Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UST Brochure

Caricato da

Novia IzmiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UST Brochure

Caricato da

Novia IzmiCopyright:

Formati disponibili

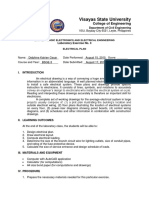

ELECTRIC

STORAGE TANK HEATERS

UST SERIES

SPECIFICATIONS

• 5’ to 20’ immersion lengths

• 10 to 330 Kw

• 1 to 12 watts per square inch of

heat flux

• Remote or integral control panel

• 120 to 600 volts operation

DESCRIPTION FEATURES

The UST (Unitary Storage Tank) heater is a com- • No need to drain tank to replace heater elements

pletely packaged tank heating unit. The UST utilizes

• Low watt density, ideal for viscous fluid heating

a flexible open coil heating element. The open coil

heater consists of nickel chromium resistance coils • Wide range of packaging and installation options

supported in high temperature ceramic insulators on

• Minimal installation cost on new or existing tanks

a flexible stainless steel strap. Each element is

housed in an individual heater tube constructed • Explosion resistant designs available

from a 3” sch. 40 pipe, capped on one end and seal

• Remote control panel available

welded through the tank adapter on the other end.

The heater tubes terminate inside the control panel • Flexible elements require only 3 feet clearance for

allowing heater replacement without draining the removal

tank. The NEMA 4 control panel is furnished as a • Available in stainless steel construction

complete, prewired, assembly ready for operation.

• Long life- 2 year warranty on open coil heaters

HEAT EXCHANGE AND TRANSFER, INC.

500 Superior Street • Carnegie, PA 15106

Phone 412-276-3388 • Fax 412-276-3397

E-mail: sales@heat-inc.com • Web: www.heat-inc.com

UST STORAGE TANK HEATERS

CONSTRUCTION FEATURES

CIRCUIT BREAKER COMPLETELY WIRED AND TESTED

HANDLE NEMA 4 CONTROL CENTER

HEATER TUBES

THERMOWELL FOR

TEMPERATURE SENSOR

TANK ADAPTOR

FLANGE

HEAT

SHIELD ''OCH'' STYLE

HEATING ELEMENTS

HEATER TUBES

The heater tube is constructed from a 3” sch. 40 carbon of the UST heater is that elements may be inspected or

steel pipe. Each tube is capped on the internal end and replaced without draining the contents from the tank.

seal welded through the tank adapter flange on the exter- Also, unlike most other immersion heaters which require

nal end to form an individual, closed well for each OCH an external clearance equal to its immersion length, the

heating element. The heater tube extends through the flexible design of the open coil element permits the

tank adapter and terminates directly into the control removal of even the longest elements with as little as 3’

enclosure. Multiple tubes are utilized for larger heat of external clearance. (see bulletin OCH-92)

loads. Standard designs utilize a 150# ANSI flanged

adapter for installation through a standard tank nozzle. CONTROL CENTER

Alternate adapter designs, such as custom plate flanges The power control center is usually mounted directly on

to match existing man way ports, or custom adapter the heater assembly, but can be furnished as a remote

boxes for field welding the unit through a slot in the tank mounting unit if required. The control center is furnished

wall, are also available. as a complete unit, wired, tested, and ready for opera-

tion. The control center consists of a weathertight NEMA

HEATING ELEMENTS 4 enclosure with the following major equipment: main

Flexible open coil heating elements are utilized in UST disconnect switch, load carrying contractors, main and

tank heaters. The open coil heater can be designed to branch circuit fusing, control circuit transformer, control

produce from 1 to 12 watts per square inch to meet vari- relays, heat selector switches, indicating lights, indicating

ous tank designs and heating applications. A key feature temperature controller, and over temperature controller.

APPLICATIONS

• ASPHALT • WATER STORAGE

• PITCH • FUEL OIL

• WAX • CAUSTIC SODA

• CREOSOTE • THERMAL FLUIDS

HEAT EXCHANGE AND TRANSFER, INC.

UST STORAGE TANK HEATERS

TANK INSTALLATION OPTIONS

FLANGED ADAPTER

For applications which require removability, or those that do not have the

capacity for field welding, the use of a standard ANSI flange provides a

convenient mounting method through a standard flanged tank nozzle.

PLATE ADAPTER

Custom plate flanges can be fabricated for applications that require an

unusual mounting method. For example, many customers prefer to have a

custom flange designed to be installed through an existing man way port.

WELD BOX ADAPTER

The fabricated weld box adapter allows for easy field welding of the tube

assembly through dished heads on horizontal tanks or curved side walls of

vertical tanks.

CUSTOM HEATER CONFIGURATIONS

TANK HEATERS BUILT TO ORDER

UST heaters are custom fabricated to meet the requirements of each customers particular application. The configuration

of each UST is based on the tank design, the fluid to be heated, and any customer preferences. Once the heat load has

been determined, the following information will be taken into consideration in the design of the UST heater:

HEAT FLUX HEATER TUBE CONFIGURATION GENERAL SPECIFICATIONS

The heat flux (or watt density) is The number of heater tubes and Once the basic configuration has

based on the heat input limitations their immersion length is based on been determined, the customer

of the fluid to be heated in the the working length of the tank, the must provide the general specifica-

storage tank. For example, water required watt density, and , very tions of the unit, such as: available

can take a very high rate of heat often, a customer preference. For power supply, choice of tank

input and would, therefore, use the example, a 10’-6” diameter by adapter, NEMA rating required,

highest watt density available at 12 15’-6” long storage tank requiring carbon or stainless construction,

watts per square inch of surface 20 Kw at 5 watts per square inch. and any special control require-

area. On the other hand, materials A vertically oriented tank would ments.

such as asphalt, tar, and pitch are require 3 tubes with a 10’ immersion

much more heat sensitive and length, while a horizontally oriented

require a heat flux of 5 watts per tank would require 2 tubes with

square inch or lower. 15’ immersion length.

HEAT EXCHANGE AND TRANSFER, INC.

UST STORAGE TANK MODELS

STANDARD MODELS

The following standard models are

the most commonly required sizes.

All UST heaters are built to order. If B

application requirements are not

covered by a standard model,

provide the information outlined in

the custom design section.

150# Flange

Number of Tubes Kilowatts

Flange Dimension Immersion Length of Heater

Unitary Storage Tank UST 10 03-20-160C-48 3 Phase

C = Carbon Steel Voltage ÷ 10

S = Stainless Steel

STANDARD UST MODELS

150# Flange No. & Size of

“B” (ft) Number Diameter Size Electrical

kW Dimension of Tubes* in Inches Circuits* Model Number

Models at 4 Watts Per Square Inch

10 19 1 6 1-24A UST 0601-10-228C-XXX

20 19 2 8 1-24A UST 0802-20-228C-XXX

30 19 3 10 1-48A UST 1003-30-228C-XXX

40 19 4 10 2-24A UST 1004-40-228C-XXX

50 19 5 12 2-48A UST 1205-50-228C-XXX

60 19 6 12 2-48A UST 1206-60-228C-XXX

70 19 7 14 2-48A UST 1407-70-228C-XXX

80 19 8 14 2-48A UST 1408-80-228C-XXX

90 19 9 16 3-48A UST 1609-90-228C-XXX

100 19 10 16 3-48A UST 1811-100-228C-XXX

110 19 11 18 3-48A UST 1610-110-228C-XXX

120 19 12 18 3-48A UST 1812-120-228C-XXX

Model at 11 Watts Per Square Inch

20 14 1 6 1-24A UST 0601-20-168C-XXX

40 14 2 8 2-24A UST 0802-40-168C-XXX

60 14 3 10 2-48A UST 1003-60-168C-XXX

80 14 4 10 2-24A UST 1004-80-168C-XXX

100 14 5 12 3-48A UST 1205-100-168C-XXX

120 14 6 12 3-48A UST 1206-120-168C-XXX

140 14 7 14 4-48A UST 1407-140-168C-XXX

160 14 8 14 4-48A UST 1408-160-168C-XXX

180 14 9 16 5-48A UST 1609-180-168C-XXX

200 14 10 16 5-48A UST 1610-200-168C-XXX

220 14 11 18 6-48A UST 1811-220-168C-XXX

240 14 12 18 6-48A UST 1812-240-168C-XXX

*Number and size of electrical circuits are based on 480 Volts, 3 Phase

XXX is voltage and phase code, for example 480 Volts, 3 Phase is 483

UST-05-04

HEAT EXCHANGE AND TRANSFER, INC.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Tutorial 1Documento5 pagineTutorial 1MuhammadSyafiqNessuna valutazione finora

- CH 1Documento17 pagineCH 1Pawan Bhattarai100% (1)

- Radiant Heaters RAYMAXDocumento24 pagineRadiant Heaters RAYMAXEliasNessuna valutazione finora

- VSD Calculator For FansDocumento10 pagineVSD Calculator For FansCésar Christian JankoNessuna valutazione finora

- Maharashtra Emerging As Wind Energy HubDocumento14 pagineMaharashtra Emerging As Wind Energy HubDevesh GhirnikarNessuna valutazione finora

- Power GenerationDocumento5 paginePower GenerationGhanvir SinghNessuna valutazione finora

- Engraving ProductsDocumento60 pagineEngraving ProductsglobalsignsNessuna valutazione finora

- PM E Bus Sewa Guidelines - MoHUADocumento27 paginePM E Bus Sewa Guidelines - MoHUARam PrakashNessuna valutazione finora

- Data Sheet - DX Air Cooled - ASR 682 A - GERMANYDocumento1 paginaData Sheet - DX Air Cooled - ASR 682 A - GERMANYLilac SongNessuna valutazione finora

- BESCOM Electricity Rates EnglishDocumento3 pagineBESCOM Electricity Rates EnglishshantappaNessuna valutazione finora

- MAC1700 OwnersDocumento20 pagineMAC1700 OwnersRonald RojasNessuna valutazione finora

- Pump Selection 2005 FINALDocumento4 paginePump Selection 2005 FINALDennis SegeraNessuna valutazione finora

- Dynamic Modelling of Gas TurbinesDocumento8 pagineDynamic Modelling of Gas TurbinesdannyNessuna valutazione finora

- 16-Bit UUID Numbers DocumentDocumento28 pagine16-Bit UUID Numbers DocumentJuan M Iñiguez RNessuna valutazione finora

- Water Volume Calculations in SystemsDocumento8 pagineWater Volume Calculations in SystemsSaahil KhaanNessuna valutazione finora

- Solarpv Referral Manual PDFDocumento62 pagineSolarpv Referral Manual PDFRathnakrajaNessuna valutazione finora

- Sample Electrical PlanDocumento6 pagineSample Electrical PlanDelphine Katrien CesarNessuna valutazione finora

- The Task of Bitcoin Miners, Mining Hardware, Energy Consumption and Ecology, MiningDocumento90 pagineThe Task of Bitcoin Miners, Mining Hardware, Energy Consumption and Ecology, MiningManoj ManuNessuna valutazione finora

- The Mathematical Theory of Communication. Shannon y Weaver.Documento374 pagineThe Mathematical Theory of Communication. Shannon y Weaver.Emilio Patané SpataroNessuna valutazione finora

- MSC Bridge - VPQDocumento7 pagineMSC Bridge - VPQVishal AnandNessuna valutazione finora

- Design of An Automated Solar-Powered Light Trap For Monitoring and Mass Trapping of Major Date Palm Pests By: Maged E.A. MohammedDocumento8 pagineDesign of An Automated Solar-Powered Light Trap For Monitoring and Mass Trapping of Major Date Palm Pests By: Maged E.A. MohammedGino NungayNessuna valutazione finora

- Working Capital MadhuconDocumento68 pagineWorking Capital MadhuconRamesh AnkithaNessuna valutazione finora

- Analysis of Power SectorDocumento38 pagineAnalysis of Power SectorAakankshaNessuna valutazione finora

- Growatt 8-10K MTLP-US manual (最新0718)Documento45 pagineGrowatt 8-10K MTLP-US manual (最新0718)Gillianne Mae VargasNessuna valutazione finora

- Chapter 4Documento24 pagineChapter 4dj5Up3r d4v3Nessuna valutazione finora

- Maximum Demand Estimation in A Single Domestic Electrical Installation (Simplified Version)Documento2 pagineMaximum Demand Estimation in A Single Domestic Electrical Installation (Simplified Version)Zulkarnain DahalanNessuna valutazione finora

- Power Supply AgreementDocumento15 paginePower Supply AgreementVanvan BitonNessuna valutazione finora

- Ielts Reading Practice 2Documento4 pagineIelts Reading Practice 2Nguyenn HonggNessuna valutazione finora

- Xerox® Igen® 5 Press: Product Safety Data SheetDocumento2 pagineXerox® Igen® 5 Press: Product Safety Data SheetChenna VijayNessuna valutazione finora

- Potential and Kinetic Energy PDFDocumento29 paginePotential and Kinetic Energy PDFLouis Fetilo FabunanNessuna valutazione finora