Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BASF MasterRoc® HCA 10 Tds PDF

Caricato da

dana setiawan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

360 visualizzazioni2 pagineTitolo originale

BASF-MasterRoc®-HCA-10-tds.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

360 visualizzazioni2 pagineBASF MasterRoc® HCA 10 Tds PDF

Caricato da

dana setiawanCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

MasterRoc® HCA 10

Formerly DELVO®CRETE STABILIZER

Cement hydration control system for wet and dry sprayed concrete, grouting and cement injection

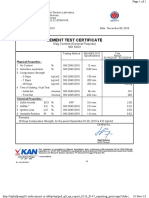

Product description Technical data

MasterRoc HCA 10 is a high quality, liquid, non Form Liquid

chloride chemical admixture which controls the Colour Red

dynamics of cement hydration. It delays hydration Density (at +20°C) 1.10 ± 0.02

by suspending the hydration process and enabling pH value <2

re-activation hours or even days later with no loss Solubility in water Total

of quality in the hardened sprayed concrete. Thermal stability +1°C

Chloride content <0.1%

When dispensed into wet or dry mixes at the Physiological effect Corrosive

batching plant it fully stabilizes the hydration

process by forming a protective barrier around the Packaging

cement particles. MasterRoc HCA 10 can be used

MasterRoc HCA 10 is packaged in 210 liter plastic

with all types of cement minerals (C3S, S3A, C2S,

drums and 1000 liter IBCs.

C4AF and gypsum).

Mixing

In order to re-activate the hydration process and

accelerate the strength gain in mixes stabilized

with MasterRoc HCA 10, MasterRoc SA alkali-free Wet-mix sprayed concrete: Premix aggregates with

cement and one half of the mixing water. Under

accelerator is added at the nozzle or injection

continuous mixing, add MasterRoc HCA 10 and a

point.

high performance superplasticizer, premixed with

the second half of the mixing water, or after all the

Fields of application

water has been added. Normal mixing time is

Tunneling and mining sufficient. To avoid slump loss, the recommended

3

Temporary and permanent support minimum water content is 200 l/m . In the event of

Slope stabilization unexpected delays, a later addition of 0.2 – 1 % of

Annulus grouting (TBM) MasterRoc HCA 10 is possible to prolong storage

Cementitious injection systems time for a few hours.

Features and benefits Dry-mix sprayed concrete: Premix aggregates with

cement. The water content should be between 3

With the use of MasterRoc HCA 10, wet and dry and 6%. Slowly add manually or with a dosing

concrete mixes can be kept workable for up to 3 device the necessary quantity of MasterRoc HCA

days. This provides considerable benefits in the 10 under constant mixing and continue to mix for 2

batching and utilization of the concrete. to 3 minutes. If evenly distributed over dry-mix

material (e.g. by spraying), mixing time can be

Fully flexible delivery options for sprayed reduced.

concrete mixes The addition of MasterRoc HCA 10 to the fresh mix

No cleaning of pumps or pipes during work is ideal. However, it can be added until up to 30

interruptions minutes after mixing of the dry-mix material without

Complete use of wet and dry mixes – no waste any problems.

disposal

Time and cost saving

In addition to these benefits related to its function

as a hydration control system, it also provides

considerable reduction of rebound and dust.

MasterRoc® HCA 10

Formerly DELVO®CRETE STABILIZER

Consumption not use pressurized air for agitation. Please

contact your local BASF representative prior to the

Recommended dosage range use of any products that have frozen.

The maximum storage temperature for MasterRoc

HCA 10 is +60°C. Performance tests should

always be carried out prior to use.

If stored in tightly closed original containers and

under the above mentioned conditions, it has a

shelf life of at least 12 months.

Typical wet-mix design for an open time of 4 to

6 hours

3

Ordinary Portland Cement 400 kg/m

3

Microsilica 30 kg/m

3

Aggregate 0-8mm 1710 kg/m

MasterRoc HCA 10 0.5 - 2.0 kg

Dosage indicated in this data sheet is only to be used as a

guideline. To obtain accurate dosage rates, field tests have to MasterGlenium 2.4 – 6.0 kg

be done with cement and aggregates under local conditions. It superplasticizer

is recommended that you consult your local BASF Water/binder ratio 0.45

representative.

Normal recommended dosage of MasterRoc HCA Safety precautions

10 varies between 0.2% - 1% by weight of cement.

MasterRoc HCA 10 is an irritant fluid. Contact with

The required dosage depends on: type of cement

skin and eyes must be avoided. It is essential that

used, w/c ratio, ambient and concrete temperature safety glasses and rubber gloves are worn during

and targeted open time.

handling. In case of contact with eyes or skin, flush

immediately with plenty of water and seek medical

Storage advice.

Minimum storage temperature for MasterRoc HCA For further information, see the Material Safety

10 is +1°C. If it has frozen, thaw and completely Data Sheet.

reconstitute with a mild mechanical agitation. Do

The information given here is true, represents our best knowledge and is based not only on laboratory work but also on field experience.

However, because of numerous factors affecting results, we offer this information without guarantee and no patent liability is assumed.

For additional information or questions, please contact your local representative.

Headquarters:

BASF SE

Underground Construction

Salzachstr. 2-12

68199 Mannheim

Germany

Phone: +49 621 60 91013

E-Mail: ugc@basf.com

For more information: Visit us: www.ugc.basf.com Contact us: ugc@basf.com

Potrebbero piacerti anche

- MasterRoc-HCA-10 Technical Data SheetDocumento2 pagineMasterRoc-HCA-10 Technical Data Sheetabukayes.abdinNessuna valutazione finora

- Duconmix RSP PCE 800 - High Early Strength, High Range Water Reducing/superplasticising, Admixture For Precast ConcreteDocumento2 pagineDuconmix RSP PCE 800 - High Early Strength, High Range Water Reducing/superplasticising, Admixture For Precast ConcreteFounTech612Nessuna valutazione finora

- Masterroc Hca 20: Liquid Hydration Inhibitor For ConcreteDocumento3 pagineMasterroc Hca 20: Liquid Hydration Inhibitor For Concretez_sheriNessuna valutazione finora

- Duconmix RSP PCE 830Documento2 pagineDuconmix RSP PCE 830FounTech612Nessuna valutazione finora

- TDS Chryso Optima K9322Documento1 paginaTDS Chryso Optima K9322Vikram ManeNessuna valutazione finora

- Technical Data Sheet Chryso Delta d876 - 6173 - 3754 PDFDocumento1 paginaTechnical Data Sheet Chryso Delta d876 - 6173 - 3754 PDFVijayshankarNessuna valutazione finora

- Renderoc SM - 230624 - 220802Documento3 pagineRenderoc SM - 230624 - 220802Amar PutraNessuna valutazione finora

- Renderoc SMDocumento2 pagineRenderoc SMMas DaffiNessuna valutazione finora

- TDS - MasterPolyheed 8320Documento2 pagineTDS - MasterPolyheed 8320Taposh Paul100% (2)

- Chryso-Optima-K9325 8395 4482Documento1 paginaChryso-Optima-K9325 8395 4482raviteja036Nessuna valutazione finora

- Chryso Delta D811: New Generation Plasticizing AdmixtureDocumento1 paginaChryso Delta D811: New Generation Plasticizing Admixtureraviteja036Nessuna valutazione finora

- Mastertop 1740m 12-04Documento3 pagineMastertop 1740m 12-04djrote4Nessuna valutazione finora

- sHOTPATCH 10 v3 PDFDocumento2 paginesHOTPATCH 10 v3 PDFAnkita Baban GavadeNessuna valutazione finora

- Soltex Additive PDFDocumento1 paginaSoltex Additive PDFAhmer AkhlaqueNessuna valutazione finora

- Masterroc® TCC 780 TdsDocumento2 pagineMasterroc® TCC 780 TdsinvestmentmanifestNessuna valutazione finora

- QQDocumento2 pagineQQdana setiawanNessuna valutazione finora

- TDS Chryso Premia S613RDocumento1 paginaTDS Chryso Premia S613RPaladi RaviNessuna valutazione finora

- Masterlife Sra900 TdsDocumento3 pagineMasterlife Sra900 TdsДанило ГадайчукNessuna valutazione finora

- Extract Page 1Documento1 paginaExtract Page 1SebastianAnNessuna valutazione finora

- CAPENTRAINDocumento2 pagineCAPENTRAINMedrar TareqNessuna valutazione finora

- Tds Aqualoc Tp60Documento1 paginaTds Aqualoc Tp60Vikram ManeNessuna valutazione finora

- Proplast RC50 - TDSDocumento2 pagineProplast RC50 - TDSAhmed AbuoelnagaNessuna valutazione finora

- tHORO STRUCTURITE PRIMER - v3Documento2 paginetHORO STRUCTURITE PRIMER - v3Ankita Baban GavadeNessuna valutazione finora

- Sirocco Am HR SPDocumento3 pagineSirocco Am HR SPThati MotlhagodiNessuna valutazione finora

- FICHA TECNICA HIDROXIPROPILMENTIL CELULOSA Kimicell KMP40000SDocumento1 paginaFICHA TECNICA HIDROXIPROPILMENTIL CELULOSA Kimicell KMP40000SCarlos SiuNessuna valutazione finora

- MasterRheobuild® 716Documento3 pagineMasterRheobuild® 716Jagan Mohana Rao ChinnalaNessuna valutazione finora

- Rheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteDocumento2 pagineRheocell 10 ME: A Liquid Admixture For The Production of Lightweight ConcreteCivil SanamNessuna valutazione finora

- Masterroc FLC 100: Description and PropertiesDocumento3 pagineMasterroc FLC 100: Description and Propertiesrobin rezkNessuna valutazione finora

- Chemrite - 520 BADocumento2 pagineChemrite - 520 BAghazanfar50% (2)

- TDS Chryso Optima S838Documento1 paginaTDS Chryso Optima S838Ankur BarsainyaNessuna valutazione finora

- Cementitious-Grout MasterFlow 718Documento2 pagineCementitious-Grout MasterFlow 718Abhi MitraNessuna valutazione finora

- Concrete Repair - Estopatch RSP - TDS - 111203Documento2 pagineConcrete Repair - Estopatch RSP - TDS - 111203Elias Jaya PerkasaNessuna valutazione finora

- Masterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksDocumento2 pagineMasterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksPradeep KumaraNessuna valutazione finora

- Masterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)Documento3 pagineMasterpozzolith® MR 25s (Formerly Known As Pozzolith® MR 25 S)RajNessuna valutazione finora

- Hyperplast PC260 - TDSDocumento2 pagineHyperplast PC260 - TDSpadashtNessuna valutazione finora

- Hyperplast PC260 PDFDocumento2 pagineHyperplast PC260 PDFpadasht100% (1)

- Masterroc Sa168 TdsDocumento3 pagineMasterroc Sa168 Tdsjheyson_mogollonNessuna valutazione finora

- Tds 108277427 ProMix PCE 300Documento3 pagineTds 108277427 ProMix PCE 300Chetal BholeNessuna valutazione finora

- Basf Masterseal m808 TdsDocumento8 pagineBasf Masterseal m808 TdsOkan KalendarNessuna valutazione finora

- Dr. Fixit Polyplus CP Admix: Integral Crystalline Waterproofing AdmixtureDocumento3 pagineDr. Fixit Polyplus CP Admix: Integral Crystalline Waterproofing AdmixtureAdityaVikramVermaNessuna valutazione finora

- MasterSeal - 551 v4Documento2 pagineMasterSeal - 551 v4piyu114Nessuna valutazione finora

- 3 26 AC Corrocoat Corrothane XT JUNE 21Documento3 pagine3 26 AC Corrocoat Corrothane XT JUNE 21moinu85Nessuna valutazione finora

- Megaflow P4: Water Reducing and Set Retarding Plasticising AdmixtureDocumento2 pagineMegaflow P4: Water Reducing and Set Retarding Plasticising AdmixtureShaik Qutubuddin100% (1)

- Masterseal 588: Description Packaging and ColorsDocumento2 pagineMasterseal 588: Description Packaging and ColorsmariaNessuna valutazione finora

- Recegrout Sl10: Product Data SheetDocumento2 pagineRecegrout Sl10: Product Data SheetAmira RamleeNessuna valutazione finora

- Renderoc LAXtra PlusDocumento2 pagineRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- MasterPolyheed 8177 v3Documento3 pagineMasterPolyheed 8177 v3Rajesh NairNessuna valutazione finora

- Sikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetDocumento4 pagineSikarep: Multi-Purpose Patching and Repair Mortar Technical Data SheetjodemodeNessuna valutazione finora

- Mastertop 1110 T PDFDocumento4 pagineMastertop 1110 T PDFFrancois-Nessuna valutazione finora

- Patchroc RSPDocumento46 paginePatchroc RSPvietpineNessuna valutazione finora

- TM - MasterSuna - SBS - 8000 ENDocumento3 pagineTM - MasterSuna - SBS - 8000 ENVyankat ChateNessuna valutazione finora

- Duconmix RBS 100 TDSDocumento2 pagineDuconmix RBS 100 TDSmasudNessuna valutazione finora

- Mastertile 530: Description Coverage / YieldDocumento2 pagineMastertile 530: Description Coverage / Yieldbassem muhannaNessuna valutazione finora

- JTCC - Neopox LiningDocumento3 pagineJTCC - Neopox LiningAdhigana QSNessuna valutazione finora

- Corrofill VE DatasheetDocumento2 pagineCorrofill VE DatasheettienNessuna valutazione finora

- Masterflow 9400: Ultra-High Strength, Cement Based Grout For Onshore Wind Turbine InstallationsDocumento4 pagineMasterflow 9400: Ultra-High Strength, Cement Based Grout For Onshore Wind Turbine InstallationsВладимир Ерёменко100% (1)

- Plastocrete 161 MRDocumento2 paginePlastocrete 161 MREmma LozanoNessuna valutazione finora

- Chemical Content Based On Modifided Polycarboyxlate Density 1,03 - 1,07 KG/L PH 7,7 - 9,7 Color Brown Total Chlorine Maximum %0,1 Alkali 5Documento5 pagineChemical Content Based On Modifided Polycarboyxlate Density 1,03 - 1,07 KG/L PH 7,7 - 9,7 Color Brown Total Chlorine Maximum %0,1 Alkali 5DilshadNessuna valutazione finora

- Aquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteDocumento2 pagineAquaarm Multicrete Aquaarm Multicrete Aquaarm MulticreteShabbir LokhandwalaNessuna valutazione finora

- Soil Support Testing With DCP ToolsDocumento2 pagineSoil Support Testing With DCP Toolsdana setiawanNessuna valutazione finora

- Label Odner BantexDocumento4 pagineLabel Odner Bantexdana setiawanNessuna valutazione finora

- Laporan Iklim HarianDocumento2 pagineLaporan Iklim HarianShofihatul MaulaNessuna valutazione finora

- PPDocumento1 paginaPPdana setiawanNessuna valutazione finora

- Laporan Iklim HarianDocumento2 pagineLaporan Iklim HarianShofihatul MaulaNessuna valutazione finora

- Soil Support Testing With DCP ToolsDocumento2 pagineSoil Support Testing With DCP Toolsdana setiawanNessuna valutazione finora

- Antisol E Curing MaterialDocumento2 pagineAntisol E Curing MaterialdiqiNessuna valutazione finora

- Every 1000M3 MixtureDocumento3 pagineEvery 1000M3 Mixturedana setiawanNessuna valutazione finora

- Conveyor Safety ChecklistDocumento1 paginaConveyor Safety Checklistdana setiawanNessuna valutazione finora

- 1 Lot 1a Vol 2 of 10 231Documento1 pagina1 Lot 1a Vol 2 of 10 231dana setiawanNessuna valutazione finora

- Temperature Control For The Gomal Zam RCC ArchDocumento10 pagineTemperature Control For The Gomal Zam RCC Archdana setiawanNessuna valutazione finora

- 1 Lot 1a Vol 2 of 10 235Documento1 pagina1 Lot 1a Vol 2 of 10 235dana setiawanNessuna valutazione finora

- AsdsaDocumento14 pagineAsdsadana setiawanNessuna valutazione finora

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocumento4 pagine2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNessuna valutazione finora

- FDocumento1 paginaFsutan simanjuntakNessuna valutazione finora

- Every 1000M3 MixtureDocumento3 pagineEvery 1000M3 Mixturedana setiawanNessuna valutazione finora

- Conveyor Safety ChecklistDocumento1 paginaConveyor Safety Checklistdana setiawanNessuna valutazione finora

- Quality Control TableDocumento12 pagineQuality Control Tabledana setiawanNessuna valutazione finora

- 311 4R-00Documento12 pagine311 4R-00farhadam50% (2)

- Inspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: DateDocumento4 pagineInspection Checklist - Batching Plant: Form Ref.: Project: Sub-Contractor: Structure Element: Datedana setiawan100% (1)

- Package Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical SpecificationsDocumento1 paginaPackage Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical Specificationsdana setiawanNessuna valutazione finora

- Norma ASTM-A641Documento5 pagineNorma ASTM-A641Dilmer CV100% (2)

- Package 1 Lot La - Upper and Lower Dams Upper Cisokan Storage Power P!ant Project Section Teclznica! SpecificationsDocumento1 paginaPackage 1 Lot La - Upper and Lower Dams Upper Cisokan Storage Power P!ant Project Section Teclznica! Specificationsdana setiawanNessuna valutazione finora

- Standard Specification For Coal Fly Ash A ND Raw or Calcined Natural Pozzolan For Use in Concrete C 618 PDFDocumento3 pagineStandard Specification For Coal Fly Ash A ND Raw or Calcined Natural Pozzolan For Use in Concrete C 618 PDFHaris Eko PujiantoNessuna valutazione finora

- ASTM D3963 D3963M 01 Epoxy Coated Steel Reinforcing Bars PDFDocumento5 pagineASTM D3963 D3963M 01 Epoxy Coated Steel Reinforcing Bars PDFdana setiawanNessuna valutazione finora

- JKDocumento4 pagineJKdana setiawanNessuna valutazione finora

- Astm C 183 Muestreo de Cemento PDFDocumento7 pagineAstm C 183 Muestreo de Cemento PDFdana setiawanNessuna valutazione finora

- Standard Specification For Coal Fly Ash A ND Raw or Calcined Natural Pozzolan For Use in Concrete C 618 PDFDocumento3 pagineStandard Specification For Coal Fly Ash A ND Raw or Calcined Natural Pozzolan For Use in Concrete C 618 PDFHaris Eko PujiantoNessuna valutazione finora

- D345 PDFDocumento3 pagineD345 PDFdana setiawanNessuna valutazione finora

- ASTM C494, PDF PDFDocumento9 pagineASTM C494, PDF PDFMuhammad Zaini Gani100% (10)

- TSLDocumento2 pagineTSLwaleed El-azabNessuna valutazione finora

- By Kenneth L. Carper: Why Case Studies?Documento3 pagineBy Kenneth L. Carper: Why Case Studies?amanpreet_ahujaNessuna valutazione finora

- Helical Stair - CalculationDocumento5 pagineHelical Stair - CalculationSuhail Ahamed0% (1)

- Keyboard Shortcut Commands by Category: However, This List Covers Many of The Out-Of-The-Box Shortcuts AvailableDocumento7 pagineKeyboard Shortcut Commands by Category: However, This List Covers Many of The Out-Of-The-Box Shortcuts AvailabledasaNessuna valutazione finora

- User Note: Double Underlined With Turquoise HighlightDocumento201 pagineUser Note: Double Underlined With Turquoise Highlightchristian reyesNessuna valutazione finora

- Sika Waterbars Pds enDocumento4 pagineSika Waterbars Pds enerhansinattraNessuna valutazione finora

- Kps Product Catalog 2013 en WebDocumento40 pagineKps Product Catalog 2013 en WebAsima Nezirevic100% (1)

- PTX R 410A Series NewDocumento112 paginePTX R 410A Series NewMohamed Fathi33% (15)

- Material ScienceDocumento810 pagineMaterial ScienceNikhil Batham67% (3)

- Phase DiagramDocumento5 paginePhase DiagramBunnimit panyacheewathonNessuna valutazione finora

- FRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsDocumento6 pagineFRP Ashland - Different FRP Resin Chemistries For Different Chemical EnvironmentsHafiz Kamal100% (1)

- Materials and Processes Quiz 3Documento6 pagineMaterials and Processes Quiz 3RuthNessuna valutazione finora

- 26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationDocumento13 pagine26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationRyan Anthony UmaliNessuna valutazione finora

- Internship TemplateDocumento3 pagineInternship TemplateGua HantuNessuna valutazione finora

- Shear StrengthDocumento56 pagineShear StrengthSamuel ChristianNessuna valutazione finora

- Pec Report KP2488 PDFDocumento11 paginePec Report KP2488 PDFMarcus AntoniusNessuna valutazione finora

- Fatigue Damage Models For Laminated Composite StructuresDocumento100 pagineFatigue Damage Models For Laminated Composite StructuresBaşar ZamanNessuna valutazione finora

- En 764-4-2002Documento44 pagineEn 764-4-2002Marija IvanovskaNessuna valutazione finora

- Pressure VesselDocumento26 paginePressure VesselMohd Azharudin Mohadi100% (1)

- Family Handyman - June 2023Documento68 pagineFamily Handyman - June 2023Ognjen MočevičNessuna valutazione finora

- 19ASC303A Assignment 8 PDFDocumento5 pagine19ASC303A Assignment 8 PDFRD412Nessuna valutazione finora

- 1-Heat & Temp - Set 1 - SolnDocumento6 pagine1-Heat & Temp - Set 1 - SolnBibhash SinghNessuna valutazione finora

- 30RB039-160 PSDDocumento16 pagine30RB039-160 PSDrudagochav3096Nessuna valutazione finora

- Reinforce Concrete Book - Prof DiasDocumento58 pagineReinforce Concrete Book - Prof DiasAnonymous 7fIHDkX22pNessuna valutazione finora

- CE2A Module Assessment 1 SolutionDocumento12 pagineCE2A Module Assessment 1 SolutionJames CapacilloNessuna valutazione finora

- Important PointsDocumento4 pagineImportant PointsRashid MinhasNessuna valutazione finora

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocumento1 paginaSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNessuna valutazione finora

- MS 1050 - Physics of Solids: - Ranjith RamaduraiDocumento25 pagineMS 1050 - Physics of Solids: - Ranjith RamaduraiproNessuna valutazione finora

- (Encyclopedia of Energy Series) Robert U Ayres, Robert Costanza, Jose Goldemberg, Marija D Ilic, Eberhard Jochem, Robert Kaufmann, Amory B Lovins, Mohan Munasinghe, R K Pachauri, Claudia Sheinbaum Par.pdfDocumento836 pagine(Encyclopedia of Energy Series) Robert U Ayres, Robert Costanza, Jose Goldemberg, Marija D Ilic, Eberhard Jochem, Robert Kaufmann, Amory B Lovins, Mohan Munasinghe, R K Pachauri, Claudia Sheinbaum Par.pdfLuis Henrique NtaNessuna valutazione finora

- Floating Ball ValveDocumento36 pagineFloating Ball ValveSureshNessuna valutazione finora