Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mpi 1012

Caricato da

Muhamad Faizal RosliTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mpi 1012

Caricato da

Muhamad Faizal RosliCopyright:

Formati disponibili

KSKV SVM 2017

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULUM

COURSE INFORMATION

PROGRAMME : INDUSTRIAL MACHINING TECHNOLOGY

COURSE NAME : FUNDAMENTAL OF WORKSHOP TECHNOLOGY

COURSE CODE : MPI 1012

LEVEL / SEMESTER : 2 SEMESTER 1

CREDIT UNIT : 2.0

CONTACT HOUR FACE TO FACE : 4.0 HOURS/WEEK

NON FACE TO FACE :

COURSE TYPE : VOCATIONAL

PRE-REQUISITE : -

CORE REQUISITE : -

MPI 1012 Document Page 1/14

KSKV SVM 2017

COURSE OUTCOMES

At the end of the course, the students should be able to:-

1. Follow workplace procedures for hazard identification, select and safety guide usage workplace tools and equipment, service and maintain

work tools and equipment

2. Identify product specification to be measured, select measuring instrument and set measuring instrument to zero setting

3. Carry out inspection with measuring instrument

4. Carry out measuring instrument storage

5. Physical properties of Ferrous and non-Ferrous metal

6. Manufacture of ferrous metal and classification of steel

COURSE DESCRIPTION

The course describe the competency in workshop safety, measuring instrument handling and identify the properties of metal. He or she is the

person at the work area to handle measuring instrument.

The person who is competent in this course shall be able to follow workplace procedures for hazard identification, select and safety guide usage

workplace tools and equipment, service and maintain work tools and equipment, select measuring instrument, identify product specification to be

measured, set measuring instrument to zero setting, carry out inspection with measuring instrument, carry out measuring instrument storage,

identify the physical properties of Ferrous and non-Ferrous metal, manufacture of ferrous metal and classification of steel.

The outcome of this course is to provide excellent in handling measuring instrument according to company’s policy, rules and regulation.

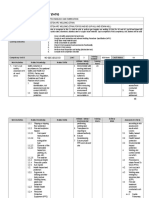

CONTENT AND LEARNING STANDARDS

MPI 1012 Document Page 2/14

KSKV SVM 2017

PROGRAMME : INDUSTRIAL MACHINING TECHNOLOGY

COURSE NAME : FUNDAMENTAL OF WORKSHOP TECHNOLOGY

CODE NAME : MPI 1012

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

(RELATED KNOWLEDGE / APPLIED SKILLS

(TRAINING DURATION) (WORK ACTIVITIES) ASSESSMENT CRITERIA

/ ATTITUDE / SAFETY / ENVIRONMENTAL)

8 HOURS 1.0 PERFORM RELATED KNOWLEDGE ASSESSMENT CRITERIA

(2 WEEKS) WORKSHOP SAFETY

1.1 Prepare for work 1.1 Identify Occupational Health

1.2 Follow basic security procedures & Hazards

1.3 Carry out basic first aid 1.2 Apply safety at workplace

1.4 Clean up work area and maintain equipment 1.3 Identify Accident Prevention

Techniques

1.4 Identify Fire Prevention &

Protection

1.5 Identify tools and equipment

safety rules

APPLIED SKILLS PERFORMANCE CRITERIA

1.1 Practice of Safety 1.1 Safety rules according to

1.2 Personal Protective job’s specifications and

1.3 Fire Safety and Extinguisher standards identified.

1.4 Machine safeguarding 1.2 Equipment and work area for

1.5 Respiratory Protection service able condition

1.6 Emergency Wash inspected in accordance with

work place.

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

(RELATED KNOWLEDGE / APPLIED SKILLS

MPI 1012 Document Page 3/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) / ATTITUDE / SAFETY / ENVIRONMENTAL) ASSESSMENT CRITERIA

1.3 Applicable tools and

equipment to meet the job

requirement and standard

identified.

1.4 Work area and equipment

were cleaned-up and

maintained in according to

Standard Operating

Procedure (SOP)

ATTITUDE / SAFETY / ENVIRONMENTAL

Safety:

1.1 Handle material with care

1.2 Ensure Personal Protective Equipment (PPE)

meet Safety Regulation & Standard

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

(RELATED KNOWLEDGE / APPLIED SKILLS

MPI 1012 Document Page 4/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) / ATTITUDE / SAFETY / ENVIRONMENTAL) ASSESSMENT CRITERIA

8 HOURS 2.0 IDENTIFY PRODUCT RELATED KNOWLEDGE ASSESSMENT CRITERIA

(2 WEEKS) SPECIFICATION TO

BE MEASURED 2.1 Product drawing 2.1 Interpret limits and fits

Limits and fits 2.2 Interpret product dimension

Product dimension 2.3 Interpret surface finish

Surface finish 2.4 Interpret drawing symbol

Drawing symbol 2.5 Determine critical dimensions

Critical dimensions 2.6 Interpret orthographic

Orthographic projection view projection view.

APPLIED SKILLS PERFORMANCE CRITERIA

2.1 Interpret product drawing 1.

limits and fits 2.

Product dimension 2.1. Product dimensions

Surface finish confirmed in accordance with

Drawing symbol specification requirement.

Critical dimensions 2.2. Product accuracy confirmed

Orthographic projection view in accordance with drawing

specification.

ATTITUDE / SAFETY / ENVIRONMENTAL

Attitude:

2.1 Observe cleanliness during handling drawing

document

LEARNING STANDARD

CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 5/14

KSKV SVM 2017

CONTACT HOURS (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

(TRAINING DURATION) / ATTITUDE / SAFETY / ENVIRONMENTAL)

11 HOURS 3.0 SELECT MEASURING RELATED KNOWLEDGE ASSESSMENT CRITERIA

INSTRUMENT

3.1 Type of measuring instrument and application 3.1 Determine type of measuring

such as: instrument and application

Micrometer 3.2 Determine the dimension unit

Vernier Caliper 3.3 Determine measuring

Vernier Height Gauge instrument accuracy

3.2 Dimension unit 3.4 Decide on measuring

3.3 Measuring instrument accuracy instrument

APPLIED SKILLS PERFORMANCE CRITERIA

3.1 Determine type of measuring instrument and 2.

application 3.

3.2 Determine dimension unit 3.1 Type of measuring

3.3 Determine measuring instrument accuracy instrument listed in

3.4 Decide on measuring instrument accordance with dimensions

specification.

3.2 Measuring instrument

functionality confirmed in

accordance with measuring

ATTITUDE / SAFETY / ENVIRONMENTAL instrument requirements.

Attitude:

3.1 Meticulous in measuring instrument handling

Safety:

3.1 Handle instrument with care

3.2 Adhere to safety requirement

LEARNING STANDARD

CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 6/14

KSKV SVM 2017

CONTACT HOURS (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

(TRAINING DURATION) / ATTITUDE / SAFETY / ENVIRONMENTAL)

9 HOURS 4.0 SET MEASURING RELATED KNOWLEDGE ASSESSMENT CRITERIA

INSTRUMENT TO

ZERO SETTING. 4.1 Gauge block application 4.1 Identify gauge block

4.2 Measuring instrument range application

4.3 Measuring instrument zeroing 4.2 Determine measuring

instrument range

4.3 Perform measuring

instrument zeroing

APPLIED SKILLS PERFORMANCE CRITERIA

4.1 Identify gauge block application 4.1 Measuring instrument zero

4.2 Identify measuring instrument range setup in accordance

4.3 Perform measuring instrument zeroing. measuring instrument

requirements

ATTITUDE / SAFETY / ENVIRONMENTAL

Attitude:

4.1 Handle instrument with care

Safety:

4.1 Adhere to safety requirement

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 7/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

/ ATTITUDE / SAFETY / ENVIRONMENTAL)

32 HOURS 5.0 CARRY OUT RELATED KNOWLEDGE ASSESSMENT CRITERIA

(8 WEEKS) INSPECTION WITH

MEASURING 5.1 Product surface/shape 5.1 Determine product

INSTRUMENT 5.2 Measuring instrument handling method surface/shape

5.3 Measuring and reading techniques 5.2 Apply measuring instrument

5.4 Measuring result handling method

5.3 Explain measuring and

reading techniques

5.4 Record measuring result

APPLIED SKILLS PERFORMANCE CRITERIA

5.1 Determine product surface/shape 5.1 Measuring instrument

5.2 Apply measuring instrument handling method utilized in accordance with

5.3 Apply measuring and reading techniques drawing specification.

5.4 Record measuring result

ATTITUDE / SAFETY / ENVIRONMENTAL

Attitude:

5.1 Handle instrument with care

5.2 Aware of burrs and sharp edges

Safety:

5.1 Adhere to safety requirement

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 8/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

/ ATTITUDE / SAFETY / ENVIRONMENTAL)

4 HOURS 6.0 CARRY OUT RELATED KNOWLEDGE ASSESSMENT CRITERIA

(1 WEEKS) MEASURING

INSTRUMENT 6.1 Storage handling 6.1 Determine storage handling

STORAGE 6.2 Cleanliness of measuring instruments 6.2 Perform cleanliness of

6.3 Measuring instrument condition measuring instruments

6.4 Proper storage 6.3 Check measuring instrument

condition

6.4 Perform proper storage

APPLIED SKILLS PERFORMANCE CRITERIA

6.1 Identify storage handling 6.1 Measuring instrument storage

6.2 Perform cleanliness of measuring instruments determined in accordance

6.3 Check measuring instrument condition with safety requirement.

6.4 Perform proper storage

ATTITUDE / SAFETY / ENVIRONMENTAL

Attitude:

6.1 Handle measuring instrument with care

6.2 Clean instrument before storage

Safety:

6.3 Adhere to safety requirement

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 9/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

/ ATTITUDE / SAFETY / ENVIRONMENTAL)

8 HOURS 7.0 PROPERTIES OF RELATED KNOWLEDGE ASSESSMENT CRITERIA

(2 WEEKS) METAL

7.1 Physical properties of metal 7.1 Identify properties of metal

Metallic luster according to types of Iron and

Good conductor of electricity steel.

Malleable and ductile 7.2 Identify and differentiate

Reflect light ferrous and nonferrous metal

Produce metallic sound upon strike and their uses according to

Generally solid. the specifications.

7.3 Identify the use of ferrous and

7.2 Ferrous and non-Ferrous metal non-ferrous metal

7.4 Identify and understand steel

7.3 Type of ferrous metal: making process according to

manufacturer specifications.

Cast iron

7.5 Identify and understand steel

Wrought iron

making process according to

Steel manufacturer specifications.

7.6 Identify the chemical

7.4 Type of non-ferrous metal composition and alloying

Copper element on steel to the

Aluminium required specification.

Silver 7.7 Identify steel classifications

Gold system follow the

Tin international steel standard

such as American Iron Steel

7.5 Manufacture of ferrous metals Institute (AISI)/ British Iron

Iron making and Steel (BIS)

Steel making

Continuous casting

Rolling mill

Main product

LEARNING STANDARD

CONTACT HOURS CONTENT STANDARD PERFORMANCE CRITERIA /

MPI 1012 Document Page 10/14

KSKV SVM 2017

(TRAINING DURATION) (WORK ACTIVITIES) (RELATED KNOWLEDGE / APPLIED SKILLS ASSESSMENT CRITERIA

/ ATTITUDE / SAFETY / ENVIRONMENTAL)

7.6 Type of alloy

Stainless steel

Brass

Pewter

High speed steel

High carbon steel

7.7 Alloying element:

Carbon

Chromium

Nickel

Molybdenum

Niobium

Manganese

7.8 Classification of steel

Carbon steels

Nickel steels

Nickel chromium steels

Molybdenum steels

Chromium steels

Chromium vanadium steels

Tungsten steels

Nickel chromium molibdenum steels

Silicon manganese steels

ATTITUDE / SAFETY / ENVIRONMENTAL

Attitude:

7.1 Handle measuring instrument with care

Safety:

7.3 Adhere to safety requirement

EMPLOYABILITY SKILLS

MPI 1012 Document Page 11/14

KSKV SVM 2017

Core Abilities Social Skills

01.01 Identify and gather information 1. Communication skills

01.02 Document information, procedures or processes 2. Conceptual skills

02.01 Interpret and follow manuals, instructions and SOP’s 3. Interpersonal skills

02.03 Communicate clearly 4. Learning skills

02.04 Prepare brief reports and checklists using standard forms 5. Leadership skills

02.05 Read/interpret flowcharts and pictorial information 6. Multitasking and prioritizing

03.02 Demonstrate integrity and apply ethical practices 7. Self-discipline

03.03 Accept responsibility for own work and work area 8. Teamwork

03.04 Seek and act constructively upon feedback about performance

03.05 Demonstrate safety skills

03.06 Respond appropriately to people and situations

06.02 Comply with and follow chain of command

06.03 Identify and highlight problems

06.04 Adapt competencies to new situations / systems

01.04 Analyse information

03.08 Develop and maintain a cooperation within work group

04.01 Organize own work activities

04.02 Set and revise own objectives and goals

04.03 Organize and maintain own workplace

04.04 Apply problem solving strategies

04.05 Demonstrate initiative and flexibility

TOOLS, EQUIPMENT AND MATERIALS (TEM)

ITEMS RATIO (TEM : Trainees)

1. Measuring instruments 1:10

MPI 1012 Document Page 12/14

KSKV SVM 2017

2. Measuring instrument cabinet 1:25

3. Measuring instrument accessories 1:5

4. Measuring instrument charts and posters 1:25

5. Product drawing 1:1

6. Cutting Tools 1:1

7. Workpiece 1:1

8. Check sheet 1:1

9. Flipchart 1:25

10. Surface table 1:15

11. Surface roughness comparator 1:10

12. Drilling Machine and Drill Bits 1:10

REFERENCES

1. Heinrich H.W. “Industrial Accident Prevention” McGraw-Hill Company, New York, 1980.

2. Krishnan N.V. “Safety Management in Industry” Jaico Publishing House, Bombay, 1997.

3. Lees, F.P., “Loss Prevention in Process Industries” Butterworth publications, London, 2nd edition, 1990.

4. John Ridley, “Safety at Work”, Butterworth and Co., London, 1983.

5. Dan Petersen, “Techniques of Safety Management”, McGraw-Hill Company, Tokyo, 1981.

6. Relevant India Acts and Rules, Government of India.

7. Relevant Indian Standards and Specifications, BIS, New Delhi.

MPI 1012 Document Page 13/14

KSKV SVM 2017

8. Blake R.B., “Industrial Safety” Prentice Hall, Inc., New Jersey, 1973.

9. “Safety and Good House Keeping”, N.P.C., New Delhi, 1985.

10. “Accident Prevention Manual for Industrial Operations”, N.S.C.Chicago, 1982.

11. Journal by Insurance company surveyors and loss assessors – Mumbai – published

12. R.S Sirohi, H.C. Radha Krishna (1991), Mechanical Measurements, John Wiley & Sons, ISBN 978-8-12-240383-1

13. Francis T. Farago, Mark Curtis (1994), Handbook of Dimensional Measurement, ISBN 978-0-83-113053-4

14. Colin H. Simmon, Dennis E. Maguire (2004) Manual Engineering Drawing, second edition ISBN 075065120-5

15. T.E Aaron, Gary Adam (1995) Handbook Machining Volume 16, ISBN 0-87170-007-79(V.1)

16. James Brown (1998) Advance Machining Technology Handbook, Mc. Graw- Hill ISBN 0-07-008243

17. Geoffrey Boothroyd,Winstona. KnightFundamentals of Machining and Machine Tool ISBN 1-57444-659-2

18. G.R Nagpal (2000) Machine Tool Engineering, Khanna Publishers ISBN 81-7409-046-0

MPI 1012 Document Page 14/14

Potrebbero piacerti anche

- MPI 1012 - Measuring Instrument ApplicationDocumento12 pagineMPI 1012 - Measuring Instrument ApplicationSyazwan ManshorNessuna valutazione finora

- Safety Practices and Procedures: Module Page 1/7 Document Page 1Documento8 pagineSafety Practices and Procedures: Module Page 1/7 Document Page 1Cikgu Azry Azeem PetronessaNessuna valutazione finora

- Etn1023 - Instrument and Test Equipment Set Up & HandlingDocumento14 pagineEtn1023 - Instrument and Test Equipment Set Up & Handlingnoor atikah allias50% (2)

- HKM 1013 Introduction To CosmetologyDocumento10 pagineHKM 1013 Introduction To CosmetologyLAILA MASTURANessuna valutazione finora

- Etn1023 - Instrument and Test Equipment Set Up & HandlingDocumento14 pagineEtn1023 - Instrument and Test Equipment Set Up & HandlingAngelinaNessuna valutazione finora

- Health and Safety Lo1Documento6 pagineHealth and Safety Lo1Md RizveeNessuna valutazione finora

- Etn 1024 - Instrument and Test Equipment Set Up HandlingDocumento14 pagineEtn 1024 - Instrument and Test Equipment Set Up HandlingpijaazizNessuna valutazione finora

- 02 CoCU - C1 - L3Documento24 pagine02 CoCU - C1 - L3Kobe FredNessuna valutazione finora

- 4.basic Practice Occupational Health and Safety ProceduresDocumento20 pagine4.basic Practice Occupational Health and Safety ProceduresEric SantosNessuna valutazione finora

- Curriculum of Competency Unit (Cocu)Documento21 pagineCurriculum of Competency Unit (Cocu)Syah RiezalNessuna valutazione finora

- Curriculum of Competency Unit (Cocu)Documento20 pagineCurriculum of Competency Unit (Cocu)Syah RiezalNessuna valutazione finora

- MTK 1012 Safety Practice and ProceduresDocumento18 pagineMTK 1012 Safety Practice and ProceduresMR FIKRINessuna valutazione finora

- Curriculum of Competency Unit (Cocu)Documento21 pagineCurriculum of Competency Unit (Cocu)Syah RiezalNessuna valutazione finora

- Contoh Teaching OutlineDocumento4 pagineContoh Teaching OutlineNorazzah AbdullahNessuna valutazione finora

- Apply Safety Practices CLMDocumento127 pagineApply Safety Practices CLMRonaldo CruzNessuna valutazione finora

- CoCU - CU6Documento21 pagineCoCU - CU6nizam1372Nessuna valutazione finora

- 1) Co - DMD 1213 Workshop PracticeDocumento8 pagine1) Co - DMD 1213 Workshop PracticeShahrizan abdul rahmanNessuna valutazione finora

- C Ability L1-NCS M1Documento3 pagineC Ability L1-NCS M1mohdazizan5019Nessuna valutazione finora

- K To 12 CG - Nail Care - v1.0Documento5 pagineK To 12 CG - Nail Care - v1.0ROWELYN DIPOSONessuna valutazione finora

- OccupationDocumento5 pagineOccupationonchiriemmanuel891Nessuna valutazione finora

- Syllabus For The Trade of Security Guard PDFDocumento24 pagineSyllabus For The Trade of Security Guard PDFabhi13Nessuna valutazione finora

- LESSON PLAN-2-Follow Principles of Occupational Health and SafetyDocumento5 pagineLESSON PLAN-2-Follow Principles of Occupational Health and Safetyjaglall chandNessuna valutazione finora

- Safety Behavior and Safety at Work Program DaraDocumento3 pagineSafety Behavior and Safety at Work Program DaraSayed Saad ShehataNessuna valutazione finora

- OHSISA Brochure A5 MailerDocumento8 pagineOHSISA Brochure A5 MailerjusticeNessuna valutazione finora

- X054 - SPEC-Saipem Safety Reporting ProceduresDocumento1 paginaX054 - SPEC-Saipem Safety Reporting ProceduresMehdi MessNessuna valutazione finora

- Curguide NailcareDocumento5 pagineCurguide NailcareOlive AsuncionNessuna valutazione finora

- Ohs Technical CompetenceDocumento10 pagineOhs Technical Competencecarlsonelectrical2015Nessuna valutazione finora

- RSL StewardingDocumento8 pagineRSL StewardingZila Saidin0% (1)

- Safety Training ProspectusDocumento24 pagineSafety Training ProspectusYourSafety100% (2)

- BSHS 1201 - Revamped - 2020 - V.5Documento201 pagineBSHS 1201 - Revamped - 2020 - V.5Hbdhd HhdhdvdvdgdNessuna valutazione finora

- CBLM Basic 4Documento24 pagineCBLM Basic 4Roi Jason De TorresNessuna valutazione finora

- KSKV HSK 3042Documento16 pagineKSKV HSK 3042NAZEERAH BT SHAIPOL MoeNessuna valutazione finora

- NEBOSH IGC-Course BrochureDocumento5 pagineNEBOSH IGC-Course Brochuredynamic_boy_007Nessuna valutazione finora

- MTK 1012 Safety Practice and ProceduresDocumento18 pagineMTK 1012 Safety Practice and ProceduresHidayat IzharNessuna valutazione finora

- DLL EIM11 1stSem1stQuarter Week1Documento4 pagineDLL EIM11 1stSem1stQuarter Week1Gelo Dela TorreNessuna valutazione finora

- Obtl Course Syllabus (Safety MGT)Documento4 pagineObtl Course Syllabus (Safety MGT)Floravie Oñate-AsombradoNessuna valutazione finora

- MODULES OF INSTRUCTION Commonsmawnc1Documento51 pagineMODULES OF INSTRUCTION Commonsmawnc1KaJong JaclaNessuna valutazione finora

- CBLM Smaw Ncii 2023com1Documento23 pagineCBLM Smaw Ncii 2023com1Marco ArellanoNessuna valutazione finora

- Course Outline 1st To 3rd TrimDocumento13 pagineCourse Outline 1st To 3rd TrimJoma RupisanNessuna valutazione finora

- SafetyOperatorDocumento18 pagineSafetyOperatorMUHXMMXD RXKIMNessuna valutazione finora

- Kurikulum Unit Kompetensi C01Documento8 pagineKurikulum Unit Kompetensi C01Mohamad Afiq Akmal Bin Mohd NizamNessuna valutazione finora

- CBLM OccupatinalDocumento78 pagineCBLM OccupatinalzaironaireNessuna valutazione finora

- Implement Occupational Health and Safety Procedures: D1.HRS - CL1.07 D1.HOT - CL1.03 D2.TCC - CL1.03 Assessor ManualDocumento44 pagineImplement Occupational Health and Safety Procedures: D1.HRS - CL1.07 D1.HOT - CL1.03 D2.TCC - CL1.03 Assessor ManualJohn brylle LlemitNessuna valutazione finora

- Occupational Health12ettDocumento28 pagineOccupational Health12ettMore Power CCNessuna valutazione finora

- Basic Fitter Module-1Documento18 pagineBasic Fitter Module-1LPK GEWELDNessuna valutazione finora

- Eim CBC NewDocumento78 pagineEim CBC NewRalfh Pescadero De Guzman71% (14)

- MTK 1032 Mechanical CuttingDocumento17 pagineMTK 1032 Mechanical CuttingMR FIKRINessuna valutazione finora

- Session Plan CAUBADocumento2 pagineSession Plan CAUBATRESHIA ANNE P. CALIBNessuna valutazione finora

- Objectives KPI 24Documento16 pagineObjectives KPI 24Senthilmani MuthuswamyNessuna valutazione finora

- New Hire Orientation: /conversion/tmp/scratch/436610580Documento2 pagineNew Hire Orientation: /conversion/tmp/scratch/436610580malik jahanNessuna valutazione finora

- L4 CoCU 6 Facilities and Equipment Coordination Mac2015Documento5 pagineL4 CoCU 6 Facilities and Equipment Coordination Mac2015Nurul Huda AliNessuna valutazione finora

- Cpccohs2001a - Module 1Documento32 pagineCpccohs2001a - Module 1Nazareno BalagaNessuna valutazione finora

- Common APPLY SAFETY PRACTICESDocumento25 pagineCommon APPLY SAFETY PRACTICESvalcyrusNessuna valutazione finora

- OAP - Common CompetenciesDocumento13 pagineOAP - Common CompetenciesFe Marie JisonNessuna valutazione finora

- Course Outline-Hotel Security Operations-300 Hours-EditedDocumento3 pagineCourse Outline-Hotel Security Operations-300 Hours-Editedzoltan2014Nessuna valutazione finora

- Mem11011b R1Documento8 pagineMem11011b R1Baladev SuraganiNessuna valutazione finora

- The UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseDa EverandThe UL 4600 Guidebook: What to Include in an Autonomous Vehicle Safety CaseNessuna valutazione finora

- Safety Fundamentals and Best Practices in Construction IndustryDa EverandSafety Fundamentals and Best Practices in Construction IndustryNessuna valutazione finora

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveDa EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveNessuna valutazione finora

- Reliability, Maintainability and Risk: Practical Methods for EngineersDa EverandReliability, Maintainability and Risk: Practical Methods for EngineersValutazione: 4.5 su 5 stelle4.5/5 (3)

- Guidelines On Use of Glass in Buildings Human SafetyDocumento31 pagineGuidelines On Use of Glass in Buildings Human Safetyg1n2Nessuna valutazione finora

- SDRRM Work Plan 2020-2021Documento26 pagineSDRRM Work Plan 2020-2021Ariane Ignao Lagatic100% (2)

- Manual MotomanDocumento64 pagineManual MotomanAriel BritoNessuna valutazione finora

- Catalogo Sherwood GLPDocumento87 pagineCatalogo Sherwood GLPMiller Alexander Mora VargasNessuna valutazione finora

- Risk Acceptance CriteriaDocumento11 pagineRisk Acceptance Criteriabaaziz2015Nessuna valutazione finora

- Msds - MEK 1 1Documento6 pagineMsds - MEK 1 1Ishaan RajNessuna valutazione finora

- E6-5 Fire Detection & Fire Alarm SystemDocumento70 pagineE6-5 Fire Detection & Fire Alarm SystemtitanwlxNessuna valutazione finora

- Hazop Surface Gas and Mud Handling Systems During Drilling OperationsDocumento14 pagineHazop Surface Gas and Mud Handling Systems During Drilling OperationsTee Shi FengNessuna valutazione finora

- ITH Bolting Tools For Liebherr Cranes WebDocumento12 pagineITH Bolting Tools For Liebherr Cranes Webphuocloi82Nessuna valutazione finora

- Risk-Ahu Fcu FansDocumento5 pagineRisk-Ahu Fcu FansUmair Liaqat75% (4)

- ADMM 2017 Artistic Denim Mills Limited - Text.markedDocumento78 pagineADMM 2017 Artistic Denim Mills Limited - Text.markedMuqaddas KhalidNessuna valutazione finora

- Public Arrest Report For 14aug2015Documento4 paginePublic Arrest Report For 14aug2015api-214091549Nessuna valutazione finora

- Screw Compressor Packages Grasso SP1 Large SeriesDocumento88 pagineScrew Compressor Packages Grasso SP1 Large SeriesManuel MartinezNessuna valutazione finora

- 47Documento7 pagine47Rohan ShresthaNessuna valutazione finora

- Factory Acceptance Test Checklist - SafetyCultureDocumento9 pagineFactory Acceptance Test Checklist - SafetyCultureMAT-LIONNessuna valutazione finora

- Livelihood PackageDocumento147 pagineLivelihood PackageMA VicNessuna valutazione finora

- Method Statement For Attending Fire Fighting Snag WorksDocumento8 pagineMethod Statement For Attending Fire Fighting Snag Worksfawzar100% (1)

- Site Safety Supervisor Competency Course: Part VI (O) - Occupational Safety Tunneling Work SafetyDocumento27 pagineSite Safety Supervisor Competency Course: Part VI (O) - Occupational Safety Tunneling Work SafetyHelmi LadinNessuna valutazione finora

- Motoman XRC Concurrent IO and Parameter ManualDocumento340 pagineMotoman XRC Concurrent IO and Parameter ManualsunhuynhNessuna valutazione finora

- Forms 3.1-3.10 Regional Assessment - CMDocumento45 pagineForms 3.1-3.10 Regional Assessment - CMDilg Quezon Cluster INessuna valutazione finora

- 01 AR DFMEA - TemplateDocumento3 pagine01 AR DFMEA - TemplateAndrew DoNessuna valutazione finora

- Liquid Coagulant PDFDocumento11 pagineLiquid Coagulant PDFMithil SawantNessuna valutazione finora

- Safety Data Sheet: Section 1. IdentificationDocumento11 pagineSafety Data Sheet: Section 1. IdentificationSarmad HussainNessuna valutazione finora

- .:R Ljwp. : Contractor'S Superintendence Experience - General (Form J-2 Key Personnel Experience)Documento37 pagine.:R Ljwp. : Contractor'S Superintendence Experience - General (Form J-2 Key Personnel Experience)anandeee88Nessuna valutazione finora

- Sodium Hypochlorite Tech MsdsDocumento4 pagineSodium Hypochlorite Tech MsdsÖzlem ÖzkiliçNessuna valutazione finora

- Project Engineer AdsDocumento2 pagineProject Engineer Adsayiep1202Nessuna valutazione finora

- MSDS Fire Retardant Solvent BasedDocumento4 pagineMSDS Fire Retardant Solvent BasedSalah Abd EldayemNessuna valutazione finora

- Produce Organic Concoction and Extract: Organic Agriculture Production NC IIDocumento3 pagineProduce Organic Concoction and Extract: Organic Agriculture Production NC IIAeronn Jass SongaliaNessuna valutazione finora

- Aircraft Information and Checklists: MaintenanceDocumento16 pagineAircraft Information and Checklists: MaintenanceQr CodeNessuna valutazione finora