Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Diploma in Brewing Examiners Report 2007

Caricato da

Adam MayCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Diploma in Brewing Examiners Report 2007

Caricato da

Adam MayCopyright:

Formati disponibili

EXAM Booklet AUT 07 11/12/07 7:44 am Page 4

structure of our examination system. To end, I am confident that everyone involved with the IBD

My final thanks go the Clarges Street based examinations team for qualifications system looks forward to the next year of examinations,

their hard work and support this year. As you may be aware, Rekha especially with the proposed new developments and I would like to take

Sandal resigned in March from the role of Examinations Administrator this opportunity to wish all prospective candidates success in the pursuit

and my sincere thanks go to Jessica Clark and Andrea Williams (who of IBD qualifications.

have adopted the examination administration between them) for their

significant contributions in organising the IBD examinations this year. Dr David G Taylor - August 2007

The Institute of Brewing & Distilling

Examinations 2007

Question Papers and Examiners’ Reports

DIPLOMA IN BREWING EXAMINATION 2007 inspection and by aroma of the sample. Physiological functions of barley

that impact on malt quality include dormancy, germination capacity,

Module 1 – Materials and Wort

germination energy, and water sensitivity. These can be measured by

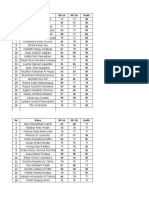

The examination was sat by 184 candidates, compared with 234 simple germination tests that however do take a few days to carry out.

candidates in 2006 and 211 in candidates in 2005. The pass rate for the The most comprehensive test for desirable barley characteristics consists

examination this year was 70%. This compares with a pass rate in 2006 of a micromalting, which when coupled to biochemical assays for

of 73% and 2005 of 67%. specific malt enzymes and wort components will give a strong indication

of the suitability and performance of a given batch, but this set of

The grade distribution was as follows (2006 in parenthesis): operations does take a week or longer to carry out.

A: 1% (4%) Question 2

B: 8% (9%) Describe the basic principles of design and operation of a specified

C: 30% (24%) malting system. Explain what parameters are controlled in the

D: 30% (36%) operations of steeping, germination and kilning, and the significance

E: 19% (16%) of their control. [20]

F: 11% (6%)

G: 1% (5%) This question was attempted by 154 candidates (84%) with 83%

achieving the pass mark. This question was generally well-answered,

It is pleasing that very few candidates did not answer six questions, time with good use of diagrams to illustrate the design and operation of the

management is a very important part of doing well. The very best different processes. Weaker answers tended to concentrate on trivial

candidates showed an ability to write quickly, legibly and clearly, using details at the expense of the bigger picture.

diagrams that were accurately labelled to enhance their answers. The Malting systems consist of three sequential operations; steeping,

skill of thinking quickly and concisely is not just important for germination and kilning. These operations may take place in one physical

examinations, it is a skill required for all aspects of life. Furthermore, the arrangement (eg tower maltings) or be separated into discreet units of

ability to communicate knowledge to others is essential. If you have a various design (for example: conical-bottom steep tank, Saladin box,

passion for producing high quality beer, it is essential that you continue single floor kiln). The purpose of steeping is to wash and hydrate grain to

to learn and communicate your knowledge. To achieve your potential in ca. 42% moisture without drowning or physically harming the grain.

examinations you must practise in the same way that athletes train for an Thus arrangements must be made for addition of grain, water, aeration,

event. It is a help to the examiners if you number each question clearly, carbon dioxide removal and air rests. Hydrated grain is then germinated

for example, Q1, Q2 etc, in this way sections or parts of answers will not at carefully controlled temperatures (15-20ºC), it being imperative to

get mixed up. physically turn the grain to avoid hot-spots and root entanglement and to

ensure homogeneity. During this process, a control of air temperature

Question 1 (air-on and air-off temperature), and moisture supply is critical to avoid

What are the desirable characteristics of barley for malting? [10] over or under-modification. Following germination, kilning is required to

Explain the analyses that are done to assess the suitability of barley halt the germination process, preserve enzyme activity and impart colour

for malting. [10] and flavour to the malt as well as influencing the DMS content of the

malt. The key parameters that must be controlled are temperature and

This question was attempted by 170 candidates (92%) with 66% airflow. Free drying at about 50ºC removes superficial water and there is

achieving the pass mark. The majority of students did very well at this 30ºC difference between air-on and air-off temperature. Once this

question, however those who presented a list of bullet points with no difference drops (break-through), the temperature can be increased to

further explanation did not score as highly as those who wrote properly 70ºC to remove water from deep in the grain. Lastly, temperatures of 80-

argued answers. 110ºC can be used to dry malt to around 5% moisture or less and impart

Poor barley will produce poor malt. Thus it is critical to assess random colour (curing). The kilning process must also minimise production of

samples of barley at intake for desirable characteristics prior to malting. nitrosamines.

The grain should be at an optimum temperature and moisture content

(12-15%) to avoid storage problems, and of favourable protein content Question 3

(10.5-11.5%), which reflects on starch content, fermentation, foam Describe the types of adjuncts used as sources of fermentable extract

production and beer stability. These functions can be assessed by NIR but in brewing. [10]

other methods are also applicable. The grain should be of an approved List the reasons for their use and their respective advantages and

variety, be accompanied by the “passport” which monitors disadvantages. [10]

agrochemicals applied to the crop, and of a minimum grain size

(reflecting high starch content) with few broken grains. Fungal This question was attempted by 158 candidates (86%) with 60%

contamination should be minimal as this can lead to storage problems, achieving the pass mark.

beer gushing and mycotoxin contamination. Insect contamination is also There is a wide range of adjuncts used in brewing as sources of

a problem during storage. These aspects can be assessed by visual fermentable extract. Many candidates tackled the question by covering

4 THE INSTITUTE OF BREWING & DISTILLING • EXAMINATION REPORT 2007

EXAM Booklet AUT 07 11/12/07 7:44 am Page 5

first the range of solid adjuncts and then the range of liquid. When regeneration costs and inordinate downtime costs due the need for

tackling a question like this, it can also be helpful to subdivide these replacing ion exchange columns. Ion exchange does however have the

major groups of adjuncts into smaller groups. For example, wheat and advantage that the ion content of liquor may be tailor-made. While the

barley have starch that gelatinises at mashing temperatures and can biggest operating costs for ion exchange systems are regeneration

therefore be added directly to the mash. In contrast, the gelatinisation chemicals, the major cost component in RO is energy i.e. electrical power

temperature of starch from rice, maize and sorghum is higher. Therefore, to operate the RO feed pump.

these adjuncts require pre-treatment before adding to the mash. This can

take the form micronisation or torrefaction to gelatinise the starch, or Question 5

cooking immediately before mash addition. Describe the action of malt enzymes during mashing that lead to the

Liquid adjuncts are either sourced from sucrose or starch. If the sugar production of a fermentable wort. [14]

is from sucrose, then invert sugar can be produced from sucrose Discuss briefly the factors that would either stabilise or degrade

hydrolysis. Liquid adjuncts can be produced from starch sources by acid these enzymes. [6]

or enzyme hydrolysis (or a combination). Barley syrups and malt

extracts can be produced with a sugar spectrum (and nitrogen This question was attempted by 170 candidates (92%) with 74%

composition) very similar to wort. achieving the pass mark. This question was generally well answered and

Adjuncts are used because they are a cheap source of fermentable good answers were accompanied with diagrams illustrating enzyme

extract, but depending on the source, the adjunct may also lead to actions, and also time/temperature profiles during mashing to explain the

improved processing due to a reduction in beta-glucans and haze forming different processes and the effect of temperature changes on these.

protein. The flavours from malt may be diluted to produce a ‘lighter’ The malt that goes into mashing should already partially modified, as

tasting beer or sweetness may be increased by fructose. Care needs to be the glucanases and proteases that break down the cell wall and protein

taken to ensure that there is adequate nitrogen available for yeast matrix components of the endosperm have been active during

metabolism, and most importantly alterations in the ratio of carbon to germination, and the starch hydrolases that break down amylose and

nitrogen can alter diacetyl and ester production. There are many reviews amylopectin (alpha-amylase, beta-amylase and limit dextrinase) have

and tests on adjunct use, but it is worth noting that there is a ‘new- been synthesised and/or activated, and have initiated limited starch

generation’ of syrups that are being produced by techniques that allow breakdown. However the bulk of starch hydrolysis takes place during

virtually any carbohydrate profile. These syrups can thus be introduced mashing. The extent of this depends on the quality of the malt (the degree

at any appropriate point in the process without altering the wort of modification/enzyme potential), the addition of adjuncts (e.g.

carbohydrate profile (Stewart, 2006, Adjuncts, Handbook of Brewing, unmodified cereals) and the conditions during mashing, since each

2nd Edition, Taylor and Francis). enzyme has optimal conditions (temperature, pH) for activity and

conditions under which activity is lost (generally thermal denaturation).

Question 4 Undermodified malt will require a stand at a reduced temperature (ca.

Outline the role and significance in brewing of calcium. [10] 50ºC) since proteases and glucanases are denatured at higher

Discuss the advantages and disadvantages of ion exchange and temperatures. Starch is much more accessible to enzymes once the grains

reverse osmosis systems for the removal of inorganic ions from have been gelatinised; this occurs at temperatures above 60ºC. Beta-

brewing water (liquor). [10] amylase is optimally active at 60-65ºC whereas alpha-amylase has a

temperature optimum at 65-68ºC. The enzyme beta-glucan solubilase is

This question was attempted by 115 candidates (63%) with 60% however thermally stable and may give problems by releasing excess

achieving the pass mark. The majority of candidates obtained similar glucans at temperatures where beta-glucanases are inactive. Enzyme

marks for both parts of the question. Good answers used appropriate stability is favoured by optimal pH (5-6), calcium ion concentration,

tables, diagrams, or equations. higher mash concentrations to protect enzymes against inactivation and

The mineral content of brewing liquor has long been recognised as optimised temperatures.

making an important contribution to the flavour of the beer, with calcium

being one of the most significant. Calcium is responsible for the fall in Question 6

pH during mashing, boiling and fermentation by reacting with buffering Describe three chemical reactions that occur during wort boiling.

compounds such as phosphates to form an insoluble compound which [15]

releases H+, causing a drop in pH. Failure to add sufficient calcium will Discuss the requirements for clarification of boiled wort. [5]

result in higher wort and beer pH, and poorer fermentation and quality. A

minimum concentration of 40 ppm calcium ions is necessary in finished This question was attempted by 157 candidates (85%) with 65%

beer. Calcium also has other beneficial effects including: protection of achieving the pass mark.

alpha-amylase from thermal degradation, improvement of protein This question gave candidates the opportunity to demonstrate their

precipitation during the boil, limitation of colour formation during the knowledge of chemical reactions occurring during wort boiling. Those

boil, improvement of yeast flocculation, removal of oxalates, and chosen included isomerisation of alpha-acids, oxidation of beta-acids to

stimulation of proteolytic and amylolytic enzyme activity. Most form hulupones, calcium phosphate precipitation, protein coagulation,

candidates highlighted the effect of pH reduction. Good answers formation of melanoidin compounds and production of DMS from s-

included description of the importance of water hardness/ calcium methylmethionine. Weaker candidates were aware of the reactions

content and of the effect of calcium on fermentation performance. taking place but were unable to describe the chemical changes that were

Reverse osmosis (RO) uses a semi-permeable membrane to achieve occurring.

separation of substances dissolved in liquid. This semi-permeable Two approaches were taken by candidates in answer to the question on

membrane is permeable to water and retains micro-organisms, colloids, the requirements for clarification of boiled wort. The key points are that

ions of dissolved salts and also molecules of organic substances. vegetable matter is removed along with insoluble proteins and protein-

Ion exchange is an exchange of ions between two electrolytes or polyphenol complexes. Some candidates focused their answer on the

between an electrolyte solution and a complex. Ion exchangers are either chemical requirements for the formation of hot trub and the need to avoid

cation exchangers that exchange positively charged ions (cations) or sheering forces that would disrupt the insoluble complexes. Failure to

anion exchangers that exchange negatively charged ions (anions). There achieve adequate wort clarification can lead to poor yeast performance,

are also amphoteric exchangers that are able to exchange both cations unsatisfactory fermentations and poor beer stability. Other candidates

and anions simultaneously. Ion exchangers can be unselective or have describe the plant requirements. For example, if whole hops were used

binding preferences for certain ions or classes of ions. Ion exchange is a the a hop back or screw hop strainer would be appropriate to remove hop

reversible process and the ion exchanger can be regenerated or loaded cones and vegetable matter.

with desirable ions by washing with an excess of these ions.

Most candidates used tables and diagrams to compare the two Question 7

processes. Advantages of using RO include the generation of high quality Outline the principal sources of liquid effluent in a brewery. [5]

water with little waste, and minimal use of chemicals. It also has higher Identify the key components of brewery liquid effluent and their

production capacity to space ratio compared with other technologies and potential impact on the environment. [5]

lower operational and maintenance costs. Ion exchange processes, on the Describe the principal features of aerobic and anaerobic digestion

other hand, incur high resin replacement costs, substantially higher systems. [10]

THE INSTITUTE OF BREWING & DISTILLING • EXAMINATION REPORT 2007 5

EXAM Booklet AUT 07 11/12/07 7:44 am Page 6

This question was attempted by 116 candidates (63%) with 77% Acid Detergents – The use of acid detergents is commonly restricted

achieving the pass mark. Each section tended to be tackled at the same to the removal of beerstone, water scale (calcium and magnesium

level. Some candidates did answer the first two sections in detail carbonates), and aluminum oxide. Tannins, hop oils, resins, and glucans

spending more time on these sections than the value warranted. are unaffected by acids. Acid detergents are more effective against

Packaging typically creates the greatest volume of liquid effluent in a bacteria than are alkaline detergents. The two most common types of acid

brewery through cleaning. Most candidates described the relative detergents are phosphoric and nitric.

contributions of the brewhouse, fermentation and yeast handling, Alkaline Detergents – Alkaline detergents are most effective in

maturations, conditioning and filtration, and packaging. Good answers removing organic soils, i.e., oils, fats, proteins, starches, and

gave a more detailed breakdown. carbohydrates encountered in brewing. Alkaline detergents work by

Effluents from individual process steps are variable and most hydrolysing peptide bonds and breaking down large, insoluble proteins

candidates recognized this. For example, bottle washing results in a large into small, more easily soluble polypeptides. In general, cleaning

volume but it contains only a minor part of the total organics discharged problems associated with organic soils can be avoided by ensuring that

from the brewery whereas effluents from fermentation and filtering are pre-rinsing is carried out with the minimum of delay and by using cold

high in organics/ biochemical oxygen demand (BOD) but low in volume. water pre-rinses at low pressure. Alkaline detergents will not remove

Most candidates correctly described the effect of organic compounds, calcium oxalate and other inorganic compounds that lead to a buildup of

suspended solids, oils, heavy metals, and yeast on the environment and beerstone. Some of the more common alkalis are sodium hydroxide,

their direct effect on aquatic life. Good answers included the effects of sodium percarbonate, sodium hydrogen carbonate, sodium orthosilicate,

ions, pH and temperature. Process specific materials e.g. normal and sodium metasilicate. Good candidates gave examples of commonly

processing aids, label glues, label pulp, inks, finings were also used detergents and their effectiveness. Others also discussed the

mentioned. additives used to improve formulations.

Biological treatment of effluent can be carried out under either aerobic A number of methods may be used to monitor plant hygiene, including

or anaerobic conditions. The basic mechanism of aerobic removal of ATP bioluminescence and culture methods. Good answers included

BOD from effluent by micro organisms can be characterized by a 2 stage these, giving examples of supplier names, and gave a description of

process that creates carbon dioxide and water – good answers contained culture techniques.

equations to describe this and named the aerobic micro organisms

involved. Aerobic treatments are either of the activated sludge or the Dr James Bryce – August 2007

attached growth type of process. Anaerobic digestion of effluent BOD is

also fundamentally a 2 stage process, and again good answers defined

each stage and named the products and micro organisms involved. In

anaerobic effluent treatment systems the micro organisms grow more

slowly than in aerobic reactors. This means that the solids need to be

retained longer in order to maintain high levels of activity and that the

sludge production is lower than in aerobic systems. An advantage is that

reactor vessels are smaller than aerobic systems.

Question 8

Discuss the relevance of brewhouse plant design to hygiene control.

[5]

Outline the range and main constituents of commercially available

cleaning agents and explain how their action can be validated. [15]

This question was attempted by 55 candidates (30%) with 60% achieving

the pass mark. 55 candidates answered this question, and for many it

seemed a ‘last resort’. As a result, the overall standard was quite poor.

In order to ensure effective cleaning of brewhouse vessels and

pipework a number of considerations must be made in plant design: The

plant capacity needs to be large enough to allow time for cleaning, the

parts pf the plant where very high standards of hygiene and sterility are

required should be capable of being cleaned hot. The materials of

construction should be capable of withstanding strong detergents like

caustic soda. The plant design should either allow access for manual

cleaning or more commonly, ensure that detergent can flow over the

surface at the speed required to give a vigorous clean. There should be as

few encumbrances in vessels as possible. Vessels must drain well. There

must be no “dead legs” in the pipework. Pipes must be designed for fast

flow of detergent during cleaning and spray heads must be sited in the

correct position. The choice of material that the plant is made from needs

to be suitable for the detergents and sterilants that are going to be used.

Most modern plants are constructed of a suitable quality of stainless

steel; however, pump glands, sensing equipment, hoses and valves must

also be compatible with what might be very corrosive substances. Most

candidates listed a number of these considerations, with good answers

containing at least five.

There are literally hundreds of detergent mixtures available that are

specifically tailored to the needs of the brewer. A detergent must be

capable of wetting surface(s) to allow it to penetrate the soil deposits and

to thus act more quickly and efficiently. The detergent must have the

capacity to break the soil into fine particles and to hold them in

suspension so that they do not redeposit on the cleaned surface.

Detergents also must have good sequestering power to keep calcium and

magnesium salts (beerstone) in solution. There are two types of cleaning

detergents: alkaline or acid which are often formulated with surfactants,

chelating agents, and emulsifiers to enhance the effectiveness of the

detergents. The most effective detergents in the brewery today are

formulated with alkaline solutions that have chelators and surfactants.

6 THE INSTITUTE OF BREWING & DISTILLING • EXAMINATION REPORT 2007

Potrebbero piacerti anche

- Diploma in Brewing Examiners Report 2006Documento28 pagineDiploma in Brewing Examiners Report 2006Adam May100% (1)

- J Institute Brewing - 2012 - Question Papers and Examiners ReportsDocumento28 pagineJ Institute Brewing - 2012 - Question Papers and Examiners Reportsmartina.capozzaNessuna valutazione finora

- 2009 Master Brewer ReportDocumento7 pagine2009 Master Brewer ReportRiyanNessuna valutazione finora

- Black Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Da EverandBlack Soldier Fly Products: Generic Description and Analysis of the Production Process for Chitosan, Proteins and Lipid from Black Soldier Fly Larvae.Valutazione: 4 su 5 stelle4/5 (1)

- Development and Validation of A Gas ChromatographicDocumento5 pagineDevelopment and Validation of A Gas ChromatographicMarcos GonzalesNessuna valutazione finora

- 3 RJST 10 4 2018Documento9 pagine3 RJST 10 4 2018StevenCarlNessuna valutazione finora

- Averil Nivya ReportDocumento35 pagineAveril Nivya ReportMustafa AhsanNessuna valutazione finora

- Optimización Industria de AlimentosDocumento7 pagineOptimización Industria de AlimentoscamycazNessuna valutazione finora

- Scale-Up, Upstream and Downstream ProcessingDocumento106 pagineScale-Up, Upstream and Downstream ProcessingAlbert KuufamNessuna valutazione finora

- 1.diseño ExperimentalDocumento10 pagine1.diseño ExperimentalYesenia QuizNessuna valutazione finora

- Shakeel Biscuit Paper 2014Documento10 pagineShakeel Biscuit Paper 2014Trung HuynhNessuna valutazione finora

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlDa EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNessuna valutazione finora

- Artigo DryingDocumento30 pagineArtigo DryingGlauciaSouzaNessuna valutazione finora

- BioPharm - Scale Down - Upstream PDFDocumento9 pagineBioPharm - Scale Down - Upstream PDFGeetanjali HubliNessuna valutazione finora

- Optimization of Ultrafiltration of Whey Using Taguchi Method For Maximizing Recovery of Lactose PPDocumento39 pagineOptimization of Ultrafiltration of Whey Using Taguchi Method For Maximizing Recovery of Lactose PPCsaba AndrásNessuna valutazione finora

- Flow-Specific Physical Properties of Coconut Ours: International Agrophysics September 2015Documento8 pagineFlow-Specific Physical Properties of Coconut Ours: International Agrophysics September 2015Enmanuel FLores ChacaNessuna valutazione finora

- Powder Technology: Mónica J. Ramírez, Gloria I. Giraldo, Carlos E. OrregoDocumento8 paginePowder Technology: Mónica J. Ramírez, Gloria I. Giraldo, Carlos E. OrregoIsmaelNessuna valutazione finora

- Effects of Particle Size and Its Distribution On Specific Cake Resistance During Rice Wine Microfiltration PDFDocumento6 pagineEffects of Particle Size and Its Distribution On Specific Cake Resistance During Rice Wine Microfiltration PDFAlexRiveraNessuna valutazione finora

- Bios Era Part Ion 2Documento10 pagineBios Era Part Ion 2Pooja Singh JainNessuna valutazione finora

- Rheological Evaluation of Some Laboratory Mills: October 2012Documento8 pagineRheological Evaluation of Some Laboratory Mills: October 2012Alexandra SoaresNessuna valutazione finora

- RVA Lab ReportDocumento7 pagineRVA Lab ReportZahid AnwarNessuna valutazione finora

- Decanting OnlineDocumento10 pagineDecanting OnlineEMAW09Nessuna valutazione finora

- Coating Effect of Modified Cassava Starch in HassDocumento8 pagineCoating Effect of Modified Cassava Starch in HassNezuko CutieeeNessuna valutazione finora

- 1 s2.0 S0733521020305701 MainDocumento9 pagine1 s2.0 S0733521020305701 MainLUIS EDUARDO CIRO PARRANessuna valutazione finora

- Rehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationDocumento10 pagineRehydration Kinetics and Soluble Solids Lixiviation of Candied Mango Fruit As Affected by Sucrose ConcentrationMiguel Angel Ramos RuizNessuna valutazione finora

- Functional Propertiesof Water Holding Capacity Oil Holding Capacity WettabilityandDocumento12 pagineFunctional Propertiesof Water Holding Capacity Oil Holding Capacity WettabilityandNUR AINI MAHMUDAHNessuna valutazione finora

- Bioremediation of Petroleum and Petroleum ProductsDa EverandBioremediation of Petroleum and Petroleum ProductsNessuna valutazione finora

- Scaled Up Process DirectlyDocumento8 pagineScaled Up Process DirectlyAnonymous 1XHScfCINessuna valutazione finora

- Extraction of Zein From Corn Co-ProductsDocumento120 pagineExtraction of Zein From Corn Co-Productsfungiman88Nessuna valutazione finora

- (2021) Fernandes Et Al. (Microcápsulas)Documento14 pagine(2021) Fernandes Et Al. (Microcápsulas)Sibele FernandesNessuna valutazione finora

- Wa0006.Documento115 pagineWa0006.Anand KumarNessuna valutazione finora

- Foods: Rapid Estimation of Parameters For Gelatinization of Waxy Corn StarchDocumento10 pagineFoods: Rapid Estimation of Parameters For Gelatinization of Waxy Corn StarchMuhammad IlyasNessuna valutazione finora

- Moisture Sorption Isotherm, Isosteric Heat and Adsorption Surface Area of Whole Chia PDFDocumento32 pagineMoisture Sorption Isotherm, Isosteric Heat and Adsorption Surface Area of Whole Chia PDFLía FCNessuna valutazione finora

- Climate Change and Cotton Production in Modern Farming SystemsDa EverandClimate Change and Cotton Production in Modern Farming SystemsNessuna valutazione finora

- DSC As A Tool To Assess Physiological Evolution of Apples PreservedDocumento6 pagineDSC As A Tool To Assess Physiological Evolution of Apples PreservedElkyn BohórquezNessuna valutazione finora

- Continuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsDocumento10 pagineContinuous and Batch Cultures of Escherichia Coli KJ134 For Succinic Acid Fermentation: Metabolic Flux Distributions and Production CharacteristicsSyed ShahNessuna valutazione finora

- Drying and Tempering AssignmentDocumento5 pagineDrying and Tempering Assignmentcjcaporado18Nessuna valutazione finora

- Alvarez Etal 2008Documento10 pagineAlvarez Etal 2008Jairo Silva CoreaNessuna valutazione finora

- Thesis Ethanol ProductionDocumento8 pagineThesis Ethanol ProductionWebsiteThatWritesPapersForYouSiouxFalls100% (1)

- Chol 2018Documento10 pagineChol 2018astriNessuna valutazione finora

- Anacardic Acid PaperDocumento7 pagineAnacardic Acid PaperMani KannanNessuna valutazione finora

- Determination of The Olive Maturity Index of Intact Fruits Using Image AnalysisDocumento9 pagineDetermination of The Olive Maturity Index of Intact Fruits Using Image AnalysisRonald Marcelo DiazNessuna valutazione finora

- Scale-Up of Bio Pesticide Production Processes Using Waste Water Sludge As A Raw MaterialDocumento8 pagineScale-Up of Bio Pesticide Production Processes Using Waste Water Sludge As A Raw MaterialPhan HoaNessuna valutazione finora

- Quality Traits of SoybeanDocumento9 pagineQuality Traits of SoybeanWaqas AhmadNessuna valutazione finora

- Optimasi Pembuatan Sohun Ubi Jalar Menggunakan Ekstruder Pemasak-PencetakDocumento10 pagineOptimasi Pembuatan Sohun Ubi Jalar Menggunakan Ekstruder Pemasak-PencetakPutri Zahra AulidhaNessuna valutazione finora

- Structural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw ExtruderDocumento17 pagineStructural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw Extrudersugiono sugionoNessuna valutazione finora

- Preparation and Physicochemical Stability of Tomato Seed OilmicroemulsionsDocumento12 paginePreparation and Physicochemical Stability of Tomato Seed OilmicroemulsionsClaudia Marcela Cortes PrietoNessuna valutazione finora

- Advances in Physicochemical Properties of Biopolymers: Part 2Da EverandAdvances in Physicochemical Properties of Biopolymers: Part 2Nessuna valutazione finora

- Caupi 2Documento14 pagineCaupi 2TATIANA CASTILLONessuna valutazione finora

- Cargill - Corn To Polylactic AcidDocumento6 pagineCargill - Corn To Polylactic AcidI. Murali KrishnaNessuna valutazione finora

- Pasteurization Process Development For Controlling Salmonella in In-ShellDocumento8 paginePasteurization Process Development For Controlling Salmonella in In-ShellcceydacatNessuna valutazione finora

- 1 Pilot Plant PDFDocumento16 pagine1 Pilot Plant PDFSwapnil ParabNessuna valutazione finora

- Scale Up PrinciplesDocumento22 pagineScale Up Principlesnitin_star201050% (2)

- 2093 6851 2 PBDocumento11 pagine2093 6851 2 PBDeyinta Apenabel SuryaNessuna valutazione finora

- Effect of TempEffect of Temperature On The Continuous Synthesis of Soybean Esters Erature On The Continuous Synthesis of Soybean EstersDocumento6 pagineEffect of TempEffect of Temperature On The Continuous Synthesis of Soybean Esters Erature On The Continuous Synthesis of Soybean EstersLauraNessuna valutazione finora

- Anaerobic Membrane Reactor With Phase Separation For Treatment The WheyDocumento7 pagineAnaerobic Membrane Reactor With Phase Separation For Treatment The WheyJuan Daniel GuaquetaNessuna valutazione finora

- 2,3,5 Aqidah Dan QHDocumento5 pagine2,3,5 Aqidah Dan QHBang PaingNessuna valutazione finora

- Bersin PredictionsDocumento55 pagineBersin PredictionsRahila Ismail Narejo100% (2)

- Indus Valley Sites in IndiaDocumento52 pagineIndus Valley Sites in IndiaDurai IlasunNessuna valutazione finora

- Invitation 2023Documento10 pagineInvitation 2023Joanna Marie Cruz FelipeNessuna valutazione finora

- Reported Speech Step by Step Step 7 Reported QuestionsDocumento4 pagineReported Speech Step by Step Step 7 Reported QuestionsDaniela TorresNessuna valutazione finora

- MGT501 Final Term MCQs + SubjectiveDocumento33 pagineMGT501 Final Term MCQs + SubjectiveAyesha Abdullah100% (1)

- Accountancy Department: Preliminary Examination in MANACO 1Documento3 pagineAccountancy Department: Preliminary Examination in MANACO 1Gracelle Mae Oraller0% (1)

- RWE Algebra 12 ProbStat Discrete Math Trigo Geom 2017 DVO PDFDocumento4 pagineRWE Algebra 12 ProbStat Discrete Math Trigo Geom 2017 DVO PDFハンター ジェイソンNessuna valutazione finora

- History of Drugs (Autosaved)Documento68 pagineHistory of Drugs (Autosaved)Juan TowTowNessuna valutazione finora

- Supporting References in Release 12 SLA PDFDocumento8 pagineSupporting References in Release 12 SLA PDFsoireeNessuna valutazione finora

- Pediatric Autonomic DisorderDocumento15 paginePediatric Autonomic DisorderaimanNessuna valutazione finora

- BHP Billiton Foundations For Graduates Program Brochure 2012Documento4 pagineBHP Billiton Foundations For Graduates Program Brochure 2012JulchairulNessuna valutazione finora

- Pagan and Wiccan Quotes and GuidanceDocumento8 paginePagan and Wiccan Quotes and GuidanceStinkyBooNessuna valutazione finora

- Echnical Ocational Ivelihood: Edia and Nformation IteracyDocumento12 pagineEchnical Ocational Ivelihood: Edia and Nformation IteracyKrystelle Marie AnteroNessuna valutazione finora

- Measuring Trend and TrendinessDocumento3 pagineMeasuring Trend and TrendinessLUCKYNessuna valutazione finora

- Business Administration: Hints TipsDocumento11 pagineBusiness Administration: Hints Tipsboca ratonNessuna valutazione finora

- BGL01 - 05Documento58 pagineBGL01 - 05udayagb9443Nessuna valutazione finora

- Preliminaries Qualitative PDFDocumento9 paginePreliminaries Qualitative PDFMae NamocNessuna valutazione finora

- E 05-03-2022 Power Interruption Schedule FullDocumento22 pagineE 05-03-2022 Power Interruption Schedule FullAda Derana100% (2)

- 30 Linux System Monitoring Tools Every SysAdmin Should Know - NixcraftDocumento90 pagine30 Linux System Monitoring Tools Every SysAdmin Should Know - Nixcraftvignesh05Nessuna valutazione finora

- Anti-Epileptic Drugs: - Classification of SeizuresDocumento31 pagineAnti-Epileptic Drugs: - Classification of SeizuresgopscharanNessuna valutazione finora

- Mathematics Trial SPM 2015 P2 Bahagian BDocumento2 pagineMathematics Trial SPM 2015 P2 Bahagian BPauling ChiaNessuna valutazione finora

- Mat Clark - SpeakingDocumento105 pagineMat Clark - SpeakingAdiya SNessuna valutazione finora

- Talent Development - FranceDocumento6 pagineTalent Development - FranceAkram HamiciNessuna valutazione finora

- Lets Install Cisco ISEDocumento8 pagineLets Install Cisco ISESimon GarciaNessuna valutazione finora

- Administrator's Guide: SeriesDocumento64 pagineAdministrator's Guide: SeriesSunny SaahilNessuna valutazione finora

- Promising Anti Convulsant Effect of A Herbal Drug in Wistar Albino RatsDocumento6 paginePromising Anti Convulsant Effect of A Herbal Drug in Wistar Albino RatsIJAR JOURNALNessuna valutazione finora

- EdExcel A Level Chemistry Unit 5 Mark Scheme Jan 2000Documento3 pagineEdExcel A Level Chemistry Unit 5 Mark Scheme Jan 2000Nabeeha07Nessuna valutazione finora

- DELA CRUZ - LAC 1 - 002 - Individual Learning Monitoring Plan - Bugtongnapulo INHSDocumento2 pagineDELA CRUZ - LAC 1 - 002 - Individual Learning Monitoring Plan - Bugtongnapulo INHSGilbert Dela CruzNessuna valutazione finora

- Instructions: Reflect On The Topics That Were Previously Discussed. Write at Least Three (3) Things Per TopicDocumento2 pagineInstructions: Reflect On The Topics That Were Previously Discussed. Write at Least Three (3) Things Per TopicGuevarra KeithNessuna valutazione finora