Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

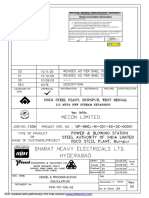

Instrument Air Dryer and Instrument Air Receiver

Caricato da

Aiman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

96 visualizzazioni1 paginaThis document provides specifications for various equipment for an instrument air system, including an air dryer package, pre-filters, after filters, and an instrument air receiver. It lists the item numbers, design pressures and temperatures, operating pressures and temperatures, capacities, materials, and notes for each item. The air dryer system uses pressure swing adsorption and is sized to dehydrate 100% of the design air consumption rate. The pre-filters and after filters are rated to remove particles according to ISO standards.

Descrizione originale:

Instrument Air Dryer and Instrument Air Receiver

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides specifications for various equipment for an instrument air system, including an air dryer package, pre-filters, after filters, and an instrument air receiver. It lists the item numbers, design pressures and temperatures, operating pressures and temperatures, capacities, materials, and notes for each item. The air dryer system uses pressure swing adsorption and is sized to dehydrate 100% of the design air consumption rate. The pre-filters and after filters are rated to remove particles according to ISO standards.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

96 visualizzazioni1 paginaInstrument Air Dryer and Instrument Air Receiver

Caricato da

AimanThis document provides specifications for various equipment for an instrument air system, including an air dryer package, pre-filters, after filters, and an instrument air receiver. It lists the item numbers, design pressures and temperatures, operating pressures and temperatures, capacities, materials, and notes for each item. The air dryer system uses pressure swing adsorption and is sized to dehydrate 100% of the design air consumption rate. The pre-filters and after filters are rated to remove particles according to ISO standards.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

ITEM NO.

A-5420 V-5435/40 A/B S-5425/30 A/B S-5445/50 A/B V-5420

SYMBOL SKID

SERVICE INSTRUMENT AIR DRYER PRE-FILTERS AFTER FILTER INSTRUMENT AIR

AIR DRYER TOWERS RECEIVER

PACKAGE

DESIGN 13.8 13.8 13.8 13.8 13.8

PRESSURE

(barg)

DESIGN 65/0 65/0 65/0 65/0 65/0

TEMPERATU

RE (˚C)

(MAX/MIN)

OPERATING 10.3 10.3 10.3 10.3 10

PRESSURE

(bar)

OPERATING 50 50 50 50 50

TEMPERATU

RE (˚C)

CAPACITY 3137 3137 3137 3137 -

(Sm3/hr)

ID × LENGTH - BY VENDOR BY VENDOR BY VENDOR 2400(ID) × 5600(T/T)

T/T (mm)

DESIGN ASME VIII DIV.1 ASME VIII DIV.1 ASME VIII DIV.1 ASME VIII DIV.1 ASME VIII DIV.1

CODE

MATERIAL CARBON STEEL CS + 3mmca + CS + 3mmca + CS + SS316L CS + 3mmca +

INTERNAL AMINE INTERNAL AMINE INTERNAL AMINE

ADDUCT EPOXY ADDUCT EPOXY ADDUCT EPOXY COAT

COAT COAT

Trim No. - 1S600 1S600 1S600 1S600

NOTES 1. Solenoid 1. Air dryer 1. Filters shall be 1. 2 × 100% after 1. Vessel is sized with

valves to system shall rated for filter sufficient inventory

control the be pressure removal of configuration to supply maximum

switching swing (dust) particles instrument air

valve adsorption in compliance demand for

actuators (PSA) type to ISO-B573-1 minimum 7

and the unit sized to class 1.2.0 minutes duration

purging dehydrate standards during loss of

valve 100% of the 2. 2 × 100% pre- power supply

actuator design air filter

2. Automatic consumption configuration

start-up of rate

the standby dehydrating

instrument the air to ISO-

air dryer 8573-1 class

train during 1.2.0

lag standards

compressor 2. 2 × 100%

start-up shall tower

be done via configuration

DCS.

Potrebbero piacerti anche

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentDa EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentValutazione: 4.5 su 5 stelle4.5/5 (3)

- NAV-10-GM-BR-IEM-035 Rev1Documento10 pagineNAV-10-GM-BR-IEM-035 Rev1Korcan ÜnalNessuna valutazione finora

- Technical Data: 150x100 FS2KA 5 90Documento5 pagineTechnical Data: 150x100 FS2KA 5 90infonetsmgNessuna valutazione finora

- G LST 001 Ab Tank Farm in ProgressDocumento270 pagineG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreNessuna valutazione finora

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocumento2 pagine7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNessuna valutazione finora

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocumento4 pagineUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNessuna valutazione finora

- Pressure Safety Valve Sizing Calculation Rev 01Documento4 paginePressure Safety Valve Sizing Calculation Rev 01Fari NazariNessuna valutazione finora

- 01 PDFDocumento6 pagine01 PDFSherif AdelNessuna valutazione finora

- Valve Sizing Calculation8Documento2 pagineValve Sizing Calculation8PIDNessuna valutazione finora

- DsdsDocumento10 pagineDsdsLinh GiangNessuna valutazione finora

- Open TankDocumento27 pagineOpen Tankhgagselim2012Nessuna valutazione finora

- JI2048-978-MS-DAT-0014 - Rev001 (SP-1090)Documento9 pagineJI2048-978-MS-DAT-0014 - Rev001 (SP-1090)Tech DesignNessuna valutazione finora

- GIPS - FC - Slam Shut-Off Valve Series Installation, Maintenance and Operation ManualDocumento29 pagineGIPS - FC - Slam Shut-Off Valve Series Installation, Maintenance and Operation ManualluieduNessuna valutazione finora

- Technical Data: 150x125 CNHA 5 18.5Documento5 pagineTechnical Data: 150x125 CNHA 5 18.5سمير البسيونىNessuna valutazione finora

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocumento15 pagineRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11Nessuna valutazione finora

- Pig Receiver Data Sheet 91303 - 8 InchDocumento4 paginePig Receiver Data Sheet 91303 - 8 InchSinaNessuna valutazione finora

- 0 WD990 EM440 00101 Equipment List RevFDocumento20 pagine0 WD990 EM440 00101 Equipment List RevFManuel Jesus Perez MelgarNessuna valutazione finora

- BOM of TankDocumento4 pagineBOM of TankArvind ShuklaNessuna valutazione finora

- Calcs 4Documento19 pagineCalcs 4Syariful Maliki NejstaršíNessuna valutazione finora

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocumento10 pagineClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarNessuna valutazione finora

- Combined Status of BoqmDocumento22 pagineCombined Status of Boqmhemant1284Nessuna valutazione finora

- Ring Wall & Foundation DsignFlow ChartDocumento1 paginaRing Wall & Foundation DsignFlow ChartsivaNessuna valutazione finora

- TLV - Manifolds Vapor y Condensado PDFDocumento4 pagineTLV - Manifolds Vapor y Condensado PDFsirballesterosNessuna valutazione finora

- PDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMDocumento24 paginePDF Created With Pdffactory Pro Trial Version: Pxd-767-Cal-02 23 MMSISIR KR BARMAN0% (1)

- Overview of PV EliteDocumento35 pagineOverview of PV EliteVishaka ThekkedathNessuna valutazione finora

- Motorised Valve: Instrument Datasheet Tag NoDocumento1 paginaMotorised Valve: Instrument Datasheet Tag Nokrishna kumarNessuna valutazione finora

- WHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsDocumento17 pagineWHCP - Design Calculation Notes For Accumulators, Pumps and Electrical MotorsYasin ElaswadNessuna valutazione finora

- Data Sheet For Heat ExchangerDocumento2 pagineData Sheet For Heat ExchangerdgmprabhakarNessuna valutazione finora

- UASB Booster Pressure CalculationDocumento143 pagineUASB Booster Pressure CalculationJayakrishnan RadhakrishnanNessuna valutazione finora

- LPG Amine Cooler-SummaryDocumento15 pagineLPG Amine Cooler-SummaryJEEVITHANessuna valutazione finora

- Item Symbol Description: Course No. HEIGHT (M) MaterialDocumento12 pagineItem Symbol Description: Course No. HEIGHT (M) MaterialReza SaeeNessuna valutazione finora

- Pump CalcDocumento5 paginePump CalcpavanNessuna valutazione finora

- Bom Storage Tank (M.S.)Documento8 pagineBom Storage Tank (M.S.)Varun MalhotraNessuna valutazione finora

- Pumps Final TeDocumento48 paginePumps Final Tegharsallah mounaNessuna valutazione finora

- 16 B 06 HDocumento20 pagine16 B 06 HVaibhav Bhoir0% (1)

- Check List JnNURMDocumento36 pagineCheck List JnNURMshahqazwsxNessuna valutazione finora

- 7-12-0008 Rev 5Documento1 pagina7-12-0008 Rev 5cynideNessuna valutazione finora

- Relief and Blowdown Report: Page 1 of 21Documento21 pagineRelief and Blowdown Report: Page 1 of 21TarekNessuna valutazione finora

- PACE Structured Column Packings: Datasheet For Existing ColumnDocumento2 paginePACE Structured Column Packings: Datasheet For Existing ColumnAabbhas GargNessuna valutazione finora

- Data Sheet For Flare Package (PK-720)Documento3 pagineData Sheet For Flare Package (PK-720)samynatha PrasathNessuna valutazione finora

- Calculation of Relief Load On ColumnDocumento5 pagineCalculation of Relief Load On Columnnghiemta18Nessuna valutazione finora

- Volume Calculation For BlowdownDocumento6 pagineVolume Calculation For BlowdownrohitkushNessuna valutazione finora

- Pages From ONGC-SPEC-02-MS-03Documento12 paginePages From ONGC-SPEC-02-MS-03Prathamesh OmtechNessuna valutazione finora

- Tie in Point (TP) 08 ADocumento19 pagineTie in Point (TP) 08 At_i_f_anoNessuna valutazione finora

- Venting Due To External Firing-12500 LTRS-R0Documento5 pagineVenting Due To External Firing-12500 LTRS-R0Dinesh VaghelaNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento21 pagineNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNessuna valutazione finora

- StrainerDocumento2 pagineStrainerRanjithNessuna valutazione finora

- BFW Cooler Datasheet Rev-2Documento3 pagineBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDNessuna valutazione finora

- Mucog 1910502 Mec DS 055Documento12 pagineMucog 1910502 Mec DS 055vinodNessuna valutazione finora

- Tds Tcs Tata Krishnapatnam Rev.r0Documento46 pagineTds Tcs Tata Krishnapatnam Rev.r0SupriyaRongNessuna valutazione finora

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Documento4 pagineENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNessuna valutazione finora

- PD - LG-STL JmaDocumento9 paginePD - LG-STL JmaTun Naing WinNessuna valutazione finora

- Instrument Air Dryer and Instrument Air ReceiverDocumento4 pagineInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNessuna valutazione finora

- Chicago Pneumatic QRS and CVPS Series 20-30 HP Service Manual (01-2008)Documento28 pagineChicago Pneumatic QRS and CVPS Series 20-30 HP Service Manual (01-2008)Philip ShaverNessuna valutazione finora

- KS Pulp Creator Final Quotation Air CompressorDocumento4 pagineKS Pulp Creator Final Quotation Air Compressoratul guptaNessuna valutazione finora

- Medical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Documento2 pagineMedical Air Treatment System With Refrigerated Air Dryers 3DRZ10-50Eng.Gihad EladlNessuna valutazione finora

- Domnick Hunter Pneudri Dme040 Secador ArDocumento23 pagineDomnick Hunter Pneudri Dme040 Secador ArRafael CardosoNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- Geotextiles and Geomembranes HandbookDa EverandGeotextiles and Geomembranes HandbookT.S. IngoldValutazione: 5 su 5 stelle5/5 (1)

- Universiti Teknologi Mara Faculty of Mechanical EngineeringDocumento3 pagineUniversiti Teknologi Mara Faculty of Mechanical EngineeringAimanNessuna valutazione finora

- Result Cloud and Pour PointDocumento1 paginaResult Cloud and Pour PointAimanNessuna valutazione finora

- Volume and Capacity of ReservoirDocumento5 pagineVolume and Capacity of ReservoirAimanNessuna valutazione finora

- Academic Calendar (Degree) Sept 2017 (130917)Documento4 pagineAcademic Calendar (Degree) Sept 2017 (130917)AimanNessuna valutazione finora

- Ethics Case Study 2Documento2 pagineEthics Case Study 2AimanNessuna valutazione finora

- Introduction and Electrical CircuitsDocumento1 paginaIntroduction and Electrical CircuitsAimanNessuna valutazione finora

- Crime Statistics ELC590Documento6 pagineCrime Statistics ELC590AimanNessuna valutazione finora

- Drilling Mud AdditivesDocumento1 paginaDrilling Mud AdditivesAimanNessuna valutazione finora

- Compile Cost of WasteDocumento11 pagineCompile Cost of WasteAimanNessuna valutazione finora

- Table of Content, 7 9 AimanDocumento4 pagineTable of Content, 7 9 AimanAimanNessuna valutazione finora

- Table of Content COWDocumento1 paginaTable of Content COWAimanNessuna valutazione finora

- Relative Dating Absolote Dating: System of Chronological Dating That Relates Geological Strata (Stratigraphy) To TimeDocumento2 pagineRelative Dating Absolote Dating: System of Chronological Dating That Relates Geological Strata (Stratigraphy) To TimeAimanNessuna valutazione finora

- March April: S M TWT F S S M TWT F SDocumento2 pagineMarch April: S M TWT F S S M TWT F SAimanNessuna valutazione finora

- Shib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Documento7 pagineShib Mandir, PO-Kadamtala Dist-Darjeeling WB - 734011 JC 18, 3RD Floor, Sector - III Salt Lake City, Kolkata 700098Rohit DhanukaNessuna valutazione finora

- 3.6.4 Details of Courses For Nuclear Medicine TechnologyDocumento2 pagine3.6.4 Details of Courses For Nuclear Medicine TechnologyhemendrasingNessuna valutazione finora

- Pex 03 02Documento5 paginePex 03 02aexillis0% (1)

- 08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Documento89 pagine08 BQ - PADSB - Elect - P2 - R2 (Subcon Empty BQ)Middle EastNessuna valutazione finora

- The Exchange Student (Dedicated To Rotary International)Documento163 pagineThe Exchange Student (Dedicated To Rotary International)Nikita100% (1)

- Relative ClausesDocumento11 pagineRelative Clausessaeed100% (1)

- HSE Inspection Report-07Documento32 pagineHSE Inspection Report-07najihahNessuna valutazione finora

- A Cultura-Mundo - Resposta A Uma SociedDocumento7 pagineA Cultura-Mundo - Resposta A Uma SociedSevero UlissesNessuna valutazione finora

- Harvester Main MenuDocumento3 pagineHarvester Main MenuWonderboy DickinsonNessuna valutazione finora

- Getting Things Done BasicsDocumento60 pagineGetting Things Done Basicswestelm12100% (10)

- OXE Training - Complete (2011)Documento94 pagineOXE Training - Complete (2011)Dhexter Villa75% (4)

- Differentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2Documento186 pagineDifferentialequations, Dynamicalsystemsandlinearalgebra Hirsch, Smale2integrationbyparths671Nessuna valutazione finora

- Oil RussiaDocumento8 pagineOil RussiaAyush AhujaNessuna valutazione finora

- Lithium Dongjin 48v100ahDocumento5 pagineLithium Dongjin 48v100ahmk7718100% (1)

- Department of Accounting and Finances Accounting and Finance ProgramDocumento3 pagineDepartment of Accounting and Finances Accounting and Finance Programwossen gebremariamNessuna valutazione finora

- 2018-2021 VUMC Nursing Strategic Plan: Vision Core ValuesDocumento1 pagina2018-2021 VUMC Nursing Strategic Plan: Vision Core ValuesAmeng GosimNessuna valutazione finora

- Book Review: Cancy Mcarn Issues in Teacher Education, Spring 2009Documento4 pagineBook Review: Cancy Mcarn Issues in Teacher Education, Spring 2009juan_carlos0733Nessuna valutazione finora

- Datasheet d801001Documento6 pagineDatasheet d801001Hammad HussainNessuna valutazione finora

- Honeymoon in Vegas Word FileDocumento3 pagineHoneymoon in Vegas Word FileElenaNessuna valutazione finora

- ProjectLookingGlassDeclassified PDFDocumento13 pagineProjectLookingGlassDeclassified PDFAmi Ferguson83% (6)

- Admission Prospectus2022 1 PDFDocumento10 pagineAdmission Prospectus2022 1 PDFstudymba2024Nessuna valutazione finora

- Alburg-Caldwell Manor 1784-1826 Draft by Fay YoungDocumento3 pagineAlburg-Caldwell Manor 1784-1826 Draft by Fay YoungNancy Cunningham100% (1)

- Macroeconomics Measurement: Part 2: Measurement of National IncomeDocumento13 pagineMacroeconomics Measurement: Part 2: Measurement of National IncomeManish NepaliNessuna valutazione finora

- Spot Welding Function R30iB Manual Del OperarioDocumento130 pagineSpot Welding Function R30iB Manual Del Operariopedro100% (2)

- Everyday Life - B1 - ShoppingDocumento7 pagineEveryday Life - B1 - ShoppingAmi BarnesNessuna valutazione finora

- Effect of Water On Quality and Preservation of FoodDocumento10 pagineEffect of Water On Quality and Preservation of FoodrupinisinnanNessuna valutazione finora

- IHRM Midterm ASHUVANI 201903040007Documento9 pagineIHRM Midterm ASHUVANI 201903040007ashu vaniNessuna valutazione finora

- BasicsDocumento1 paginaBasicsRishi Raj100% (1)

- Shock Cat 2009Documento191 pagineShock Cat 2009gersonplovasNessuna valutazione finora

- Noten - Detective Conan - Case ClosedDocumento2 pagineNoten - Detective Conan - Case ClosedBLU-NYTE GamingNessuna valutazione finora