Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WPS Format For Asme Ix - Wps - Gtaw - Overlay

Caricato da

The Welding Inspections CommunityTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WPS Format For Asme Ix - Wps - Gtaw - Overlay

Caricato da

The Welding Inspections CommunityCopyright:

Formati disponibili

The Welding Inspections Community

https://www.weldinginspections.net

contact@weldinginspections.net

Vung Tau City, SR. Viet Nam

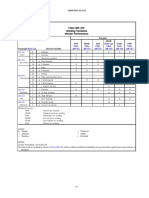

WELDING PROCEDURE SPECIFICATION

(ASME Section IX – 2019 Edition)

DESCRIPTION JOINT SKETCH

1 WPS no. -

2 Date of issue -

3 Applicable code -

4 Welding process -

JOINTS (QW-402)

.16 Min. finished thickness (t) -

BASE METALS (QW-403) POSITIONS (QW-405)

.4 Position -

.20 P-Number -

PREHEAT (QW-406)

.23 T qualified -

FILLER METALS (QW-404) .4 Pre-heat temperature -

.3 Wire size -

.12 Classification - PWHT (QW-407)

.14 Filler metal - .6 PWHT -

.23 Filler metal product form - .9 PWHT -

.37 A-Number -

ELECTRICAL CHARACTERISTICS (QW-409)

.4 Current & polarity -

.8 I & E range -

.12 Tungsten electrode -

.26 Heat input (first layer) -

TECHNIQUE (QW-410)

.1 String / weave -

.3 Orifice, nozzle or gas cup size -

.5 Method cleaning -

.7 Oscillation -

.15 Electrode spacing -

.25 Manual or automatic -

GAS (QW-408) .26 Peening -

.38 Multi/Single layer -

.2 Single, mixture, or % -

.50 No. of electrode -

.3 Flow rate -

.52 Filler metal delivery -

REMARKS

(*)

WELDING PARAMETERS

Filler metal Current & Ampere Travel speed Heat Input

Layer Process Voltage range Others

Class. Dia. polarity Range [mm/minute] [kJ/mm]

Root GTAW - - - - - - - -

Hot GTAW - - - - - - - -

Fill GTAW - - - - - - - -

Cap GTAW - - - - - - - -

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

Page | 1

Potrebbero piacerti anche

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw SmawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- ASME IX Sample WPS GTAW SMAWDocumento1 paginaASME IX Sample WPS GTAW SMAWDeepak ShrivastavNessuna valutazione finora

- WPS Format For ASME IX - PQR-AllDocumento3 pagineWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Documento2 pagineASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Brazing BPS 107-1 PDocumento5 pagineBrazing BPS 107-1 Pmbe josephNessuna valutazione finora

- GMAWDocumento12 pagineGMAWsushant47Nessuna valutazione finora

- Supercito (E 42 5 B 32 h5)Documento1 paginaSupercito (E 42 5 B 32 h5)brunizzaNessuna valutazione finora

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- CIGWELDDocumento244 pagineCIGWELDrodastrid5653100% (1)

- Exam Narative Cswip 3.2Documento5 pagineExam Narative Cswip 3.2yuwantoniNessuna valutazione finora

- Iwe Iwt IwsDocumento2 pagineIwe Iwt IwsINSTECH ConsultingNessuna valutazione finora

- Gouging ProcedureDocumento11 pagineGouging Procedurealizadeh222275% (4)

- WPS for Welding SA-335 P11 to SA-234 WP11Documento3 pagineWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNessuna valutazione finora

- Interpass Temperature WeldingDocumento2 pagineInterpass Temperature Weldinghareesh13hNessuna valutazione finora

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 pagineWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- ASME SECTION IX INTERPRETATIONSDocumento95 pagineASME SECTION IX INTERPRETATIONSnizam1372Nessuna valutazione finora

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocumento3 pagineTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNessuna valutazione finora

- Asme Sec 9 - ADocumento144 pagineAsme Sec 9 - Anidhinchandranvs67% (3)

- S235jr Carbon SteelDocumento2 pagineS235jr Carbon Steelcheligp1981Nessuna valutazione finora

- Highlights On ASME Essential VariablesDocumento8 pagineHighlights On ASME Essential VariableschowhkNessuna valutazione finora

- Wel 13 HDocumento8 pagineWel 13 HWilly Uio100% (1)

- Submerged Arc WeldingDocumento5 pagineSubmerged Arc Weldingmanikandan.vNessuna valutazione finora

- 6GR RequirementsDocumento1 pagina6GR Requirementswalitedison100% (1)

- BohlerThyssen PDFDocumento386 pagineBohlerThyssen PDFElMacheteDelHuesoNessuna valutazione finora

- Storing and Redrying Electrodes-Lincoln ElectricDocumento3 pagineStoring and Redrying Electrodes-Lincoln ElectricjasminneeNessuna valutazione finora

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocumento8 paginePFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74Nessuna valutazione finora

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCDocumento1 pagina22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforNessuna valutazione finora

- WPSGMAW90 102011ExamplePDFDocumento1 paginaWPSGMAW90 102011ExamplePDFBhavani PrasadNessuna valutazione finora

- QW 483Documento2 pagineQW 483delta lab sangliNessuna valutazione finora

- PWHTDocumento3 paginePWHTharishcsharmaNessuna valutazione finora

- IIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesDocumento81 pagineIIW-ANB Refresher Course: Gas Welding, Brazing, Soldering and Cutting ProcessesAsad Bin Ala QatariNessuna valutazione finora

- JIS G3452 PipeDocumento0 pagineJIS G3452 PipefaridyeniNessuna valutazione finora

- Qualification of Welding Procedures and WeldersDocumento20 pagineQualification of Welding Procedures and WeldersZanuardi YahyaNessuna valutazione finora

- JNK Heaters Co - LTD: Ferrite Test ReportDocumento1 paginaJNK Heaters Co - LTD: Ferrite Test ReportUzorNessuna valutazione finora

- Welder Visual Inspection ReportsDocumento24 pagineWelder Visual Inspection ReportsKyNessuna valutazione finora

- Sample Forms WPS PQRDocumento22 pagineSample Forms WPS PQRGMNessuna valutazione finora

- PRES TIG Hot Wire Narrow Gap Welding enDocumento25 paginePRES TIG Hot Wire Narrow Gap Welding enRavishankarNessuna valutazione finora

- Hydro Aluminium - AlSi7Mg0.6Documento2 pagineHydro Aluminium - AlSi7Mg0.6Raj PrasanthNessuna valutazione finora

- Poster DIN EN 1090-1 ENG Final PDFDocumento1 paginaPoster DIN EN 1090-1 ENG Final PDFlth770310Nessuna valutazione finora

- S355 European Standard SteelDocumento7 pagineS355 European Standard SteelmaiquelernNessuna valutazione finora

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocumento1 paginaSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcNessuna valutazione finora

- KGP-Flamme Cutting Proce For BEI PDFDocumento4 pagineKGP-Flamme Cutting Proce For BEI PDFoomoomNessuna valutazione finora

- MIG Welding Aluminum Guide: Equipment, Settings & TechniquesDocumento8 pagineMIG Welding Aluminum Guide: Equipment, Settings & TechniquesHandri YantoNessuna valutazione finora

- Welding Procedure For BOXNR Wagon (WPS)Documento8 pagineWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- General Welding Procedure - Rev0Documento27 pagineGeneral Welding Procedure - Rev0Jayan VKNessuna valutazione finora

- Astm A335 p91 PipeDocumento1 paginaAstm A335 p91 PipeBhagwati SteelageNessuna valutazione finora

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDocumento4 pagineCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55Nessuna valutazione finora

- Procedure for Flame Straightening Structural SteelDocumento3 pagineProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- OCS Engineering & Construction Visual Inspection ReportDocumento1 paginaOCS Engineering & Construction Visual Inspection ReportvinothNessuna valutazione finora

- ADOR Booklet F Web FDocumento132 pagineADOR Booklet F Web FbadesharamkNessuna valutazione finora

- WPS Format For ASME IX - WPS - SAWDocumento1 paginaWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Gtaw SawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For Asme Ix - Wps - GtawDocumento1 paginaWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For Asme Ix - Wps - SmawDocumento1 paginaWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNessuna valutazione finora

- Asmeix Wps Fcawgmaw 191019041529 PDFDocumento1 paginaAsmeix Wps Fcawgmaw 191019041529 PDFvinod100% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For ISO 15614-1 PWPSDocumento1 paginaWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For AWS D1.1 - PQR - SMAWDocumento3 pagineWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- WPS Format For ISO 15614-1 WPSDocumento1 paginaWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For ISO 15614-1 PQRDocumento3 pagineWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- WPS Format For Asme Ix - Wps - SmawDocumento1 paginaWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - SMAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For ISO 9606-1 WelderDocumento2 pagineWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPS Format For AWS D1.1 - WPS - SAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For ASME IX - WQTDocumento1 paginaWPS Format For ASME IX - WQTThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For AWS D1.1 - WelderDocumento1 paginaWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For ASME IX - WPS - SAWDocumento1 paginaWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For Asme Ix - Wps - GtawDocumento1 paginaWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For Asme Ix - Wps - Gtaw SawDocumento1 paginaWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For Asme Ix - Wps - Fcaw GmawDocumento1 paginaWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNessuna valutazione finora

- Welding Questions and AnswersDocumento10 pagineWelding Questions and AnswersUmaibalan100% (2)

- Oerlikon Citotig Force enDocumento6 pagineOerlikon Citotig Force enDermantoNessuna valutazione finora

- WPS 02Documento2 pagineWPS 02ZaidiNessuna valutazione finora

- Roberto T. EsquilloDocumento6 pagineRoberto T. EsquillomikeeNessuna valutazione finora

- Welding ConsumablesDocumento128 pagineWelding ConsumablesAsad Bin Ala Qatari100% (1)

- Esab Electrode Storage RecommendationsDocumento22 pagineEsab Electrode Storage RecommendationsDhanush NairNessuna valutazione finora

- ArunDocumento14 pagineArunAyanokoji kunNessuna valutazione finora

- Wps Fillet AWSDocumento4 pagineWps Fillet AWSMohd Ashraf100% (1)

- Table - QW-416 Welding Variables For Welder Performance PDFDocumento1 paginaTable - QW-416 Welding Variables For Welder Performance PDFAnonymous VohpMtUSNNessuna valutazione finora

- WeldingDocumento93 pagineWeldingPradeepNessuna valutazione finora

- Weldwell Catalogue 2015Documento8 pagineWeldwell Catalogue 2015jaganelrNessuna valutazione finora

- Great Yuva Cutting and WeldingDocumento20 pagineGreat Yuva Cutting and WeldingCOSMO WELDNessuna valutazione finora

- PWPS - GTSM-73 Rev-ADocumento5 paginePWPS - GTSM-73 Rev-AVimin PrakashNessuna valutazione finora

- UWI 150 TP Owners ManualDocumento20 pagineUWI 150 TP Owners Manualajshsu5682Nessuna valutazione finora

- Arc Inverter: Instruction ManualDocumento12 pagineArc Inverter: Instruction ManualAdamNessuna valutazione finora

- BMP - Electric Arc WeldingDocumento91 pagineBMP - Electric Arc Weldingsujay nayakNessuna valutazione finora

- RA Arc, Welding 150310Documento4 pagineRA Arc, Welding 150310Mohd FikryNessuna valutazione finora

- Welding Feasibility of Copper and Mild Steel Using TIG WeldingDocumento3 pagineWelding Feasibility of Copper and Mild Steel Using TIG WeldingselavilizationNessuna valutazione finora

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Documento1 paginaWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNessuna valutazione finora

- Welding Procedure Qualification of A36 Steel Plates Using The GTADocumento33 pagineWelding Procedure Qualification of A36 Steel Plates Using The GTAKYAW SOENessuna valutazione finora

- Fabrication ProcessDocumento5 pagineFabrication ProcessKashan Aamir Aamir IshaqNessuna valutazione finora

- Welding DesignDocumento28 pagineWelding DesignSitaram JhaNessuna valutazione finora

- Welding ConsumablesDocumento79 pagineWelding Consumablesazam RazzaqNessuna valutazione finora

- ASMe Sec2 PartcDocumento53 pagineASMe Sec2 PartcSARSAN NDTNessuna valutazione finora

- Gas Tungsten Arc WeldingDocumento37 pagineGas Tungsten Arc WeldingRed ChaNessuna valutazione finora

- ESAB Renegade ES 300i Portable MMA Arc Welder User ManualDocumento32 pagineESAB Renegade ES 300i Portable MMA Arc Welder User Manualaxisd47Nessuna valutazione finora

- Anti Toxic PicklingDocumento2 pagineAnti Toxic PicklingGaurav Bedi0% (1)

- 201ufrep ME ISRO2020Paper 2020 PDFDocumento42 pagine201ufrep ME ISRO2020Paper 2020 PDFkiran kittuNessuna valutazione finora

- Piping ConsumableDocumento13 paginePiping ConsumablenikunjNessuna valutazione finora

- Isotrend Ir 192 Brochure PDFDocumento2 pagineIsotrend Ir 192 Brochure PDFSafiq UddinNessuna valutazione finora