Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Issue No 68 - Stress Intensity and Fracture Toughness

Caricato da

Tomy AntonioCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Issue No 68 - Stress Intensity and Fracture Toughness

Caricato da

Tomy AntonioCopyright:

Formati disponibili

Issue No.

68 – August 2014 New Publication

Stress Intensity and Fracture Toughness

(This issue of Technical Tidbits continues the materials science refresher series on basic concepts of

How intense is your material properties.) In prior editions, we have demonstrated how to estimate the fatigue life of a

stress level – An component through characterization of test specimens using cyclically applied stresses or strain, followed

introduction to fracture by analysis of the data. The fracture mechanics method is fundamentally different, since it is the study of

how fatigue cracks grow through a given material, and is more concerned with what is happening at the tips

mechanics.

of growing cracks than with macro-scale loading. A quick introduction to fracture mechanics is required

before any discussion of how to apply it to fatigue analysis can begin.

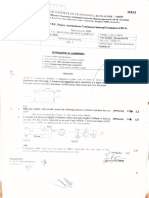

A quick overview of the method starts with the test specimens used to generate the data. Each specimen

starts with a pre-existing crack of a given length "a". Stress intensity is categorized according to mode, as ,

shown in Figure 1. Mode I is a spreading apart of the two halves of the crack interface, recognizable as the

most severe case. (When people split logs with a wedge, they are using Mode I fracture mechanics,

although they are most likely unaware that they are doing so.) Failures due to Mode I crack propagation

Stress Intensity are by far the most common, while Mode III is mainly of academic interest.

Stress Intensity Undeformed Mode I

Factors

(KI, KII, KIII)

Critical Stress

Intensity Factors

(KIC, KIIC, KIIIC)

Plane Strain

Fracture

Toughness

Critical Crack

Length Mode II Mode III

The next issue of

Technical Tidbits will Figure 1. Stress Intensity Modes - In these images, undeformed areas are shown in dark blue,

introduce the fracture while the highest levels of deformation are shown in red.

mechanics approach to

The stress intensity factor (K) is a defined as the product applied macroscale stress (σ), the square root of

fatigue analysis. the crack length(a), and a constant that depends on the particular fracture mode and geometry of the test

specimen. The stress intensity factor for Mode I is designated KI, KII for Mode II, and KIII for Mode III.

©2014 Materion Brush Inc.

Stress Intensity and Fracture Toughness (continued)

C is a dimensionless constant, but is determined by the fracture mode and test specimen geometry. The References:

mathematics to derive this constant are complex, and its value depends on the crack location in the ASTM E1823 Standard

sample, load orientation relative to the crack, crack length, size and shape of the test specimen, and Terminology Relating to Fatigue

loading mode. However, these problems have been solved multiple times, and handbooks exist and Fracture Testing

containing the tabulated values for most known conditions. Therefore, the author strongly recommends

ASTM E399 Standard Test

that you look up the values, as opposed to trying to calculate them on your own, unless you enjoy such Method for Linear-Elastic Plane-

academic pursuits, or if you really want to author a new handbook yourself. Strain Fracture Toughness KIC of

Metallic Materials

The units for stress intensity, probably the ugliest engineering units you will ever see, are expressed as ASTM E1820 Standard Test

stress times square root of length. In SI units, this would typically be MPa√m, and ksi√in in British Method for Measurement of

imperial (American) units. It is difficult to conceive of a real meaning of square root of length, but it Fracture Toughness

does have real implications in engineering. (It can be thought of in a similar fashion to the concept of

imaginary numbers in mathematics, which also have real implications in engineering.)

Please contact your local

The critical stress intensity factor designates the minimum stress intensity required to get an existing sales representative for

crack in a material to propagate. The critical stress intensity factor for mode I is designated as KIC, that further information on

for mode II is KIIC, and that for mode III is KIIIC. If the test specimen is thick enough, Mode I is the fatigue or other

becomes a plain strain condition, so KIC is often referred to as the plain strain fracture toughness of a questions pertaining to

material. Materion or our products.

Given KIC and a loading condition, it is possible to estimate the mimimum length of a crack that will

propagate under those conditions. This is known as the critical crack length. Cracks smaller than this

size will not propagate, but larger cracks will.

Health and Safety

Unlike other measures of toughness that calculate the energy required to fracture a material, plane strain Handling copper beryllium in

fracture toughness is is a measure of the stress intensity necessary to initiate fracture of a material with a solid form poses no special

health risk. Like many

known flaw size under plane strain conditions. So, while Izod and Chapry V-Notch (CVN) impact tests industrial materials, beryllium-

will provide fracture toughness data in Joules or foot-pounds, KIC provides fracture toughness data in containing materials may pose a

ksi√in or MPa√m. The two former test methods are relatively easy to measure and understand, while the health risk if recommended safe

handling practices are not

latter is more complicated, but provides more useful information in terms of shock load bearing followed. Inhalation of airborne

capability and crack propagation over time. That is to say, Izod and CVN data will only provide the beryllium may cause a serious

energy required for fracture in one single catastrophic event, but critical stress intensity factor data lung disorder in susceptible

allows for predition of failure with slowly propagating cracks overa number of cycles. individuals. The Occupational

Safety and Health

Administration (OSHA) has set

Now, recall that a fatigue failure occurs by initiation and propagation of cracks throughout a material mandatory limits on

undergoing cyclic loading. Fracture mechanics provides a means of relating stress intensity levels to occupational respiratory

exposures. Read and follow the

propagation of cracks of various sizes. Therefore, it stands to reason that fracture mechanics methods guidance in the Material Safety

can be used to predict fatigue behavior of metals. This is the basis of the fracture mechanics approach to Data Sheet (MSDS) before

fatigue analysis. working with this material. For

additional information on safe

handling practices or technical

Written by Mike Gedeon of Materion Brush Performance Alloys Marketing Department. Mr. data on copper beryllium,

Gedeon’s primary focus is on electronic strip for the automotive, telecom, and computer contact Materion Brush

Performance Alloys or your

markets with emphasis on application development. local representative.

Materion Performance Alloys

6070 Parkland Blvd.

Mayfield Heights, OH 44124

(216) 486-4200

(216) 383-4005 Fax

(800) 375-4205 Technical Service

©2014 Materion Brush Inc.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Allround BrochureDocumento24 pagineAllround BrochureMs. ThuNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Aircraft Structure - FractureDocumento40 pagineAircraft Structure - FractureLi-chung JeaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Steels For Bearings - BhadeshiaDocumento168 pagineSteels For Bearings - BhadeshiaDouglas RodriguesNessuna valutazione finora

- Unit Price For Retrofitting WorksDocumento2 pagineUnit Price For Retrofitting Workslaxmi29Nessuna valutazione finora

- KAKINADA Launching Scheme Designs-11-06-2021Documento22 pagineKAKINADA Launching Scheme Designs-11-06-2021Akhil BabuNessuna valutazione finora

- Electric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFDocumento48 pagineElectric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFSuresh Damu BhadNessuna valutazione finora

- Pump TroubleshootingDocumento514 paginePump Troubleshootingmohamed hamedNessuna valutazione finora

- Final - Fire Safety in High Rise BuildingsDocumento37 pagineFinal - Fire Safety in High Rise BuildingsAshwini AnandNessuna valutazione finora

- API-653-Mar 2016Documento7 pagineAPI-653-Mar 2016Khaled Gamal100% (3)

- ASTM1550 - Flexural TestsDocumento13 pagineASTM1550 - Flexural TestsertwerNessuna valutazione finora

- Design of Anchor For Curb Inlet FilterDocumento2 pagineDesign of Anchor For Curb Inlet FilterAaron PaulNessuna valutazione finora

- BT Innovation Btspannschloss Web enDocumento28 pagineBT Innovation Btspannschloss Web enartomiNessuna valutazione finora

- HANO-K H7 MEP Maintenance Check Sheets - 210424Documento51 pagineHANO-K H7 MEP Maintenance Check Sheets - 210424Hùng MạnhNessuna valutazione finora

- Cement and Steel Rates For The Month of September 2012Documento1 paginaCement and Steel Rates For The Month of September 2012Guru PrasadNessuna valutazione finora

- Dental Casting Procedures: Snegha S 2Nd Yr BdsDocumento32 pagineDental Casting Procedures: Snegha S 2Nd Yr BdsKeerthikaNessuna valutazione finora

- Grid MiragridDocumento12 pagineGrid MiragridAfidatul AdnNessuna valutazione finora

- Jowatac 47160 TDSDocumento2 pagineJowatac 47160 TDSTruong LeoNessuna valutazione finora

- IRJET-Study of Plastic Bricks Made From Waste Plastic: Related PapersDocumento7 pagineIRJET-Study of Plastic Bricks Made From Waste Plastic: Related PapersNicole Cometa1724Nessuna valutazione finora

- Try MeDocumento9 pagineTry MeKrizzete HernandezNessuna valutazione finora

- IES-01 Wall ScheduleDocumento1 paginaIES-01 Wall ScheduleDick van der SpuyNessuna valutazione finora

- Maz Umder 1982Documento9 pagineMaz Umder 1982Alejandra PradoNessuna valutazione finora

- SKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRDocumento4 pagineSKUM Over The Top Foam Generators OFG OFGR - FDS14334 0214 LRValentin A.Nessuna valutazione finora

- Product Data SheetsDocumento44 pagineProduct Data Sheetssalem elhajNessuna valutazione finora

- Blowdown Valves 6DB Series Rev 2 (MS-02-118)Documento2 pagineBlowdown Valves 6DB Series Rev 2 (MS-02-118)herysyam1980Nessuna valutazione finora

- Metal Treatment: of Aluminium and Aluminium AlloysDocumento1 paginaMetal Treatment: of Aluminium and Aluminium AlloysAnkur PatelNessuna valutazione finora

- Ventilation Requirements For Indoor Pools: Technical FeatureDocumento9 pagineVentilation Requirements For Indoor Pools: Technical FeaturetasabajcNessuna valutazione finora

- Comparitive Study On Flyash Based Geopolymer Concrete WithDocumento32 pagineComparitive Study On Flyash Based Geopolymer Concrete Withjs kalyana ramaNessuna valutazione finora

- Dom 1Documento10 pagineDom 1C1DA20ME030 Hemanth SNessuna valutazione finora

- Lesson 10 - Construction - FieldworkDocumento66 pagineLesson 10 - Construction - FieldworkJubillee MagsinoNessuna valutazione finora

- Bearing N PDFDocumento160 pagineBearing N PDFAnonymous hxQ7PNOQNessuna valutazione finora