Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Use of Sludge Ash As A Stabilizing Additive in Soil-Cement Mixtures For Use in Road Pavements

Caricato da

Andream_56pjhmTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Use of Sludge Ash As A Stabilizing Additive in Soil-Cement Mixtures For Use in Road Pavements

Caricato da

Andream_56pjhmCopyright:

Formati disponibili

Technical Note

Use of Sludge Ash as a Stabilizing Additive in Soil-Cement

Mixtures for Use in Road Pavements

1 2 3

Maria P. Durante Ingunza ; Kiev Luiz de Araújo Pereira ; and Olavo Francisco dos Santos Junior

personal use only; all rights reserved.

Abstract: This paper presents a study evaluating the use of sludge ash as a stabilizing additive to soil-cement mixtures for use in base and subbase

road pavements by investigating the mechanical behavior of these mixtures. The methodology consisted of materials testing, including the

geotechnical characterization of the soil and the mechanics of the soil-cement and the soil-cement-sludge ash mixtures. An unconfined

compression test evaluated the mechanical behavior of soil-cement mixtures with cement contents of 3, 6, and 9% compressed with normal,

intermediate, and modified pressures. The sludge ash contents added were of 5, 10, 20, and 30%. The results indicate increasing strength for all

ash levels studied. The largest gain in strength was for a mixture with 20% sludge ash, which increased the strength by 26% compared with the

mixture without sludge ash. DOI: 10.1061/(ASCE)MT.1943-5533.0001168. © 2014 American Society of Civil Engineers.

Author keywords: Soil-cement; Chemical stabilization of soil; Ash sewage sludge.

Introduction Materials and Methods

Downloaded from ascelibrary.org by Universidad Militar Nueva Granada on 07/31/19. Copyright ASCE. For

Sewage treatment plants produce a residue known as sewage sludge. The soil used in this study is a fine, red-colored soil often found on

The most common form of treatment is to incinerate this residue, the Brazilian northeastern coast. According to the Unified Soil

which significantly reduces its volume. There is a global need for the Classification System (USCS), the soil classification is ML, i.e., silt

development of methods used to recover the waste sludge. The search of low compressibility. A AASHTO classifies this soil as A-4, with

for environmentally friendly and economically viable so-lutions for an index group of 5.3 California Bearing Ratio (CBR); tests per-

the final disposal of waste sludge is a challenge. Currently, a major formed according to ASTM D1883-07e2 (ASTM 2007) presented

concern for environmental managers is eliminating this waste values less than 6% CBR and 0.05% expansion, indicating a low

correctly and reducing its storage costs. One solution is to use the support capacity for use in pavement bases and subbases. Thus, the

sewage sludge ash as a construction material. Sludge ash is consid- use of such a soil as a construction material for pavement layers is

ered by the Federal Highway Administration (FHWA), U.S. Depart- only possible through a chemical stabilization.

ment of Transportation as a byproduct material in pavement The stabilizer used was ordinary portland cement. The sludge ash

construction [FHWA RD-97-148 (FHWA 2008)]. Several research was produced from sludge dredged on an anaerobic lagoon sys-tem

studies have used sludge ash as raw material, such as the following: for domestic wastewater stabilization. The fresh sludge was classified

1. Addition of ash sludge to concrete: Tay (1987), Monz´ et al. as a Class II-A waste (not inert and nonhazardous) according to

(1996), Fontes (2003), and Geyer et al. (1998); Brazilian standards [Associaçāo Brasileira de Normas Técnicas

2. Cement produced from sludge ash: Morales (1994), Onaka (ABNT) 10:005 2004a, b] based on international stan-dards.

(2000), and Tay and Show (1991); Compression tests considered three energy levels: normal [ASTM

3

3. Addition of sludge and sludge ash in paving: Brosch (1975), D698-12 (ASTM 2012a); 600 kN · m=m of applied pres-sure],

Al Sayed et al. (1995), Durante Ingunza et al. (2013b), and intermediate, and modified [ASTM D1557-12 (ASTM 2012b); 2,700

Feitosa (2009); and 3

kN · m=m of applied pressure]. The intermediate energy test

4. As a raw material in the production of ceramics: Alleman and followed the same steps as the modified energy test, except for the

Berman (1984) and in asphalt mixtures, Al Sayed et al. number of strokes per layer, which was 25 strokes, resulting in

(1995), Durante Ingunza et al. (2013a). 3

energy of 1.260 kN · m=m .

In this context, this paper evaluates the use of sludge ash from The tests used soil and soil-cement mixtures with cement con-

a sewage treatment plant as an additive for soil-cement mixtures tents of 3, 6, and 9%.

for base and subbase layers of pavement. The test used cast specimens with cement contents of 0, 3, 6, and

9% for three compaction modes of the unconfined compression test.

1 The test calculated the cement content relative to the dry soil mass.

Professor, Dept. of Civil Engineering, Federal Univ. of Rio Grande

do Norte, Brazil; and Campus Universitário, Natal/RN 59072-970, Brazil The specimens were cured for 28 days in a humidified cham-ber. The

(cor-responding author). E-mail: durante@ct.ufrn.br; unconfined compression tests followed the procedures rec-ommended

pilarduranteingunza@gmail .com by ASTM D2166-06 (ASTM 2006).

2

M.Sc. in Civil Engineering, Federal Univ. of Rio Grande do Norte, To evaluate the effect of the sludge ash additive, the study per-

Brazil. formed unconfined compression tests on samples with sludge ash

3

Professor, Dept. of Civil Engineering, Federal Univ. of Rio Grande additive levels of 5, 10, 20, and 30% relative to the solid-state

do Norte, Brazil; and Campus Universitário, Natal/RN 59072-970, Brazil.

weight. The mixture selected to perform the study was the soil-

Note. This manuscript was submitted on December 22, 2013; approved on

July 28, 2014; published online on September 4, 2014. Discussion per- cement mixture with 9% cement, using an intermediate energy

iod open until February 4, 2015; separate discussions must be submitted for test for the specimens. Table 1 provides the characteristics of the

individual papers. This technical note is part of the Journal of Materials in studied materials. For each condition indicated in Table 1, the

Civil Engineering, © ASCE, ISSN 0899-1561/06014027(3)/$25.00. study includes three experiments to evaluate the variability.

© ASCE 06014027-1 J. Mater. Civ. Eng.

J. Mater. Civ. Eng., 2015, 27(7): 06014027

25

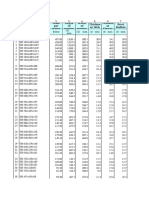

Table 1. Identification of Analyzed Materials S100 S94C6

Identification Soil (%) Cement (%) Ash (%) S97C3 S91C9

20

(%)

S100 100 — —

waterconten

S97C3 97 3 —

S94C6 94 6 — 15

t

S91C9 91 9 —

S86C9A5 86 9 5

S81C9A10 81 9 10 10

Optimum

S71C9A20 71 9 20

S61C9A30 61 9 30

5

Downloaded from ascelibrary.org by Universidad Militar Nueva Granada on 07/31/19. Copyright ASCE. For personal use only; all rights reserved.

0

Results Normal Intermediate Modified

Compaction energy

Mechanical Characterization Testing of Soil and

Fig. 2. Effect of compaction effort and cement content on the

Soil-Cement

optimum moisture content in the compaction tests

This study expressed the compaction test results in terms of the

compaction effect on the maximum dry weight and the optimum

moisture content. Fig. 1 shows that for the same compaction energy,

the specific maximum dry weight increases with increasing cement

content, and that for a given cement content, the dry weight increases Brazilian pavement specifications are based on standards and

with increasing compaction energy. Fig. 2 shows that for a given procedures of the National Department of Transport Infrastructure

compaction energy, the optimum moisture content decreases with (DNIT) and the standards of the Brazilian Association of

increasing cement content, and that for given cement content, the Technical Standards (ABNT) using the specifications of ASTM

optimum moisture content decreases with increasing compact energy. as main regulatory compliances.

In the compaction curves, a shift toward the left and above was

observed, which means a dry unit weight increases and optimum

Mechanical Characterization Testing of

moisture content decreases, as expected. The increase of the dry unit

Soil-Cement-Sludge Ash Mixtures

weight is because the cement has a higher dry unit weight value than

the soil. To study the addition of sewage sludge ash to the soil-cement

Fig. 3 shows the results of the unconfined compression tests in mixture, the trace chosen after the compression test was 91% soil þ

terms of the variation of the compressive strength with the cement 9% cement, molded at the intermediate energy. This trace has a

content and the compaction effort. As shown in Fig. 3, the strength strength of 2,261 MPa, which meets the minimum refer-ence value

increases with the compaction effort and, for a given compaction (2.1 MPa) defined by the Brazilian standard [DNIT 143/ 2010 (DNIT

effort, the strength increases with increasing cement content. 2010)] for pavement base materials. The experiment added sludge

According to the specifications of the Brazilian standards, soil ash contents of 5, 10, 20, and 30% of the solid weight to the selected

stabilization with cement should provide a minimum strength of trace (91% soil þ 9% cement). Fig. 4 shows the un-confined

2.1 MPa. The data in Fig. 3 show that in the intermediate energy, compressive strength results of the sludge ash blends. The addition of

this value is reached with the maximum cement content (9%). In sludge ash at all weight percentages tested increased the strength of

the modified energy, the specification is reached with lower ce- the soil-cement mixtures. The greatest strength was with 20% sludge

ment content (3%). ash, resulting in a 26% increase in strength compared

18 4

strength

S100 S100 S94C6

S97C3

m 3)

S97C3 S91C9

(kN/

S94C6

17

Unconfined compression

3

S91C9

weight

(MPa)

unit

dry

16 2

Maximum

15 1

14 0

Normal Intermediate Modified Normal Intermediate Modified

Compaction energy Compaction energy

Fig. 1. Effect of compaction energy and cement content on the max- Fig. 3. Test results of unconfined compression strength of soil-

imum dry unit weight in the compaction tests cement mixtures

© ASCE 06014027-2 J. Mater. Civ. Eng.

J. Mater. Civ. Eng., 2015, 27(7): 06014027

3

Unconfined compression strength

be performed with a life-cycle cost analysis (LCCA), as related

by Praticò et al. (2011).

2 References

Alleman, J. E., and Berman, N. A. (1984). “Constructive sludge manage-

ment: Biobrick.” J. Environ. Eng., 10.1061/(ASCE)0733-9372(1984)

M

P

a

(

1

110:2(301), 301–311.

Al Sayed, M. H., Madany, I. M., and Buali, A. R. M. (1995). “Use of

sew-age sludge ash in asphalt paving mixes in hot regions.” Constr.

Build. Mater., 9(1), 19–23.

Associaçāo Brasileira de Normas Técnicas (ABNT). (2004a). “Standard test

Downloaded from ascelibrary.org by Universidad Militar Nueva Granada on 07/31/19. Copyright ASCE. For personal use only; all rights reserved.

0 methods for solid waste.” NBR 10:004-10007, Rio de Janeiro, Brazil.

0 5 10 20 30

Associaçāo Brasileira de Normas Técnicas (ABNT). (2004b). “Standard

Ash content (%)

test methods for solid waste.” NBR 10005—Solid waste—Procedure

for obtaining lixiviate from solid waste, Rio de Janeiro, Brazil.

Fig. 4. Simple compressive strength of soil-cement-ash mixtures

ASTM. (2006). “Standard method for unconfined compressive strength of

cohesive soil.” D2166-06, West Conshohoken, PA.

ASTM. (2007). “Standard test method for CBR (California bearing ratio)

of compacted soils.” D1883-07e2, West Conshohoken, PA.

17 ASTM. (2012a). “Standard methods for laboratory compaction character-

istics of soil using standard effort (600 kN=m3).” D698-12, West

Conshohoken, PA.

ASTM. (2012b). “Standard methods for laboratory compaction character-

Dry unit weight (kN/m 3)

16

istics of soil using modified effort (2,700 kN=m3).” D1557-12, West

Conshohoken, PA.

15 Brosch, C. D. (1975). Lightweight aggregate production from sewage

sludge, Brazilian Congress of Sanitary Engineering, Rio de Janeiro,

Brazil.

Durante Ingunza, M. P., Dantas Lima, A., and Calado Araujo, A. L.

14 (2013a). “Use of septic tank sludge as raw material in the manufacture

of bricks.” Adv. Mater. Res., 712–715, 921–924.

Durante Ingunza, M. P., Santos Junior, O., and Andrade Medeiros, S.

13 (2013b). “Sewage sludge as raw material in asphalt mixtures.” Adv.

0 5 10 20 30 Ma-ter. Res., 664, 638–643.

Ash content (%) Federal Highway Administration (FHWA). (2008). “User guidelines for

waste and byproduct materials in pavement construction.” FHWA

Fig. 5. Effect of adding ash on the dry unit weight observed in the RD-97-148, Washington, DC.

molding of test specimens for unconfined compressive strength Feitosa, M. C. A. (2009). “Sewage sludge: Applications in engineering.”

Master thesis, Post-graduation Program in Civil Engineering, Catholic

Univ. of Pernambuco, Brazil.

to the control trace (without sludge ash). Monz´ et al. (1996) Fontes, C. M. A. (2003). “Potential of ash sludge from sewage treatment

plants as supplementary material for portland cement concrete.”

obtained similar results. The samples were molded with the opti-

Master thesis, Post-graduation Programo f Engineering, Federal Univ.

mum moisture content obtained in sample S91C9, which corre- of Rio de Janeiro—COPPE, Rio de Janeiro, Brazil.

sponds to 18.3%. Fig. 5 shows the dry specific weight values after Geyer, A. L. B., Consoli, N. C., and Dal Molin, D. C. (1998). “Recycling

applying the intermediate compaction energy. The results show of sewage sludge from treatment plants of Porto Alegre city, Brazil,

that the dry specific weight decreases with the increase in sludge and its use as admixture in concrete.” Challenges for concrete in the

ash because sludge ash is less dense than soil. next mil-lennium, G. den Boer, ed., CRC Press, Boca Raton, FL.

Monz´o, J., Payá, J., Borrachero, M. V., and C´orcoles, A. (1996). “Use

of sewage sludge ash (SSA)-cement admixtures in mortars.” Cem.

Concr. Res., 26(9), 1389–1398.

Conclusions Morales, G. (1994). “Verification and evaluation of the pozzolanic

reactiv-ity of the ash of sewage sludge in Londrina.” Doctoral thesis,

The results of this study confirmed the feasibility of using sludge Politecnic School, Univ. of São Paulo, Brazil.

ash as a stabilizing additive for soil-cement mixtures, and indicate National Department of Transport Infrastructure (DNIT). (2010). “ES—

that it is possible to incorporate up to 30% sewage sludge ash Procedures for base pavement layer construction using soil-cement

con-tent to a soil-cement mixture (91% soil and 9% cement) com- admixture (in Portuguese).” 143/2010, Brazil.

pressed at an intermediate energy to produce a strength increase. Onaka, T. (2000). “Sewage can make portland cement: A new technology for

The largest gain in strength was with a 20% sludge ash content, ultimate reuse of sewage sludge.” Water Sci. Technol., 41(8), 93–98.

which increased the strength by 26% compared with the mixture Praticò, F. G., Saride, S., and Puppala, A. (2011). “Comprehensive life cycle

without sludge ash. cost analysis for the selection of stabilization alternatives for better

performance of low volume roads.” Transportation Research Re-cord

To assess the correct use of sludge ash as a stabilizing additive in

2203, Transportation Research Board, Transportation Research Board of

soil-cement mixtures, it is necessary to evaluate the consequences in the National Academies, Washington, DC, 120–129.

terms of life-cycle cost analysis of the pavement. Research carried Tay, J. (1987). “Bricks manufactured from sludge.” J. Environ. Eng.,

out in the last decade shows the economic, technical, and 278–284.

environmental feasibility of the use of sludge in civil construc-tion. Tay, J. H., and Show, K. Y. (1991). “Properties of cement made from

Nevertheless, to implement in real scale, a further study shall sludge.” J. Environ. Eng., 236–246.

© ASCE 06014027-3 J. Mater. Civ. Eng.

J. Mater. Civ. Eng., 2015, 27(7): 06014027

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- State of The Art and Practice in Geotechnical EngineeringDocumento23 pagineState of The Art and Practice in Geotechnical EngineeringAndream_56pjhmNessuna valutazione finora

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Documento49 pagine1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNessuna valutazione finora

- Polished Concrete Flooring - Metro Mix ConcreteDocumento9 paginePolished Concrete Flooring - Metro Mix ConcreteMetroMix ConcreteNessuna valutazione finora

- Rab Venturi Wet Scrubber 00Documento2 pagineRab Venturi Wet Scrubber 00rudiawanNessuna valutazione finora

- Tile Adhesives, Tile Grouts and Plastering SkimDocumento30 pagineTile Adhesives, Tile Grouts and Plastering SkimNykha Alenton100% (1)

- Unit 1. Itroduction To Wastewater TreatmentDocumento28 pagineUnit 1. Itroduction To Wastewater Treatmentsssshekhar100% (1)

- Bloi Boiji C: Co-Composting of Sewage Sludge and Coal Fly Ash: Nutrient TransformationsDocumento6 pagineBloi Boiji C: Co-Composting of Sewage Sludge and Coal Fly Ash: Nutrient Transformationsorangie844Nessuna valutazione finora

- MAPA Asphalt Paving Design Guide WebDocumento92 pagineMAPA Asphalt Paving Design Guide WebJorge Mauricio de SouzaNessuna valutazione finora

- Fly Ash-Based Geopolymer Clean Production, Properties and ApplicationsDocumento15 pagineFly Ash-Based Geopolymer Clean Production, Properties and ApplicationsAndream_56pjhmNessuna valutazione finora

- Waste Management: Comparative Study On The Characteristics of Fly Ash and Bottom Ash GeopolymersDocumento5 pagineWaste Management: Comparative Study On The Characteristics of Fly Ash and Bottom Ash GeopolymersAndrew PiNessuna valutazione finora

- Class F Fly Ash Amended Soils As Highway Base MaterialsDocumento10 pagineClass F Fly Ash Amended Soils As Highway Base MaterialsAndream_56pjhmNessuna valutazione finora

- Analysis and Design Af A Stabilized Fly-Ash As Pavement Base MaterialDocumento12 pagineAnalysis and Design Af A Stabilized Fly-Ash As Pavement Base MaterialAndream_56pjhmNessuna valutazione finora

- 12 Mechanical and PhysicalDocumento8 pagine12 Mechanical and PhysicalAndream_56pjhmNessuna valutazione finora

- 05 HybridDocumento7 pagine05 HybridAndream_56pjhmNessuna valutazione finora

- Portland Cement Systems With Addition of Sewage Seludge Ash. Application in Concretes For The Manufacture of BlocksDocumento13 paginePortland Cement Systems With Addition of Sewage Seludge Ash. Application in Concretes For The Manufacture of BlocksAndream_56pjhmNessuna valutazione finora

- Recycling and Recovery For SSIBADocumento13 pagineRecycling and Recovery For SSIBAYong Hui OngNessuna valutazione finora

- Technological and Environmental Behavior of Sewage Sludge Ash (SSA) in Cement-Based MaterialsDocumento12 pagineTechnological and Environmental Behavior of Sewage Sludge Ash (SSA) in Cement-Based MaterialsAndream_56pjhmNessuna valutazione finora

- A Technique For The Calibration of Hydraulic Models Using Uncertain Satellite Observations of FloodDocumento7 pagineA Technique For The Calibration of Hydraulic Models Using Uncertain Satellite Observations of FloodAndream_56pjhmNessuna valutazione finora

- Economics of Cable-Stayed BridgesDocumento2 pagineEconomics of Cable-Stayed Bridgesdebjyoti_das_6Nessuna valutazione finora

- Ground Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDocumento1 paginaGround Floor-Key Plan Mirror Part Plan at 2000Mm LVL: ArchitectureDhairyaNessuna valutazione finora

- Attachment 07.1 - ARGAL - Vertical PumpsDocumento28 pagineAttachment 07.1 - ARGAL - Vertical PumpsJefferson GilNessuna valutazione finora

- Glazing Supporting Structure Design Calculation, College Building, AIIMS Nagpur (03.02.2020)Documento8 pagineGlazing Supporting Structure Design Calculation, College Building, AIIMS Nagpur (03.02.2020)abdul samadNessuna valutazione finora

- New Power Supply Installation for 8 Aircon UnitsDocumento2 pagineNew Power Supply Installation for 8 Aircon UnitsJohn Ralph VegaNessuna valutazione finora

- BOQ Sipil GI 150 KV TarjunDocumento5 pagineBOQ Sipil GI 150 KV TarjunMarketing MptNessuna valutazione finora

- Catalogo NovumDocumento72 pagineCatalogo NovumrodgutieNessuna valutazione finora

- Mill Certification: Other Test ResultsDocumento1 paginaMill Certification: Other Test ResultsAlonso FraireNessuna valutazione finora

- Progress Billing No. 21 for Peninsula Garden Midtown Homes - Mahogany TowerDocumento100 pagineProgress Billing No. 21 for Peninsula Garden Midtown Homes - Mahogany TowerJohn Philip GarciaNessuna valutazione finora

- Popatlal Ni Haveli 1 PDFDocumento1 paginaPopatlal Ni Haveli 1 PDFMaithily PatelNessuna valutazione finora

- FLOW CONTROL VALVESDocumento6 pagineFLOW CONTROL VALVESkulkarni278Nessuna valutazione finora

- SECTION 16110 Residential Wiring Connections, Rev 0Documento12 pagineSECTION 16110 Residential Wiring Connections, Rev 0Ahmed HashimNessuna valutazione finora

- MT 25 BFB1Documento74 pagineMT 25 BFB1Meritz DanNessuna valutazione finora

- BS 4550-0 1978 - General IntroductionDocumento8 pagineBS 4550-0 1978 - General IntroductionAhmed BabikirNessuna valutazione finora

- Vice President Procurement Supply Chain in Dallas TX Resume Gary McKownDocumento3 pagineVice President Procurement Supply Chain in Dallas TX Resume Gary McKownGarymckownNessuna valutazione finora

- 18 Silbond and SilaidDocumento4 pagine18 Silbond and SilaidsviruindiaNessuna valutazione finora

- Contractor Design and Standard Form ContractsDocumento14 pagineContractor Design and Standard Form ContractskuvjNessuna valutazione finora

- QuizDocumento7 pagineQuizVirgilio VelascoNessuna valutazione finora

- Hilton Hotels Corporation: A Leader in HospitalityDocumento26 pagineHilton Hotels Corporation: A Leader in HospitalityFarzana KhanNessuna valutazione finora

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDocumento2 pagineFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloNessuna valutazione finora

- Concrete Mix Design Methods, Verification StudyDocumento26 pagineConcrete Mix Design Methods, Verification StudyAhmed M AminNessuna valutazione finora

- Muhammad Rehan Khalil: Summary of CareerDocumento3 pagineMuhammad Rehan Khalil: Summary of CareerRehAn KhAlil100% (1)

- EML e BrochureDocumento21 pagineEML e BrochureECCSNessuna valutazione finora

- Pipe's Minor LossesDocumento95 paginePipe's Minor LossesJosept RevueltaNessuna valutazione finora

- Equipos John DeereDocumento1 paginaEquipos John DeereGustavo GonzalezNessuna valutazione finora

- Architecture March 2017Documento19 pagineArchitecture March 2017ArtdataNessuna valutazione finora