Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2510-Article Text-6054-1-10-20151009

Caricato da

SOURAVCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2510-Article Text-6054-1-10-20151009

Caricato da

SOURAVCopyright:

Formati disponibili

V. Naveen Kumar et al /International Journal of Advances in Scientific Research 2015; 1(08): 331-339.

331

International Journal of Advances in Scientific Research

ISSN: 2395-3616 (Online)

Journal DOI: 10.7439/ijasr Research Article

Investigation of Drag and Lift Forces over the Profile of Car with

Rearspoiler using CFD

V. Naveen Kumar*, K. Lalit Narayan, L. N. V. Narasimha Rao and Y. Sri Ram

Mechanical Engineering, Sir. C.R. Reddy College of Engineering, Andhra Pradesh, India

*Correspondence Info:

V. Naveen Kumar

Mechanical Engineering,

Sir. C.R. Reddy College of Engineering, Andhra Pradesh, India

E-mail: naveenmech524@gmail.com

Abstract

Now a days demand of a high speed car is increasing in which vehicle stability is of major

concern. Forces like drag& lift, weight, side forces and thrust acts on a vehicle when moving on road which

significantly affect the fuel consumption The drag force is produced by relative motion between air and vehicle

and about 60% of total drag is produced at the rear end. Reduction of drag force at the rear end improves the

fuel utilization. This work aims to reduce the drag force which improves fuel utilization and protects

environment as well. In the stage of work a sedan car with different types of spoilers are used to reduce the

aerodynamic drag force. The design of sedan car has been done on CATIA-2010 and the same is used for

analysis in ANSYS-(fluent). The analysis is done for finding out drag and lift forces at different velocities, and

spoilers. This study proposes an effective numerical model based on the computational fluid dynamics (CFD)

approach to obtain the flow structure around a passenger car with a rear spoiler

Keywords: Car, Rearspoiler, CFD.

1. Introduction

Nowadays the everyday cars are changed by lift and drag. The reduction of drag force can save

their owners to make the look sportier. Having more fuel; moreover spoiler also can be used to control

power under the hood leads to higher speeds for which stability at cornering. Besides can reduce drag and

the aerodynamic properties of the car given by the reduce rear-axle lift, rear spoiler also can reduce dirt

designer are not enough to offer the required down on the rear surface.

force and handling. The performance, handling, safety,

and comfort of an automobile are significantly

affected by its aerodynamic properties. Extra parts are

added to the body like rear spoilers, lower front and

rear bumpers, air dams and many more aerodynamics

aids as to direct the airflow in different way and offer

greater drag reduction to the car and at the same time

enhance the stability. In case of that, many

aerodynamics aids are sold in market mostly rear

spoiler. Rear spoiler is a component to increase down

Figure 1: The rear spoiler

force for vehicle especially passenger car. It is an

aerodynamic device that design to „spoil‟ unfavourable

1.1. What is Aerodynamics?

air movement across a car body. Main fixing location

Aerodynamics is the way objects move

is at rear portion, depends on shape of the rear portion

through air. The rules of aerodynamics explain how an

either the car is square back, notchback or fastback

airplane is able to fly. Anything that moves through air

because not all rear spoiler can be fix at any type of

is affected by aerodynamics, from a rocket blasting

rear portion of a car. However spoiler also can be

off, to a kite flying. Since they are surrounded by air,

attached to front rear bumper as air dam. Rear spoiler

even cars are affected by aerodynamics.

contributed some major aerodynamics factor which is

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 332

“Aerodynamics” is a branch of fluid dynamics windshield; it accelerates, causing the pressure to

concerned with studying the motion of air, particularly drop. This lower pressure literally lifts on the car‟s

when it interacts with a moving object roof as the air passes over it. Worse still, once the air

1.2. What IS CFD? makes its way to rear window, the notch created by the

“CFD (Computational fluid dynamics) is a set window dropping down to the trunk leaves a vacuum

of numerical methods applied to obtain approximate or lower pressure space that the air is not able to fill

solution of problems of fluid dynamics and heat properly. The flow is said to detach and the resulting

transfer.” lower pressure creates lift that then acts upon the

surface area of the trunk. To reduce lift that acted on

the rear trunk, a rear spoiler can attach on it to create

more high pressure. Spoilers are used primarily on

sedan-type cars. They act like barriers to air flow, in

order to build up higher air pressure in front of the

spoiler. This is useful, because as mentioned

previously, a sedan car tends to become "Light" in the

rear end as the low pressure area above the trunk lifts

Figure 2: The different disciplines contained within the rear end of the car.

computational fluid dynamics

3. Vehicle generic models and dimensions

According to this definition, CFD is not a

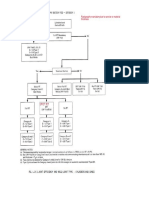

The below Figure 4, outlines the steps before

science by itself but a way to apply methods of one

the lift and drag coefficient of New manza is obtained.

discipline (numerical analysis) to another (heat and

The coefficient of lift is obtained for the front and rear

mass transfer). In retrospect, it is integrating not only

section of the car. Overall surface of the new manza is

the disciplines of fluid mechanics with mathematics

scanned and exported to CAD modeling software

but also with computer science as illustrated in Figure

(CATIA) to smooth and repair the surface. The CFD

2. The physical characteristics of the fluid motion can

analysis is done using Star-CFD software. For the

usually be described through fundamental

initial run, the result of Cd is compared to the standard

mathematical equations, usually in partial differential

published new manza value of Cd which is around

form, which govern a process of interest and are often

0.32. If the initial run is far away from the standard

called governing equations in CFD. Jiyuan Tu, Guan

value, then the CAD model is checked and repaired

Heng Yeoh and Chaoqun Liu [2] have discussed how

again until the Cd value comes within 0.3> Cd >0.4

to solve mathematical equations with using CFD:

range. The values of drag and pressure coefficient is

run at least 5 times and averaged. It is important to

average this value to ensure the result is consistent and

acceptable. The post-processor plot the data of

pressure distribution and velocity vector on the centre

section of the car. The center section of the car is the

ideal value since it represents the closest outline to the

real shape of the car. Then, the target is to analyze the

pressure distribution and velocity vectors pattern that

effect the drag, lift or down force. Finally to ensure the

Figure 3: The three basic approaches to solve vehicle achieve the occurrence of down forces at both

problems in fluid dynamics and heat transfer.

the front and the rear side of the vehicle which ensure

CFD has also become one of the three basic

good vehicle stability.

methods or approaches that can be employed to solve

problems in fluid dynamics and heat transfer. As

demonstrated in Figure 3.each approach is strongly

interlinked and does not lie in isolation.

2. Problem Statement

When a driver drives his or her car in high

speed condition, especially at highway which is speed

limit 110 km/h, the car has high tendency to lift over.

This is possible to happen because as the higher Figure 4: Dimensions of the generic vehicle model

pressure air in front of the windshield travels over the [Side-view]

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 333

Figure 5: Dimensions of the generic vehicle model

[frant-view]

Figure 8: Vehicle 3D CAD model

4. Spoiler generic models and dimensions

In the numerical analyze, two different

spoiler styles have been used. The first spoiler was a

“wing” style spoiler, which was mounted 28 cm above

the surface of the vehicle‟s rear-end, on the other

hand the second spoiler was mounted edge of the rear

side of the vehicle without leaving a gap between

spoiler and the surface of vehicle. The generic model

of the first spoilers is shown in Figure 6.below, while

the generic model of second spoilers is shown in

Figure 7, with relevant dimensions.

Figure 9: Assembly 3D CAD model of vehicle and

first spoiler

Figure 6: Generic model and dimensions of first

spoiler

Figure 10: Assembly 3D CAD model of vehicle and

second spoiler

5. Virtual wind tunnel and vehicle orientation

A virtual air-box has been created around the

3D CAD model (Figure 11.), which represents the

wind tunnel in the real life. Since we are more

interested in the rear side of vehicle, which is where

the “wake of vehicle” phenomenon occurs, more space

has been left in the rear side of the vehicle model to

capture the flow behavior mostly behind the vehicle.

Figure 7.Generic model and dimensions of second

spoiler

The vehicle itself (Figure 8.), vehicle with

first spoiler (Figure 9.) and vehicle with second

spoiler (Figure 10.) 3D CAD models shown above

have been orientated in the virtual wind tunnel one-by

one to performed three cases, benchmark #1,

benchmark #2 and benchmark #3. Figure11: Virtual wind tunnel and the vehicle

orientation

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 334

Due to the complexity of the simulation with available, coupled with unrivaled modelling

limited computer resources and time, the complete capabilities, to help you achieve a faster total time to

domain was divided to half using a symmetry plane solution. More product development leaders

(YZ plane), which means, the simulation would be worldwide trust ANSYS software as their fluid

calculated for just the one side of the vehicle and since dynamics simulation platform for its accuracy,

the other side is symmetric and YZ plane has been reliability and speed. ANSYS is committed to

defined as symmetric boundary in the solver to make providing world-class high-fidelity fluid dynamics

the boundary condition as “a slip wall with zero shear technology for Simulation Driven Product

forces”; the simulation results would be valid for full Development. In addition to providing the most well

model as well. All 5 surfaces of the virtual wind tunnel validated and used CFD products on the market its

(air-box) have been named so the numerical solver of ANSYS® Workbench™ platform is built on the

ANSYS FLUENT® would recognize them and apply ability to co-simulate. Users of ANSYS‟ CFD

the appropriate boundary conditions automatically. solutions can include structural mechanics or electrical

The final meshing can be seen in Figure 12. The same aspects to a model through our other industry-leading

procedure to create high resolution meshing has been solver solutions. By that means customers reduce

followed for all cases (Case #1: Vehicle itself, Case engineering assumptions and increase the fidelity of

#2: Vehicle with first spoiler, Case #3: Vehicle with their models.CFD solutions from ANSYS deliver

second spoiler) exactly the same. unprecedented productivity to help you analyze

multiple, automated parametric design variations all

without complex programming. ANSYS provides

integrated tools that not only help you to conveniently

understand which parameters your design is most

sensitive to, but also determine which design

parameters require the tightest control. Integrated tools

for design (shape) optimization and Six Sigma

analysis are also available. ANSYS simulation

software gives you the power to design for robust

performance and deliver better products, faster. CFD

Figure 12: The final mesh solutions from ANSYS are readily customizable and

Table1: Mesh sizing parameters extensible to meet your ongoing simulation and

Face Boundary Type Zone name workflow process requirements - whether it‟s

In front of the car Velocity Inlet Inlet

extending solver capabilities to predict unique

Side opposite the Car Symmetry Side

Above the Car Symmetry Top environmental factors or customizing our products to

Below the Car Wall Ground automate your design work flow. With ANSYS tools,

Two faces created at Symmetry Symmetry your designers have the power to create better

the car center plane Plane

products more profitably. Because they can yield

Behind the car Pressure Outlet Outlet

Faces of the car Wall Car significant benefits (incl. more innovation, cost

savings, reduced development time, increased quality),

6. CFD Analysis they have become an integral part of the engineering

Computational fluid dynamics (CFD) is an design and analysis environment of companies in the

engineering method for simulating the behaviour of widest range of industries.

systems, processes and equipment involving flow of

gases and liquids, heat and mass transfer, chemical 6.1. Importance of computational fluid

reactions and related physical phenomena. More dynamics

specifically CFD, or fluid simulation, can be used to There are three methods in study of Fluid:

reduce pressure drops, to predict aerodynamic lift or theory analysis, experiment and simulation (CFD). As

drag, to predict the rotor thrust, to calculate the airflow a new method, CFD has many advantages compared to

in air conditioned rooms, to ensure adequate cooling, experiments. Please refer Table2

to optimize mixing rates, and so on .ANSYS combines Table 2: Comparison of Simulation and Experiment

the most respected names in fluid simulation — Simulation (CFD) Experiment

ANSYS ® FLUENT® and ANSYS® CFX® — to Cost Cheap Expensive

Time Short Long

expertly address your evolving CFD needs at a time Scale Any Small/Middle

when product reliability, safety and market Information All Measured point

performance are paramount. ANSYS offers the most Repeatable Yes Some

complete suite of advanced CFD software tools Safety Yes Some Dangerous

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 335

6.2. CFD Analysis without spoiler

Figure 14(d). Velocity and magnitude [130km/hr]

Figure 13(a): Static pressures

Figure 14(e). Velocity and magnitude [150km/hr]

Figure 14(a,b,c,d,e). represents CFD analysis

without spoiler on different velocities [70,

Figure 13(b): Dynamic pressure 90,110,130,150 km/hr]

6.4 CFD Analysis (Spoiler1)

Figure 13(c): Pathlines by static pressure Figure 15(a): Velocity and magnitude [70km/hr]

The figure 13(a,b,c) represents the static and

dynamic pressure of the vehicle. It is observed that the

maximum pressure is 75.5 Pascal infront of the vehicle

at bottom of the wind shield and infront of hood

because of sharp edges

6.3. Velocity analysis Figure 15(b): Velocity and magnitude [90km/hr]

Figure 15 (c): Velocity and magnitude [110km/hr]

Figure 14(a). Velocity and magnitude [70km/hr]

Figure 14(b). Velocity and magnitude [90km/hr]

Figure 15 (d): Velocity and magnitude [130km/hr]

Figure 14(c). Velocity and magnitude [110km/hr]

Figure 15 (e). Velocity and magnitude [150km/hr]

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 336

Figure 15(a,b,c,d,e).represents CFD analysis add to the present body of literature as well as to justly

with spoiler1 on different velocities [70, the scope and direction of the present research effort

90,110,130,150 km/hr]

6.5 CFD Analysis (Spoiler2) 7.1 Data Presentation

Table 6.1: Car without Rear Spoiler

S. Velocity Drag Lift Cd Cl

No (Km/h) Force (N) Force (N)

1 70 153.86 51.109 0.329 0.1183

2 90 255.0 85.711 0.330 0.117

3 110 383.397 129.588 0.331 0.1153

4 130 536.83 182.00 0.333 0.108

Figure 16(a): Velocity and magnitude [70km/hr] 5 150 718.946 248.474 0.334 0.096

Table 6.2: Car with Rear Spoiler 1

S. Velocity Drag Lift Cd Cl

No (Km/h) Force (N) Force (N)

1 70 147.431 49.646 0.3326 0.112

2 90 244.117 80.6639 0.329 0.110

3 110 396.157 125.973 0.331 0.115

Figure 16(b): Velocity and magnitude [90km/hr] 4 130 512.359 172.825 0.330 0.113

5 150 684.323 224.034 0.333 0.110

Table 6.3: Car with Rear Spoiler 2

S. Velocity Drag Lift Force Cd Cl

No (Km/h) Force (N) (N)

1 70 144.062 49.867 0.325 0.1125

2 90 241.185 82.839 0.329 0.1130

Figure 16(c). Velocity and magnitude [110km/hr]

3 110 364.775 127.397 0.333 0.1163

4 130 503.183 168.237 0.329 0.1100

5 150 670.066 216.906 0.329 0.1060

16. Graphical representation

Figure 16(d): Velocity and magnitude [130km/hr]

Figure 17: Variation of lift forces & drag forces

Figure 16(e). Velocity and magnitude [150km/hr] with increase in speed for without spoiler

Figure 16(a,b,c,d,e) represents CFD analysis

with spoiler2 on different velocities [70, 7.2. Variation of lift and drag forces with increase

90,110,130,150 km/hr] in speed for without Spoiler:

Figure 17 shows the Variation of lift forces &

7. Results and Discussion drag forces with increase in speed for without spoiler.

The purpose of this chapter is to provide a It can be observed that the drag force increases and the

review of past research efforts related to car lift force decreases slightly with increase in speed of

aerodynamic drag & lift and its attachment for the car.

aerodynamics aids which is rear spoiler. A review of

other relevant research studies is also provided.

Substantial literature has been studied on aerodynamic

drag, aerodynamic lift and influences from both and

purpose of rear spoiler as one of the aerodynamic aids.

The review is organized chronologically to offer

insight to how past research efforts have laid the

groundwork for subsequent studies, including the

present research effort. The review is detailed so that Figure 18: Variation of lift forces&drag forces with

the present research effort can be properly tailored to increase in speed for with spoiler1

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 337

7.3 Variation of lift forces & drag forces 7.6 Comparison of lift forces for 3 cases with

with increase in speed for with spoiler1: increase in speed

Figure 18 shows the Variation of lift forces & • Figure 21 shows the Comparison of lift forces for 3

drag forces with increase in speed for With spoiler1. It cases with increase in speed.

can be observed that slight fluctuation in drag force • The coefficient of lift for body without spoiler is

diminishing gradually.

and lift force with increase in speed of the car.

• The Cl for body with spoiler 1 yields the increment

compared with body with spoiler 2 is nearer to

results with the both body without spoiler and with

spoiler 1.

• The spoiler 2 is preferred because there is no rapid

increment or decrement in CL and reduction in

coefficient of drag is also taken into consideration.

7.7. Reasons for selection of car body with spoiler 2

Figure 19: Variation of lift forces&drag forces with

increase in speed for with spoiler2

7.4 Variation of lift forces & drag forces with

increase in speed for with spoiler2:

Figure 19 shows the Variation of lift forces &

drag forces with increase in speed for with spoiler2. It

can be observed that slight fluctuation in drag force

and lift force with increase in speed of the car. Figure 22: Velocity streamlines of flow in the

symmetry plane for case 1

Figure 20: Comparison of drag forces for 3 cases Figure 23.Velocity streamlines of flow in the

with increase in speed symmetry plane for case 2

7.5 Comparison of drag forces for 3 cases with

increase in speed:

Figure 20 shows the Comparison of drag forces for

3 cases with increase in speed.

From the above results the spoiler 2 yields the better

results compared to spoiler1 and without spoiler

because of diminishment of recirculation zones.

The coefficient of drag for rear end of car body with

spoiler 1 and without spoiler at 110 Km/hr yields the

similar results and also the coefficient of drag for

rear end of car body with spoiler 1 and ith spoiler 2 Figure 24: Velocity streamlines of flow in the

at 90 Km/hr yields the similar results because of symmetry plane for case 3

constant stream lines

Contours of velocity for a high-speed vehicle

at the symmetry plane for all 3 cases are shown in

Figure 22, Figure 23 and Figure 24 respectively. The

vehicles with rear spoiler (case 2 and case 3) have

large and double air swirls at the rear end. It has been

found that there were recirculation zones behind the

rear end of the vehicle. By comparing the cases in

figures, the recirculation zone behind the rear end of

.

vehicle with spoiler situations (case 2 and case 3) were

Figure 21: Comparison of lift forces for 3 cases

with increase in speed clearly larger. As we have seen in the Figure 5.8 there

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 338

were two different recirculation zones at the rear end performance Evaluation of a Car” Journal of

of the vehicle (one behind the vehicle, and one above Scientific & Industrial Research 2008.

the rear window). By comparing Figure 22and Figure [7] Aniket A Kulkarni et al Analysis of Flow over a

23 it has been seen that; the recirculation zone above Convertible Computer-Aided Design &

the rear window was almost gone by using spoiler. Applications, PACE (2), 2012, 69-75,2012 CAD

from the figure 23 and figure 27 it is concluded that Solutions, LLC

the recirculation zones in figure 27 have negligible [8] Mohan Jagadeesh Kumar M et.al Effect of Vortex

impact on the performance because it‟s magnitude is generators on Aerodynamics of a Car: CFD

less. Analysis vol-2 issue 2 april-2013.ISSN-2319-

1058

8. Conclusions [9] K. Lowe. Automotive steels. Engineering, Feb.

Based on this study of the aerodynamic flow 1995, 20-21.

around a car, second spoiler of the car stood best [10] Baker, C. The flow around high speed trains.

among the three cases of car based on results obtained Journal of Wind Engineering and Industrial

in terms of Drag it is about 0.329 and Lift force is Aerodynamics 2010; 98: 277-298.

0.106. To estimate the drag coefficient and flow [11] Mahmoud Khaled, Hischam., Fabien, and Hassan

visualization is achieved successfully by the use of P. Some innovative concepts for a car reduction:

CFD simulations. Aerodynamics drag for car body of Parametric analysis of aerodynamic forces on

profiles are successfully simulated with ANSYS simplified body.

Fluent solver, the analysis shows aerodynamics drag [12] Simon Watkins, Gioacchino Vino. The effect of

in term of drag forces or drag coefficient the vehicle spacing on the aerodynamics of a

proportionally increased to the square of velocity for representative vehicle. Journal of Wind

car body. This computational analysis shows that there Engineering and Industrial Aerodynamics 96

is possibility of improving the aerodynamic (2008).

performance of car by modifications in exterior design [13] Jasinki, W. and Selig, M.,Experimental Study of

of car body. These modifications are helpful in Open - Wheel Race-Car Front Wings, SAE

reducing the coefficient of drag i.e. Cd which effects Technical Paper 983042, 1998,

the fuel consumption. By these modifications the doi:10.4271/983042

coefficient of drag is reduced by approximately 2.18% [14] Fundamentals of Fluid Mechanics by Munson,

Advantages of using spoiler2: Young, Okiishi, Huebsch: 515,513.

Increases tires capability to produce cornering force [15] Anderson CFD book: the basic with application

Stabilizes vehicles at high speed McGraw-Hill series in aeronautical and aerospace

Improves braking performance engineering.

Gives better traction [16] ANSYS® Academic Research, Release 13.0,

Help System, FLUENT Theory guide, ANSYS,

References Inc.

[1] Wolf-Heinrich Hucho: Aerodynamic of Road [17] Ahmed, G. Ramm, and G. Faltin. Some salient

Vehicle; Fourth Edition; Society of Automotive features of the time averaged ground vehicle

Engineers, Inc. 1998. wake. SAE Paper 1984; 840300.

[2] Heinz Heisler: Advanced Vehicle Technology: [18] Bayraktar, I., Landman, D., and Baysal, O.

Second Edition; Elsevier Butterworth Heinemann. Experimental and Computational Investigation of

2002. Ahmed Body for Ground Vehicle Aerodynamics.

[3] Rosli Abu Bakar, Oleg Zikanov, Fazli Ismail, SAE Technical Paper 2001; 01: 2742.

Design and Development of Hybrid Electric [19] Baker, C. A., Grossman, B., Haftka, R. T., Mason,

Vehicle Rear Diffuser, Science, Technology & W. H., & Watson, L. T. HSCT configuration

Social Sciences 2008 (STSS), Malaysia. design space exploration using aerodynamic

[4] Luca Iaccarino. Cranfield University Formula 1 response surface approximations. AIAA 1999; 98:

Team: An Aerodynamics Study of the Cockpit. 4803.

School of Engineering. Cranfield University. [20] Braus, M., Lanfrit, M. (2001). Simulation of the

August 2003. Ahmed Body. 9th ERCOFACT/IAHR Workshop

[5] Carr. G. W., (1982), “The aerodynamics of basic on Refined Turbulence Modelling.

shapes of road vehicles, part 1, Simple rectangular [21] Guo, L., Zhang, Y., & Shen, W. Simulation

bodies”, MIRA report No.1982/2. Analysis of Aerodynamics Characteristics of

[6] Manan Desai1, et al/,“A Comparitive Assessment Different Two-Dimensional Automobile Shapes.

of two Experimental Methods for Aerodynamic

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

V. Naveen Kumar et al / Investigation of Drag and Lift Forces over the Profile of Car with Rearspoiler using CFD 339

Journal of Computers, 2011; 6(5), 999-1005. Biographies

doi:10.4304/jcp.6.5.999- 1005. V. Naveen Kumar

Master of Engineering in Machine

[22] Peddiraju, P., Papadopoulous, A., Singh, R. Design, Mechanical Engineering,

(2009). CAE framework for aerodynamic design Sir.C.R. Reddy College of Engineering,

Andhra Pradesh, India

development of automotive vehicles. 3rd ANSA &

μETA International Conference. Dr.K. Lalit Narayan

[23] S. N. Singh, L. Rai, A. Bhatnagar. “Effect of Professor,

Dept of Mechanical Engineering,

moving surface on the aerodynamic drag of road Sir.C.R.Reddy College of Engineering,

vehicles” Proceeding of IMech E. J Automobile Andhra Pradesh, India.

Engineering, 2004; 219 Part D: 127- 134. L.N.V. Narasimha Rao

[24] Samareh, J. A. Aerodynamic shape optimization Assistant Professor,

Dept of Mechanical Engineering,

based on free-form deformation. AIAA, 2004; Sir.C.R.Reddy College of Engineering,

4630. Andhra Pradesh, India.

[25] Wolf-Heinrich Hucho (1998) “Aerodynamics of Y.Sri Ram

Assistant Professor,

Road Vehicles”, SAE International, Warrendale Dept of Mechanical Engineering,

Websites Sir.C.R. Reddy College of Engineering,

1) www.wikipedia.com Andhra Pradesh, India.

2) www.cardesignonline.com

IJASR|VOL 01|ISSUE 08|2015 www.ssjournals.com

Potrebbero piacerti anche

- Investigating The Effect of Rear Spoiler and Rear Diffuser On Aerodynamic Forces Using CFD IJERTCONV3IS26037Documento6 pagineInvestigating The Effect of Rear Spoiler and Rear Diffuser On Aerodynamic Forces Using CFD IJERTCONV3IS26037Voona RanganadhanNessuna valutazione finora

- 58.Aerodynamics-in-Cars. ReportDocumento22 pagine58.Aerodynamics-in-Cars. ReportSudhir PatelNessuna valutazione finora

- Aerodynamic Analysis of A Car PDFDocumento110 pagineAerodynamic Analysis of A Car PDFdhirendarji100% (1)

- Literature Review PDFDocumento12 pagineLiterature Review PDFpoudelNessuna valutazione finora

- Mini ProjectDocumento13 pagineMini ProjectOm SalunkeNessuna valutazione finora

- CFD Analysis & Aerodynamic Study of A Sedan Car: (Peer-Reviewed, Open Access, Fully Refereed International Journal)Documento5 pagineCFD Analysis & Aerodynamic Study of A Sedan Car: (Peer-Reviewed, Open Access, Fully Refereed International Journal)IRJMETS JOURNALNessuna valutazione finora

- 2D CFD Analysis of Racing Car For Studen PDFDocumento3 pagine2D CFD Analysis of Racing Car For Studen PDFBig FloresNessuna valutazione finora

- Analysis of Flow over Passenger Cars using Computational Fluid DynamicsDocumento8 pagineAnalysis of Flow over Passenger Cars using Computational Fluid Dynamicshung phungNessuna valutazione finora

- Aerodynamics in CarsDocumento20 pagineAerodynamics in CarsSagar KnNessuna valutazione finora

- Aerodynamic Modeling and SimulationDocumento33 pagineAerodynamic Modeling and Simulationjabach_ahrimanNessuna valutazione finora

- Aerodynamics Analysis of FS CarDocumento9 pagineAerodynamics Analysis of FS CarYash KatareNessuna valutazione finora

- CFD Analysis of Diffuser Angle for Maximum Downforce GenerationDocumento7 pagineCFD Analysis of Diffuser Angle for Maximum Downforce GenerationBig Flores100% (1)

- (IJETA-V10I3P1) :abdullah Al Hasan, Md. Shamim RayhanDocumento7 pagine(IJETA-V10I3P1) :abdullah Al Hasan, Md. Shamim RayhanIJETA - EighthSenseGroupNessuna valutazione finora

- Tata Nano AerodynamicDocumento4 pagineTata Nano AerodynamicAndres Fernando Sokol UrzagasteNessuna valutazione finora

- Estimation of Drag and Lift On Ahmed Body Using CFD AnalysisDocumento6 pagineEstimation of Drag and Lift On Ahmed Body Using CFD AnalysisAhmedNessuna valutazione finora

- Estimation of Drag and Lift On Ahmed BodyDocumento6 pagineEstimation of Drag and Lift On Ahmed Bodymark mutimushiNessuna valutazione finora

- Vehicle Aerodynamics ThesisDocumento6 pagineVehicle Aerodynamics Thesiskimberlythomasarlington100% (2)

- Report of Mini ProjectDocumento7 pagineReport of Mini ProjectTachfine El OuchariNessuna valutazione finora

- Research Paper On Aerodynamics in CarDocumento8 pagineResearch Paper On Aerodynamics in Carjbuulqvkg100% (1)

- Icmiee20 011Documento6 pagineIcmiee20 011nayenzaman6Nessuna valutazione finora

- Solar Panel Car ProposalDocumento16 pagineSolar Panel Car ProposalRamith MindulaNessuna valutazione finora

- Group 2 4620 Group ReportDocumento15 pagineGroup 2 4620 Group ReportAtitat Rattanachata100% (1)

- Aerodynamics in High Performance VehiclesDocumento20 pagineAerodynamics in High Performance VehiclesJithen Mankad100% (1)

- Effect of Spoilers On Aerodynamic ProperDocumento10 pagineEffect of Spoilers On Aerodynamic ProperNguyễn Đình ĐứcNessuna valutazione finora

- Icmere2015 Pi 282Documento8 pagineIcmere2015 Pi 282Mohamed GamalNessuna valutazione finora

- 1 s2.0 S2214785321075659 MainDocumento16 pagine1 s2.0 S2214785321075659 Mainalejandro.garcia.curraisNessuna valutazione finora

- F0752835 With Cover Page v2Documento9 pagineF0752835 With Cover Page v2Nahik KabirNessuna valutazione finora

- Computational Techniques and Their Usage To Optimize Car Design For Better PerformanceDocumento17 pagineComputational Techniques and Their Usage To Optimize Car Design For Better PerformanceINNOVATIVE COMPUTING REVIEWNessuna valutazione finora

- Kamil RRA 1Documento13 pagineKamil RRA 1P24 Innovation CenterNessuna valutazione finora

- Simulation Ofaerodynamic Flow Parametersovera Simplified Sedan CarDocumento10 pagineSimulation Ofaerodynamic Flow Parametersovera Simplified Sedan CarSujit MishraNessuna valutazione finora

- Methods to Reduce Vehicle Drag and Boost Fuel EconomyDocumento7 pagineMethods to Reduce Vehicle Drag and Boost Fuel EconomyhdrthNessuna valutazione finora

- Effect of dirty air on aerodynamic performanceDocumento17 pagineEffect of dirty air on aerodynamic performanceYuvaraj BadigerNessuna valutazione finora

- Drag Reduction by Application of Aerodynamic Devices in A Race CarDocumento20 pagineDrag Reduction by Application of Aerodynamic Devices in A Race CarVoona RanganadhanNessuna valutazione finora

- Research Paper On Vehicle AerodynamicsDocumento9 pagineResearch Paper On Vehicle Aerodynamicsikrndjvnd100% (1)

- Vehicle Dynamics: Chapter 2: Road LoadsDocumento50 pagineVehicle Dynamics: Chapter 2: Road LoadsArjun NbNessuna valutazione finora

- Aerodynamics Assessment Using CFD For A Low Drag Shell Eco-Marathon CarDocumento10 pagineAerodynamics Assessment Using CFD For A Low Drag Shell Eco-Marathon CarrobertNessuna valutazione finora

- Commercial Vehicle Aerodynamic Drag Reduction (Tipper Truck)Documento9 pagineCommercial Vehicle Aerodynamic Drag Reduction (Tipper Truck)Prakash ShaktiNessuna valutazione finora

- CFD Analysis NACA0012Documento34 pagineCFD Analysis NACA0012Ebaad shahNessuna valutazione finora

- Abstract-: - Research Is Going On in The Field of The Automobile For The Past Many YearsDocumento10 pagineAbstract-: - Research Is Going On in The Field of The Automobile For The Past Many YearsShubham SinghNessuna valutazione finora

- Aerodynamic Drag Reduction and Flow Control of Ahm PDFDocumento17 pagineAerodynamic Drag Reduction and Flow Control of Ahm PDFChaimae Idrissi100% (1)

- AERODYNAMICS OF AUTOMOTIVES FinalDocumento4 pagineAERODYNAMICS OF AUTOMOTIVES FinalShuvam RayNessuna valutazione finora

- Design and Analysis of Air Intake System and FilteDocumento7 pagineDesign and Analysis of Air Intake System and FilteSalomon CureNessuna valutazione finora

- Optimum Aerodynamic Design of A High SpeDocumento11 pagineOptimum Aerodynamic Design of A High SpeMuhammad QasimNessuna valutazione finora

- CFD Simulation of Solar Loading in Car: Ravi. DDocumento6 pagineCFD Simulation of Solar Loading in Car: Ravi. DTJPRC PublicationsNessuna valutazione finora

- Aerodynamics in CarsDocumento20 pagineAerodynamics in CarssaifpawaskarNessuna valutazione finora

- Spoiler CompressedDocumento9 pagineSpoiler CompressedSanjeet KumarNessuna valutazione finora

- Monash University Sunway Campus: MEC3458 Experimental ProjectDocumento6 pagineMonash University Sunway Campus: MEC3458 Experimental ProjectAndy SevenNessuna valutazione finora

- CFD Analysis and Optimization of Geometrical Modifications of Ahmed BodyDocumento13 pagineCFD Analysis and Optimization of Geometrical Modifications of Ahmed BodyIOSRjournalNessuna valutazione finora

- Drag Force Analysis of CarDocumento56 pagineDrag Force Analysis of CarFrederic ReblewskiNessuna valutazione finora

- Study and Overview of Aerodynamic Active Rear Wing of High Speed VehiclesDocumento6 pagineStudy and Overview of Aerodynamic Active Rear Wing of High Speed VehicleszxcvbnmnNessuna valutazione finora

- AERODYNAMICS IN CARS ReportDocumento13 pagineAERODYNAMICS IN CARS ReportRama Shankar SharmaNessuna valutazione finora

- CFD Analysis of Aerodynamics of Car: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocumento5 pagineCFD Analysis of Aerodynamics of Car: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologysatyamNessuna valutazione finora

- CFD Modeling of Vehicle Aerodynamics · CFD Flow EngineeringDocumento30 pagineCFD Modeling of Vehicle Aerodynamics · CFD Flow EngineeringBhawesh SthaNessuna valutazione finora

- Intake WjoeDocumento6 pagineIntake WjoeDarshan SoniNessuna valutazione finora

- Rexca Anak JamitDocumento36 pagineRexca Anak Jamitjohn mwangiNessuna valutazione finora

- Aerodynamic Enhancement of Formula Sae Car Using Split Rear WingsDocumento6 pagineAerodynamic Enhancement of Formula Sae Car Using Split Rear WingsMd Abdullah Al KhosruNessuna valutazione finora

- Vehicle Collision Dynamics: Analysis and ReconstructionDa EverandVehicle Collision Dynamics: Analysis and ReconstructionNessuna valutazione finora

- ASME - PTC4.1 .Boiler Efficiency TestDocumento29 pagineASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- 4 - 2D REPRESENTATION CADWorxDocumento1 pagina4 - 2D REPRESENTATION CADWorxSOURAVNessuna valutazione finora

- Cogeneration and TurbinesDocumento9 pagineCogeneration and TurbinesAtif HussainNessuna valutazione finora

- Energy Performance Assessment of FurnacesDocumento14 pagineEnergy Performance Assessment of FurnacesCatinca GeorgianaNessuna valutazione finora

- 5 - CADWorx BASE PROFILEDocumento1 pagina5 - CADWorx BASE PROFILESOURAVNessuna valutazione finora

- HVAC & Refrigeration SystemDocumento22 pagineHVAC & Refrigeration SystemSivakumar NadarajaNessuna valutazione finora

- VFD Pumping SystemsDocumento22 pagineVFD Pumping Systemsrajurajangam100% (1)

- 3Ch8 - 8. LIGHTING SYSTEM PDFDocumento11 pagine3Ch8 - 8. LIGHTING SYSTEM PDFstarykltNessuna valutazione finora

- Chapter 3.7 Cooling TowerDocumento17 pagineChapter 3.7 Cooling TowerDeep DasNessuna valutazione finora

- Compressed Air SystemDocumento29 pagineCompressed Air SystemPrathmesh GujaratiNessuna valutazione finora

- HVAC & Refrigeration SystemDocumento22 pagineHVAC & Refrigeration SystemSivakumar NadarajaNessuna valutazione finora

- Old Spring Redesign: Theoretical Cold (Installation) Load Must Not Be Specified. Old Spring DesignDocumento1 paginaOld Spring Redesign: Theoretical Cold (Installation) Load Must Not Be Specified. Old Spring DesignSOURAVNessuna valutazione finora

- Fans & Blowers-Calculation of PowerDocumento20 pagineFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Fans & Blowers-Calculation of PowerDocumento20 pagineFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- 3 CH 2Documento20 pagine3 CH 2Mary HarrisonNessuna valutazione finora

- Bureau of Energy EfficiencyDocumento23 pagineBureau of Energy Efficiencypbs0707Nessuna valutazione finora

- 3 - Constant Effort Support DesignDocumento1 pagina3 - Constant Effort Support DesignSOURAVNessuna valutazione finora

- CADWorx Equipment Console GuideDocumento2 pagineCADWorx Equipment Console GuideSOURAVNessuna valutazione finora

- 2 - Can DesignDocumento1 pagina2 - Can DesignSOURAVNessuna valutazione finora

- Simple Hanger Design GuideDocumento1 paginaSimple Hanger Design GuideSOURAVNessuna valutazione finora

- 4 - Existing Spring DesignDocumento1 pagina4 - Existing Spring DesignSOURAVNessuna valutazione finora

- 2 - Pipe and Hanger Support From VesselDocumento1 pagina2 - Pipe and Hanger Support From VesselSOURAVNessuna valutazione finora

- 5 - Multiple Can DesignDocumento1 pagina5 - Multiple Can DesignSOURAVNessuna valutazione finora

- Effects of Wind on StructuresDocumento5 pagineEffects of Wind on StructuresShoaib BhatiNessuna valutazione finora

- CFD Simulation For Predicting The Wind Effect On The High Rise Building: NET Tower SurabayaDocumento10 pagineCFD Simulation For Predicting The Wind Effect On The High Rise Building: NET Tower SurabayaIkhsan SetiawanNessuna valutazione finora

- Drying PlantsDocumento1 paginaDrying PlantsSOURAVNessuna valutazione finora

- Ulw 51Documento1 paginaUlw 51SOURAVNessuna valutazione finora

- 3 - Table 23.3Documento1 pagina3 - Table 23.3SOURAVNessuna valutazione finora

- Ulw 52Documento1 paginaUlw 52SOURAVNessuna valutazione finora

- 1 - Joint EfficiencyDocumento1 pagina1 - Joint EfficiencySOURAVNessuna valutazione finora

- Building An Online Shopping Cart Using C Sharp Part 2Documento17 pagineBuilding An Online Shopping Cart Using C Sharp Part 2TrungChanhNguyenNessuna valutazione finora

- BTech Seminar on MICROPILES: ADVANCED FOUNDATION ENGINEERINGDocumento17 pagineBTech Seminar on MICROPILES: ADVANCED FOUNDATION ENGINEERINGTrudeep DaveNessuna valutazione finora

- BingDocumento5 pagineBingdheaNessuna valutazione finora

- Ramcharan Plastic News Letter Issue 6 - September 2012Documento4 pagineRamcharan Plastic News Letter Issue 6 - September 2012Madan SainiNessuna valutazione finora

- Modern Control Technology Components & Systems (2nd Ed.)Documento2 pagineModern Control Technology Components & Systems (2nd Ed.)musarraf172Nessuna valutazione finora

- 2011 PG Parts CatalogDocumento181 pagine2011 PG Parts CatalogHaitem FarganiNessuna valutazione finora

- Essentials For A Good Night'S Sleep: Mattresses, Duvets and PillowsDocumento4 pagineEssentials For A Good Night'S Sleep: Mattresses, Duvets and PillowselizondomaruNessuna valutazione finora

- Object Oriented - AnalysisDocumento43 pagineObject Oriented - AnalysisAbdela Aman MtechNessuna valutazione finora

- Note-145 Biostat Prof. Abdullah Al-Shiha PDFDocumento157 pagineNote-145 Biostat Prof. Abdullah Al-Shiha PDFAdel Dib Al-jubeh100% (2)

- 431510nt PDFDocumento14 pagine431510nt PDFkbryantperez2012Nessuna valutazione finora

- VeinFinder_VE800 Brochure V1.0Documento2 pagineVeinFinder_VE800 Brochure V1.0hanrong912Nessuna valutazione finora

- List of Portmanteau Words: GeneralDocumento7 pagineList of Portmanteau Words: GeneraltarzanNessuna valutazione finora

- BBU - Maintenance User GuideDocumento578 pagineBBU - Maintenance User GuideSibte Hassan100% (2)

- Alejandrino, Michael S. Bsee-3ADocumento14 pagineAlejandrino, Michael S. Bsee-3AMichelle AlejandrinoNessuna valutazione finora

- Apple's Iphone Launch A Case Study in Effective MarketingDocumento7 pagineApple's Iphone Launch A Case Study in Effective MarketingMiguel100% (1)

- MVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressDocumento10 pagineMVVNL RGGVY Approved Vendor List: S.NO. Name of Material Vendor Name AddressELMEF LaboratoryNessuna valutazione finora

- Forbes Investor Jan2014 Master Buy List PDFDocumento1 paginaForbes Investor Jan2014 Master Buy List PDFForbesNessuna valutazione finora

- About The Business 1.1 Business Profile Positif CorporationDocumento7 pagineAbout The Business 1.1 Business Profile Positif CorporationLinh DalanginNessuna valutazione finora

- Personal PositioningDocumento4 paginePersonal PositioningJaveria MasoodNessuna valutazione finora

- Libro Desarrollo Organizacional Xady Nieto - AntiCopy - CompressedDocumento190 pagineLibro Desarrollo Organizacional Xady Nieto - AntiCopy - Compressedleandro cazarNessuna valutazione finora

- 02 - MDS System and ControlDocumento55 pagine02 - MDS System and Controlchinith100% (1)

- Market Plan On Vodafone vs. Pakistani OperatorsDocumento47 pagineMarket Plan On Vodafone vs. Pakistani OperatorswebscanzNessuna valutazione finora

- Strategic MGMT 4Documento33 pagineStrategic MGMT 4misbahaslam1986Nessuna valutazione finora

- Atheros Valkyrie BT Soc BriefDocumento2 pagineAtheros Valkyrie BT Soc BriefZimmy ZizakeNessuna valutazione finora

- Data Book: Automotive TechnicalDocumento1 paginaData Book: Automotive Technicallucian07Nessuna valutazione finora

- Pierre Schaeffer and The Theory of Sound ObjectsDocumento10 paginePierre Schaeffer and The Theory of Sound ObjectsdiegomfagundesNessuna valutazione finora

- Flux Cored Wires (Elga) PDFDocumento15 pagineFlux Cored Wires (Elga) PDFVladan TimotijevicNessuna valutazione finora

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Documento10 pagineDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYNessuna valutazione finora

- Default passwords for 3COM network devicesDocumento42 pagineDefault passwords for 3COM network devicesJamey ParkerNessuna valutazione finora

- Tm3 Transm Receiver GuideDocumento66 pagineTm3 Transm Receiver GuideAl ZanoagaNessuna valutazione finora