Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Eil Spec For Pmi PDF

Caricato da

sonnu151Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Eil Spec For Pmi PDF

Caricato da

sonnu151Copyright:

Formati disponibili

STANDARD SPECIFICATION

tg

STANDARD SPECIFICATION No.

I

151fRiseA ENGINEERS FOR POSITIVE MATERIAL

si at efaleg INI NA LIMITED

/A “nul na. Lnden.,), IDENTIFICATION (PMI) AT

6 - 81 - 0001 Rev. 2

SUPPLIER'S WORKS Page I of 8

covingii 4

c 1T

,flcomoict) TIPTth LI 111

f'6g itta-vr

STANDARD SPECIFICATION

FOR

POSITIVE MATERIAL

IDENTIFICATION

(PMI)

AT SUPPLIER'S WORKS

40D ., 15,

2 20.10.11 REVISED AND RE-ISSUED AKC DM

1 15.07.08 REVISED AND RE-ISSUED

NKR SSL SKP VC

0 07.12.00 ISSUED AS STANDARD SPECIFICATION AKC AKB AKB MI

Standards Standards

Rev. Prepared Checked Committee Bureau

No Date Purpose

by by Convenor Chairman

Approved by

Formal No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1642 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

151Mae? - le.' ENGINEERS FOR POSITIVE MATERIAL

imegver INDIA LIMITED

yin eRaWanJelwill Govl of India Undertakno IDENTIFICATION (PM I) AT

6-81-0001 Rev. 2

SUPPLIER'S WORKS Page 2 of 8

Abbreviations:

API American Petroleum Institute

AS Alloy Steel

LSTK Lump Sum Turn Key

PMI Positive Material Identification

Sch Schedule

SS Stainless Steel

TPI or TPIA Third Party Inspection Agency

Inspection Standards Committee

Convenor: Mr.AK Chaudhary

Members: Mr. SS Lotay

Mr. SC Gupta

Mr. RK Singh

Mr. Rajeev Kumar

Mr. Anoop Goel

Mr. G Suresh

Mr. G Poornachandra Rao

Mr. MP Jain (Projects)

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1643 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

151M4-e?fte ENGINEERS FOR POSITIVE MATERIAL

Ogrir tfigtegW INDIA LIMITED

Gorl of India undertaking} IDENTIFICATION (PMI) AT

6-81-0001 Rev. 2

SUPPLIER'S WORKS Page 3 of 8

CONTENTS

1.0 SCOPE 4

2.0 REFERENCE DOCUMENTS 4

3.0 DEFINITIONS 4

4.0 PMI EXAMINATION 5

5.0 ACCEPTABLE METHODS FOR PMI 5

6.0 EXTENT OF PMI EXAMINATION 6

7.0 RECORDING AND DOCUMENTATION 7

8.0 MARKING 7

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL —All rights reserved

Page 1644 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

ft/ ENCJNEERS FOR POSITIVE MATERIAL

beire,altateg ‘60

'- -1 INDIA LIMITED 6-81-0001 Rev. 2

IDENTIFICATION (PMT) AT

SUPPLIER'S WORKS Page 4 of 8

1.0 SCOPE

1.1 This specification applies to the requirements for Positive Material Identification (PMI) to be

performed at the Supplier's works on Metallic Materials procured either directly by the

Owner/EIL/ LSTK contractor or indirectly through the sub-Suppliers.

1.2 Any post order deviation from this specification must be approved by Owner/EIL in the

Deviation/ Waiver Permit format (No. 5-0000-0180-F1) enclosed with Material Requisition.

1.3 This specification covers the procedures and methodology to be adopted to assure that the

chemical composition of the material is consistent with the material specifications as specified

in purchase documents using 'Alloy Analyzer' at the time of final inspection before dispatch.

1.4 The scope of this specification shall include but shall not be limited to Positive Material

Identification (PMI) to be performed on Materials listed below:

1.4.1 For alloy Steel materials as below:

Alloy Steel Pipes including Clad Pipes

Alloy Steel Flanges & Forgings

Alloy Steel Fittings including Clad Fittings

Alloy Steel Fasteners

Alloy Cast & Forged steel valves

Alloy Steel Instrumentation Items (Control Valves, Safety Valves etc.)

Longitudinal Pipe & Fittings Welds.

Gaskets (for Ring Type Joints)

1.4.2 For Carbon Steel materials as below:

All Carbon Steel Piping items under NACE or HIC or H2

Carbon Steel flanges and valves (Rating 900# and above)

Carbon Steel Pipes & fittings for following thicknesses:

Size 1"- 2" NB : Sch 160 & above

Size 3" NB : Sch XS & above

Size 4" - 12" NB : Sch 120 & above

Following items shall be excluded from scope of PMI examination.

Gaskets other than for Ring Type Joints

Internal Components of Valves

1.5 All grades of material supplies including Stainless Steels shall be liable for PMI test at site. In

case of any defective materials being found at site, the Supplier shall be responsible to effect

replacement of such defective materials at project site without any delays to the satisfaction of

EIL site RCM (Resident Construction Manager).

2.0 REFERENCE DOCUMENTS

2.1 API Recommended Practice 578 (First Edition, May 1999) - Material Verification Program for

New and Existing Alloy Piping Systems.

3.0 DEFINITIONS

3.1 Supplier: Any Supplier or Manufacturer on whom an order is placed for the supply of referred

items. This definition shall also include any sub-Supplier or manufacturer on whom a sub-order

is placed by the Supplier.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1645 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

SaIRCIELM—; ENGINEERS FOR POSITIVE MATERIAL

Par taiReZ VW INDIA LIMITED 6-81-0001 Rev. 2

IDENTIFICATION (PM I) AT

SUPPLIER'S WORKS Page 5 of 8

3.2 Inspection Lot: A group of items offered for inspection covered under same size, Heat and

Heat treatment lot.

3.3 Alloy Material: Any metallic material (including welding filler materials) that contains

alloying elements such as chromium, nickel, molybdenum or vanadium, which are intentionally

added to enhance mechanical or physical properties and/or corrosion resistance.

4.0 PMI EXAMINATION

4.1 The Supplier shall submit a procedure of PMI to comply with the requirements of this

Specification Approval of PMI Procedure shall be obtained from Owner/EIL/TPIA prior to

commencing manufacture/ inspection of product.

4.2 PMI examination of materials is independent of any certification, markings or colour coding

that may exist and is aimed at verifying that the alloy used are as per specified grades.

4.3 The Supplier shall identify all incoming alloy materials and maintain full traceability of all alloy

materials, including all off-cuts. Transfer of identification marks shall be undertaken prior to

cutting to ensure maintenance of identification on off-cuts.

4.4 The Supplier shall ensure that all alloy materials are segregated and stored in separately

identified locations to prevent the mix up of materials of different alloy specifications or alloy

material with carbon steel. Non ferro-magnetic materials shall be segregated at all times from

ferro-magnetic materials.

4.5 PMI examination is subject to surveillance inspection by Owner/EIL/TPIA.

5.0 ACCEPTABLE METHODS FOR PMI

5.1 The method used for PMI examination shall provide a quantitative determination of the alloying

elements like chromium, nickel, molybdenum or vanadium in Alloy Steel items.

5.2 Instruments or methods used for PMI examination shall be able to provide quantitative,

recordable, elemental composition results for positive identification of alloying elements

present.

5.3 The acceptable instruments for alloy analyzer shall be either "Portable X-Ray fluorescence" or

"Optical Emission" type each capable of verifying the percentage of alloy elements within

specified range.

5.4 Chemical spot testing, magnets, alloy sorters and other methods using eddy current or

triboelectric testing methods are not acceptable for PMI examination.

5.5 The PMI instrument used shall have the sensitivity to detect the alloying elements in the

specified range.

5.6 All PMI instruments shall have been serviced within a 6 month period of the time of use to

verify the suitability of batteries, sources etc., and the data of the last service shall be stated on

the PMI Report Form (Sample enclosed).

5.7 Each analyzer must be calibrated according to the manufacturer's specification at the beginning

and end of each shift. Instrument must be checked against known standard for each alloy type

to be inspected during the shift.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1646 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

ISillaZreq e ENGINEERS FOR POSITIVE MATERIAL

s'Ig7e2eg W

INDIA UMITED

Govt a Inaa Undenakingi IDENTIFICATION (PMI) AT

6-81-0001 Rev. 2

SUPPLIER'S WORKS Page 6 of 8

5.8 Certified samples, with full traceability, of a known alloy materials shall be available for use as

a random spot check on the instrument calibration.

5.9 The surfaces to be examined shall be prepared by light grinding or abrasive paper and solvent

cleaner. Evidence of Arc burn resulting from examination shall be removed by light grinding or

abrasive paper. No permanent marks, which are injurious to the usage of product in service, are

acceptable.

5.10 Alloy Steel ring type joint Gaskets shall be inspected by using portable X-Ray fluorescence

instrument.

5.11 Testing shall be done as per the procedures outlined by the manufactures of alloy analyzer

being used. Modification of these procedures if any must be approved by Owner/EIL.

5.12 The persons performing PMI shall demonstrate their capabilities to the satisfaction of

Owner/EIL/TPIA visiting engineer. If the Supplier has qualified operator on their rolls, he may

perform the examination. Otherwise PMI examination shall be sub-contracted to an independent

testing agency approved by EIL.

5.13 Whenever material is identified as not meeting requirements by the visiting engineer a rejection

note shall be issued.

6.0 EXTENT OF PMI EXAMINATION

Following sampling plans shall be applicable for PMI examination of various items.

Flanges, Fittings 100%

Valves, RTJ Gaskets

Pipes 100% (for pipes procured from traders).

2 random samples drawn from each

Size/Heat/Lot (for pipes procured directly from mills)

C. Fasteners

Lot Size Sample Size

Upto 100 2% (Min 2)

101 to 500 1% (Min 3)

501 and above 0.5% (Min 5)

Note:

For Welded Pipes and Fittings, PMI shall be performed on Base Metal as well as

weldments.

Whenever any sample drawn to PMI test on the basis of percentage selection in B & C

above, fails to meet specification requirements, 100% of items of lot shall be tested for

PMI.

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1647 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

i.311-aelti . ENGINEERS FOR POSITIVE MATERIAL

ogrir EiRtegi INDIA LIMITED

IA Go' at India Undertaking) IDENTIFICATION (PMI) AT

6-81-0001 Rev. 2

SUPPLIER'S WORKS Page 7 of 8

7.0 RECORDING AND DOCUMENTATION

The results of PMI examination shall be recorded in a Report Format as enclosed with this

specification.

8.0 MARKING

8.1 All alloy materials tested by PMI shall be identified using either of the following methods by

indicating "PMI OK"

Bar Code/Hologram Sticker

A low stress stamp marking

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1648 of 2542

STANDARD SPECIFICATION STANDARD SPECIFICATION No.

012-ael ie ENGINEERS FOR POSITIVE MATERIAL

st",ar &Reg W INDIALIMTED 6-81-0001 Rev. 2

GOA Of India undertakng) IDENTIFICATION (PMI) AT

SUPPLIER'S WORKS Page 8 of 8

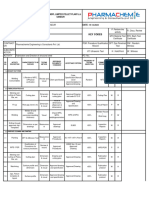

POSITIVE MATERIAL IDENTIFICATION REPORT Page of

BULK MATERIALS

Project: Client Job No.

PMI Report No. Supplier/Sub-Supplier

Purchase Order No. Testing Agency

Purchase PMI Location

Requisition No:

Bulk Item Type (as per Requisition)

Material Specification/Grade

Number of items in Lot

Requisition Item No./ Description Major content, Weight Percent Remarks

Accept/Reject

Element Cr Mo Ni V

Specified Range

Actual observations

Instrument Type / ID

Last Service Date Witnessed By

Inspection Agency

Format No. 8-00-0001-F1 Rev. 0 Copyright EIL — All rights reserved

Page 1649 of 2542

Potrebbero piacerti anche

- Token Ring Technology ReportDa EverandToken Ring Technology ReportNessuna valutazione finora

- Standard Specification For Positive Material Identification (PMI) at Supplier's WorksDocumento8 pagineStandard Specification For Positive Material Identification (PMI) at Supplier's WorksmanuneedhiNessuna valutazione finora

- 6 44 0005 A2Documento25 pagine6 44 0005 A2S.selvakumarNessuna valutazione finora

- 6-44-0005 Rev 7Documento446 pagine6-44-0005 Rev 7MDhana SekarNessuna valutazione finora

- 6-44-0013 Rev 5-FLUSHING AND TESTING OF PIPING SYSTEM PDFDocumento9 pagine6-44-0013 Rev 5-FLUSHING AND TESTING OF PIPING SYSTEM PDFsumit tiwariNessuna valutazione finora

- 6-17-0007 Rev 5Documento8 pagine6-17-0007 Rev 5Anonymous 2zcLfLjWNessuna valutazione finora

- Doc. Req. From ContractorsDocumento9 pagineDoc. Req. From ContractorsAjinkyaKarlekarNessuna valutazione finora

- Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocumento9 pagineStandard Specification For Inspection, Flushing and Testing of Piping SystemsJITENDER KUMARNessuna valutazione finora

- 6-65-0013 Rev 3Documento7 pagine6-65-0013 Rev 3rajanjisri2259Nessuna valutazione finora

- Tech Notes For ValvesDocumento20 pagineTech Notes For ValvesmanuneedhiNessuna valutazione finora

- Mucg06m1tw - List of DocumentsDocumento62 pagineMucg06m1tw - List of DocumentsKalai SelvanNessuna valutazione finora

- 6-44-0053 Rev 6 FlangesDocumento7 pagine6-44-0053 Rev 6 Flangesहेमंत कुमार मीणाNessuna valutazione finora

- 04 1 Sec IV STD Specs PipingDocumento152 pagine04 1 Sec IV STD Specs PipingdzungNessuna valutazione finora

- 6-44-0012 Rev 4-FABRICATION AND ERECTION OF PIPING PDFDocumento15 pagine6-44-0012 Rev 4-FABRICATION AND ERECTION OF PIPING PDFsumit tiwariNessuna valutazione finora

- Annexure To SOW 10 Standard Specification For Steam TracingDocumento9 pagineAnnexure To SOW 10 Standard Specification For Steam TracingASHISH GORDENessuna valutazione finora

- Fire Proofing SpecificationDocumento16 pagineFire Proofing SpecificationSalman ShaikhNessuna valutazione finora

- 6-79-0013 Rev 2Documento6 pagine6-79-0013 Rev 2Foryoutube JobsNessuna valutazione finora

- 6-79-0013 Rev 2Documento6 pagine6-79-0013 Rev 2MONER MANUSNessuna valutazione finora

- 6 44 0005 A1 PDFDocumento15 pagine6 44 0005 A1 PDFS.selvakumarNessuna valutazione finora

- Specification For QMS Requirements 6-78-0001 - Rev. 1Documento7 pagineSpecification For QMS Requirements 6-78-0001 - Rev. 1Ayush Choudhary100% (1)

- Itp For All MaterialsDocumento59 pagineItp For All MaterialsTauqueerAhmad100% (1)

- FlangesDocumento30 pagineFlangesGautam BhardwajNessuna valutazione finora

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocumento7 pagine6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007Nessuna valutazione finora

- Eil SpecDocumento37 pagineEil SpecJames100% (1)

- 6-24-0004 Catridge FilterDocumento9 pagine6-24-0004 Catridge FilterMurli ramchandran100% (1)

- Technical Notes For ValvesDocumento41 pagineTechnical Notes For ValvesGautam BhardwajNessuna valutazione finora

- Atirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesDocumento7 pagineAtirkfch-G Tat Tr4Ri: Standard Specification For Orifice Plates and FlangesBharat TrivediNessuna valutazione finora

- 6 77 0001 Rev - 4 PDFDocumento40 pagine6 77 0001 Rev - 4 PDFRam Kadam0% (1)

- Standard Specification For Restriction Orifice PlatesDocumento6 pagineStandard Specification For Restriction Orifice PlatesJITENDER KUMARNessuna valutazione finora

- PipesDocumento37 paginePipesGautam BhardwajNessuna valutazione finora

- Eil Steam Trap StanderedDocumento56 pagineEil Steam Trap StanderedVIVEK TIWARINessuna valutazione finora

- General Specification For Wire Mesh Demisters: Fgeir FmfgitgDocumento6 pagineGeneral Specification For Wire Mesh Demisters: Fgeir Fmfgitgpriti kumariNessuna valutazione finora

- ITB-spc For Tape Coating For UG Piping PDFDocumento15 pagineITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNessuna valutazione finora

- 6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocumento9 pagine6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsdgkmurtiNessuna valutazione finora

- 6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsDocumento20 pagine6-41-0006 Rev 3 - EIL STD Specs For Centrifugal PumpsSachinShinde100% (2)

- 6-76-0002 Bolt Tension For FlangesDocumento33 pagine6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- ITP For Instrumentation WorksDocumento80 pagineITP For Instrumentation WorksTauqueerAhmadNessuna valutazione finora

- Mov EIL SpecsDocumento10 pagineMov EIL SpecsveenaNessuna valutazione finora

- Packing Marking and Shipping Specifications For Trays and Tower InternalsDocumento6 paginePacking Marking and Shipping Specifications For Trays and Tower Internalspriti kumariNessuna valutazione finora

- Specification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsDocumento15 pagineSpecification Att - 3-18 - 6-51-0032 20rev 205 - Spec For Medium Voltage Induction MotorsAvinash ShuklaNessuna valutazione finora

- 6-15-0091 STD Spec For Hardness Req of Static EqDocumento5 pagine6-15-0091 STD Spec For Hardness Req of Static EqMurli ramchandranNessuna valutazione finora

- Standard Specification For Concrete Lining in CanalsDocumento6 pagineStandard Specification For Concrete Lining in CanalsJITENDER KUMARNessuna valutazione finora

- 6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFDocumento13 pagine6-12-0031 - Standard Specification For Storage Tanks For Package Items PDFpl_arunachalam79Nessuna valutazione finora

- 6-12-0015 - Standard Specification For Clad Plates.Documento5 pagine6-12-0015 - Standard Specification For Clad Plates.pl_arunachalam79100% (1)

- 1-Ael Ftteur A Iteur: Copsil, Turt / C4 1 (14-1-1Documento7 pagine1-Ael Ftteur A Iteur: Copsil, Turt / C4 1 (14-1-1Murli RamchandranNessuna valutazione finora

- PMI Report May 2019Documento19 paginePMI Report May 2019RifanjshshNessuna valutazione finora

- EIL-STD Specifiction For Centrifugal Pumps PDFDocumento21 pagineEIL-STD Specifiction For Centrifugal Pumps PDFM Danish john paul100% (1)

- Technical Specification For On-Off Valves - 20140225 - 174713Documento120 pagineTechnical Specification For On-Off Valves - 20140225 - 174713fraihafraiha100% (1)

- QAP1Documento2 pagineQAP1akshaymehra2354Nessuna valutazione finora

- Specifications of LR BendDocumento11 pagineSpecifications of LR BendPrafulla PatilNessuna valutazione finora

- Ih Setup 38tDocumento1 paginaIh Setup 38tmuthuselvanNessuna valutazione finora

- 6-15-0001 - General Specification For Heat Exchangers PDFDocumento21 pagine6-15-0001 - General Specification For Heat Exchangers PDFpl_arunachalam79100% (1)

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocumento8 paginePDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimNessuna valutazione finora

- QAP FinalDocumento6 pagineQAP FinalANSHUMAN KUMARNessuna valutazione finora

- E.21 ITP For GasketsDocumento5 pagineE.21 ITP For GasketsManoj DhimanNessuna valutazione finora

- 6-79-0015 Rev 1Documento12 pagine6-79-0015 Rev 1abhishek0% (1)

- Qap TataDocumento5 pagineQap TataDesign VardhNessuna valutazione finora

- 6-79-0016 Rev 1Documento11 pagine6-79-0016 Rev 1abhishek100% (1)

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesDa EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNessuna valutazione finora

- Review of Is 1367 Part 13Documento2 pagineReview of Is 1367 Part 13sonnu151Nessuna valutazione finora

- Doc. Required by Quality Order ReviewDocumento1 paginaDoc. Required by Quality Order Reviewsonnu151Nessuna valutazione finora

- Tpia Feedback FormDocumento1 paginaTpia Feedback Formsonnu151Nessuna valutazione finora

- Paharpur-1 Pallet NEWDocumento102 paginePaharpur-1 Pallet NEWsonnu151Nessuna valutazione finora

- Graph f-7424Documento1 paginaGraph f-7424sonnu151Nessuna valutazione finora

- Visual Inspection of FastenersDocumento1 paginaVisual Inspection of Fastenerssonnu151Nessuna valutazione finora

- SST Test DefectsDocumento2 pagineSST Test Defectssonnu151Nessuna valutazione finora

- I.No CDD PDD Item Weight KG: Customer Maste R List SR - NoDocumento1 paginaI.No CDD PDD Item Weight KG: Customer Maste R List SR - Nosonnu151Nessuna valutazione finora

- T 1Documento1 paginaT 1sonnu151Nessuna valutazione finora

- No 33Documento15 pagineNo 33sonnu151Nessuna valutazione finora

- Supplier Quality Requirement Form (SSQRF) : Inspection NotificationDocumento1 paginaSupplier Quality Requirement Form (SSQRF) : Inspection Notificationsonnu151Nessuna valutazione finora

- Sample-1 Sample-2 Sample-3 Sample-4 Sample-5 Mean M 179 182 189 195 199 944 188.8 35645.44 Sq. of Mean MDocumento1 paginaSample-1 Sample-2 Sample-3 Sample-4 Sample-5 Mean M 179 182 189 195 199 944 188.8 35645.44 Sq. of Mean Msonnu151Nessuna valutazione finora

- Quality Order Review Sheet I.O-NO.:: Client:: D.P (PDD) PaymentDocumento2 pagineQuality Order Review Sheet I.O-NO.:: Client:: D.P (PDD) Paymentsonnu151Nessuna valutazione finora

- DP Amendment 15.06.2020Documento1 paginaDP Amendment 15.06.2020sonnu151Nessuna valutazione finora

- 1367 5 PDFDocumento11 pagine1367 5 PDFsonnu151Nessuna valutazione finora

- Note: This Is A Computer Generated Receipt and Does Not Require Any Signature/stampDocumento1 paginaNote: This Is A Computer Generated Receipt and Does Not Require Any Signature/stampsonnu151Nessuna valutazione finora

- Indian Income Tax Return Acknowledgement: Do Not Send This Acknowledgement To CPC, BengaluruDocumento1 paginaIndian Income Tax Return Acknowledgement: Do Not Send This Acknowledgement To CPC, Bengalurusonnu151Nessuna valutazione finora

- NoteDocumento4 pagineNotesonnu151Nessuna valutazione finora

- Is 10238 - 2001Documento6 pagineIs 10238 - 2001sonnu151Nessuna valutazione finora

- 04.annexure R - B016-VRMP-LT-COM-QA-QD-0005 - Positive Material Identification Procedure PDFDocumento10 pagine04.annexure R - B016-VRMP-LT-COM-QA-QD-0005 - Positive Material Identification Procedure PDFsonnu151Nessuna valutazione finora

- Height GaugeDocumento2 pagineHeight Gaugesonnu151Nessuna valutazione finora

- Technical Supply Conditions FOR Threaded Steel Fasteners: Indian StandardDocumento5 pagineTechnical Supply Conditions FOR Threaded Steel Fasteners: Indian Standardsonnu151Nessuna valutazione finora

- Is 1870Documento165 pagineIs 1870sonnu151Nessuna valutazione finora

- Steel Limited,: Bar Mill & Billet CasterDocumento1 paginaSteel Limited,: Bar Mill & Billet Castersonnu151Nessuna valutazione finora

- Electrodeposited Coatings On Threaded Fasteners (Unified Inch Screw Threads (UN/UNR) )Documento10 pagineElectrodeposited Coatings On Threaded Fasteners (Unified Inch Screw Threads (UN/UNR) )sonnu151Nessuna valutazione finora

- CUIT 201 Assignment3 March2023Documento2 pagineCUIT 201 Assignment3 March2023crybert zinyamaNessuna valutazione finora

- Admission: North South University (NSU) Question Bank Summer 2019Documento10 pagineAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- ISO-50001-JK-WhiteDocumento24 pagineISO-50001-JK-WhiteAgustinusDwiSusantoNessuna valutazione finora

- Kunst 1600 Case AnalysisDocumento3 pagineKunst 1600 Case AnalysisrakeshNessuna valutazione finora

- Lennox IcomfortTouch ManualDocumento39 pagineLennox IcomfortTouch ManualMuhammid Zahid AttariNessuna valutazione finora

- 3DD5036 Horizontal.2Documento6 pagine3DD5036 Horizontal.2routerya50% (2)

- Mobility StrategyDocumento38 pagineMobility StrategySoubhagya PNessuna valutazione finora

- Romano Uts Paragraph Writing (Sorry For The Late)Documento7 pagineRomano Uts Paragraph Writing (Sorry For The Late)ទី ទីNessuna valutazione finora

- A Presentation On-: E-Paper TechnologyDocumento19 pagineA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruNessuna valutazione finora

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Documento2 paginePermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNessuna valutazione finora

- Swot Matrix Strengths WeaknessesDocumento6 pagineSwot Matrix Strengths Weaknessestaehyung trash100% (1)

- Dissertation MA History PeterRyanDocumento52 pagineDissertation MA History PeterRyaneNessuna valutazione finora

- Concept of Lokmitra Kendra in Himachal PradeshDocumento2 pagineConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaNessuna valutazione finora

- LQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQDocumento5 pagineLQZLQM ) So"L/L6H Klans LN : Sfof (No K - Of) HGSF) Nflu DFQSAJAL KOIRALANessuna valutazione finora

- Reviewer in PE&H 1st Quarter 18-19Documento7 pagineReviewer in PE&H 1st Quarter 18-19rhex minasNessuna valutazione finora

- Control System PPT DO1Documento11 pagineControl System PPT DO1Luis AndersonNessuna valutazione finora

- Classical Theories of Economic GrowthDocumento16 pagineClassical Theories of Economic GrowthLearner8494% (32)

- Drsent PT Practice Sba OspfDocumento10 pagineDrsent PT Practice Sba OspfEnergyfellowNessuna valutazione finora

- Learning Plans in The Context of The 21 ST CenturyDocumento29 pagineLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNessuna valutazione finora

- Design of Footing R1Documento8 pagineDesign of Footing R1URVESHKUMAR PATELNessuna valutazione finora

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Documento6 pagineSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonNessuna valutazione finora

- Pascal Die Casting Machine SystemDocumento20 paginePascal Die Casting Machine Systemenascimento32Nessuna valutazione finora

- SemDocumento583 pagineSemMaria SantosNessuna valutazione finora

- Make Yeast StarterDocumento2 pagineMake Yeast StarterAlexandraNessuna valutazione finora

- Application Letter For Promotion T2 T3Documento24 pagineApplication Letter For Promotion T2 T3FGacadSabadoNessuna valutazione finora

- Bombas KMPDocumento42 pagineBombas KMPReagrinca Ventas80% (5)

- Thesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKDocumento194 pagineThesis - A Surlyn® Ionomer As A Self-Healing and Self-Sensing Composite - 2011 - UKAhmedNessuna valutazione finora

- Biography Worksheet: Name: Gerardo Angeles MartinezDocumento1 paginaBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNessuna valutazione finora

- Contribution of Medieval MuslimDocumento16 pagineContribution of Medieval Muslimannur osmanNessuna valutazione finora

- Medrano, Rene LynnDocumento2 pagineMedrano, Rene LynnRene Lynn Labing-isa Malik-MedranoNessuna valutazione finora