Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Application Note AN-Lift-0019v114EN Brake Checking Signal For UCM Compliance (EN81-1 + A3)

Caricato da

sg mesTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Application Note AN-Lift-0019v114EN Brake Checking Signal For UCM Compliance (EN81-1 + A3)

Caricato da

sg mesCopyright:

Formati disponibili

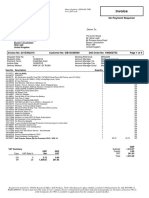

APPLICATION NOTE AN-Lift-0019v114EN

Brake checking signal for UCM compliance (EN81-1 + A3)

Inverter type FRENIC-Lift

Software version Software version 1750/1751 and later

Required options Not needed

Related documentation INR-SI47-1038b-E_FRENIC Lift_Instruction Manual.pdf

INR-SI47-1068b-E_Lift_Reference Manual.pdf

INR-SI47-1092b-E_Lift_Multifunction Keypad panel

Instruction Manual.pdf

Author Jaume Alonso

Use Public, web

Date 10/04/2012

Version 1.1.4

Languages English

1. Introduction.

From January 2012 lift standard EN 81-1:1998+A3:2009 has to be applied. A3

addendum is related to Unintended Car Movement (UCM).

In case of electrical traction lifts, one possible solution to fulfill the new A3

addendum of the EN81-1 standard, is to use the two brakes certified according

to this standard and additionally monitor their status individually, by using one

limit switch for each brake that detects the actual brake status (released or

applied). If the detected brake status is not correct the operation of the elevator

must be prevented.

On this application note, it is explained how to program and use a specific

function for brake monitoring signal (BRKE1, BRKE2).

2. How to recognize inverters which UCM function available.

Basically, all standard family of FRENIC-Lift inverter (European version), with

the software number mentioned on the description of the document (or later

versions), will have this function available. There are two name plates on the

inverter where inverter type is written. Both name plates are shown in figure 1.

TYPE FRN15LM1S-4C

SER.No. 4Z3710K1208

(a) Main Name plate (b) Sub Name plate

Figure 1. Inverter name plate.

The position where each name plate is placed is shown on figures 2, 3 and 4.

Application Note AN-Lift-0019v114EN 1

Figure 2. Name plate position in FRN4.0LM1S-4□□ and FRN2.2LM1S-7□□.

Figure 3. Name plate position in FRN5.5LM1S-□□□~ FRN22LM1S-□□□.

Figure 4. Name plate position in FRN30LM1S-4□□~ FRN45LM1S-4□□.

So, according to this, FRENIC-Lift types which include this function can be

recognized by the below type code.

Application Note AN-Lift-0019v114EN 2

Software version can be checked on Menu 5 (MAINTENANCE) on page 6/7 as

it is shown on figure 5.

Software version of the inverter (MAIN)

Figure 5. Page 6 of Menu 5 (MAINTENANCE) on TP-G1-ELS.

Software version depends on the communications protocol. On the table 1, it is

shown from which software version this function is available depending on the

inverter type.

Table 1. Software version depending on inverter type.

Software

Inverter type

version

1750 -□E

1751 -□EA

As mentioned before, software can be updated, so this number might be

different. In this case, software version will have a higher number. For numbers

showed in table 1 and higher numbers this function will be included as

described on this manual.

Application Note AN-Lift-0019v114EN 3

3. FRENIC-Lift basic diagram

On the figure 6, it is shown a basic diagram of the inverter.

Figure 6. Basic diagram of the inverter.

4. Description of the function and parameters.

The parameters and functions related are shown in table 2:

Table 2. Parameters and functions related to UCM function.

Default

Parameter Name Setting range Symbol Unit

setting

E01 to E08, Command 0 to 112 (1000 to BRKE1 - -

E98 and E99 Assignment 1112)

[X1] to [X8], [FWD] 111(1111): Check

and [REV] Brake Control 1

112(1112): Check BRKE2 - -

Brake Control 2

E20 to E24, Signal Assignment 0 to 116 (1000 to BRKS - -

and E27 to [Y1] 1116)

to [Y4], [Y5A/C] 57(1057): Brake

Control

H95 bbe alarm reset 0 to 255 - - 0

H96 Check brake control 0 to 1 - - 0

select

L84 Brake control 0.00 to 10.00 s - s 0.00

(Brake check time)

Application Note AN-Lift-0019v114EN 4

This function is not active in factory default settings. It means that this function

has to be activated. The parameter used to activate this function is H96. The

functionality of H96 is explained below.

a) When H96 = 0

Even BRKE1 and BRKE2 functions are correctly programmed and wired,

monitoring function for UCM is not active.

BRKE function can be used. For additional information, please, refer to

FRENIC-Lift Reference Manual.

b) When H96 = 1

Brake monitoring operation is performed by BRKE1 and BRKE2

according to UCM. When BRKE1 or BRKE2 status mismatches, timer of

brake check time (L84) starts. bbe alarm is generated when BRKE1

or BRKE2 function remain in a mismatching condition during brake

check time (L84). During lift travel, alarm is not issued, alarm is

generated as soon as BRKS function is OFF and L84 timer passes. For

additional details, please refer to chapter “5. Function behavior”.

5. Function behaviour.

On the following figures, each possible scenario using BRKE1 and BRKE2

functions are explained.

a) Brake feedback is abnormal at starting

Inverter trips bbe

Figure 7. bbe alarm at starting.

b) Brake feedback is abnormal at stopping

Application Note AN-Lift-0019v114EN 5

Inverter trips bbe

Figure 8. bbe alarm at stopping.

c) Brake feedback is abnormal during travel

Inverter trips bbe

Figure 9. bbe alarm at stopping because BRKE1 signal is missing.

Application Note AN-Lift-0019v114EN 6

Inverter doesn’t trip bbe

Inverter doesn’t trip bbe, because of L84

timer is not expired.

Figure 10. bbe alarm does not appear at stopping even BRKE2 signal was missing.

d) Brake feedback is abnormal when motor is stopped

Inverter doesn’t trip bbe

Inverter doesn’t trip bbe, because of L84

timer is not expired.

Figure 11. bbe alarm at motor stopped.

Application Note AN-Lift-0019v114EN 7

6. Example of wiring and setting.

Figure 12 shows an example of connection. On this example, there is a motor

with two brakes (brake 1 and brake 2). Each brake has a normally closed

switch; it means that when brake is closed, switch is closed. In this case

terminal X6 is programmed with function BRKE1 and X7 is programmed with

function BRKE2.

Additionally, a relay output (Y5A/C) is programmed to control the brake with the

function BRKS.

U

FRENIC-Lift

Brake 1

PLC (+24 V)

V X6 (BRKE1)

M X7 (BRKE2)

W Brake 2

Y5A Brake power

(BRKS) supply

Y5C

Figure 12. Example of monitoring and control of the brake done by the inverter.

According to figure 12, related parameters have to be set as described in table

3.

Table 3. Parameters setting according to figure 12 example.

Parameter Name Setting

E06 Terminal [X6] 111

E07 Terminal [X7] 112

H96 Check brake control select 1

L84 Brake control (Brake check time) 1.00 s

Application Note AN-Lift-0019v114EN 8

7. Alarm reset and alarm messages related.

As explained before, there is a specific alarm for this function. Also, on the

existing alarm er6, a SUB code is added. In table 4, additional information for

each alarm is shown.

Table 4. Alarm and SUB codes.

Alarm

SUB

message Description Possible causes

code

displayed

H96 is set to 1 but Check that BRKE1 function is correctly set.

er6 14 some settings related Check that BRKE2 function is correctly set.

are missing. Check that BRKS function is correctly set.

Check status of micro switch in brake 1.

Check status of brake 1 and its power

BRKE1 signal is supply.

11

abnormal. Check status of inverter input/output related

to brake 1.

Check L84 time.

bbe

Check status of micro switch in brake 2.

Check status of brake 2 and its power

BRKE2 signal is supply.

12

abnormal. Check status of inverter input/output related

to brake 2.

Check L84 time.

Because bbe alarm blocks the inverter according to UCM, it cannot be reset

following the standard procedure. Additionally bbe alarm cannot be auto reset

by the inverter (H04, H05), neither can be reset by switching OFF and switching

ON inverter’s power supply.

In order to reset the alarm, following procedure has to be done:

1. Set parameter H95 to 111. Cursor can be moved by SHIFT button.

2. Push FUNC/DATA button. H95 reverts to 0 automatically.

3. Push PRG button until main screen is shown. In main screen bbe

alarm is shown.

4. Push RESET button.

bbe can only be reset after the cause of the problem has been fixed.

8. Function test procedure.

According to the standard, each time that a new lift is tested, this function has to

be also tested. On the following charts, it is explained how to test the function.

In order to make the chart more understandable, as a reference it is taken the

example shown on figure 12. In case of using a NO contactor, test has to be

done removing the cable from the terminal.

Application Note AN-Lift-0019v114EN 9

TEST OF BRKE1 FUNCTION

BRKE1 function checking at

starting

Make a normal call on

the elevator

As soon as the

inverter is in RUN

mode make a bridge

between X6 and PLC

(or its equivalent)

L84 time is expired

Inverter trips

bbE ?

NO

YES

Remove the bridge Function not properly

working. Replace the

inverter.

Follow the procedure NO

explained in Chapter 7

to reset the error.

Error is reset?

YES

Function checking

finished

Figure 13. Test of BRKE1 function at starting.

Application Note AN-Lift-0019v114EN 10

BRKE1 function checking

during travel

Make a normal call on

the elevator

During high speed

make a bridge

between X6 and PLC

(or its equivalent)

L84 time is expired

Travel is finished

Inverter trips

bbE ?

NO

YES

Remove the bridge Function not properly

working. Replace the

inverter.

Follow the procedure NO

explained in Chapter 7

to reset the error.

Error is reset?

YES

Function checking

finished

Figure 14. Test of BRKE1 function during normal travel.

Application Note AN-Lift-0019v114EN 11

TEST OF BRKE2 FUNCTION

BRKE2 function checking at

starting

Make a normal call on

the elevator

As soon as the

inverter is in RUN

mode make a bridge

between X7 and PLC

(or its equivalent)

L84 time is expired

Inverter trips

bbE ?

NO

YES

Remove the bridge Function not properly

working. Replace the

inverter.

Follow the procedure NO

explained in Chapter 7

to reset the error.

Error is reset?

YES

Function checking

finished

Figure 15. Test of BRKE2 function at starting.

Application Note AN-Lift-0019v114EN 12

BRKE2 function checking

during travel

Make a normal call on

the elevator

During high speed

make a bridge

between X7 and PLC

(or its equivalent)

L84 time is expired

Travel is finished

Inverter trips

bbE ?

NO

YES

Remove the bridge Function not properly

working. Replace the

inverter.

Follow the procedure NO

explained in Chapter 7

to reset the error.

Error is reset?

YES

Function checking

finished

Figure 16. Test of BRKE2 function during normal travel.

Application Note AN-Lift-0019v114EN 13

9. Conclusion.

On this application note it is explained:

- How to use correctly FRENIC-Lift function related to UCM (EN81-1 +

A3).

- How to recognize inverters which are provided with this function.

- How to test this function by the end user.

With this function, and using a motor with brake certified according to EN81-1 +

A3, FRENIC-Lift can be used in an elevator in order to fulfil the requirements

related to UCM.

In case of lifts with pre opening doors and/or re-levelling function, additional

functional safety functions might be needed which will be implemented installing

additional components.

9. Document history.

Version Changes applied Date Written Checked Approved

1.0.0 First version 05/01/2012 J. Alonso

1.0.1 Some small changes 05/01/2012 J. Alonso D. Bedford D. Bedford

1.1.0 Chapter 2, 3 and 8 are added 10/01/2012 J. Alonso D. Bedford

according to IMQ

recommendations.

1.1.1 Last sentence on conclusions 16/01/2012 J. Alonso D. Bedford

modified.

1.1.2 Sub codes have been changed. 24/01/2012 J. Alonso D. Bedford

1.1.3 Figure 14 and figure 16 are 03/02/2012 J. Alonso D. Bedford M. Belloli

modified.

1.1.4 Small text errors corrected. 10/04/2012 J. Alonso

Application Note AN-Lift-0019v114EN 14

Potrebbero piacerti anche

- Application Note AN-VG7-001v101EN Encoder Check and Pole Tuning Procedure For PMSM in Lift ApplicationsDocumento4 pagineApplication Note AN-VG7-001v101EN Encoder Check and Pole Tuning Procedure For PMSM in Lift ApplicationshassanNessuna valutazione finora

- Automatic Pole-Tuning with Incremental EncoderDocumento4 pagineAutomatic Pole-Tuning with Incremental EncoderhassanNessuna valutazione finora

- D31 37 39ShopM T&A BeforeProof-2Documento385 pagineD31 37 39ShopM T&A BeforeProof-2data9999Nessuna valutazione finora

- 2 084 644 en 20010706Documento4 pagine2 084 644 en 20010706Yves MartinosNessuna valutazione finora

- HHT Parameter (Finished) 0227Documento10 pagineHHT Parameter (Finished) 0227Rachmad Maulana Ramadhan83% (6)

- English - Definitivo EASY-TRONIC - MRL3 - GEARLESS - INSTALLATION - ITA - ENDocumento15 pagineEnglish - Definitivo EASY-TRONIC - MRL3 - GEARLESS - INSTALLATION - ITA - ENMahmoud RobNessuna valutazione finora

- Volvo L30 PDFDocumento20 pagineVolvo L30 PDFاياد القباطيNessuna valutazione finora

- Commissioning StepsDocumento24 pagineCommissioning StepsKhwaja KhanzadeNessuna valutazione finora

- e-manage ECU Tuning System OverviewDocumento23 paginee-manage ECU Tuning System Overviewanthony dizonNessuna valutazione finora

- 160.49-RP3!7!98 Microcomputer Control Center YK Styles A, B, C and DDocumento8 pagine160.49-RP3!7!98 Microcomputer Control Center YK Styles A, B, C and Dsabalito81Nessuna valutazione finora

- Moog-ServoDrives-RMC T161 Operating Instructions en 10VDocumento112 pagineMoog-ServoDrives-RMC T161 Operating Instructions en 10VJorge SarmientoNessuna valutazione finora

- CMC4+ Commissioning StepsDocumento28 pagineCMC4+ Commissioning StepsPedro Kalvin88% (8)

- Quick SetupDocumento15 pagineQuick SetupIngeniería AplicacionesNessuna valutazione finora

- Msb-14exml00 23 42-501Documento6 pagineMsb-14exml00 23 42-501ossoskiNessuna valutazione finora

- MITSUBISHI DIESEL ENGINE TECHNICAL INFORMATION MANUALDocumento13 pagineMITSUBISHI DIESEL ENGINE TECHNICAL INFORMATION MANUALSalman Arif100% (2)

- Cycle 2 Experiment 2Documento12 pagineCycle 2 Experiment 2SarrahNessuna valutazione finora

- Constant Volts/Hertz Operation For Variable Speed Control of Induction MotorsDocumento25 pagineConstant Volts/Hertz Operation For Variable Speed Control of Induction MotorsshaktikumarjhaNessuna valutazione finora

- 스미토모 리치Documento360 pagine스미토모 리치01033948385pjhNessuna valutazione finora

- Propvalve eDocumento38 paginePropvalve eMohamed Rashed100% (1)

- Lab 10 - PLC Programming: F o R M A TDocumento3 pagineLab 10 - PLC Programming: F o R M A TRichard De Medeiros CastroNessuna valutazione finora

- Specifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16Documento15 pagineSpecifications: FANUC Series 16/18-MB/TB/MC/TC FANUC Series 16avalente112Nessuna valutazione finora

- Transmission Error Codes - CargadorasDocumento36 pagineTransmission Error Codes - CargadorasTeresa Marina Peralta80% (5)

- Pitch Control-Descripcion de FuncionamientoDocumento5 paginePitch Control-Descripcion de FuncionamientoquetecagoNessuna valutazione finora

- Kalmar DRF 450 EngineDocumento32 pagineKalmar DRF 450 Enginetuấn anh nguyễn100% (1)

- Manual EP100 enDocumento23 pagineManual EP100 enEBNessuna valutazione finora

- LHB Coach Maintenance HandbookDocumento28 pagineLHB Coach Maintenance HandbookMUZZAMMILSHERIFF89% (9)

- An Lift2 0001v140en Use of Frenic Lift Sto Inputs in Elevator ApplicationsDocumento8 pagineAn Lift2 0001v140en Use of Frenic Lift Sto Inputs in Elevator ApplicationsMileNessuna valutazione finora

- Auto Idle System Trouble Shooting: Kubota Construction MachineryDocumento16 pagineAuto Idle System Trouble Shooting: Kubota Construction MachineryYadi100% (6)

- Lmi OperationDocumento24 pagineLmi OperationMohamed Rashed100% (2)

- fc5200 ComponentesDocumento62 paginefc5200 ComponentesMar LoyolaNessuna valutazione finora

- OMRON L7 MANUAL EnglishDocumento36 pagineOMRON L7 MANUAL EnglishDhanil PattaliNessuna valutazione finora

- Elevador SWORD HAMCB Tipo OtisDocumento41 pagineElevador SWORD HAMCB Tipo OtisRaul GutierrezNessuna valutazione finora

- Application Note AN-MEGA-0007v105EN UP/Down With Reset Function Using Customizable Logic of Frenic MegaDocumento3 pagineApplication Note AN-MEGA-0007v105EN UP/Down With Reset Function Using Customizable Logic of Frenic MegaDouglas TamayoNessuna valutazione finora

- A3-Nxpin 02Documento8 pagineA3-Nxpin 02AliRouyouNessuna valutazione finora

- Troubleshooting WorkCentre Pro 275Documento96 pagineTroubleshooting WorkCentre Pro 275pppcoprsNessuna valutazione finora

- Matrix T5x Error CodesDocumento32 pagineMatrix T5x Error CodesJose MustienesNessuna valutazione finora

- Applications Manual: Honda/Acura Immobiliser SystemDocumento17 pagineApplications Manual: Honda/Acura Immobiliser Systemaoh1226Nessuna valutazione finora

- Downloaded From Manuals Search EngineDocumento161 pagineDownloaded From Manuals Search EngineBruce LiNessuna valutazione finora

- Goliath 90 v129 eDocumento129 pagineGoliath 90 v129 eerkanNessuna valutazione finora

- Maintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysDocumento293 pagineMaintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysTA CWMNessuna valutazione finora

- ComponentryDocumento57 pagineComponentryCoque de LunaNessuna valutazione finora

- Open Collector FX To ServoDocumento13 pagineOpen Collector FX To Servoanon_670965762Nessuna valutazione finora

- J3 Meter Removal Installation and Troubleshooting GuideDocumento32 pagineJ3 Meter Removal Installation and Troubleshooting GuideWaqar KhattakNessuna valutazione finora

- B737 Thrust ReverserDocumento4 pagineB737 Thrust ReverserBeing AirWindNessuna valutazione finora

- P Annexe E5.1 Digipro Pour cd2000 GB v01 - 2001Documento24 pagineP Annexe E5.1 Digipro Pour cd2000 GB v01 - 2001Putra Eka Wiguna MandiriNessuna valutazione finora

- C1742 PDFDocumento8 pagineC1742 PDFbob loblawNessuna valutazione finora

- Electric Sistem SCHOTTELDocumento106 pagineElectric Sistem SCHOTTELmisaelandres1100% (5)

- NEWKer 18imi Series Controller Installation GuideDocumento12 pagineNEWKer 18imi Series Controller Installation GuideElenilton MelchiorsNessuna valutazione finora

- Yuema CHCDocumento36 pagineYuema CHCyan.yanismanNessuna valutazione finora

- HPK In001 - en PDocumento36 pagineHPK In001 - en Pdavid cruzNessuna valutazione finora

- Bomag 851Documento108 pagineBomag 851Taras Kutsyk88% (8)

- Ergo Mover 600AC Service Manual 212892-040Documento50 pagineErgo Mover 600AC Service Manual 212892-040TotalNessuna valutazione finora

- Dokumen - Tips - Bomag-Bw-120-Ad-Drum-Roller-Service-Repair-Manual-1629905308 BomagDocumento19 pagineDokumen - Tips - Bomag-Bw-120-Ad-Drum-Roller-Service-Repair-Manual-1629905308 BomagSergio Hernandez0% (2)

- A750 TransmissionDocumento30 pagineA750 Transmissionjohnatan chui100% (2)

- BCN 15345 S2 PDFDocumento26 pagineBCN 15345 S2 PDFGiovani AlaskakiNessuna valutazione finora

- Keysight 34401A Multimeter: Manual UpdatesDocumento46 pagineKeysight 34401A Multimeter: Manual UpdatestomichelNessuna valutazione finora

- AVR On-Line Maintenance InstructionsDocumento13 pagineAVR On-Line Maintenance InstructionsAmit BiswasNessuna valutazione finora

- File - 20190918 - 110015 - 5872 - 368 - 002 5 WG-261 311Documento50 pagineFile - 20190918 - 110015 - 5872 - 368 - 002 5 WG-261 311Dinh Sang100% (3)

- Operational Amplifier Circuits: Analysis and DesignDa EverandOperational Amplifier Circuits: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (2)

- Aluminum Electrolytic Capacitors: Screw Terminal TypesDocumento5 pagineAluminum Electrolytic Capacitors: Screw Terminal Typessg mesNessuna valutazione finora

- Dinoxcope User ManualDocumento16 pagineDinoxcope User Manualsg mesNessuna valutazione finora

- Radial 13: Aluminum Electrolytic CapacitorsDocumento2 pagineRadial 13: Aluminum Electrolytic Capacitorssg mesNessuna valutazione finora

- O1 Prisma Fox Door Drive PDFDocumento11 pagineO1 Prisma Fox Door Drive PDFfirasalthiyabyNessuna valutazione finora

- Au6805 PDFDocumento108 pagineAu6805 PDFsg mesNessuna valutazione finora

- NICE3000Documento322 pagineNICE3000SawonNessuna valutazione finora

- Fermator vf5Documento28 pagineFermator vf5jay100% (2)

- Description Dimensions, MM SOP-8: Cmos Ic For Switching Power Supply ControlDocumento15 pagineDescription Dimensions, MM SOP-8: Cmos Ic For Switching Power Supply ControlMalfo10Nessuna valutazione finora

- O1 Prisma Fox Door Drive PDFDocumento11 pagineO1 Prisma Fox Door Drive PDFfirasalthiyabyNessuna valutazione finora

- 1988 OKI Microprocessor Databook PDFDocumento434 pagine1988 OKI Microprocessor Databook PDFsg mes100% (1)

- 18.314 Practice Final ExamDocumento4 pagine18.314 Practice Final ExamLionel CarlosNessuna valutazione finora

- Wily Intro Scope FaqDocumento3 pagineWily Intro Scope Faqramprasad_ks75% (4)

- DICA Lab Manual R16 2019Documento54 pagineDICA Lab Manual R16 2019Sobha MuraliNessuna valutazione finora

- ZKW 40 50Documento52 pagineZKW 40 50ricardo100% (1)

- IBM Storwize V3700 7.5Documento1 paginaIBM Storwize V3700 7.5Silvio Ferreira CoutinhoNessuna valutazione finora

- WorksheetWorks Singular Plural Nouns 1Documento2 pagineWorksheetWorks Singular Plural Nouns 1cristina rossini100% (1)

- The Mother BoardDocumento7 pagineThe Mother BoardMadhav KumarNessuna valutazione finora

- Exam Exam Exam Exam::::: Cisco Cisco Cisco Cisco 640-802 640-802 640-802 640-802Documento17 pagineExam Exam Exam Exam::::: Cisco Cisco Cisco Cisco 640-802 640-802 640-802 640-802dmbowie89Nessuna valutazione finora

- GRI 20F-12-B Data SheetDocumento3 pagineGRI 20F-12-B Data SheetJMAC SupplyNessuna valutazione finora

- Danfoss FC 301-302 AngDocumento268 pagineDanfoss FC 301-302 AngkudakwasheNessuna valutazione finora

- Wa470 5 PDFDocumento12 pagineWa470 5 PDFDino Oporto PrudencioNessuna valutazione finora

- SR1200 Server ConfigDocumento8 pagineSR1200 Server Configmev sterNessuna valutazione finora

- Tissin Positioner TS900-manual EDocumento52 pagineTissin Positioner TS900-manual Ejose aguirreNessuna valutazione finora

- SOSPB-3512-05D 20D 40D 1.25g Bidi SinovoDocumento10 pagineSOSPB-3512-05D 20D 40D 1.25g Bidi SinovomelissaNessuna valutazione finora

- ACFrOgC3ap IsdwuxtEJ5MGSg 6Co9vDg1-DSyHV2glL1tO WWhGCRh-t7 ASS BNnVcP81mcNrzk0aEBZuDa-iEDL638Dofbm7MKfW-SmIfrCeQZBWuTSl3az1drvYDocumento4 pagineACFrOgC3ap IsdwuxtEJ5MGSg 6Co9vDg1-DSyHV2glL1tO WWhGCRh-t7 ASS BNnVcP81mcNrzk0aEBZuDa-iEDL638Dofbm7MKfW-SmIfrCeQZBWuTSl3az1drvYjleafe8957Nessuna valutazione finora

- DF11 CatalogDocumento14 pagineDF11 Catalogscualoboy2006Nessuna valutazione finora

- Independent University, BangladeshDocumento47 pagineIndependent University, BangladeshShahinul KabirNessuna valutazione finora

- 6040z User ManualDocumento29 pagine6040z User Manualscribd1-22Nessuna valutazione finora

- MasterSeries 856 Specification SheetDocumento2 pagineMasterSeries 856 Specification SheetFEBCONessuna valutazione finora

- Processor OrganizationDocumento6 pagineProcessor Organizationgo2_sumit100% (1)

- DIALux Evo ManualDocumento92 pagineDIALux Evo ManualIngenieroSinTitulo100% (1)

- Agilent Medalist I3070 In-Circuit Test SystemDocumento6 pagineAgilent Medalist I3070 In-Circuit Test SystemAli BabarNessuna valutazione finora

- Mfvisualcobol Eclipse R4u1 Release NotesDocumento28 pagineMfvisualcobol Eclipse R4u1 Release NotesHafedh TrimecheNessuna valutazione finora

- Nevion DVB Ts MuxDocumento4 pagineNevion DVB Ts MuxDramane BonkoungouNessuna valutazione finora

- HawkJaw 65K-ALS Operation, Maintenance and Service ManualDocumento139 pagineHawkJaw 65K-ALS Operation, Maintenance and Service ManualHailan ChengNessuna valutazione finora

- ABB AC800M Brochure PDFDocumento12 pagineABB AC800M Brochure PDFEstebanPieraNessuna valutazione finora

- Tesla K40 Active Board Spec BD 06949 001 v03Documento25 pagineTesla K40 Active Board Spec BD 06949 001 v03ronald_edinsonNessuna valutazione finora

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocumento32 pagineEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- Gas Turbine Control System1 - NemaDocumento50 pagineGas Turbine Control System1 - Nemaveerclaire100% (1)

- Innovair Oasis Mini Split 2nd Gen 9K 24K Troubleshooting Guide EnglishDocumento8 pagineInnovair Oasis Mini Split 2nd Gen 9K 24K Troubleshooting Guide Englishsergio123451Nessuna valutazione finora