Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

US4922043 Methyl Chloride

Caricato da

Rizal Effendi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni7 pagineUnited State Patent

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoUnited State Patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

22 visualizzazioni7 pagineUS4922043 Methyl Chloride

Caricato da

Rizal EffendiUnited State Patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

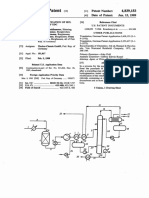

United States Patent [191 [11] Patent Number: 4,922,043

Petrosky [45] Date of Patent: May 1, 1990

[54] MANUFACTURE OF METHYL CHLORIDE Vulcan Materials Company, “Manufacture of Chlo

BY HYDROCHLORINATING METHANOL, romethanes from Methyl Alcohol and Chlorine”.

USING A SPLIT METHANOL FEED Sconce, “Chlorine, Its Manufacture, Properties and

[75] Inventor: Jimmy T. Petrosky, Wichita, Kans. Uses”, ACS Monograph No. 154, pp. 363-364, and

FIG. 12—6 on p. 365.

[73] Assignee: Vulcan Materials Company, Encyclopedia of Chemical Processing and Design, vol.

Birmingham, Ala. 8, pp. 256-259 (1979).

[21] Appl. No.: 279,093 Vulcan Materials Company In-House literature

searches dated Jun. 17, 1982; Jan. 7, 1987; and Jul. 23,

[22] Filed: Dec. 2, 1988 1987.

[51] Int. Cl.5 ............................................ .. C07C 17/16 Primary Examiner-Howard T. Mars

[52] US. Cl. . ..... ... .. ... .. . . . . . . . . . .. 570/258

[58] Field of Search ............................. .. 570/258, 259 [57] ABSTRACT

[56] References Cited In a process for making methyl chloride by the catalytic

hydrochlorination of methanol in the liquid phase, the

U.S. PATENT DOCUMENTS common formation of unwanted dimethyl ether by-pro

2,026,131 12/1935 Klein et a1. . duct is reduced by conducting the process in at least

2,091,986 9/1937 Holt et al. . two reactors operating in series and by introducing all

2,421,441 6/1947 Thronson et a1. . or substantially all of the required hydrogen chloride

2,847,484 8/1958 Kolker . feed into the ?rst reactor while splitting the introduc

3,981,938 9/1976 Steele et a1. .

tion of methanol feed, preferably as a vapor, between or

FOREIGN PATENT DOCUMENTS among the reactors.

2447551 4/1975 Fed. Rep. of Germany . The overall feed ratio of methanol to hydrogen chloride

1560892 2/ 1980 United Kingdom . is in the range between about 0.65 to about 1.0 mol

methanol per mol hydrogen chloride. Aqueous zinc

OTHER PUBLICATIONS chloride is the preferred catalyst.

“Kirk-Othmer Encyclopedia of Chemical Technol

ogy”, vol. 3, p. 741, (1949). 5 Claims, 1 Drawing Sheet

US. Patent _ . May 1,1990 } 4,922,043

4,922,043

1 2

with cold dilute sodium hydroxide solution, and the

MANUFACTURE OF METHYL CHLORIDE BY water and DME are removed by scrubbing with cold

HYDROCHLORINATING METHANOL, USING A concentrated sulfuric acid. The resulting pure methyl

SPLIT METHANOL FEED chloride vapor is compressed, condensed with cold‘

water, and placed in storage tanks.

BACKGROUND OF THE INVENTION While removal of DME from the methyl chloride is

1. Field of the Invention readily accomplished by scrubbing with sulfuric acid,

This invention relates to an improved process for not only is its formation wasteful in terms of greater raw .

making methyl chloride by reacting methanol with material costs, but the disposal of unwanted sulfuric

hydrogen chloride in the presence of a metal chloride 10 acid-containing DME presents a problem in view of

catalyst, e.g., zinc chloride. As such a process normally increasing ecological concerns and resulting restriction

results in the formation of substantial amounts of di on the disposal of industrial waste streams.

methyl ether (DME) as an unwanted by-product, the

improvement is particularly concerned with a method SUMMARY AND OBJECTS OF THE

of reducing such ether formation. 2. Description of the INVENTION

Prior Art According to the present invention, when the hydro

Methyl chloride has many uses in industry and sci chlorination reaction is carried out in two or more reac

ence. For instance, it not only ?nds wide use as a sol tors in series, an improvement in performance is ob

vent, extractant, propellant or refrigerant, it is also used tained by splitting the methanol feed such that only part

as a methylating agent in organic synthesis and, impor of the methanol feed is introduced into the ?rst reactor

tantly, as a starting material in the production of dichlo

together with the gaseous hydrogen chloride feed while '

romethane, trichloromethane and carbon tetrachloride

by reaction with chloride. Another important use of the ef?uent from the ?rst reactor is fed into the subse

methyl chloride is as an intermediate in the production quent reactor or reactors together with the balance of

of silicones. 25 the methanol and with no or only a small amount of

Acommon and economical process for providing additional hydrogen chloride.

methyl chloride involves the hydrochlorination of While this novel split-feed arrangement was initially

methanol according to the reaction MeOH+HCl tried in the expectation that it would increase the con

—>MeCl+H2O. As it is described, for instance, in the version of methanol to methyl chloride, surprisingly, no

Encyclopedia of Chemical Processing and Design, Vol. such increase was found to occur. On the contrary, the

8, pp 256-9 (1979), this reaction can be carried out using conversion of methanol to methyl chloride remained

either a liquid or a solid catalyst. However, the object of substantially unchanged and the total methanol conver

sion decreased. However, this seeming disadvantage

this invention is concerned only with the reaction when

it is conducted in the liquid phase. was more than offset by an entirely unexpected and

The liquid-phase reaction system is usually con 35 highly desirable decrease in the conversion of methanol

ducted in an aqueous medium, at or near atmospheric to DME, resulting in a little more unreacted methanol

pressure and at a reaction temperature of from about in the reactor ef?uent but signi?cantly less DME. Of .

100° to about 200° C. Catalysts for the liquid-phase course, unreacted methanol can easily be recovered

reaction are water solutions of metal chlorides, such as from the ef?uent and recycled to the reactors.

ferric chloride or bismuth oxychloride or most prefera 40 Accordingly, it is an object of this invention to re

bly zinc chloride. The reaction has been most com duce-raw material costs in the manufacture of methyl

monly carried out by bubbling HCl and methanol as a chloride by hydrochlorination of methanol.

gaseous mixture through a single reactor or several It is another object to reduce the production of eco

reactors operating in parallel, although sometimes the logically objectionable by-products, notably DME, in

reactors have been operated in series. In all such con 45 the manufacture of methyl chloride from methanol.

ventional cases, however, substantially all of the metha It is further object to provide an improved process _

nol and all of the I-ICl is fed through a single-feed sys

tem into the ?rst and in some cases the only reaction

for making methyl chloride from methanol in a series of

stage. As shown in U.S. Patent 2,847,484, when more at least two reaction stages, such that the production of

than one reactor is used, the effluent vapors are passed 50 DME is reduced and the amount of sulfuric acid re

from the ?rst reactor through a subsequent reactor or quired as a scrubbing liquid in the process is thereby 7

reactors operating in series. The temperature of the also reduced.

solution and the concentration of catalyst are so main These and other objects, as well as the nature and

tained that the water of‘reaction is continuously vapor scope of the invention, and of the manner and process of

ized from the reaction mixture along with the methyl 55 using it, including the best mode thereof, are more fully

chloride, thereby providing continuous operation. By described in and will become apparent from the follow

product hydrogen chloride, such as that available from ing speci?cation and claims.

the chlorination of methane or ethane, can be used. It is to be understood that all parts, concentrations,

As the desired methanol hydrochlorination reaction percentages, and proportions of materials are expressed

is generally accompanied by a side reaction wherein 60 throughout on a weight basis unless otherwise indi

dimethyl ether (DME) is formed from methanol ac cated.

cording to the equation 2MeOH—>DME+H2O, the DESCRIPTION OF THE DRAWINGS

crude methyl chloride obtained by the hydrochlorina

tion of methanol contains not only water, unreacted The drawing is a schematic ?ow diagram for a pro

methanol, and hydrochloric acid but also a substantial 65 cess of the invention, comprising two hydrochlorina

proportion of DME as an impurity. The methanol and tion reactors in series followed by a plurality of scrub

hydrochloric acid are usually removed by scrubbing the bing towers wherein the crude methyl chloride vapor

crude methyl chloride vapor with cold water and then produced in the reactors is puri?ed prior to recovery.

4,922,043

3 4

In other words, it is characteristic of the improved

DETAILED DESCRIPTION OF THE methanol hydrochlorination process of this invention

INVENTION

that it is carried out in a series of at least two reactors,

In practicing this invention, methyl chloride (b.p. or in a pair of such series reactors connected in parallel,

—23.7° C.) is prepared in a continuous process by heat such that the mol ratio of MeOI-I/HCl in the ?rst reac

ing methanol (b.p. 64.5’ C.) and hydrogen chloride as a tion stage is at least about 0.05 MeOH/ 1.5 I-ICl and up

vapor mixture in contact with a hydrochlorination cata to about 0.95 MeOH/l.0 HCl, preferably at least about

lyst, e.g., an aqueous solution of ferric chloride, bismuth 0.55 MeOI-I/ 1.5 HCl and up to about 0.9 MeOH/ 1.05

oxychloride or, most preferably, zinc chloride. The HCl, and the MeOH/HCI mol ratio in the second or

water of reaction is removed from the reaction zone subsequent reaction stage or stages is at least up to about

together with the methyl chloride product, by-products 0.95 MeOH/0.95 HCl, preferably at least about 0.1

such as dimethyl ether (b.p. —-24.5° C.), and some un MeOH/0.6HC1 and up to about 0.45 MeOH/0.5O HCl.

converted methanol and hydrogen chloride. For instance, in a two-reactor system operated in series

Predetermined amounts of methanol and hydrogen with an overall methanol-to-HCl ratio of 1.0/ 1.1, it is

chloride are fed to the process preferably, though not suitable to split the methanol feed between the two

necessarily, as substantially anhydrous vapors in an reactor stages such that the MeOI-I/HCl mol ratio is

overall ratio in the range between about 0.65 and about between about 0.95/ 1.1 and 0.05/ 1.1 in the ?rst reactor

1.0, preferably between about 0.75 and 0.95 mol metha and between about 0.05/0.15 and 0.95/ 1.05 in the sec

nol per mol HCl, with all or substantially all of the ond reactor, it being understood that the portion of the

hydrogen chloride being fed into a ?rst reactor while originally fed HCl which remains unreacted in the ?rst

the methanol feed is split between consecutive reactors stage is then introduced into the second stage as part of

operating in series. the ?rst-stage ef?uent.

The aqueous catalyst solution desirably contains zinc Referring to the drawing, and by way of illustration,

chloride in a concentration from about 45 to 85 percent, a representative embodiment of the invention may be

preferably about 65 to 75 percent. 25 carried out as follows.

The methanol and HCl are reacted together in the Reactors l0 and 20 are reaction vessels substantially

presence of the hydrochlorination catalyst at a tempera ?lled with an aqueous solution containing about 68

ture in the range between about 100° and about 200° C., percent zinc chloride. Reactors l0 and 20 are main

preferably between about 135° C. and 190° C., with a tained at a temperature of about 150° C. and a pressure

pressure in the range between about 1 and about 5 atmo of about 30 psig. Anhydrous hydrogen chloride (line 1)

spheres, preferably between about 1 and 3 atmospheres. and methanol vapor (line 2) are mixed and introduced

In the prior art this hydrochlorination reaction has into a bottom portion of reactor 10, preferably through

commonly been carried out in a single reaction stage or a perforated sparger tube (not shown). For instance,

about 110 pounds mols per hour of I-ICl and about 80

in a plurality of such reaction stages connected in paral

pound mols per hour of MeOH may thus be fed into the

lel or in series, but in each such case all of the methanol reactor 10 and reacted there upon upward passage

and HCl are fed into the ?rst reaction stage in substan through the liquid catalyst phase. The crude vapor

tially or nearly an equimolar amount or with a molar

excess of HCl. Often these reactions have been operated

effluent, which contains methyl chloride, unreacted

hydrogen chloride and methanol, as well as some DME

with 0-l5% excess HCl (an HCl/methanol ratio of 1.00 and water, is withdrawn from reactor 10 via line 5,

to 1.15). By contrast, it is the essence of the present mixed with about 20 pound mols per hour of additional

invention that the hydrochlorination reaction is carried methanol which is introduced via line 6, and introduced

out in a plurality of successive reaction stages such that to a bottom portion of the second reactor 20, where this

all or substantially all the HCl is introduced into the ?rst additional methanol is reacted with the RC1 introduced

stage whereas not more than 95 percent, and preferably 45 as part of the reaction mixture withdrawn from reactor

between 30 and 90 percent, and most preferably only 10 via line 5.

between 40 and 80 percent of the total normal targeted Reactor 20 contains aqueous zinc chloride solution in

amount of methanol feed required to maintain the prese about the same amount and concentration as reactor 10

lected overall methanol-to-HCl molar ratio for the sys and is usually maintained under essentially the same

tem is introduced into the ?rst reaction stage while the conditions of temperatures and pressure as reactor 10.

balance of the methanol is introduced into the second The vaporous reaction mixture containing crude

reaction stage or is split in any suitable proportions methyl chloride formed in reactor 20 is withdrawn from

between or among several further reaction stages. an upper portion thereof via line 25 and is then puri?ed

For instance, when such a process uses three consec in an otherwise conventional manner. For instance, as

utive reactors, 30 to 40 percent of the total methanol described in U.S. Patent 2,421,441, the crude methyl

feed may be introduced into the ?rst reactor and the chloride product withdrawn from reactor 20 via line 25

remaining 60 to 70 percent may be split among the other may be consecutively treated in a quench tower 30, a

two reactors either in substantially equal or in different caustic scrubber 40 and a sulfuric acid scrubber 50 be

proportions, but all or substantially all of the hydrogen fore the puri?ed methyl chloride is ?nally liqui?ed for

- chloride is introduced only into the ?rst reactor. The 60 storage by compression and cooling.

effluent from the ?rst reactor, which in such a case of Thus, the aqueous scrubbing liquid circulated

course contains a substantial proportion of unconverted through tower 30 via lines 31 and 32 is suitably cooled

HCl, is then introduced into the second reactor where to a temperature preferably not in excess of 40° C., e.g.,

the unconverted HCl reacts with the methanol intro 20° to 35° C., by passing through a heat exchanger 34,

duced into this reactor, and the effluent from this reac 65 cooling the incoming crude methyl chloride vapor and

tor then continues to the third reactor where the re‘ condensing the water of reaction produced in the pro

maining unconverted HCl reacts with the methanol cess, such excess water being removed in the form of a

feed introduced into it, and so on. weak hydrochloric acid solution via line 33 for appro

4,922,043

5 6

priate further treatment. As the crude methyl chloride In all of the tests, the above described laboratory

withdrawn from reactor 25 has a temperature of about reactor was used to simulate two reactors operating in

150° C. it is preferably cooled to between 50° and 60° C. series. To do this, in simulating the operation of the

by passing through heat exchanger 21 before it is intro ?rst-stage reactor the methanol and HCl vapors were

duced into water scrubber 30, although this is not essen fed into the reactor through a mixed-feed line extending

tial. By ?rst cooling the crude product stream, a consid into the bottom portion of the reactor, where the vapors

erable proportion of hydrochloric acid will be con became mixed in the catalyst solution and rose up

densed from the gaseous product. Good operation is wardly through it. The reactor contents were main

obtained if the water entering the scrubber has a tem tained at 150‘ C. and 30 psig pressure as the gaseous

perature between 10° and 20‘ C. when the methyl chlo reactants bubbled upwardly through the liquid-phase

ride vapor entering the scrubber has a temperature of ‘ catalyst solution and reacted. The ef?uent from the

about 50° C. If the methyl chloride entering the scrub reactor was recovered and analyzed. A gas mixture

ber has a higher temperature, the water entering the having the same composition as the effluent from the

scrubber should be adjusted in volume and temperature ?rst-stage reactor, either by itself or mixed with an

so that the water leaving the scrubber will preferably appropriate amount of additional methanol, was then

not be hotter than about 40° C. To avoid undesirable fed as a vapor to the same reactor to simulate the opera

solubility losses of methyl chloride in the scrubbing tion of the second-stage reactor operating in series with

liquid, the temperature of the water leaving the quench the ?rst stage reactor. Again the reactor'contents were

tower 30 is preferably maintained between about 30° maintained at 150° C. and 30 psig pressure. The effluent

and 40° C. ‘ from the simulation of the second stage reactor was

After scrubbing in tower 30, the vapor is passed via recovered and analyzed to determine overall two-reac

line 35 to a caustic scrubber 40. The dilute caustic solu tor system performance and ef?ciencies.

tion circulated through scrubber 40 may contain, for

instance, about 7 to 10 percent sodium hydroxide and is RUN 1. Prior Art: 100% methanol to ?rst reactor, 0%

25

desirably cooled by passing through heat exchanger 44 to second reactor

to a temperature between about 10° and 25° C., spent To the glass reactor already described above, 1941

caustic solution being withdrawn from the system via grams of aqueous solution containing 1281 grams zinc

line 43 while make-up caustic solution is introduced via chloride as catalyst was charged, producing a static

line 41. The sodium hydroxide solution circulating in 30 column of catalyst solution 30 inches (76 cm) deep. In

scrubber 40 preferably has a concentration not in excess simulating a ?rst reaction stage, 12.1 gram moles per

of 10 percent. If desired, two or more alkali scrubbers hour of vaporized methanol and 13.3 gram moles per

can be used in series with successively stronger concen hour of anhydrous HCl gas were fed to this system as a

trations. Preferably, the sodium hydroxide solution mixed feed, the effluent was analyzed, and then, simu

should contain at least 3 percent sodium hydroxide, and 35 lating a second reaction stage, a gas mixture having the

the alkali scrubbers should be operated preferably at same composition as the ef?uent from the ?rst-stage

temperatures not exceeding 25° C., as higher tempera reactor was fed to the same system (without any addi

tures can cause some hydrolysis of the methyl chloride.

The vapor scrubbed in tower 40 is ?nally passed to a

tional methanol). The following overall performance

conversions were obtained:

drying tower 50 where it is scrubbed with concentrated

sulfuric acid, e.g., sulfuric acid the strength of which is

at least 60“ Be (78% H2504). Referring to the drawing, Carbon to Methyl Chloride 98.12%

fresh treating acid is introduced via line 51 while spent Carbon to DME 1.40%

acid is withdrawn via line 53, and a heat exchanger 54 is Total Carbon 99.52%

l-ICl 91.82%

used to cool the circulating acid. The acid serves to 45 Unconverted Methanol 0.48%

purify the product vapor by removing from it both

water and organic by-products, notably DME. Finally,

the puri?ed product vapor is compressed by means of RUN 2. Split methanol: 90% to ?rst reactor, 10% to

compressors 60, liqui?ed by passing through heat ex second reactor

changer 64 and stored in tank 70. . 50

The scrubbers are usually ?lled with a suitable pack As in Run 1, about 13.3 gram mols per hour of anhy

ing material such as Raschig rings and all process units, drous HCl gas were fed to the reactor serving as a ?rst

including both the reactors and the scrubbers, are of stage. However, to exemplify the present invention,

course constructed of suitable corrosion-resistant mate only 90% or 10.9 gram mols per hour of vaporized

rials, as is otherwise well known. 55 methanol was fed to this ?rst stage. The remaining 1.2

gram mols per hour of vaporized methanol were added

EXAMPLES to a gas feed mixture having the same composition as

To illustrate the effectiveness and advantages of the the vapor ef?uent mixture from the ?rst reaction stage

invention, three comparative test runs were conducted. and such mixed feed was then fed into the reactor in

In all these runs, a single laboratory reactor was used. simulation of two reactors operating in series. The cata

This reactor consisted of an electrically heated and lyst charge and the reactor temperatures and pressures

insulated glass pipe 36 inches (91.4 cm) long having a were the same as in Run 1. The following overall per

2-inch (5.08 cm) internal diameter. The reactor was set formance conversion vwere obtained:

up in an upright position and closed off at both ends

with Te?on polytetra?uoroethylene flanges and was 65

equipped with one mixed-feed inlet line passing into the Carbon to Methyl Chloride 97.88%

Carbon to DME 0.81%

bottom portion of the reactor and a vapor exit line at the Total Carbon 98.68%

upper end. 1 HCl 92.68%

4,922,043

7 8

-continued reaction stages, the process can of course be similarly

Unconverted Carbon 1.32%

conducted using a greater number of reaction stages in

series, e.g., anywhere from 3 to 5 or more stages, and

the methanol feed can in such a case be suitably split

It can be seen that the conversion to unwanted DME in 5 among all such stages. The total number of stages uti

Run 2 is 42.9% less than in Run 1. lized depends primarily on the economics of the addi

RUN 3. Split methanol: 75% to the ?rst reactor, 25% to tional capital required versus the improved ef?ciencies

the second reactor obtained by additional reactors. Instead of carrying out

the hydrochlorination reaction in a series of separate

As in Run 1 and Run 2, 13.3 gram mols per hour of 10 reactors, it may be similarly carried out in a column

anhydrous HCl gas was fed to the reactor in a ?rst containing a suitable solid packing as well as the liquid

stage. To further exemplify the present invention, only 7 phase catalyst, in which case the hydrogen chloride gas

75% or 9.08 gram mols per hour of vaporized methanol

and some of the methanol are introduced at the bottom

was fed to the reactor in this ?rst stage. The remaining

and suitable additional amounts of methanol are then

3.03 gram mols per hour of vaporized methanol and a 15

gas feed mixture having the same composition as the introduced at various consecutively higher levels of the

vapor effluent from the ?rst stage were then fed to column.

gether into the reactor serving as a second reaction Although the invention has been described with pre

stage. The catalyst charge and the reactor temperatures ferred embodiments, it is to be understood that varia

and pressures were the same as in Runs 1 and 2. The 20 tions and modi?cations may be employed without de

following overall performance conversions were ob parting from the scope or spirit of this invention, as will

tained: be apparent to those skilled in the art. Such variations

and modi?cations are to be considered within the scope

of the appended claims.

Carbon to Methyl Chloride 97.82% What is claimed is:

Carbon to DME 0.53% 25

Total Carbon 98.35% 1. In a process for making methyl chloride by react

HCI 91.73% ing methanol and hydrogen chloride in aqueous liquid

Unconverted Methanol 1.65% phase in the presence of a catalyst in a reaction system

comprising at least two reaction stages in series, said

The conversion to DME in Run 3 represents a 62.1% 30 methanol and hydrogen chloride being introduced into

reduction in DME production versus Run 1. the process in total amounts corresponding to an overall

For a better overview, the data referred to in Runs 1, ratio of between about 0.65 and 1.0 mol of methanol per

2 and 3 are presented in Table I below. mol of hydrogen chloride, the improvement which

TABLE I

comprises

35 (a) introducing from about 5 to about 95 percent of

LIQUID-PHASE HYDROCHLORINATION OF METI-IANOL the total amount of methanol and substantially all

STAGED METI-IANOL ADDITION RUNS

Zinc Chloride Catalyst, 30 psig Pressure of the hydrogen chloride into a ?rst reaction stage

150' C. Temperature, 30-inch Bed Height containing a metal chloride catalyst in a ?rst aque

Run Number 1 2 3 ous liquid phase, and intimately contacting said

Stage 1 Feeds introduced methanol and hydrogen chloride with

Gram Mols/I-Ir said ?rst liquid phase, thereby producing methyl

CI-lgOH 12.11 10.90 9.08 chloride, dimethyl ether and water,

HCl 13.32 13.32 13.32

Stage 2 Feed (b) withdrawing from said ?rst reaction stage a ?rst

Gram Mols/Hr ’ product vapor stream comprising unreacted hydro

Additional CH3Ol-I 0 1.20 45 gen chloride and substantially all the water, di

% of Total Methanol methyl ether and methyl chloride produced in said

Feed to ?rst reaction stage and introducing said vapor

Stage 1 9O 75 stream into at least one successive reaction stage

Stage 2 0 1O 25

Overall Performance containing a metal chloride catalyst in a second

Conversion, % 50 aqueous liquid phase, also introducing the balance

Carbon to CH3Cl 98.12 97.88‘ 97.82 of the total amount of methanol into said at least

Carbon to DME 1.40 .81 .53 one successive reaction stage, and intimately con

Total Carbon 99.52 98.68 98.35 tacting said ?rst product vapor stream and said

HCl 91.82 92.68 91.73

additional methanol with said second liquid phase,

(c) withdrawing from the last of said series of succes

It can be seen from these data that splitting the metha sive reaction stages a second product vapor stream

nol feed between consecutive stages of a process for comprising methyl chloride admixed with hydro

making methyl chloride by hydrochlorination of metha gen chloride, dimethyl ether and water vapor, and

nol results in a very substantial reduction in the produc (d) separating and recovering methyl chloride from

tion of unwanted DME. While the total conversion of 60 said withdrawn product vapor stream.

methanol is also reduced somewhat when the methanol 2. A process according to claim 1 wherein the reac

feed is split between consecutive reaction stages, the tion system comprises two consecutive reaction stages

_ unreacted methanol can easily be recovered from the wherein from 30 to 90 percent of the total amount of

crude reaction product and recycled to the process as methanol is fed into the ?rst of said reaction stages and

feed to the ?rst reaction stage or to any subsequent from 10 to 70 percent of the total amount of methanol is

reaction stage. fed into the second of said reaction stages.

It should be noted that while in the described embodi 3. A process according to claim 1 which comprises

ments the methanol feed was split between only two more than two reaction stages operating in series and

4,922,043

10

wherein a product vapor stream is withdrawn from liquidphase, thereby producing methyl chloride,

each but the last reaction stage and fed into the next dimethyl ether and water,

consecutive reaction stage, and the product vapor (b) withdrawing from said ?rst reaction stage a ?rst

stream withdrawn from the last reaction stage is recov product vapor stream comprising unreacted hydro

ered and methyl chloride is separated therefrom. gen chloride and substantially all thewater, di

4. A process according to claim 1 in which the cata methyl ether and methyl chloride produced in said

lyst-containing liquid phases are maintained at tempera ?rst reaction stage and introducing said vapor

tures in the range between 135° and 190° C. stream into a second reaction stage containing a

5. In a process for making methyl chloride by react second aqueous liquid solution comprising 45 to 85

ing methanol and hydrogen chloride in aqueous liquid weigh percent zinc chloride, also introducing the

phase at a reaction temperature in the range between

balance of the methanol as a vapor into said second

135° and 190° C. in the presence of a hydrochlorination

catalyst in a reaction system comprising two reaction reaction stage, and intimately contacting said ?rst

stages in series, said methanol and hydrogen chloride product vapor stream and said additional methanol

being introduced into the process in total amounts cor with said second aqueous liquid solution,

responding to an overall ratio of between about 0.65 and (c) withdrawing from said second reaction stage a

1.0 mol of methanol per mol of hydrogen chloride, the second product vapor stream comprising methyl

improvement which comprises chloride admixed with hydrogen chloride, di

(a) introducing from about 10 to about 90 percent of methyl ether and water vapor,

the total amount of methanol and substantially all. (d) consecutively scrubbing said withdrawn second

of the hydrogen chloride as vapors into a ?rst reac product stream with liquid water, an aqueous caus

tion stage containing a ?rst aqueous liquid solution tic solution and a concentrated sulfuric acid solu

comprising 45 to 85 weight percent zinc chloride, tion, and

and intimately contacting said introduced metha _ (e) recovering methyl chloride therefrom.

nol and hydrogen chloride vapors with said ?rst 25 * * Ill 1.! 1F

30

35

50

55

65

Potrebbero piacerti anche

- YES-O Action-Plan - 2022-2023Documento2 pagineYES-O Action-Plan - 2022-2023carmina duldulao100% (6)

- Building SOR 01.12.2020 Volume 1Documento437 pagineBuilding SOR 01.12.2020 Volume 1Shiv Shankar Shukla82% (11)

- Acrylic (And Methacrylic) Acid Polymers PDFDocumento18 pagineAcrylic (And Methacrylic) Acid Polymers PDFIvaniaa100% (1)

- MethanolDocumento27 pagineMethanolUsman HameedNessuna valutazione finora

- Heat Exchanger DesignDocumento19 pagineHeat Exchanger DesignRankhamb ShubhamNessuna valutazione finora

- Review of Methane Catalytic Cracking For Hydrogen ProductionDocumento32 pagineReview of Methane Catalytic Cracking For Hydrogen ProductionVishal GoswamiNessuna valutazione finora

- Properties and Manufacture of Ammonium Perchlorate: September 2020Documento11 pagineProperties and Manufacture of Ammonium Perchlorate: September 2020Aditya Pathak50% (2)

- Production of Methanol From GlycerolDocumento64 pagineProduction of Methanol From GlycerolHafizuddin AdzharNessuna valutazione finora

- Cambridge IGCSE: MATHEMATICS 0580/41Documento20 pagineCambridge IGCSE: MATHEMATICS 0580/41TatiannahNessuna valutazione finora

- Ullmann S Encyclopedia of Industrial ChemistryDocumento24 pagineUllmann S Encyclopedia of Industrial ChemistryAuraandreea50% (2)

- Chen 2007Documento9 pagineChen 2007Arisya JulvianaNessuna valutazione finora

- Methanol ProDocumento126 pagineMethanol Proinju rehaman100% (1)

- VCM ManufacturingDocumento43 pagineVCM ManufacturingRAHUL SEN SHARMA100% (2)

- Modeling and Simulation of Methanol Synthesis From SyngasDocumento72 pagineModeling and Simulation of Methanol Synthesis From Syngasshanku_biet75% (4)

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDocumento14 pagineDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNessuna valutazione finora

- Production of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationDocumento14 pagineProduction of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationParaiba da Paraiba100% (2)

- US5917099Documento7 pagineUS5917099محمد عليNessuna valutazione finora

- Review Methyl Chloride ProcessesDocumento13 pagineReview Methyl Chloride ProcessesAlfredo PeñaNessuna valutazione finora

- Chloromethanes: Anfred Ossberg Ilhelm Endle Erhard Fleiderer GelDocumento28 pagineChloromethanes: Anfred Ossberg Ilhelm Endle Erhard Fleiderer Gelgeek0Nessuna valutazione finora

- A06 233 ClorometanosDocumento28 pagineA06 233 ClorometanosAlfredo PeñaNessuna valutazione finora

- 2.4 Manufacturing Process: Chlorination of MethaneDocumento6 pagine2.4 Manufacturing Process: Chlorination of MethaneAnonymous XSuXpopx0QNessuna valutazione finora

- Trichloroethylene ThesisDocumento62 pagineTrichloroethylene Thesisessakkirajm19902116100% (1)

- Improved Technology For Pollution Prevention in Polyvinyl Chloride ManufacturingDocumento4 pagineImproved Technology For Pollution Prevention in Polyvinyl Chloride ManufacturingsylviealNessuna valutazione finora

- Ullmann's Encyclopedia of Industrial Chemistry-Methanol ProductionDocumento22 pagineUllmann's Encyclopedia of Industrial Chemistry-Methanol ProductionabubakarNessuna valutazione finora

- US3983180Documento7 pagineUS3983180Agustina TriyaniNessuna valutazione finora

- Terephthalic Acid, Dimethyl Terephthalate, and Isophthalic Acid (2011) - Richard J. SheehanDocumento12 pagineTerephthalic Acid, Dimethyl Terephthalate, and Isophthalic Acid (2011) - Richard J. SheehanBugra Can KesimNessuna valutazione finora

- Thesis 2020Documento104 pagineThesis 2020Dinesh guhanNessuna valutazione finora

- Us 2792435Documento4 pagineUs 2792435Maria AraujoNessuna valutazione finora

- Escalante 2019Documento9 pagineEscalante 2019sulucomoshakaNessuna valutazione finora

- PAtentDocumento9 paginePAtentTri RudiNessuna valutazione finora

- US4343954 FormaldehydeDocumento4 pagineUS4343954 FormaldehydeRuchita PoilkarNessuna valutazione finora

- NHDT FoulingDocumento6 pagineNHDT FoulingJulio RamirezNessuna valutazione finora

- Catalytic Hydrogenation of Carbon Dioxide To Formic Acid: Arno Behr, and Kristina NowakowskiDocumento36 pagineCatalytic Hydrogenation of Carbon Dioxide To Formic Acid: Arno Behr, and Kristina NowakowskiDanCosminNessuna valutazione finora

- Chelsea PDFDocumento3 pagineChelsea PDFKelly SisonNessuna valutazione finora

- Manning 1984 B3Documento25 pagineManning 1984 B3febrianirrNessuna valutazione finora

- 2015 - Kinetic and Modeling Study of The EthyleneDocumento13 pagine2015 - Kinetic and Modeling Study of The EthylenevictorNessuna valutazione finora

- US5093538Documento6 pagineUS5093538PrimoNessuna valutazione finora

- Jurnal Penting REAKTOR PDFDocumento8 pagineJurnal Penting REAKTOR PDFGilang PerdanaNessuna valutazione finora

- Effect of Poly (Acrylic Acid) End-Group Functionality On Inhibition of Calcium Oxalate Crystal GrowthDocumento7 pagineEffect of Poly (Acrylic Acid) End-Group Functionality On Inhibition of Calcium Oxalate Crystal GrowthPencils SharpenerNessuna valutazione finora

- 1 s2.0 S0360319919343666 MainDocumento18 pagine1 s2.0 S0360319919343666 MaincailiiiNessuna valutazione finora

- Castor OilDocumento6 pagineCastor OilÖzlem YılmazNessuna valutazione finora

- United States Patent (19) : Correia Et AlDocumento3 pagineUnited States Patent (19) : Correia Et AlVatsal KardaniNessuna valutazione finora

- Utilization of Carbon Dioxide in Heterogeneous Catalytic SynthesisDocumento12 pagineUtilization of Carbon Dioxide in Heterogeneous Catalytic SynthesisDanCosminNessuna valutazione finora

- J165 Alarifi1 SSSimulationofaNovelAnnularMultitubularReactorMethanolie4006589Documento8 pagineJ165 Alarifi1 SSSimulationofaNovelAnnularMultitubularReactorMethanolie4006589Gauri KapseNessuna valutazione finora

- Aranzabal 2009Documento9 pagineAranzabal 2009bruno barrosNessuna valutazione finora

- Modelling in Methanol Synthesis: Control Engineering LaboratoryDocumento43 pagineModelling in Methanol Synthesis: Control Engineering LaboratoryBikashGuptaNessuna valutazione finora

- Process For Purification of HCL From Edc PyrolysisDocumento6 pagineProcess For Purification of HCL From Edc Pyrolysisu2051721Nessuna valutazione finora

- Zinc-Catalyzed Williamson Ether Synthesis in The Absence of BaseDocumento6 pagineZinc-Catalyzed Williamson Ether Synthesis in The Absence of BaseAngie Yetzell Rico LópezNessuna valutazione finora

- A26 193Documento13 pagineA26 193Syarif HidayatNessuna valutazione finora

- Hazards of Organic Chloride To Petroleum Processing in Chinese Refineries and Industrial CountermeasuresDocumento4 pagineHazards of Organic Chloride To Petroleum Processing in Chinese Refineries and Industrial CountermeasuresIrene CarrilloNessuna valutazione finora

- Test PPDocumento4 pagineTest PPTHANGVUNessuna valutazione finora

- Alhaji Massoud Juma - Petroleum AssignmentDocumento9 pagineAlhaji Massoud Juma - Petroleum AssignmentAlhaj MassoudNessuna valutazione finora

- Tetrahydrofuran PDFDocumento6 pagineTetrahydrofuran PDFMaximiliano TaubeNessuna valutazione finora

- DSGHRTHDDocumento12 pagineDSGHRTHDMary Grace VelitarioNessuna valutazione finora

- Ullmann S Encyclopedia of Industrial Chemistry - MethanolDocumento24 pagineUllmann S Encyclopedia of Industrial Chemistry - MethanolKellyCristinaNessuna valutazione finora

- Energies: /Zno/AlDocumento25 pagineEnergies: /Zno/AlAnonymous Ksq1dyPRhNessuna valutazione finora

- Energies 13 00610 v2 PDFDocumento25 pagineEnergies 13 00610 v2 PDFIsmail ŞahbazNessuna valutazione finora

- Dharangadhara Chemical Works (DCW) LTD.Documento18 pagineDharangadhara Chemical Works (DCW) LTD.ABINESH S 16CHR00267% (3)

- US5208393 - Patent Reduction CCl4Documento7 pagineUS5208393 - Patent Reduction CCl4aldo BMCNessuna valutazione finora

- Nanoporous Catalysts for Biomass ConversionDa EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNessuna valutazione finora

- Method of Recovering CumeneDocumento3 pagineMethod of Recovering CumeneRizal EffendiNessuna valutazione finora

- Alkylaromatics ProductionDocumento9 pagineAlkylaromatics ProductionRizal EffendiNessuna valutazione finora

- Nov. 11, 1958 E. K. Jones Et Al: Manufacture of Isopropyl Benzene by Alkylation Filed JanDocumento8 pagineNov. 11, 1958 E. K. Jones Et Al: Manufacture of Isopropyl Benzene by Alkylation Filed JanRizal EffendiNessuna valutazione finora

- Activation of ZeolitesDocumento10 pagineActivation of ZeolitesRizal EffendiNessuna valutazione finora

- Cbse Class 6 Science Notes Chapter 13Documento4 pagineCbse Class 6 Science Notes Chapter 13rohinimr007Nessuna valutazione finora

- CatalogDocumento52 pagineCatalogtalabiraNessuna valutazione finora

- PTFE HZ-2 HoerbigerDocumento2 paginePTFE HZ-2 HoerbigerТатьяна ВасильеваNessuna valutazione finora

- A Study On Risk Assessment in The Construction of High-Rise BuildingsDocumento5 pagineA Study On Risk Assessment in The Construction of High-Rise BuildingsMohamedSaidNessuna valutazione finora

- Buk Uuuuuu UuuuuuuDocumento92 pagineBuk Uuuuuu UuuuuuuJanaliyaNessuna valutazione finora

- Pearson Correlation ValueDocumento7 paginePearson Correlation ValuemarianaNessuna valutazione finora

- Video Wall, Digital Signage & C'Type Serial NumberDocumento8 pagineVideo Wall, Digital Signage & C'Type Serial NumberAbhijit BarmanNessuna valutazione finora

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BDocumento8 pagineBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BKeni KenizaNessuna valutazione finora

- Ags 30Documento1 paginaAgs 30Anonymous jIzz7woS60% (1)

- Bleeding Disorders and Periodontology: P V & K PDocumento13 pagineBleeding Disorders and Periodontology: P V & K PAdyas AdrianaNessuna valutazione finora

- 10 To 11-ClassDocumento111 pagine10 To 11-ClassVikaas SagerNessuna valutazione finora

- Federal Bylaw 12 Air Pollution 2006 English Translation v2 OCRDocumento63 pagineFederal Bylaw 12 Air Pollution 2006 English Translation v2 OCRIsmail SultanNessuna valutazione finora

- XVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Documento7 pagineXVI - Magneticpropertiesofmanganese ContainingsolidsolutionsofbismuthorthoniobateBiNiO4Chukwuebuka UgochukwuNessuna valutazione finora

- TAS360VoIP ExDocumento56 pagineTAS360VoIP ExOscar Damián Gómez HernándezNessuna valutazione finora

- Parker - Twin FilterDocumento6 pagineParker - Twin FilterNAHASALI11Nessuna valutazione finora

- AngelDocumento21 pagineAngelNoj ZachNessuna valutazione finora

- DSE MC G11 G12 Equations Straight Lines 2023Documento6 pagineDSE MC G11 G12 Equations Straight Lines 2023ernestchan501Nessuna valutazione finora

- Lit 1 ReportDocumento21 pagineLit 1 ReportTrexie De Vera JaymeNessuna valutazione finora

- Middle East ManufacturerDocumento6 pagineMiddle East Manufacturerhsco rdNessuna valutazione finora

- An Automated Energy Meter Reading System Using GSM TechnologyDocumento8 pagineAn Automated Energy Meter Reading System Using GSM TechnologyBarNessuna valutazione finora

- IJHIM 6 - Nur Husnina (36 SD 42)Documento7 pagineIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNessuna valutazione finora

- COR5500U Series: Digital and CRT Readout OscilloscopeDocumento7 pagineCOR5500U Series: Digital and CRT Readout OscilloscopeFlavio FalcãoNessuna valutazione finora

- Nfpa 13d 2007 IndexDocumento3 pagineNfpa 13d 2007 Indexsaladin1977Nessuna valutazione finora

- Transdermal Drug Delivery System ReviewDocumento8 pagineTransdermal Drug Delivery System ReviewParth SahniNessuna valutazione finora

- Unit 21Documento22 pagineUnit 21Yuni IndahNessuna valutazione finora

- Bushing TestingDocumento8 pagineBushing TestingjoseNessuna valutazione finora