finora

- WorkSafeBC - Forklift Inspection ChecklistDocumento0 pagineWorkSafeBC - Forklift Inspection ChecklistjohnzepolNessuna valutazione finora

- 1-Mock Drill Report of Aegis Gas On 16-01-2018Documento3 pagine1-Mock Drill Report of Aegis Gas On 16-01-2018Parth PatelNessuna valutazione finora

- MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and PurposeDocumento2 pagineMSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purposesarge18100% (1)

- DM-PH&SD-GU93-LAP - E - Work Permit and Precautionary Measures For Labor Acc PDFDocumento14 pagineDM-PH&SD-GU93-LAP - E - Work Permit and Precautionary Measures For Labor Acc PDFMuhammad JahangirNessuna valutazione finora

- 658 - Eng - Sigma Phenguard 935 BaseDocumento1 pagina658 - Eng - Sigma Phenguard 935 BasetariqueNessuna valutazione finora

- HS00-Man-0001 HSE ManualDocumento120 pagineHS00-Man-0001 HSE ManualRocker MazNessuna valutazione finora

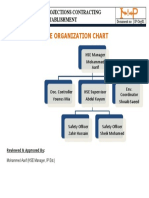

- Hse Organization Chart: Industrial Projections Contracting EstablishmentDocumento1 paginaHse Organization Chart: Industrial Projections Contracting EstablishmentHaleemUrRashidBangash100% (1)

- Unitech Metro - SAFE WORK METHOD STATEMENT - PAINTINGDocumento4 pagineUnitech Metro - SAFE WORK METHOD STATEMENT - PAINTING'David TeeNessuna valutazione finora

- Fire Water TankDocumento1 paginaFire Water TankAnonymous yCpjZF1rF100% (1)

- Note Emshe - Hazard Identification ControlDocumento38 pagineNote Emshe - Hazard Identification ControlMel Yusoff100% (1)

- Excavation ManuallyDocumento1 paginaExcavation ManuallyJack PNessuna valutazione finora

- Appendix A-Job Safety Analysis FormDocumento3 pagineAppendix A-Job Safety Analysis Formjiks_i4uNessuna valutazione finora

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocumento3 paginePpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- PMSS Building Walkthrough HSE Observations CloseoutDocumento11 paginePMSS Building Walkthrough HSE Observations Closeoutbalasubramaniam ranjuNessuna valutazione finora

- Spill Kit HandlingDocumento2 pagineSpill Kit HandlingHanan SarwarNessuna valutazione finora

- Lifting Hoisting Hazard HuntDocumento1 paginaLifting Hoisting Hazard Hunt曹庆园100% (1)

- DM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFDocumento9 pagineDM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFdemie figueroaNessuna valutazione finora

- 4 Steps To Spill Response: Prevention: The Best SolutionDocumento4 pagine4 Steps To Spill Response: Prevention: The Best SolutionJuan Carlos Guerrero RNessuna valutazione finora

- Equipment Maintenance and Measuring Equipment ProcedureDocumento2 pagineEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Metal Chop Saw SopDocumento2 pagineMetal Chop Saw SopkylealamangoNessuna valutazione finora

- JSA - Blasting - EXTERNALDocumento13 pagineJSA - Blasting - EXTERNALAzad pravesh khanNessuna valutazione finora

- PPE Disposal SOPDocumento2 paginePPE Disposal SOPAmit MakwanaNessuna valutazione finora

- Sabic 3Documento5 pagineSabic 3Farrukh Javed0% (1)

- Hand and Portable Power Tools Pre Use Inspection ChecklistDocumento1 paginaHand and Portable Power Tools Pre Use Inspection ChecklistRoselyn SharronNessuna valutazione finora

- Awareness On Working at HeightDocumento3 pagineAwareness On Working at Heightsubhadipmanna8100% (1)

- Scaffolder Erector Medical ExaminationDocumento6 pagineScaffolder Erector Medical ExaminationZulqarnain RamliNessuna valutazione finora

- 185 - Argon Gas 0185E-CHBDocumento1 pagina185 - Argon Gas 0185E-CHBFurqan GujjarNessuna valutazione finora

- Health Safety Original ManualDocumento74 pagineHealth Safety Original ManualVictor TasieNessuna valutazione finora

- DM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFDocumento11 pagineDM-PHSD-P7-A-TG - (Guidelines For Rope Access Work) English PDFdemie figueroaNessuna valutazione finora

- DM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFDocumento2 pagineDM PH&SD P4 TG22 (Guidelines+for+Acetylene+Generators) PDFdemie figueroaNessuna valutazione finora

- Dubai Municipality Codes ListDocumento8 pagineDubai Municipality Codes Listdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG27 - (Guidelines For Liquefied Petroleum Gas Cylinders)Documento4 pagineDM-PH&SD-P4-TG27 - (Guidelines For Liquefied Petroleum Gas Cylinders)ngueadoumNessuna valutazione finora

- DM-PH&SD-P7-WI18 - (Health Requirements For The Services Provided Inside Labours Accommodations) PDFDocumento4 pagineDM-PH&SD-P7-WI18 - (Health Requirements For The Services Provided Inside Labours Accommodations) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFDocumento9 pagineDM-PH&SD-P4-TG15 - (Guidelines For Personal Protective Equipment-Respiratory Protection) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG16 - (Guidelines For Safe Use of Industrial Organic Solvents)Documento8 pagineDM-PH&SD-P4-TG16 - (Guidelines For Safe Use of Industrial Organic Solvents)narma143Nessuna valutazione finora

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDocumento5 pagineDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFDocumento3 pagineDM-PH&SD-P4-TG10 - (Guidelines For Personal Protective Equipment-Hearing Protection) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery) PDFDocumento7 pagineDM-PH&SD-P4-TG06 - (Guidelines For Guarding of Dangerous Machinery) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFDocumento5 pagineDM-PH&SD-P4-TG12 (Guidelines For Personal Protective Equipment-Hand Protection) PDFdemie figueroaNessuna valutazione finora

- DM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)Documento5 pagineDM-PH&SD-P4-TG02 - (Guidelines For Safety Audit Reports)kevinNessuna valutazione finora

- Emergency Response Procedures: Toolbox TalksDocumento2 pagineEmergency Response Procedures: Toolbox TalksmahlasbarlasNessuna valutazione finora

- Manual Nice9000v A04Documento151 pagineManual Nice9000v A04hoang tamNessuna valutazione finora

- Environmental, Health and Safety Risks AnalysisDocumento3 pagineEnvironmental, Health and Safety Risks AnalysisKrishna PatilNessuna valutazione finora

- Asme B30.8 PDFDocumento43 pagineAsme B30.8 PDFjemorpeNessuna valutazione finora

- Common Sense Risk Management of Trees National Tree Safety GroupDocumento104 pagineCommon Sense Risk Management of Trees National Tree Safety Groupadmin866Nessuna valutazione finora

- Bromine HandlingDocumento5 pagineBromine HandlingYogesh DhekaleNessuna valutazione finora

- SDS - Astm P 133 01Documento6 pagineSDS - Astm P 133 01Omar SaaedNessuna valutazione finora

- San Quintin NHS - Contingency - Plan - Fire Preparedness and EmergencyDocumento55 pagineSan Quintin NHS - Contingency - Plan - Fire Preparedness and EmergencyJeffril Dela CruzNessuna valutazione finora

- Magnaflux UnitDocumento28 pagineMagnaflux UnithamedmosadeqNessuna valutazione finora

- HRPD 513-HRM 5006 - 2013Documento7 pagineHRPD 513-HRM 5006 - 2013Anonymous jvVjibbmmNessuna valutazione finora

- Construction Safety Manual PDFDocumento68 pagineConstruction Safety Manual PDFMonica AstridNessuna valutazione finora

- Hsse and Pipe Check ListDocumento6 pagineHsse and Pipe Check ListSandip PalNessuna valutazione finora

- EN VEGASWING 63 Two WireDocumento48 pagineEN VEGASWING 63 Two WireLucas FiordelisiNessuna valutazione finora

- MATERIAL SAFETY DATA SHEET 3M™ Novec ™ 1230 Fire Protection Fluid (FK-5-1-12)Documento8 pagineMATERIAL SAFETY DATA SHEET 3M™ Novec ™ 1230 Fire Protection Fluid (FK-5-1-12)Juan LuisNessuna valutazione finora

- Workplace Safety and Health (General Provisions) RDocumento65 pagineWorkplace Safety and Health (General Provisions) RRamesh-NairNessuna valutazione finora

- Wa5700js DC68-03517B-05 en PDFDocumento44 pagineWa5700js DC68-03517B-05 en PDFEdgar Frances VillamorNessuna valutazione finora

- EHS Approved Agency For Testing & Certification of Fire Fighting EquipmentDocumento8 pagineEHS Approved Agency For Testing & Certification of Fire Fighting Equipmenttp101267Nessuna valutazione finora

- Plan de Securitate Al Facilitatii Portuare - ChecklistDocumento3 paginePlan de Securitate Al Facilitatii Portuare - ChecklistAndreea Albulet100% (1)

- JSA Manual Cleaning 6205-F (Filter Water Tank)Documento7 pagineJSA Manual Cleaning 6205-F (Filter Water Tank)imam dianiNessuna valutazione finora

- Bulletin January 2023Documento6 pagineBulletin January 2023Fikri HidayatNessuna valutazione finora

- Tetrasteel 800 BrochureDocumento4 pagineTetrasteel 800 BrochurejcrandleNessuna valutazione finora

- OHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 8, 2022Documento2 pagineOHS-PR-09-26-F01 INITIAL INCIDENT NOTIFICATION SS8358 Misk City ABC, January 8, 2022Shafie ZubierNessuna valutazione finora

- Safety ChecklistDocumento2 pagineSafety ChecklistsammeikNessuna valutazione finora

- Bartending NC II (PDFDrive)Documento80 pagineBartending NC II (PDFDrive)Joey ArtuzNessuna valutazione finora

- Tool Box Talk: House KeepingDocumento1 paginaTool Box Talk: House KeepingAli Alqaisy100% (1)

- 项目经理手册1203 Project manager handbookDocumento18 pagine项目经理手册1203 Project manager handbookr_atneshNessuna valutazione finora