Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MTC Forged Fitting Elbow

Caricato da

freeman11072000Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MTC Forged Fitting Elbow

Caricato da

freeman11072000Copyright:

Formati disponibili

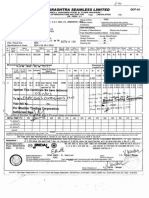

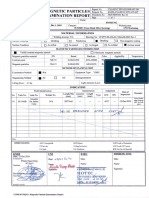

HangZhou Double-Peace Industry & Trading Co.,Ltd.

Add.: Room 1204, No.2 Building, Boee Center, Ningwei Street, Xiaoshan District, Hangzhou City, Zhejiang Province 311215, China

Tel: +86-571-87799920 Fax: +86-571-87799910

Inspection Certificate

(EN 10204-3.1)

BUYER: THANH SON CO., LTD DESCRIPTION: FITTINGS 770PCS ISSUE NO.: DBP170925-007

STARTING MATERIAL: CARBON STEEL SEAMLESS PIPE IN ACCORDANCE WITH STANDARD CODES: ASTM A234/A234M-07 ISSUE DATE: SEP 25,2017

PAGE NO.: 1 OF 1

HEAT TREATMENT

ITEM STANDARD OF

No. DESCRIPTION TYPE MATERIAL SIZE (IN) CLASS/SCH QTY HEAT NO A: Hot form with final (620 ~ 950) NDE/PMI REMARK

NO. DIM.

SR: stress relieving (595 ~ 690)

1 7-0406 ELBOW 45 SR BW A234 WPB ASME B16.9-12 Ed. 3/4'' SCH160 50 016100459 A

2 7-0407 ELBOW 90LR BW A234 WPB ASME B16.9-12 Ed. 3/4'' SCH80 80 16-213807 A

3 7-0408 ELBOW 90LR BW A234 WPB ASME B16.9-12 Ed. 1-1/2'' SCH160 80 17-102990 A

4 7-0409 ELBOW 90LR BW A234 WPB ASME B16.9-12 Ed. 1-1/2'' SCH80 100 17-102990 A

5 728 REDUCER BW A234 WPB ASME B16.9-12 Ed. 2x1-1/2'' SCH160 300 17-102923 SR

6 756 REDUCER BW A234 WPB ASME B16.9-12 Ed. 2x1-1/2'' SCH80 40 17-201014 SR

7 767 REDUCER BW A234 WPB ASME B16.9-12 Ed. 2x1/2'' SCH80 100 17-201014 SR

8 783 REDUCER BW A234 WPB ASME B16.9-12 Ed. 2x1'' SCH80 20 17-204646 SR

9

10

MECHANICAL PROPERTY IMPACT TEST (ft lbf) Hydro Test

CHEMICAL COMPOSITION (%)

Spec. T. S. Y. S. EL. R.A Hardness Temp. () Size (2mm-v) (Mpa)

ITEM Spec.

No. C Si Mn P S Cr Ni Mo Cu V CE Mpa Mpa (%) (%) HBW

NO.

MIN 0.100 0.290 MIN 415 240 30 Min. () Ave. () Pressure test

MAX 0.300 1.060 0.050 0.580 0.400 0.400 0.150 0.400 0.080 MAX 187 Act. Ave.

1 7-0406 L 0.220 0.220 0.910 0.010 0.012 0.025 0.130 0.060 0.260 0.010 0.417 515 315 34 135/140

2 7-0407 L 0.240 0.240 0.820 0.017 0.011 0.020 0.030 0.016 0.200 0.010 0.401 P 562 367 34 142/142

3 7-0408 L 0.230 0.270 0.920 0.020 0.011 0.022 0.010 0.020 0.220 0.010 0.409 P 580 325 34 142/146

4 7-0409 L 0.230 0.270 0.910 0.018 0.009 0.018 0.010 0.018 0.220 0.002 0.405 P 564 324 34 138/143

5 728 L 0.260 0.230 0.890 0.021 0.006 0.026 0.015 0.010 0.190 0.001 0.429 P 520 360 36 139/143

6 756 L 0.240 0.230 0.910 0.018 0.010 0.022 0.013 0.021 0.190 0.002 0.414 P 530 330 33 146/144

7 767 L 0.230 0.230 0.930 0.017 0.015 0.022 0.013 0.021 0.260 0.001 0.412 P 495 330 33 145/141

8 783 L 0.220 0.230 0.900 0.019 0.010 0.019 0.010 0.022 0.240 0.001 0.395 P 515 347 36 148/146

9

10

Note: We hereby certify that the materials described herein have been manufactured, inspected and

1. L: LADDLE ANALYSIS, P: PRODUCT ANALYSIS, A: tested in accordance with the customer’s specification(s), and that they satisfy the requirements.

2. T.S.: TENSILE STRENGTH, Y.S.: YEILD STRENGTH, EL.: ELONGATION, R.A: REDUCTION AREA

Authorized Inspection Representive:

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Documento1 paginaQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNessuna valutazione finora

- Inspection Certificate: Customer: CommodityDocumento1 paginaInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- MTC Elbow 6inDocumento1 paginaMTC Elbow 6inhenryNessuna valutazione finora

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocumento1 paginaWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- Mag General Business: Mill Test CertificateDocumento1 paginaMag General Business: Mill Test CertificateRaul Sebastiam67% (3)

- M 001 22Documento1 paginaM 001 22LUISNessuna valutazione finora

- Test CertificateDocumento2 pagineTest CertificatePRITESH100% (1)

- 4.0X1500. 23920 E250a DoDocumento1 pagina4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- 304 1.5MM PCDocumento1 pagina304 1.5MM PCsabir hussain100% (1)

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Documento1 paginaASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- MTC 4500528257 Iii - 210209Documento3 pagineMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNessuna valutazione finora

- Material Test Report: ISO EN 10204 2004-3.1Documento4 pagineMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNessuna valutazione finora

- Mgoha : ' "Xsjjl8Documento1 paginaMgoha : ' "Xsjjl8PetroPower OilandgasNessuna valutazione finora

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Documento3 pagineMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNessuna valutazione finora

- Fittings ThrededDocumento2 pagineFittings ThrededreniNessuna valutazione finora

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Documento8 pagine2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocumento1 paginaT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNessuna valutazione finora

- Neway Gate 6 X 150 RFDocumento6 pagineNeway Gate 6 X 150 RFcomercial 3Nessuna valutazione finora

- Flange 24 InchDocumento2 pagineFlange 24 InchreniNessuna valutazione finora

- Ball Valve MTCDocumento1 paginaBall Valve MTCAdnanAtifNessuna valutazione finora

- 075P80-321 TubacexDocumento1 pagina075P80-321 Tubacexsakshi patilNessuna valutazione finora

- Quality Mill Certificate 3:1: 1 9550 290 71050 AISI4140 290 6000 3Documento1 paginaQuality Mill Certificate 3:1: 1 9550 290 71050 AISI4140 290 6000 3Mohamed NabeilNessuna valutazione finora

- MTR's PO# 2113-06-12 PDFDocumento14 pagineMTR's PO# 2113-06-12 PDFAgustinaDeWinneNessuna valutazione finora

- MTC FITTINGSDocumento5 pagineMTC FITTINGSAzee TitouNessuna valutazione finora

- Mill Test Certificate Certificate Conform To: EN 10204/3.1Documento1 paginaMill Test Certificate Certificate Conform To: EN 10204/3.1GLORIA MONSALVE SALAZARNessuna valutazione finora

- Red DN80 50 50936Documento1 paginaRed DN80 50 50936slimane AIT-IDIRNessuna valutazione finora

- MTC For SCN-574 PDFDocumento154 pagineMTC For SCN-574 PDFthomasNessuna valutazione finora

- Mill Test Certificate: Zibo Camel Material Co., LTDDocumento1 paginaMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisNessuna valutazione finora

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Documento1 paginaAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNessuna valutazione finora

- MTC 5Documento1 paginaMTC 5Muthazhagan SaravananNessuna valutazione finora

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocumento1 paginaLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNessuna valutazione finora

- T T - Tubacex Ubos Inox Dables S A: Mill Test C T IcateDocumento3 pagineT T - Tubacex Ubos Inox Dables S A: Mill Test C T IcatePRANAY OMTECHNessuna valutazione finora

- MTCDocumento6 pagineMTCNauman Zia100% (1)

- 08.05.2019 Npu 400Documento2 pagine08.05.2019 Npu 400Yasin BaturNessuna valutazione finora

- Zdocs - Hu 773007136-ADocumento1 paginaZdocs - Hu 773007136-AMohamed RaafatNessuna valutazione finora

- Sau - MTC 0001-002163 - Acc.aºcºDocumento24 pagineSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaNessuna valutazione finora

- Mag General Business: Mill Test CertificateDocumento1 paginaMag General Business: Mill Test CertificateRaul Sebastiam100% (1)

- LF' JLRDocumento1 paginaLF' JLRIslam SahafayatNessuna valutazione finora

- SS304-1 2THK PDFDocumento1 paginaSS304-1 2THK PDFrajNessuna valutazione finora

- Additional Valves CertificatesDocumento98 pagineAdditional Valves CertificatesDiana100% (1)

- WN RF Flanges SCH 40 CL 150 19Documento1 paginaWN RF Flanges SCH 40 CL 150 19Mohamed RaafatNessuna valutazione finora

- TubacexDocumento1 paginaTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNessuna valutazione finora

- Mill Test Certificate 122Documento1 paginaMill Test Certificate 122Zaid Raslan AyoubNessuna valutazione finora

- Test Certification PDFDocumento1 paginaTest Certification PDFDany ChlNessuna valutazione finora

- Test Certificates Stainless SteelDocumento4 pagineTest Certificates Stainless SteelSurajPandey33% (3)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Documento2 pagineMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNessuna valutazione finora

- 0342 Mill TestDocumento19 pagine0342 Mill Test11tkt1133% (3)

- MTC 4500528257 Iii - 210209Documento3 pagineMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNessuna valutazione finora

- Mill Test Certificate - ExampleDocumento1 paginaMill Test Certificate - ExampleAlejandro Martinez100% (4)

- Pipe & Fitting-Example PDFDocumento24 paginePipe & Fitting-Example PDFSaravoot MetahNessuna valutazione finora

- 3604 1Documento17 pagine3604 1Tiffany WilsonNessuna valutazione finora

- 041101Documento1 pagina041101Carolina MolfinoNessuna valutazione finora

- 16 MM MS Plate 355 JR - India-MTCDocumento1 pagina16 MM MS Plate 355 JR - India-MTCQc QatarNessuna valutazione finora

- Essar MTCDocumento1 paginaEssar MTCGowtham Vishvakarma33% (3)

- MTC - Rel-01 (Rev.00)Documento16 pagineMTC - Rel-01 (Rev.00)Alam MD SazidNessuna valutazione finora

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocumento1 paginaTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- MTC, Test Report & Packing ListDocumento63 pagineMTC, Test Report & Packing Listjubair100% (1)

- Certificado Brida WN 80 4 InstratecDocumento1 paginaCertificado Brida WN 80 4 InstratecYerson CubaNessuna valutazione finora

- Colada 5306Documento1 paginaColada 5306Lizz EstradaNessuna valutazione finora

- QIS Giay Phep RT 10-06Documento1 paginaQIS Giay Phep RT 10-06freeman11072000Nessuna valutazione finora

- QIS Giay Phep RT 12-06Documento1 paginaQIS Giay Phep RT 12-06freeman11072000Nessuna valutazione finora

- QIS Giay Phep RT 16-06Documento1 paginaQIS Giay Phep RT 16-06freeman11072000Nessuna valutazione finora

- 2021-06-17 Summary Van Phong 1Documento1 pagina2021-06-17 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-18 Summary Van Phong 1Documento3 pagine2021-06-18 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- QIS Giay Phep RT 11-06Documento1 paginaQIS Giay Phep RT 11-06freeman11072000Nessuna valutazione finora

- 2021-06-28 Summary Van Phong 1Documento3 pagine2021-06-28 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-03 Summary Van Phong 1Documento1 pagina2021-06-03 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- Project Management & Action ListDocumento3 pagineProject Management & Action Listfreeman11072000Nessuna valutazione finora

- 2021-06-16 Summary Van Phong 1Documento1 pagina2021-06-16 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-01 Summary Van Phong 1Documento1 pagina2021-06-01 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-09 Summary Van Phong 1Documento2 pagine2021-06-09 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-08 Summary Van Phong 1Documento1 pagina2021-06-08 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-11 Summary Van Phong 1Documento2 pagine2021-06-11 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-10 Summary Van Phong 1Documento1 pagina2021-06-10 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-07-28 Summary Van Phong 1Documento1 pagina2021-07-28 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- 2021-06-12 Summary Van Phong 1Documento1 pagina2021-06-12 Summary Van Phong 1freeman11072000Nessuna valutazione finora

- PP1-2M90-1043-006 - B - Inspection Test Plan - CODE B PDFDocumento5 paginePP1-2M90-1043-006 - B - Inspection Test Plan - CODE B PDFfreeman11072000Nessuna valutazione finora

- HD1-2M90-1042-006 - B - Inspetion Test Plan - CODE BDocumento5 pagineHD1-2M90-1042-006 - B - Inspetion Test Plan - CODE Bfreeman11072000Nessuna valutazione finora

- Utl 001 002 PDFDocumento2 pagineUtl 001 002 PDFfreeman11072000Nessuna valutazione finora

- NDT CONTROL-CNI-PP5 04-Nov-2020 Rev00Documento33 pagineNDT CONTROL-CNI-PP5 04-Nov-2020 Rev00freeman11072000Nessuna valutazione finora

- PP1-2M90-1043-007 - B - Inspection Test Procedure - CODE BDocumento11 paginePP1-2M90-1043-007 - B - Inspection Test Procedure - CODE Bfreeman11072000Nessuna valutazione finora

- Liner Magnetic Particles Examination Report: ZaisfDocumento10 pagineLiner Magnetic Particles Examination Report: Zaisffreeman11072000Nessuna valutazione finora

- Summary RT - 2018-10-18Documento2 pagineSummary RT - 2018-10-18freeman11072000Nessuna valutazione finora

- External Pressure DesignDocumento395 pagineExternal Pressure DesignrsubramaniNessuna valutazione finora

- Utl 001 002 PDFDocumento2 pagineUtl 001 002 PDFfreeman11072000Nessuna valutazione finora

- Manual Valve NDE QISDocumento4 pagineManual Valve NDE QISfreeman11072000Nessuna valutazione finora

- IB17 021 Interpretation Permanent Tack WeldsDocumento3 pagineIB17 021 Interpretation Permanent Tack Weldsfreeman11072000Nessuna valutazione finora

- Mechanical Design SpreadsheetDocumento1 paginaMechanical Design SpreadsheetHoney TiwariNessuna valutazione finora

- Tecnicas Monitoreo CorrosionDocumento8 pagineTecnicas Monitoreo CorrosionJavier GonzalezNessuna valutazione finora

- Title DefenseDocumento3 pagineTitle DefenseLiezl Sabado100% (1)

- Socio Economic Conditions of Migrant LabourDocumento7 pagineSocio Economic Conditions of Migrant LabourDR SEKHARNessuna valutazione finora

- Segway v1 04 Eng Segway Atv Snarler Manual t3b L7eDocumento192 pagineSegway v1 04 Eng Segway Atv Snarler Manual t3b L7eMarouane LASRYNessuna valutazione finora

- Rizal and The Theory of NationalismDocumento37 pagineRizal and The Theory of NationalismLiza Betua Sotelo78% (58)

- Cn101386595-Chemical Synthesis Method of 10-Methoxyl-5H-Dibenz (B, F) AzapineDocumento4 pagineCn101386595-Chemical Synthesis Method of 10-Methoxyl-5H-Dibenz (B, F) AzapineDipti DodiyaNessuna valutazione finora

- TOC - Question AnswerDocumento41 pagineTOC - Question AnsweretgegrgrgesNessuna valutazione finora

- Planmeca Promax 3D Max CBVT Product PresentationDocumento36 paginePlanmeca Promax 3D Max CBVT Product PresentationAD TwentyOne DentalNessuna valutazione finora

- Lovelock PPT Chapter 09Documento35 pagineLovelock PPT Chapter 09krunal kapatelNessuna valutazione finora

- Excel Tips Tricks e-BookV1.1 PDFDocumento20 pagineExcel Tips Tricks e-BookV1.1 PDFSulabhNessuna valutazione finora

- Ineo+ 200 Parts Guide ManualDocumento90 pagineIneo+ 200 Parts Guide ManualOláh GyörgyNessuna valutazione finora

- Czujniki Temperatury MOTOMETERDocumento7 pagineCzujniki Temperatury MOTOMETERhelp3rNessuna valutazione finora

- PD 0018 Well Intervention Pressure Control Syllabus Level 3 4Documento94 paginePD 0018 Well Intervention Pressure Control Syllabus Level 3 4Salim AlgerianNessuna valutazione finora

- Sepction - 3Documento3 pagineSepction - 3k koradiaNessuna valutazione finora

- Oakite 61B - TIDocumento2 pagineOakite 61B - TI顏煥杰Nessuna valutazione finora

- Report On Mango Cultivation ProjectDocumento40 pagineReport On Mango Cultivation Projectkmilind007100% (1)

- Airsprings - TroubleshootingDocumento4 pagineAirsprings - TroubleshootingCihan CantaşNessuna valutazione finora

- Features and ApplicationsDocumento36 pagineFeatures and ApplicationsFWEFWEFWNessuna valutazione finora

- Towards A Governance Dashboard For Smart Cities InitiativesDocumento6 pagineTowards A Governance Dashboard For Smart Cities Initiatives吳 澍 WU SU F74056297Nessuna valutazione finora

- TRANSLATIONDocumento4 pagineTRANSLATIONGarren Jude Aquino100% (1)

- Skinner Reinforcement TodayDocumento6 pagineSkinner Reinforcement TodayEnrique Hernández RosasNessuna valutazione finora

- SP Post ListDocumento54 pagineSP Post ListJoel Eljo Enciso SaraviaNessuna valutazione finora

- Multidisciplinary Research: EPRA International Journal ofDocumento5 pagineMultidisciplinary Research: EPRA International Journal ofMathavan VNessuna valutazione finora

- Deck Manual PDFDocumento217 pagineDeck Manual PDFBozidar TomasevicNessuna valutazione finora

- Current Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Documento11 pagineCurrent Office Phone Number Vijayawada, Andhra Pradesh (A.p.)Manoj Digi Loans100% (1)

- Java ProgrammingDocumento134 pagineJava ProgrammingArt LookNessuna valutazione finora

- Frequency Spectrum On XXX OperatorsDocumento4 pagineFrequency Spectrum On XXX OperatorsPeng Yuan FengNessuna valutazione finora

- Remembering Thanu Padmanabhan - The HinduDocumento3 pagineRemembering Thanu Padmanabhan - The HinduIucaa libraryNessuna valutazione finora

- An Example of A Rating Scale To Q4Documento4 pagineAn Example of A Rating Scale To Q4Zeeshan ch 'Hadi'Nessuna valutazione finora

- 10th Syllbus PDFDocumento104 pagine10th Syllbus PDFGagandeep KaurNessuna valutazione finora