Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Concrete Repair

Caricato da

69badbutchDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Concrete Repair

Caricato da

69badbutchCopyright:

Formati disponibili

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

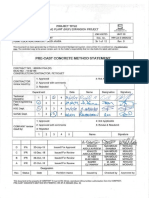

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

CATEGORY METHOD STATEMENT

TITLE REPAIR OF CONCRETE

DOCUMENT REFERENCE NSH-SAOMPP-CMS-CI-005

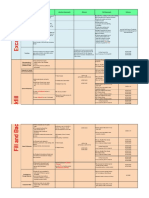

Index

1.0 Introduction

2.0 Scope

3.0 Reference

4.0 Procedure

5.0 Curing

6.0 Safety Plan

7.0 Attachments

Copies with no seal are Uncontrolled copies. Page 1 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

0 15/02/2015 For Approval Tinu David Jacob Bobby Paul

Revision Date Description Prepared By Reviewed By Approved By

REVISION HISTORY

1.0 Introduction

This document states the procedures that NSH propose to adopt and carry out the

repairing of concrete required in the concreting works such as foundations, walls,

columns, footings, pits, manholes etc. at Saudi Aramco Onshore Maintain Potential

Program-NA1A - KSA.

2.0 Scope

This method statement covers the repair of non-structural types of concrete defects. The

defects like honey combing, blow holes, peeling, blistering, tie rod holes etc. which are

not affecting the strength of structure can be rectified as per this statement. For structural

type of repairs, specific method statement and material to be adapted with approval

3.0 Reference

SAER-5803 Concrete Repair Manual

SAES-H-003 Protective Coating for Industrial Concrete Structures

Manufacturer’s Recommendations for Repair Material

4.0 Procedure

4.1 Identify the Repair

After the removal of formwork, NSH QC personnel and PID SAUDI ARAMCO

shall thoroughly check whether any voids, honey combs, blistering, air holes, hair

line cracks etc. have appeared on the concrete surface. If found any, the repair

shall be as per the procedure mentioned below using the factory prepared

repairing materials according to manufacturer’s recommendation.

Copies with no seal are Uncontrolled copies. Page 2 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

4.2 Preparation & Repair of Concrete

Any repair should be done only after the curing period, PMT approval and

a) The air holes, honey combs or the defects which are less than 10mm

depth (Vertically or Horizontally) can be repaired with Approved Repair

Material as per the manufacturer’s recommendation.

Remove the laitance, loose materials using appropriate tools and make

the surface rough & sound concrete without any cavity, clean the

roughened area with water and soak the surface thoroughly. Then apply

an approved bonding agent if recommended by the manufacturer and

apply Approved Repair Material with trowel/ scrapper and cure it for

required time as per manufacturer’s recommendation.

b) If the defective surface in vertical faces is more than 10mm and below

50mm Approved Repair Material shall be used as per manufacturer’s

recommendation

c) The repair thickness more than 50mm and up to 75mm vertically shall be

repaired with Approved Repair Material as per manufacturers specification/

recommendation.

For repairing defective surface more than 10mm, all loose concrete should

be removed carefully till a non-porous sound concrete surface is obtained.

To perform this hilti hammer with flat chisel or brush hammer can be used.

Also care should be taken to avoid damage to surrounding concrete

surfaces and rebar.

d) If the repair thickness is beyond the reinforcement, special attention to be

given for the repair and it should be informed to the competent authority to

decide the type of repairing method to be obtained.

e) Tie rod holes will be chipped off to 75mm thickness and PVC sleeves

should remove to a depth of 75mm and use backup road before applying

Approved Repair Material extra for sealing tie rod holes.

Special care should be taken for repairing the defect where reinforcement

is exposed. It should also be cared to avoid damaging the coating of rebar,

if the coating is damaged it should be rectified before applying mortar.

Copies with no seal are Uncontrolled copies. Page 3 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

f) Hair line cracks can be repaired by cutting groove (45 degree) to a

minimum of 10 to 15mm depth on both sides of the crack. Make the

surface rough throughout the groove cut area and use Approved Repair

Material as per the recommendation of the manufacturer.

The repair material, receiving inspection shall be done for review and

approval prior to use. Sample mock up shall be provided prior to start the

repairs. All repair materials shall comply with ASTM or ACI requirements.

Qualified repair crews shall repair the defects and technical support can be

obtained from supplier first time for right application.

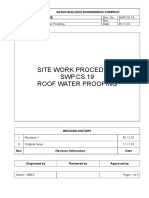

5.0 Curing

Curing will be done as per the manufacturer’s Instruction

6.0 Safety Plan

Safety for men and material have higher priority and all safety measures should be taken

before doing any of these activities mentioned above. MSDS must be available at work

location and material storage area. Rubber glove and chemical protective PPE as per

MSDS should use for this job.

7.0 Attachments

7.1 Safety Plan

7.2 Catalogue of repair mortar Nitomotar TC2000

7.3 Catalogue of repair mortar Masterbrace ADH2200

7.4 Catalogue of repair mortar Mastermaco N301

7.5 Catalogue of repair mortar Mastermaco S488

7.6 Catalogue of repair mortar Renderoc FC

7.7 Catalogue of repair mortar Renderoc TG

7.1 SAFETY PLAN

7.1.1 Tool Box/ Safe Work Plan

Copies with no seal are Uncontrolled copies. Page 4 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

Tool box talks shall strictly be observed before starting the work

shift to discuss the Safe Work Plan and other safety concerns for

the work.

Tool box talk shall be conducted by the site supervisor with the

safety supervisor assisting and signing the attendance sheet.

Work can only start when all the provisions in the safe work plan

are fully complied, to include all safety precautions needed.

All tool box talk attendance sheets must be turned over for

submission to HSE department.

7.1.2 General Safety Requirements

7.1.2.1 Personal Protective Equipment’s

All personnel (workers, drivers, operators, contractor

personnel, client personnel) must wear the project

mandatory PPE (long pants, long sleeve shirt, hard hat,

safety dark glass, safety clear glass, safety shoes, high

visibility vest, hand gloves).

Special PPE for noise, hand protection, dust pollution, etc.

shall be provided to all concerned workers/ personnel.

All PPE must be inspected prior to use, damage PPE must

be replaced.

7.1.2.2 Housekeeping

Unwanted materials/ supplies shall be removed from site to

ensure clear access and assigned roads for equipment

traffic.

Proper barricading and signage shall be implemented.

Maintain proper access and egress for workers and

equipment.

Keep all work areas clean and free of trash.

Copies with no seal are Uncontrolled copies. Page 5 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

7.1.2.3 Work Environment

Portable toilets provided.

Drinking water provided in 2CHtter coolers.

Replacement drink (juice with salt, sugar and glucose)

provided to all workers twice during morning and afternoon

to minimize impact d heat exposure.

Rest shelters provided near the working area.

During high wind where visibility will hamper the operation,

Construction and Safety will advise the workers on

approved action to take.

7.1.2.4 Tools and Equipment

All tools shall be inspected color coded prior to use replace

damage tools from store.

Electrical tools/ equipment must be properly checked color

coded before using (project standard is 110 volts supply).

Operate the tools according to the operations manual.

7.1.2.5 Permit to Work

All permits to work required must be valid and approved

before the start of the job.

Permit original copies must be in the site inside the permit

box.

All conditions provided in the permit must be compiled and

maintained form the start up to completion of the works.

For night work, workers list shall be attached on all permits.

7.1.2.6 Electricity

Lighting facility (tower fights & flashing lights) for night work

are provided.

All energized equipment shall be properly grounded.

Copies with no seal are Uncontrolled copies. Page 6 of 7

NASSER S AL HAJRI CORPORATION

SAUDI ARAMCO ONSHORE MAINTAIN POTENTIAL PROGRAM- NA1A

CONTRACT # 6600033948

NSH-SAOMPP-CMS-CI-005 METHOD STATEMENT FOR REPAIR OF CONCRETE

Rev-00 Date: 15 Feb 2015

Qualified mechanic/ electrician shall be deployed during the

operation to respond the need for lighting relocation etc.

and also to act as fire watchers.

Panel boards or extension cords used in site shalt be

properly checked and color coded.

To mitigate tripping hazard, power/ electrical cables shall be

either installed in between scaffold planks or elevated in

access/ egress portions.

7.1.2.7 Other Specific Safety Requirements

MSDS: To be provided in the site. MSDS box, site clinic and

work site area.

For medical team/facility: Provide certified nurse certified

first aider, ambulance driver, ambulance (to be parked

near the work area during night time).

Working in pair (“buddy-system”) is strictly required

especially during night works.

A prescribed cheek time (CT) schedule must be observed.

Check times are Intervals between working times and rest

times. Construction and Safety will check the workers

conditions before re-starting the work. For day shift check

time shall depend on the heat index level.

Provide scaffold planks as required to walk while working

on rebars

END OF THE DOCUMENT

Copies with no seal are Uncontrolled copies. Page 7 of 7

Potrebbero piacerti anche

- Ms Repair For Large Honeycomb Areas Rev 01Documento48 pagineMs Repair For Large Honeycomb Areas Rev 01moytabura96100% (1)

- Methods of Concrete RepairDocumento27 pagineMethods of Concrete RepaircharlessimoNessuna valutazione finora

- Cms 0031 Concrete Crack Repair at WWTP Rev. ADocumento18 pagineCms 0031 Concrete Crack Repair at WWTP Rev. Azahangir100% (1)

- 04b Concrete Repair MethodsDocumento37 pagine04b Concrete Repair MethodsUbaid Mazhar Abidi Syed80% (5)

- DESIGN Method Statement For Concrete RepairDocumento14 pagineDESIGN Method Statement For Concrete RepairBleep NewsNessuna valutazione finora

- Mos For Precast Concrete WorksDocumento28 pagineMos For Precast Concrete Worksabrahmanjazbi100% (3)

- Method of Statement For Concrete RepairDocumento9 pagineMethod of Statement For Concrete RepairMohammed Ghareib NasrNessuna valutazione finora

- Repairing ConcreteDocumento10 pagineRepairing ConcreteWan HabibNessuna valutazione finora

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Documento9 pagineMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. 02Imho TepNessuna valutazione finora

- Method For Concrete Repair - 11.12.13Documento3 pagineMethod For Concrete Repair - 11.12.13imran11novNessuna valutazione finora

- MS - CONCRETE REPAIR Rev 3Documento25 pagineMS - CONCRETE REPAIR Rev 3Mariam Mousa100% (3)

- Method Statement For Installation of Pre-Cast MH.: Prepared byDocumento8 pagineMethod Statement For Installation of Pre-Cast MH.: Prepared byBara'a ManciNessuna valutazione finora

- PQCP-06.03.09 Concrete Crack RepairDocumento3 paginePQCP-06.03.09 Concrete Crack RepairmiaicarbaNessuna valutazione finora

- Method StatementDocumento7 pagineMethod StatementTenuki JapanNessuna valutazione finora

- Saes A 114Documento2 pagineSaes A 114Nino Celso AstilleroNessuna valutazione finora

- 2 Method Statement of Repair of HCS CracksDocumento4 pagine2 Method Statement of Repair of HCS CracksSk Prabhu ReddyNessuna valutazione finora

- 1 MS - Pouring of ConcreteDocumento8 pagine1 MS - Pouring of ConcreteFauzi MastamNessuna valutazione finora

- MS Concrete Crack RepairDocumento5 pagineMS Concrete Crack Repairjoseph guiyab100% (1)

- Polyurea Hot Spray Steel Surfaces Method StatementDocumento9 paginePolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyNessuna valutazione finora

- Cms 0002 Concrete Repair Rev. ADocumento19 pagineCms 0002 Concrete Repair Rev. Azahangir100% (1)

- Sikafloor® Technical Services: Surface Preparation GuideDocumento12 pagineSikafloor® Technical Services: Surface Preparation GuideMIGUEL ANGEL ACON ROBLEDANessuna valutazione finora

- Methods of Repairing Concrete StructuresDocumento22 pagineMethods of Repairing Concrete StructuresManzeer Fasaludeen100% (3)

- RC RepairDocumento4 pagineRC RepairPcEngNessuna valutazione finora

- Curing MethodsDocumento4 pagineCuring MethodsrmdarisaNessuna valutazione finora

- Brick MasonryDocumento8 pagineBrick MasonrybulzaeNessuna valutazione finora

- Concrete Repair MsDocumento2 pagineConcrete Repair MsVinodh Palanichamy100% (2)

- Concrete Crack and Partial-Depth Spall RepairDocumento78 pagineConcrete Crack and Partial-Depth Spall RepairRafeeq WazirNessuna valutazione finora

- Concrete RepairDocumento112 pagineConcrete RepairAymanZakariaNessuna valutazione finora

- Qaqc Inspector QuestionaireDocumento4 pagineQaqc Inspector QuestionaireNiño Celso AstilleroNessuna valutazione finora

- Pull Off Testing ProcedureDocumento5 paginePull Off Testing ProcedureWamiq100% (1)

- Concrete Pre Pour Planning For Civil ProjectsDocumento6 pagineConcrete Pre Pour Planning For Civil ProjectshemantrulzNessuna valutazione finora

- Method Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01Documento9 pagineMethod Statement For Termite Control (AUVA-MS-Civil-MS-023) Rev 01hammad21100% (1)

- 02 MS Waterproofing WORKSDocumento10 pagine02 MS Waterproofing WORKSNhel G. Pascual67% (3)

- Method Statement For HoneycombDocumento2 pagineMethod Statement For HoneycombCHAR JIN CHEENessuna valutazione finora

- Blockwork and Plastering WorksDocumento12 pagineBlockwork and Plastering Worksfaizan khanNessuna valutazione finora

- Crack Injection Repair To Concrete Structures: Method Statement For ApplicationDocumento3 pagineCrack Injection Repair To Concrete Structures: Method Statement For ApplicationbotchNessuna valutazione finora

- Interior & Exterior PaintingDocumento11 pagineInterior & Exterior PaintingGabriel Gabe50% (2)

- Method Statement For ConcretingDocumento23 pagineMethod Statement For ConcretingVinod MasaniNessuna valutazione finora

- Checklist For Terrace WaterproofingDocumento2 pagineChecklist For Terrace WaterproofingSantosh YadavNessuna valutazione finora

- Repairing of Plaster WallsDocumento4 pagineRepairing of Plaster WallsSayan GharNessuna valutazione finora

- Method Statement of Construction Joint RepairingDocumento1 paginaMethod Statement of Construction Joint RepairingSupun Sandaruwan100% (2)

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Documento4 pagineWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIANNessuna valutazione finora

- Ms For Rubbed ConcreteDocumento6 pagineMs For Rubbed Concreteᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔Nessuna valutazione finora

- Spall Repair by The Preplaced Aggregate Method: Field Guide To Concrete Repair Application ProceduresDocumento7 pagineSpall Repair by The Preplaced Aggregate Method: Field Guide To Concrete Repair Application ProcedurescustomerxNessuna valutazione finora

- Method Statement For Sign Board Excavation & Installation - Safe Work Method of StatementDocumento2 pagineMethod Statement For Sign Board Excavation & Installation - Safe Work Method of StatementUmair AslamNessuna valutazione finora

- Polyurea Waterproofingitp-1 PDFDocumento3 paginePolyurea Waterproofingitp-1 PDFgops1963Nessuna valutazione finora

- Method Statement For Cmu Block WorkDocumento8 pagineMethod Statement For Cmu Block WorkAnwar MohiuddinNessuna valutazione finora

- Method Statement FOR Roof Waterproofing Works: Revision RecordDocumento18 pagineMethod Statement FOR Roof Waterproofing Works: Revision RecordYash Sharma100% (6)

- 6.method Statement For Concrete Repairs Rev. 1Documento14 pagine6.method Statement For Concrete Repairs Rev. 1mohsin100% (5)

- Method Statement For Stone WorksDocumento10 pagineMethod Statement For Stone WorksRangamal DahanayakeNessuna valutazione finora

- Method Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Documento41 pagineMethod Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Domie Neil Bucag SalasNessuna valutazione finora

- Concrete ExamDocumento26 pagineConcrete ExamKyra AlesonNessuna valutazione finora

- Roof Waterproofing-Method StatementDocumento5 pagineRoof Waterproofing-Method StatementTATATAHER100% (1)

- Method Statement For Cement Board Dry Wall PartitionsDocumento10 pagineMethod Statement For Cement Board Dry Wall PartitionsComet GroupNessuna valutazione finora

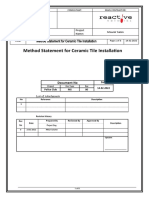

- MS For Ceramic Tile InstallationDocumento8 pagineMS For Ceramic Tile InstallationNikita KasyanovNessuna valutazione finora

- MST For Concrete RepairDocumento6 pagineMST For Concrete RepairDelta akathehusky100% (1)

- Ms - Chipping and Restoration On Mep InstallationsDocumento8 pagineMs - Chipping and Restoration On Mep Installationsmoytabura9667% (3)

- Method Statement GRP MANHOLES REPAIR AND INSTALLATION OF EXTENSION RINGS PDFDocumento19 pagineMethod Statement GRP MANHOLES REPAIR AND INSTALLATION OF EXTENSION RINGS PDFbryanNessuna valutazione finora

- Saic A 1016Documento2 pagineSaic A 1016Ansar Ali VemmullyNessuna valutazione finora

- MS For Core Walls Dowels Location Repair (Towers)Documento5 pagineMS For Core Walls Dowels Location Repair (Towers)rayNessuna valutazione finora

- Module-1-ISO 13485-DocumentDocumento7 pagineModule-1-ISO 13485-Documentsri manthNessuna valutazione finora

- Chapter 2 Body CoordinationDocumento25 pagineChapter 2 Body CoordinationnanarahmannaimNessuna valutazione finora

- DR - Vyshnavi Ts ResumeDocumento2 pagineDR - Vyshnavi Ts ResumeSuraj SingriNessuna valutazione finora

- Calcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYDocumento6 pagineCalcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYbacabacabacaNessuna valutazione finora

- Drugstudy - Delivery RoomDocumento12 pagineDrugstudy - Delivery RoomAUBREY MARIE . GUERRERONessuna valutazione finora

- Construction of Genomic and cDNA Libraries-AmitDocumento10 pagineConstruction of Genomic and cDNA Libraries-AmitPrashant BajpaiNessuna valutazione finora

- DSE8620 MKII Operator ManualDocumento224 pagineDSE8620 MKII Operator Manualhenrygrados44Nessuna valutazione finora

- Digital Meter: KIT No: 0349 307 620Documento6 pagineDigital Meter: KIT No: 0349 307 620Garlin MunarNessuna valutazione finora

- Xtra ReportDocumento8 pagineXtra ReportTahfeem AsadNessuna valutazione finora

- VálvulasDocumento44 pagineVálvulasCarlos LópezNessuna valutazione finora

- Lean Six Sigma Green BeltDocumento7 pagineLean Six Sigma Green Beltmulpuru sai snehaNessuna valutazione finora

- Components of FitnessDocumento3 pagineComponents of Fitnessapi-3830277100% (1)

- Developments in Injection Moulding 3Documento331 pagineDevelopments in Injection Moulding 3Salah HammamiNessuna valutazione finora

- 21 Day Level Up Challenge My PathDocumento52 pagine21 Day Level Up Challenge My PathDavid Stark100% (1)

- P2 Nursing InfoDocumento14 pagineP2 Nursing InfoMargarita Limon BalunesNessuna valutazione finora

- 1 s2.0 S0378517311000226 MainDocumento9 pagine1 s2.0 S0378517311000226 MainFIRMAN MUHARAMNessuna valutazione finora

- CoasteeringDocumento1 paginaCoasteeringIrishwavesNessuna valutazione finora

- Roadshow Advanced 7.2 V3.2 221004 FinalDocumento347 pagineRoadshow Advanced 7.2 V3.2 221004 FinalEddy StoicaNessuna valutazione finora

- Co JetDocumento4 pagineCo JetJaime PaulNessuna valutazione finora

- Eaton 092394 T5B 3 7 E en - GBDocumento6 pagineEaton 092394 T5B 3 7 E en - GBJorge AmayaNessuna valutazione finora

- BCRSPDocumento2 pagineBCRSPDastan YermegaliyevNessuna valutazione finora

- Pin ContentDocumento20 paginePin ContentSwetha100% (2)

- Model CV QLDocumento6 pagineModel CV QLMircea GiugleaNessuna valutazione finora

- E4 - Review Unit 11 To Unit 20Documento16 pagineE4 - Review Unit 11 To Unit 20Tuyen NgoNessuna valutazione finora

- Pipe Conveyor System: Effective Solutions For Long DistancesDocumento8 paginePipe Conveyor System: Effective Solutions For Long DistancesEugenepaccelli Kolandai SamyNessuna valutazione finora

- Devoir de Contrôle N°2 - Anglais - 2ème Economie & Gestion (2015-2016) Mme Chaima JallebDocumento3 pagineDevoir de Contrôle N°2 - Anglais - 2ème Economie & Gestion (2015-2016) Mme Chaima JallebSassi LassaadNessuna valutazione finora

- Sample Emg/Ncv Report - Normal StudyDocumento5 pagineSample Emg/Ncv Report - Normal StudyPhysiotherapist AliNessuna valutazione finora

- Client Travel Policy Guidelines Nunavut Health Care PlanDocumento8 pagineClient Travel Policy Guidelines Nunavut Health Care PlanNunatsiaqNewsNessuna valutazione finora

- DMD 2018 Stem and Non Stem Checklist Effective 2020-2021Documento8 pagineDMD 2018 Stem and Non Stem Checklist Effective 2020-2021Elle DyNessuna valutazione finora

- Kevin Coleman's Sentencing MemoDocumento26 pagineKevin Coleman's Sentencing MemoThe Valley IndyNessuna valutazione finora