Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aws D1.1 - WPS - Smaw-Fcaw PDF

Caricato da

BernathTurnipTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aws D1.1 - WPS - Smaw-Fcaw PDF

Caricato da

BernathTurnipCopyright:

Formati disponibili

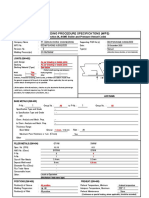

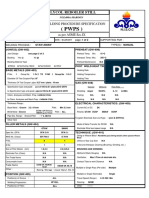

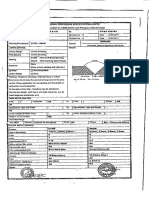

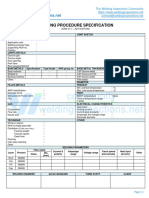

The Welding Inspections Community

https://www.weldinginspections.net

contact@weldinginspections.net

WELDING PROCEDURE SPECIFICATION

(AWS D1.1 – 2015 EDITION)

DESCRIPTION JOINT SKETCH

WPS no. : WIC-WPC-xx Rev. 00

Date of issue : dd-mmm-yyyy 60°

Applicable code : AWS D1.1 2015 Edition

Welding process/Type : FCAW / Semiauto

Supporting PQR no. : - n-1 n

Position : -

-

JOINTS DETAILS

T1

T2

- -

Groove type :

Groove angle : 2

Root opening : 1

Root face :

Back gouging : 3.2mm 1 mm

Method :

BASE METALS Specification Type/Grade AWS group no. BASE METAL THICKNESS As welded With PWHT

Base material - - I or II CJP Groove welds - -

Welded to - - I or II CJP Groove w/CVN - -

Backing material - - - PJP Groove welds - -

Other: - Fillet welds - -

DIAMETER 100mm and over

FILLER METALS PREHEAT

AWS classification :- Min. preheat temperature : ºC

Filler metal diameter :- Max. inter-pass temperature : ºC

Manufacturer/Trade name :- PWHT

PWHT temperature : None

Time at temperature range :-

T limits :-

SHIELDING GAS ELECTRICAL CHARACTERISTICS

Composition :- Max. heat input: :-

Flow rate :- Transfer mode :-

Nozzle size :- Current type & polarity: :-

A & V range :-

Power source type :-

TECHNIQUE

String or weave :- Number of electrodes :

Multi to single pass/side : Contact tube-to-work distance :

Oscillation (GTAW mech./Auto.) : Peening :

Traverse length : Inter-pass cleaning :

Traverse speed : Other :

Dwell time :

WELDING PARAMETERS

Filler metal Wire

Current & Travel speed Heat input

Layer Process Amp. Volt. feed Other

Class. Dia. polarity [mm/minute] [kJ/mm]

speed

Root FCAW

Hot FCAW

Fill FCAW

Cap FCAW

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

Page | 1

Potrebbero piacerti anche

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocumento6 pagineWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNessuna valutazione finora

- Wps - Asme Ix - Gtaw - PipaDocumento5 pagineWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocumento1 paginaAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNessuna valutazione finora

- ASME IX Sample WPS GTAW SMAWDocumento1 paginaASME IX Sample WPS GTAW SMAWDeepak ShrivastavNessuna valutazione finora

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocumento3 pagineWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNessuna valutazione finora

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Documento2 pagineWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNessuna valutazione finora

- GTAW Welding Process ParametersDocumento12 pagineGTAW Welding Process Parametersmiteshpatel191Nessuna valutazione finora

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Documento2 pagineWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNessuna valutazione finora

- WPS Api 1104Documento3 pagineWPS Api 1104miguelNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 pagineWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNessuna valutazione finora

- Wps - Asme Ix - Gtaw - Plat SteDocumento6 pagineWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Welder ID Card BRE KarahaDocumento5 pagineWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Welding Procedure Specification GuideDocumento2 pagineWelding Procedure Specification GuidepoulmackNessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- Welding Procedure Specification for Vertical Storage TanksDocumento6 pagineWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNessuna valutazione finora

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- 004 Gtaw P5aDocumento16 pagine004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocumento3 pagineWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNessuna valutazione finora

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 pagine(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Fit Up Welding Visual Inspection ReportDocumento2 pagineFit Up Welding Visual Inspection Reportgst ajah100% (1)

- WOPQ Form English1Documento2 pagineWOPQ Form English1oaperuchenaNessuna valutazione finora

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNessuna valutazione finora

- WPQ-1083 3G PDFDocumento2 pagineWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure SpecificationDocumento27 pagineWelding Procedure SpecificationGopakumar K100% (2)

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocumento1 paginaPT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNessuna valutazione finora

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 pagineList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNessuna valutazione finora

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- All Position Stainless Steel Welding ProcedureDocumento6 pagineAll Position Stainless Steel Welding ProcedureJaime PatrónNessuna valutazione finora

- WPS D1.6 Annex m1 PDFDocumento1 paginaWPS D1.6 Annex m1 PDFbollascribdNessuna valutazione finora

- Gtaw WPQDocumento3 pagineGtaw WPQMuhammadShabbirNessuna valutazione finora

- QW-484A (WPQ) GTAW 4MM FilletDocumento2 pagineQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 pagineWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WPS Sitelca S002Documento2 pagineWPS Sitelca S002Jose Antonio GomezNessuna valutazione finora

- Draft WPSDocumento3 pagineDraft WPSWale OyeludeNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- PQR Template (Asme)Documento2 paginePQR Template (Asme)jok1974Nessuna valutazione finora

- FIT UP ReportDocumento2 pagineFIT UP Reportsiva8000Nessuna valutazione finora

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocumento2 pagineASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNessuna valutazione finora

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 paginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Madina Group W.L.L. Procedure Qualification Record 152Documento38 pagineMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNessuna valutazione finora

- WPQR Welding Procedure Qualification RecordsDocumento3 pagineWPQR Welding Procedure Qualification Recordsramesh rajaNessuna valutazione finora

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocumento2 pagineGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNessuna valutazione finora

- Aws 001Documento1 paginaAws 001akshay sarfareNessuna valutazione finora

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocumento4 pagineWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNessuna valutazione finora

- WPS PQR PDFDocumento23 pagineWPS PQR PDFtomj9104Nessuna valutazione finora

- WPSDocumento2 pagineWPSAlam MD Sazid100% (1)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocumento2 pagineProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNessuna valutazione finora

- WPQ Sample PrintoutDocumento1 paginaWPQ Sample PrintoutKannan VelNessuna valutazione finora

- Sembcorp Marine Integrated Yard PteDocumento3 pagineSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Fit-Up Inspection Report PDFDocumento1 paginaFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- Welder qualification test recordDocumento3 pagineWelder qualification test recordTuTuy AnNessuna valutazione finora

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocumento5 pagineWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Consumables Control RegisterDocumento5 pagineWelding Consumables Control RegisterAli Mhaskar100% (2)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - SAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - SMAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNessuna valutazione finora

- Awsd1 191019041556 PDFDocumento1 paginaAwsd1 191019041556 PDFBiswasNessuna valutazione finora

- Pickling Passivation Procedure1Documento4 paginePickling Passivation Procedure1Er Md AamirNessuna valutazione finora

- OPS - 2 Engineer, QA/QCDocumento1 paginaOPS - 2 Engineer, QA/QCBernathTurnipNessuna valutazione finora

- 02 Manual Work Cycle Time AnalysisDocumento17 pagine02 Manual Work Cycle Time AnalysisBernathTurnipNessuna valutazione finora

- Zietsman Layout (2012)Documento71 pagineZietsman Layout (2012)Varun KumarNessuna valutazione finora

- API 571 QustionDocumento37 pagineAPI 571 QustionBernathTurnip100% (1)

- 27 PsychrometryDocumento16 pagine27 PsychrometryPRASAD326100% (1)

- API 570 Exam QuastionsDocumento18 pagineAPI 570 Exam QuastionsBernathTurnipNessuna valutazione finora

- New Fire Protective Intumescent CoatingsDocumento8 pagineNew Fire Protective Intumescent CoatingsBernathTurnipNessuna valutazione finora

- Joing LatterDocumento3 pagineJoing LatterBernathTurnipNessuna valutazione finora

- 1st Article On Total Quality Control by Feigenbaum-1956Documento9 pagine1st Article On Total Quality Control by Feigenbaum-1956BernathTurnipNessuna valutazione finora

- 27 PsychrometryDocumento16 pagine27 PsychrometryPRASAD326100% (1)

- 30 October 2021 Reading Passage 1 Mor EveDocumento5 pagine30 October 2021 Reading Passage 1 Mor EveBernathTurnipNessuna valutazione finora

- Relative Humidity TableDocumento1 paginaRelative Humidity TableHEPPYNessuna valutazione finora

- Quality Inspectors: For More InformationDocumento3 pagineQuality Inspectors: For More InformationBernathTurnipNessuna valutazione finora

- 27 PsychrometryDocumento16 pagine27 PsychrometryPRASAD326100% (1)

- 6.0 Dew Point TableDocumento1 pagina6.0 Dew Point TableBernathTurnipNessuna valutazione finora

- Relative Humidity TableDocumento1 paginaRelative Humidity TableHEPPYNessuna valutazione finora

- Dew Point Calculation Chart: For Adhesive and Coating Applications Ambient Air Temperature in Degrees FahrenheitDocumento1 paginaDew Point Calculation Chart: For Adhesive and Coating Applications Ambient Air Temperature in Degrees FahrenheitBernathTurnipNessuna valutazione finora

- Conf Iden Tial Prot Otyp E FT in Stru Ctio NS-: Elcometer 319 Dewpoint MeterDocumento41 pagineConf Iden Tial Prot Otyp E FT in Stru Ctio NS-: Elcometer 319 Dewpoint MeterBernathTurnipNessuna valutazione finora

- Soil Dynamic & EQ Engineering by B B PrasadDocumento583 pagineSoil Dynamic & EQ Engineering by B B PrasadBernathTurnip0% (1)

- Project Quality Management: 1 WWW - Cahyo.web - Id IT Project Management, Third Edition Chapter 8Documento45 pagineProject Quality Management: 1 WWW - Cahyo.web - Id IT Project Management, Third Edition Chapter 8cahyod100% (1)

- Emerging Materials For Civil - Infrastructure - State of The ArtDocumento46 pagineEmerging Materials For Civil - Infrastructure - State of The ArtBernathTurnipNessuna valutazione finora

- How To Calculate The Percent VOC and Density of A Multi-Part CoatingDocumento2 pagineHow To Calculate The Percent VOC and Density of A Multi-Part CoatingBernathTurnipNessuna valutazione finora

- Tabel RH (Tabel Kelembaban Relatif Berdasarkan Suhu Bola Basah Dan Suhu Bola Kering)Documento1 paginaTabel RH (Tabel Kelembaban Relatif Berdasarkan Suhu Bola Basah Dan Suhu Bola Kering)Derek Schultz100% (1)

- Vdocuments - MX - Quality Management Six SigmaDocumento23 pagineVdocuments - MX - Quality Management Six SigmaBernathTurnipNessuna valutazione finora

- 11 115en01Documento2 pagine11 115en01BernathTurnipNessuna valutazione finora

- Surveying Engineering & Instruments Valeria Shank 2012Documento108 pagineSurveying Engineering & Instruments Valeria Shank 2012BernathTurnipNessuna valutazione finora

- Teaching Six Sigma Quality With R: Emilio L. Cano, Javier M. Moguerza and Andres RedchukDocumento53 pagineTeaching Six Sigma Quality With R: Emilio L. Cano, Javier M. Moguerza and Andres RedchukBernathTurnipNessuna valutazione finora

- Surface CoatingDocumento18 pagineSurface Coatingaaftab ahmed100% (1)

- Ink PaintDocumento198 pagineInk PaintGovinda GajulaNessuna valutazione finora

- 4c - Expanded - RevisedDocumento132 pagine4c - Expanded - RevisedMartín Serena75% (4)

- Library Management System Project ReportDocumento50 pagineLibrary Management System Project ReportSURAJ GAMINGNessuna valutazione finora

- Search Engine Collocations Frequency PhrasesDocumento2 pagineSearch Engine Collocations Frequency PhrasesDinda NoviarmachdaNessuna valutazione finora

- Answers About HubSpotDocumento1 paginaAnswers About HubSpotPrasetyaNessuna valutazione finora

- Ite 001aDocumento6 pagineIte 001ajoshuaNessuna valutazione finora

- Geo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterDocumento5 pagineGeo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterVinod Vincy67% (3)

- Astm D-2361Documento4 pagineAstm D-2361Claudia Da Rolt0% (1)

- Timeline of Programming Languages PDFDocumento11 pagineTimeline of Programming Languages PDFMohd Khir ZainunNessuna valutazione finora

- Programmability in SPSS 16 & 17, Jon PeckDocumento36 pagineProgrammability in SPSS 16 & 17, Jon PeckJasmin MaricNessuna valutazione finora

- BSC Prospectus 2019-20Documento37 pagineBSC Prospectus 2019-20Gaurav VamjaNessuna valutazione finora

- Sean Dickerson ResumeDocumento3 pagineSean Dickerson ResumeSeanNessuna valutazione finora

- Needle System Guide For Old Industrial Singer Sewing MachinesDocumento4 pagineNeedle System Guide For Old Industrial Singer Sewing MachinesWilberth FrancoNessuna valutazione finora

- Audio (Amplifier) - Electrical DiagnosticsDocumento195 pagineAudio (Amplifier) - Electrical DiagnosticsRafael CherechesNessuna valutazione finora

- The Causes of Shear Cracking in Prestressed Concrete Box Girder BridgesDocumento10 pagineThe Causes of Shear Cracking in Prestressed Concrete Box Girder BridgesVipin Kumar ParasharNessuna valutazione finora

- General Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDocumento1 paginaGeneral Ledger Senior Accountant in Charlotte NC Resume Diana ShipeDianaShipeNessuna valutazione finora

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Documento5 pagineLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNessuna valutazione finora

- Ref Paper 2Documento4 pagineRef Paper 2Subhanjali MyneniNessuna valutazione finora

- Study of Step Up & Step Down Transformer: Experiment 9Documento3 pagineStudy of Step Up & Step Down Transformer: Experiment 9Apna VeerNessuna valutazione finora

- Dsd-060 Earthquake Shutdown Unit: DescriptionDocumento2 pagineDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifNessuna valutazione finora

- Touch Panel Debug Info Register ValuesDocumento17 pagineTouch Panel Debug Info Register ValuesAlghazyNessuna valutazione finora

- D72140GC10 46777 UsDocumento3 pagineD72140GC10 46777 UsWilliam LeeNessuna valutazione finora

- Gpa 2145Documento15 pagineGpa 2145Sergio David Ruiz100% (1)

- Holux M-1000C Bluetooth GPS Logger Manual GuideDocumento22 pagineHolux M-1000C Bluetooth GPS Logger Manual Guidenabiloo2003Nessuna valutazione finora

- Factors Effecting PerformanceDocumento47 pagineFactors Effecting Performancebembie83Nessuna valutazione finora

- RS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1Documento2 pagineRS-485 2X227 AWG SFUTP PVC - 9FY7F1V129 - V - 1 - R - 1jeffv65Nessuna valutazione finora

- Inspection and Maintenance of Drillpipe Ebook PDFDocumento39 pagineInspection and Maintenance of Drillpipe Ebook PDFAntónio OliveiraNessuna valutazione finora

- Sample Lab ReportDocumento4 pagineSample Lab ReportHolley WrightNessuna valutazione finora

- Design Rules CMOS Transistor LayoutDocumento7 pagineDesign Rules CMOS Transistor LayoututpalwxyzNessuna valutazione finora

- Stereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010Documento50 pagineStereoscopic Restitution Instruments: Materi Kuliah GD3204 Fotogrametri I, Semester I-2009/2010ththaalNessuna valutazione finora

- Zhao PeiDocumento153 pagineZhao PeiMuhammad Haris HamayunNessuna valutazione finora