Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MWM TCG2020

Caricato da

Md Iqbal HossainCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MWM TCG2020

Caricato da

Md Iqbal HossainCopyright:

Formati disponibili

TCG 2020 K

Maintenance schedule

5

Maintenance

Please note that the following maintenance schedule is a standard maintenance sched-

ule.

A fixed definition of the maintenance intervals for all applications is not possible due to the

various relations between ambient conditions, operating mode and quality of the fuels.

A shortening of the given interval may be necessary under critical operating conditions. The

normal maintenance plan is then to be adapted. Normally, the local operating conditions are

already taken into account in the projection phase.

Critical operating conditions are for example:

- contamination of the combustion gases by wear promoting constituents such as sili-

con, sulphur, chlorine, ...

- Frequent starts, e.g. less than 12 operating hours per start

- Multiple emergency stops

- increased load in the intake air

Talk to your service partner if in doubt.

General

This engine is built exclusively for the purpose set out in the scope of supply - defined by

the equipment manufacturer (use for the intended purpose). Depending on the purpose, the

engine is identified by a performance code or a type of gas code which is embossed on the

rating plate. The rating plate is described in detail in chapter 2.

The maintenance schedule lists the measures for maintaining the nominal condition and

thus operational safety of the engine with the corresponding intervals.

When the specified interval or operating hours have been reached, or if necessary, the work

specified in the maintenance schedule must be carried out.

The activities are described on job cards. The job cards are listed in chapter 9. The operat-

ing manual contains the job cards up to the maintenance and service schedule E40. The

workshop manual lists the job cards up to the maintenance and service schedule E70.

! The intervals specified in the maintenance schedule are maximum values and assume

that installation, intended purpose and operating conditions comply with the specifica-

tions. It must be ensured that all running materials such as combustion gas, lube oil

and coolant are of the prescribed quality.

It must be ensured especially that the gas quality meets the minimum requirements accord-

ing to TR 0199 - 99 - 3017 to avoid operating malfunctions and/or premature engine wear.

! The maintenance schedule only applies to the engine itself and the parts mounted on

the engine. System parts must be serviced according to the times and instructions

specified by the manufacturer. The appropriate information can be found in the manu-

facturer documents supplied.

! The measures described must be carried out by technically skilled personnel or author-

ized specialists. The competencies are listed in the maintenance and service schedule

table.

OBJ_DOKU-17295-001.fm 7 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule

Maintenance and service schedules

The operating hour-dependent maintenance measures are divided into maintenance and

service schedules. All the listed measures are to be carried out carefully according to the

maintenance schedule specifically defined for the engine.

Please note that maintenance and service schedules may be added or omitted depending

on the speed and gas group.

Maintenance and service schedules Carried out by

E10 Due once after commissioning and after Technically skilled personnel

E60 and E70 respectively

E20 Daily inspection round

E30 Periodic maintenance (small scope)

E40 Periodic maintenance (medium scope)

E50 Periodic maintenance (extended scope) Authorised specialists

E60 Intermediate overhaul

E70 General overhaul

Selection and installation

A suitable maintenance schedule is allocated for the engine, depending on the speed and

gas group.

The maintenance plan consists of several sections:

- Maintenance measures

- Data on the average service life of wear parts

- Master copy for proof of execution

Plan in plenty of time when the the maintenance and service schedules are due in accord-

ance with the engine's number of operating hours.

Arrange in advance the anticipated date with your service partner. When making the ap-

pointment, inform him of any irregularities in the engine.

If appropriate, draw up a maintenance contract with your service partner. All due mainte-

nance measures, and any repair measures depending on the agreement, will then be

planned and carried out properly by the service partner conformant as set out in the con-

tract. Your local service partner will provide the details.

OBJ_DOKU-17295-001.fm 8 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule

5

Definition of tasks in the maintenance schedule

Settings

Setting torques, dimensions, pressures etc.; extra work may be necessary to renew com-

ponents.

Draining

Draining condensation for example.

Replacing

Replacement of components, function blocks and liquids.

Reworking

Material acceptance within the permissible tolerances to maintain a nominal condition.

Checks

Checks according to criteria in the job card. If all criteria are not satisfied, the cause must

be determined and the nominal condition reinstated.

Cleaning

Cleaning by hand or machine (automatic), replacement of cleaning components (e.g. air

filter) may be necessary.

Visual inspection

Visual inspection according to criteria in the job card. If all criteria are not satisfied, the

cause must be determined and the nominal condition reinstated.

Overhauling

Checking of function blocks; rework or renewal of components.

Maintenance

Maintenance according to job card. Checking functions; reworking or renewal of compo-

nents may be necessary.

Changing

Changing lube oil for example

OBJ_DOKU-17295-001.fm 9 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule

Gas groups

The maintenance intervals also depend on the quality of the combustion gases.

The combustion gasses are divided into three groups according to their wear properties, for

which the different normal maintenance plans are valid, also see Technical Bulletin 0199 -

99 - 3017.

Gas group 1

Natural gas

Pit gas

Liquefied gas such as propane, LNG (liquefied natural gas)

Wellhead gas (petroleum gas)

Gas group 2

Sewage gas

Landfill gas

Bio-gas

Gas group 3

All gases in which the concentration of every single pollutant gas component does not ex-

ceed 20% of the permissible limit value (see limit value list).

e.g. bio-gas after a desulphurisation treatment

Maintenance interval

If using combustion gases with a high pollutant load, the maintenance intervals (TBO/Time

Between Overhaul) have to be reduced because of the high level of abrasion.

To ensure the required tool life, the composition of the combustion gases must be deter-

mined at regular intervals by means of a comprehensive gas analysis.

For more information, see Technical Bulletin 0199-99-3017.

If necessary the maintenance intervals must be reduced accordingly.

OBJ_DOKU-17295-001.fm 10 © MWM GmbH 01/2009

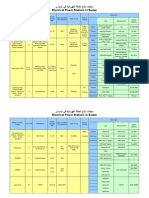

TCG 2020 K

Maintenance schedule 5-1

5

Maintenance schedule

Valid for: Engine type: V12 and V16 engines

Speed: n = 1500 rpm

Combustion gas : Gas group 1

Performance abbreviations ICN

Type of application: Current generators

Maintenance measures

E10 E20 E30 E40 E45 E50 E55 E60 E70 Description

every 24 hours (daily)

after every 12000 oh

after every 16000 oh

after every 24000 oh

after every 32000 oh

after every 64000 oh

after every 2000 oh

after every 4000 oh

1x after 50 Oh

as specified

In accordance with Technical Bulletin 0199 - 99 - Gas engines - lubricating oil

2105 Lube oil analysis, lube oil change, etc.

In accordance with Technical Bulletin 0199 - 99 - Renew lube oil filter cartridge

2105

In accordance with Technical Bulletin 0199 - 99 - Engine coolant

2091 Engine coolant analysis, engine coolant change, etc.

In accordance with Technical Bulletin 0199 - 99 - Engine corrosion protection

2116 Engine corrosion protection, etc.

as required Renew intake air cleaner

- when low pressure limit value is reached (note main-

tenance indicator)

- if damaged (leakage)

- after 4000 oh at the latest

as required Overhaul cylinder heads

- when the max. valve clearance is reached (according

to Chapter 8)

- after 32000 oh at the latest

Further information can be found in Appendix A

as required Clean the engine

as required Replace or recondition the starter

Monthly Test run, if the engine was not run in operational read-

iness within a month

Monthly Service the battery, if the engine was not run in opera-

tional readiness within a month

every 4 months Carry out a gas analysis (according to Technical Bulle-

tin 0199 - 99 - 3017)

every 6 months Check engine coolant (according to Technical Bulletin

0199 - 99 - 2091)

every 6 months Check pressure drop of the gas filter

OBJ_DOKU-17296-001.fm 11 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule 5-1

E10 E20 E30 E40 E45 E50 E55 E60 E70 Description

every 24 hours (daily)

after every 12000 oh

after every 16000 oh

after every 24000 oh

after every 32000 oh

after every 64000 oh

after every 2000 oh

after every 4000 oh

1x after 50 Oh

as specified

every 12 months Check regulating devices, pressure setting and imper-

maebility of the gas control process

every 12 months Replace gas filter insert

After every 24 months Replace engine coolant

After maintenance work Run-in the engine (after e.g. replacing pistons, cylin-

der liners, etc.)

According to manufacturer specifications Service the generator

According to manufacturer specifications Service the clutch

According to manufacturer specifications Service spring elements (underframe)

According to manufacturer specifications Service intermediate gearbox

- only 60 Hz applications

x x x x x x Test and function run

x x x x x x Check and set inlet and exhaust valve clearance

x x x x x x Check valve lag (cylinder head fitted)

x Visual inspection of the system

x x x x x Maintaining the battery

x x x x x Check throttle body

x x x x x Check speed governor linkage

x Check the spark plugs, renew if necessary

x x x x Replace spark plugs

x x x x Check ignition time

x x x x Maintain crankcase breather (model UPF)

- renew the outer filter (filter stage 2) every 4000 oh

- renew the inner filter (filter stage 1) every 8000 oh

x x x x Auxiliary units test by TEM system

x x Check combustion chambers with endoscope

x Check, clean turbocharger

- Observe manufacturer's documentation

x Overhaul the exhaust gas turbocharger

- Observe manufacturer's documentation

x x x Check engine mounting

x x x Check starter pinion and gear rim on the flywheel

x x x Check exhaust line

x Check mixture cooler (using a bore scope)

x x Clean mixture cooler

OBJ_DOKU-17296-001.fm 12 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule 5-1

5

E10 E20 E30 E40 E45 E50 E55 E60 E70 Description

every 24 hours (daily)

after every 12000 oh

after every 16000 oh

after every 24000 oh

after every 32000 oh

after every 64000 oh

after every 2000 oh

after every 4000 oh

1x after 50 Oh

as specified

x x Cleaning the gas-air mixer

x Overhauling the gas-air mixer

x Check rubber compensators

x Renew rubber compensators

x x Renew viscosity rotary vibration dampers

x x Check vibration dampers, hoses and flexible lines

x x Check fittings and control units on engine side

x x Check electric cabling, cable set plug and sensor sys-

tem

x Check crankshaft axial clearance

x Check camshaft, axial clearance

x Check small end bushings

x x Renew big end bearing

x x Renew cylinder liners

x x Check crankcase, collar rest of cylinder liners and

water chambers

x Check piston bolt

x Renew piston rings

x Check the piston

x Renew pistons (complete)

x x Renew valve tappet

x Visually check camshaft (camshaft installed)

x Check camshaft

x Renew camshaft bearing

x Renew valve actuator

x Check conrod

x Renew connecting rods

x Renew crankshaft sealing ring on the drive side

x Renew crankshaft sealing ring on the free side

x Check crankshaft

x Renew main bearing and axial bearing or stop rings

x Check and clean gear drive

x Renew lubricating oil pump

OBJ_DOKU-17296-001.fm 13 © MWM GmbH 01/2009

TCG 2020 K

Maintenance schedule 5-1

E10 E20 E30 E40 E45 E50 E55 E60 E70 Description

every 24 hours (daily)

after every 12000 oh

after every 16000 oh

after every 24000 oh

after every 32000 oh

after every 64000 oh

after every 2000 oh

after every 4000 oh

1x after 50 Oh

as specified

x Renew lubricating oil pressure limiting valve

x Renew exhaust gas compensators

x Recondition actuator

All the filter elements of the crankcase breather must be renewed if coolant penetrates the

lubricating oil system.

OBJ_DOKU-17296-001.fm 14 © MWM GmbH 01/2009

Potrebbero piacerti anche

- Joinery and Fitting (Wooden Windows Detail - Casement) : Department of Interior & Furniture Design LsadDocumento19 pagineJoinery and Fitting (Wooden Windows Detail - Casement) : Department of Interior & Furniture Design LsadAnmol MehanNessuna valutazione finora

- Technical Note 016 - Ground Bearing PRDocumento3 pagineTechnical Note 016 - Ground Bearing PRAnonymous UebIaD8A8CNessuna valutazione finora

- Technical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Documento205 pagineTechnical Guide On Internal Audit of Automobile Industry: ISBN: 978-81-8441-853-8Dev JainNessuna valutazione finora

- Boilers, Evaporators, and CondensersDocumento852 pagineBoilers, Evaporators, and CondensersJosé Carlos Chan Arias86% (7)

- Champion Industrial Spark Plugs - DigipubZDocumento8 pagineChampion Industrial Spark Plugs - DigipubZiyan22suryana_827197Nessuna valutazione finora

- Izombe Pareto Analysis Report 2016Documento88 pagineIzombe Pareto Analysis Report 2016Wariebi Oghene Lawani100% (1)

- 1 Technical-Description MWM 2032v16-2Documento20 pagine1 Technical-Description MWM 2032v16-2Panda1388100% (4)

- Analysis of Geopolymer Concrete ColumnsDocumento10 pagineAnalysis of Geopolymer Concrete ColumnsRodick AndyNessuna valutazione finora

- Overview of API 682 and ISO 21049Documento7 pagineOverview of API 682 and ISO 21049pedpixNessuna valutazione finora

- Waukesha Libro de Partes 2016 - New-Price-User-PortalDocumento718 pagineWaukesha Libro de Partes 2016 - New-Price-User-PortalLenin Marcel Fajardo Almeida100% (2)

- Cost Calculation TCG 2020 V16K With CNGDocumento2 pagineCost Calculation TCG 2020 V16K With CNGR_afflyNessuna valutazione finora

- G3306Documento4 pagineG3306carlucido247970100% (1)

- MBH Conversion References - Deutz-MWM TBD 6M 628Documento1 paginaMBH Conversion References - Deutz-MWM TBD 6M 628Marbun Benny100% (1)

- Food PackagingDocumento107 pagineFood PackagingVikram SinghNessuna valutazione finora

- Generator Set and System Spec Review - 05!12!2016Documento38 pagineGenerator Set and System Spec Review - 05!12!2016Hai LeNessuna valutazione finora

- MWM TCG 2020Documento5 pagineMWM TCG 2020ppourmoghaddamNessuna valutazione finora

- HIMSEN Catalog 2010 PDFDocumento46 pagineHIMSEN Catalog 2010 PDFGabriela SanchezNessuna valutazione finora

- MWM TCG 2020V16 Engine Technical SpecificationDocumento8 pagineMWM TCG 2020V16 Engine Technical Specificationudelmark0% (1)

- 0006 Maintenance Schedule TCG2020K PDFDocumento8 pagine0006 Maintenance Schedule TCG2020K PDFMd Iqbal HossainNessuna valutazione finora

- White Paper Gasoline BlendingDocumento12 pagineWhite Paper Gasoline BlendingHeniNessuna valutazione finora

- Effi Ciency Straight Down The LineDocumento5 pagineEffi Ciency Straight Down The LineZiaur Rahman67% (3)

- Corken Compresores Amoniaco PDFDocumento100 pagineCorken Compresores Amoniaco PDFNicolas BurgosNessuna valutazione finora

- MWM Gas Engine Tcg2020 enDocumento8 pagineMWM Gas Engine Tcg2020 enPankaj Kamble100% (1)

- J920 Jenbacher Factsheet EnglishDocumento8 pagineJ920 Jenbacher Factsheet Englishoverlord5555Nessuna valutazione finora

- Boiler Internal & External TreatmentDocumento62 pagineBoiler Internal & External Treatmentmdnor100% (1)

- MWM Gas Engine Tcg2016 enDocumento8 pagineMWM Gas Engine Tcg2016 enPankaj KambleNessuna valutazione finora

- WartsilaDocumento55 pagineWartsiladavinci engineering100% (1)

- Catalogue TCG2032V16 4Documento4 pagineCatalogue TCG2032V16 4Mizan SarkarNessuna valutazione finora

- Efficiency On A New Level.: TCG 2032B V16Documento5 pagineEfficiency On A New Level.: TCG 2032B V16ppourmoghaddamNessuna valutazione finora

- 0006 Maintenance Schedule TCG2020K PDFDocumento8 pagine0006 Maintenance Schedule TCG2020K PDFMd Iqbal HossainNessuna valutazione finora

- Comparation Gas Engine 030714Documento2 pagineComparation Gas Engine 030714GunturMudaAliAkbarNessuna valutazione finora

- Practice of Painting PDFDocumento46 paginePractice of Painting PDFChris WalkerNessuna valutazione finora

- Faraz Ahmed C.VDocumento3 pagineFaraz Ahmed C.Vfaraz24Nessuna valutazione finora

- TCG2032Documento4 pagineTCG2032sdiamanNessuna valutazione finora

- MWM TCG 2020Documento4 pagineMWM TCG 2020MohammadFaisalAmjadNessuna valutazione finora

- B-1435 Galaxy 3D TRASAR Automation Cooling Water PDFDocumento8 pagineB-1435 Galaxy 3D TRASAR Automation Cooling Water PDFGabriel ZorattiNessuna valutazione finora

- Grove Rt890e Presentation 1334591359Documento23 pagineGrove Rt890e Presentation 1334591359ابراهيم حافظNessuna valutazione finora

- Caterpillar CG260 - 60 y 50 HZDocumento5 pagineCaterpillar CG260 - 60 y 50 HZEdutam67% (3)

- Efficiency Assessment of Condensing Steam Turbine-DL From Wseas - UsDocumento6 pagineEfficiency Assessment of Condensing Steam Turbine-DL From Wseas - UsGirish OniyilNessuna valutazione finora

- TCR Turbocharger - Balancing The Rotor Assembly After Exchanging The Compressor Wheel / Turbine RotorDocumento2 pagineTCR Turbocharger - Balancing The Rotor Assembly After Exchanging The Compressor Wheel / Turbine RotormariodalNessuna valutazione finora

- 156 2018BookletRevDA5WEB PDFDocumento24 pagine156 2018BookletRevDA5WEB PDFthomas1313Nessuna valutazione finora

- DEUTZ Gas Engine Limit - Oil AnalysisDocumento13 pagineDEUTZ Gas Engine Limit - Oil Analysisgilar herliana putraNessuna valutazione finora

- MWM Gas Engine TCG 3016Documento7 pagineMWM Gas Engine TCG 3016ppourmoghaddamNessuna valutazione finora

- MWM Factsheet 2011 enDocumento2 pagineMWM Factsheet 2011 enAbhijit MannaNessuna valutazione finora

- MWM Gas Engine tcg2020 ENDocumento5 pagineMWM Gas Engine tcg2020 ENUlilNessuna valutazione finora

- 2011 - Engine - KlammerDocumento23 pagine2011 - Engine - KlammerTiago HenriquesNessuna valutazione finora

- MWM Interface400VContainerTCG2016CDocumento3 pagineMWM Interface400VContainerTCG2016Cgabinetedeiniciativa100% (1)

- Training ReportDocumento44 pagineTraining Reportshaur20Nessuna valutazione finora

- TDI Catalog TurboStartTwo Brochure PDFDocumento4 pagineTDI Catalog TurboStartTwo Brochure PDFEva Karia colorado MartinezNessuna valutazione finora

- J312V02 enDocumento4 pagineJ312V02 enMartin KratkyNessuna valutazione finora

- MWM DEUTZ Natural Gas Generator 63Documento1 paginaMWM DEUTZ Natural Gas Generator 63Pankaj KambleNessuna valutazione finora

- 275GL Series 12V 275GL+: Gas Engine With ESM 2Documento2 pagine275GL Series 12V 275GL+: Gas Engine With ESM 2Jaadi 786100% (1)

- tr0199990210510 - en Oil GDocumento26 paginetr0199990210510 - en Oil GSojib hossainNessuna valutazione finora

- محطات إنتاج الطاقة الكهربائية في السودانDocumento6 pagineمحطات إنتاج الطاقة الكهربائية في السودانTruuth SeekerNessuna valutazione finora

- C275D5 Data SheetDocumento3 pagineC275D5 Data SheetnandanaNessuna valutazione finora

- Green Power International (P) LTD.: Selection Chart For Natural Gas Based GensetsDocumento1 paginaGreen Power International (P) LTD.: Selection Chart For Natural Gas Based GensetssanitermNessuna valutazione finora

- Plumb, Drainage RBADocumento7 paginePlumb, Drainage RBAThuo Paul Thuo100% (1)

- ERS M22 PC4 FerryDocumento2 pagineERS M22 PC4 FerryouakgoodNessuna valutazione finora

- Lubrication of Power Plant Equipment PDFDocumento34 pagineLubrication of Power Plant Equipment PDFRavinder SharmaNessuna valutazione finora

- Wartsila SP A Id TugDocumento7 pagineWartsila SP A Id TugRoy ChaiNessuna valutazione finora

- Man BW Stationary Engines and Small Bore Gensets ProgrammeDocumento62 pagineMan BW Stationary Engines and Small Bore Gensets ProgrammeRhaanzahNessuna valutazione finora

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDocumento3 pagineGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNessuna valutazione finora

- THERMACT Solid FuelsDocumento4 pagineTHERMACT Solid FuelsAjit SidhuNessuna valutazione finora

- Indian Standard On Fire Safety Equipments PDFDocumento31 pagineIndian Standard On Fire Safety Equipments PDFShubham RoyNessuna valutazione finora

- TCG 2020 OlsDocumento4 pagineTCG 2020 Olssdiaman100% (1)

- Caterpillar RC1000 Containerized Diesel Generator SetDocumento4 pagineCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryNessuna valutazione finora

- Engin Airflow Calculation GuideDocumento9 pagineEngin Airflow Calculation GuideRodolfo Perez100% (3)

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocumento13 pagine208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNessuna valutazione finora

- MotoHawk Software PSDocumento6 pagineMotoHawk Software PSCABean1Nessuna valutazione finora

- Pres RosgrenDocumento24 paginePres RosgrenAnuj SharmaNessuna valutazione finora

- J616V02 enDocumento4 pagineJ616V02 enMartin KratkyNessuna valutazione finora

- STF Industrial BoilersDocumento20 pagineSTF Industrial BoilersDaniellzhangNessuna valutazione finora

- TCG 2032 V16Documento20 pagineTCG 2032 V16Ilya DovgalukNessuna valutazione finora

- KrausNaimer CGCHCHR CatalogueDocumento50 pagineKrausNaimer CGCHCHR CatalogueNesil AbieraNessuna valutazione finora

- SPI Mold Finish - Practical Approach: ShareDocumento2 pagineSPI Mold Finish - Practical Approach: ShareDavid Lay IINessuna valutazione finora

- Improvement in The Overall Efficiency of Mining Equipment PDFDocumento7 pagineImprovement in The Overall Efficiency of Mining Equipment PDFAndres Mujica MorovicNessuna valutazione finora

- Advanced Applications of Multifunction Digital Generator ProtectionDocumento10 pagineAdvanced Applications of Multifunction Digital Generator ProtectionShambhu Poddar100% (1)

- Exemptions Granted To Large Taxpayers January, 2010 To September, 2014 PDFDocumento82 pagineExemptions Granted To Large Taxpayers January, 2010 To September, 2014 PDFRashid BumarwaNessuna valutazione finora

- Welding Certifications and Welder Qualification Tests PDFDocumento7 pagineWelding Certifications and Welder Qualification Tests PDFArjun JpNessuna valutazione finora

- Mazda Protege 5 Control SystemDocumento14 pagineMazda Protege 5 Control SystemJGAR2009Nessuna valutazione finora

- Mohammad Abu Shattal July2017Documento3 pagineMohammad Abu Shattal July2017Mohammad Abu ShattalNessuna valutazione finora

- Skills Framework For Aerospace Skill Standard For Licensed Aircraft Maintenance Engineer - B1 (Mechanical)Documento129 pagineSkills Framework For Aerospace Skill Standard For Licensed Aircraft Maintenance Engineer - B1 (Mechanical)Thupten Gedun Kelvin OngNessuna valutazione finora

- Model 8700: Technical Bulletin 8700 - TBDocumento4 pagineModel 8700: Technical Bulletin 8700 - TBaymenkaramNessuna valutazione finora

- List of MaterialDocumento3 pagineList of MaterialAchmed Farrin OthmanNessuna valutazione finora

- B.Tech ECE 028 05 DEC12Documento407 pagineB.Tech ECE 028 05 DEC12Prateek GuptaNessuna valutazione finora

- EMT16 Tech Manual PDFDocumento273 pagineEMT16 Tech Manual PDFDonnie AshleyNessuna valutazione finora

- CL-E131 Stator Earth Fault Protection 90%: Commissioning Check List EDocumento2 pagineCL-E131 Stator Earth Fault Protection 90%: Commissioning Check List Emirage1977Nessuna valutazione finora

- B4 GEGuarantee LM6000 PFDocumento7 pagineB4 GEGuarantee LM6000 PFJulian JairNessuna valutazione finora

- P2-FYP2-Conformity of Thesis FormatDocumento2 pagineP2-FYP2-Conformity of Thesis FormatMuhd Ashraf AzmiNessuna valutazione finora

- Younis and Abdelati With HeaderDocumento6 pagineYounis and Abdelati With HeaderScott MelgarejoNessuna valutazione finora