Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ARES Escalator B

Caricato da

GutmonarchCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ARES Escalator B

Caricato da

GutmonarchCopyright:

Formati disponibili

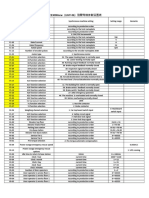

SIGMA Date : 2007.04.

25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page : 1 - 1 / 2

FIM 0 Index

Index

A. General items

1. Symbols explanation

2. Recommended tools

3. Maintain item and cycle

4. Oiling position

B. Precondition work and finishing work

1. Precondition work and finishing work

2. Disassemble Step

C. Machine room

1. Machine room

D. Terminal gear device

1. Drive examination

2. Check terminal gear chain and oiling

3. Upper Terminal Gear examination

4. Lower R-Guide examination

5. Traction Machine examination and maintenance

6. Examine Oil state

E. Handrail part

1. Handrail examination

2. Upper Handrail driving device and lower isolation roller examination.

F. Step part

1. Step examination

2. Examine the gap between Step and Skirt Guard.

3. Step examination and oiling to Bush.

4. Examine the clearance between Steps

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page : 1 - 2 / 2

FIM 0 Index

Index

G. Oiling device

1. Automatic, manual oiling device examination

H. Lighting part

1. Green Lighting examination

I. Safety switch

1. Key Switch Panel examination

2. Main Switch, MSB Connector, Normal&Maintenance Select Switch

examination.

3. Lower E-Stop Switch examination

4. Electric part examination

5. Examine the capability of Comb Plate safety switch( Upper and Lower)

6. Handrail Inlet safety switch examination

7. D.C.S examination

8. Step safety switch examination

J. Clean

1. Clean the machine room

2. Clean terminal balustrade

3. Clean adornment

4. Clean Handrail

5. Handrail Sealing

Unpublished Work Copyright © SIGMA Elevator Company

Potrebbero piacerti anche

- An Etymological Dictionary of The Scottivol 2Documento737 pagineAn Etymological Dictionary of The Scottivol 2vstrohmeNessuna valutazione finora

- SIGMA ARES Escalator 11Documento4 pagineSIGMA ARES Escalator 11Gutmonarch100% (1)

- SIGMA ARES Escalator 11Documento4 pagineSIGMA ARES Escalator 11Gutmonarch100% (1)

- ARES Maintenance Manual: IndexDocumento7 pagineARES Maintenance Manual: IndexGutmonarchNessuna valutazione finora

- FUJI2000 蓝光主板说明书-英文Documento199 pagineFUJI2000 蓝光主板说明书-英文Ahmed Al-RabayahNessuna valutazione finora

- Manual Agy-Ev GBDocumento214 pagineManual Agy-Ev GBstankovukanovicNessuna valutazione finora

- Afpelevator Doorcontroller Ec10 DDocumento40 pagineAfpelevator Doorcontroller Ec10 DTroubleshootingNessuna valutazione finora

- Hidral Maintenance HandbookDocumento32 pagineHidral Maintenance HandbookBaltija MechanikasNessuna valutazione finora

- Claim &: Change ProposalDocumento45 pagineClaim &: Change ProposalInaam Ullah MughalNessuna valutazione finora

- NICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFDocumento232 pagineNICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFAsdrubal Fredy GutierrezNessuna valutazione finora

- ASKO GearlessDocumento20 pagineASKO GearlessRaja DuraiNessuna valutazione finora

- EC 160elevator Intelligent Integrated Machine - V1.2Documento227 pagineEC 160elevator Intelligent Integrated Machine - V1.2BùiNghĩaNessuna valutazione finora

- ARES Maintenance Manual: IndexDocumento10 pagineARES Maintenance Manual: IndexGutmonarchNessuna valutazione finora

- ARES Maintenance Manual: IndexDocumento10 pagineARES Maintenance Manual: IndexGutmonarchNessuna valutazione finora

- ARES Maintenance Manual: IndexDocumento10 pagineARES Maintenance Manual: IndexGutmonarchNessuna valutazione finora

- 200cory Board DescriptionDocumento2 pagine200cory Board DescriptionChang ChangNessuna valutazione finora

- Hamcb SwordDocumento101 pagineHamcb SwordNaseh Ya NasehNessuna valutazione finora

- D10C604电气随机文件 英文Documento39 pagineD10C604电气随机文件 英文Habibulla Bavaji0% (1)

- Bg101 User Manual1Documento22 pagineBg101 User Manual1MikeNessuna valutazione finora

- Elevator Mechanic: Passbooks Study GuideDa EverandElevator Mechanic: Passbooks Study GuideNessuna valutazione finora

- System Diagram Ec3000a 5r5 011 4 (Ups Epm S)Documento24 pagineSystem Diagram Ec3000a 5r5 011 4 (Ups Epm S)Tuân HoàngNessuna valutazione finora

- Steel W Orks Products (Thailand) : Elevator Controller SystemDocumento4 pagineSteel W Orks Products (Thailand) : Elevator Controller Systemtran xobonNessuna valutazione finora

- OTIS EscalatorDocumento7 pagineOTIS EscalatorGutmonarch0% (1)

- PU3200 English ManualDocumento71 paginePU3200 English Manualعلاء صقرNessuna valutazione finora

- Hyundai Elevator Preventive Maintenance ProcedureDocumento19 pagineHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- Error TableDocumento19 pagineError TableJesús David Diaz MontesNessuna valutazione finora

- ML60XS UserGuide A1Documento5 pagineML60XS UserGuide A1Bojan DrljachaNessuna valutazione finora

- AS350 Series Elevator Intergrated Controller User Instruction V1.0Documento109 pagineAS350 Series Elevator Intergrated Controller User Instruction V1.0Nguyen VuongNessuna valutazione finora

- B. Fault-FindingDocumento29 pagineB. Fault-FindingJesús David Diaz MontesNessuna valutazione finora

- NICE3000new Integrated Elevator Controller User Manual (2) KO ZawDocumento209 pagineNICE3000new Integrated Elevator Controller User Manual (2) KO Zawkolwin .chindwin100% (1)

- Elevator Inspector: Passbooks Study GuideDa EverandElevator Inspector: Passbooks Study GuideNessuna valutazione finora

- Asanor Compact Iran 2 PDFDocumento71 pagineAsanor Compact Iran 2 PDFSatisNessuna valutazione finora

- STVF5 Trouble REV0 PDFDocumento42 pagineSTVF5 Trouble REV0 PDFUpien Ayah MahardikaNessuna valutazione finora

- GSD SM Instruction Book PDFDocumento15 pagineGSD SM Instruction Book PDFMitro100% (1)

- 02 IRIS2 - NV - Controller-ENDocumento36 pagine02 IRIS2 - NV - Controller-ENAhmedNessuna valutazione finora

- On The Linguistic Turn in Philosophy - Stenlund2002 PDFDocumento40 pagineOn The Linguistic Turn in Philosophy - Stenlund2002 PDFPablo BarbosaNessuna valutazione finora

- Nova Ev3200 ManualDocumento25 pagineNova Ev3200 ManualCarolina Sansón100% (1)

- SpaceDocumento28 pagineSpaceDemme Abdi NasaNessuna valutazione finora

- Mitsubishi Elenessa Encoder CalibrationDocumento6 pagineMitsubishi Elenessa Encoder CalibrationGutmonarchNessuna valutazione finora

- Grammar For TOEFLDocumento23 pagineGrammar For TOEFLClaudia Alejandra B0% (1)

- ARES Escalator 5Documento3 pagineARES Escalator 5GutmonarchNessuna valutazione finora

- MCTC Ard C English 1Documento11 pagineMCTC Ard C English 1Khaled ZakariaNessuna valutazione finora

- FILE 20221010 095658 X11joDocumento22 pagineFILE 20221010 095658 X11joNguyễn ThànhNessuna valutazione finora

- ME-LIFT-P Microprocessor Control User Manual 20071226 PDFDocumento38 pagineME-LIFT-P Microprocessor Control User Manual 20071226 PDFKen LeeNessuna valutazione finora

- FC 3000 SDocumento60 pagineFC 3000 SMohamedElsawiNessuna valutazione finora

- Fuji Driver Gearless EnglishDocumento3 pagineFuji Driver Gearless EnglishBojan DrljachaNessuna valutazione finora

- ARL 700 Hydraulic EN81 20.enDocumento48 pagineARL 700 Hydraulic EN81 20.enMazen AlhouseenNessuna valutazione finora

- FC 3000s PDFDocumento60 pagineFC 3000s PDFAgnelo FernandesNessuna valutazione finora

- Inovance Monarch Nice3000 Elevator User Manual 7 enDocumento184 pagineInovance Monarch Nice3000 Elevator User Manual 7 enMehedi HasanNessuna valutazione finora

- EDCA PresentationDocumento31 pagineEDCA PresentationToche DoceNessuna valutazione finora

- ARES Escalator BDocumento2 pagineARES Escalator BGutmonarchNessuna valutazione finora

- Elevador SWORD HAMCB Tipo OtisDocumento41 pagineElevador SWORD HAMCB Tipo OtisRaul GutierrezNessuna valutazione finora

- ARES Escalator 6Documento7 pagineARES Escalator 6GutmonarchNessuna valutazione finora

- ARES Escalator 6Documento7 pagineARES Escalator 6GutmonarchNessuna valutazione finora

- Acd2-Mrl Sur en PDFDocumento100 pagineAcd2-Mrl Sur en PDFGutmonarch88% (16)

- Drawing Number: Code: Pages MN11001BTDocumento23 pagineDrawing Number: Code: Pages MN11001BTJesús David Diaz MontesNessuna valutazione finora

- A6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDDocumento197 pagineA6000 Integrated Elevator Controller: QMA (Shanghai) Electric Co., LTDJesús David Diaz MontesNessuna valutazione finora

- Mitsubishi VFGL Mon Set SettingsDocumento8 pagineMitsubishi VFGL Mon Set SettingsGutmonarch71% (14)

- Is-A300is-M300 Lift Control PanelDocumento28 pagineIs-A300is-M300 Lift Control PanelUnique Product100% (1)

- JSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraDocumento63 pagineJSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraEbert mancilla100% (1)

- Caregiving Learning Activity Sheet 3Documento6 pagineCaregiving Learning Activity Sheet 3Juvy Lyn CondaNessuna valutazione finora

- Nice 3000Documento98 pagineNice 3000NAIMUR RAHAMANNessuna valutazione finora

- MonarchDocumento126 pagineMonarchJorge Perez GuerraNessuna valutazione finora

- Nice 9000Documento91 pagineNice 9000Samuel AcevedoNessuna valutazione finora

- Elevator Programming CodeDocumento178 pagineElevator Programming Code100mphNessuna valutazione finora

- BL3-U Quick Commissioning Menu V1.2 PDFDocumento32 pagineBL3-U Quick Commissioning Menu V1.2 PDFRandy VanegasNessuna valutazione finora

- WB Installation Manual EL ENG 4.3Documento121 pagineWB Installation Manual EL ENG 4.3dianelys Sivada100% (1)

- Door Dive: User ManualDocumento67 pagineDoor Dive: User ManualRoyal AkashNessuna valutazione finora

- F U J I: Ud Tren Main Dieu KhienDocumento3 pagineF U J I: Ud Tren Main Dieu KhiendongbahienNessuna valutazione finora

- Gate Controller Manual: AAD03010 Frequency Control SystemDocumento17 pagineGate Controller Manual: AAD03010 Frequency Control SystemKen LeeNessuna valutazione finora

- Jarless Con Door DriveDocumento1 paginaJarless Con Door Drivewakeel ahmedNessuna valutazione finora

- Main Control Board User ManualDocumento15 pagineMain Control Board User Manualmohammedalathwary100% (1)

- 07 IRIS NV PCB OtherDocumento15 pagine07 IRIS NV PCB OtherArnaldo cordovaNessuna valutazione finora

- Ard Based Elevator Control SystemDocumento7 pagineArd Based Elevator Control SystemIRJIENessuna valutazione finora

- Elevator Control Board in EgyptDocumento10 pagineElevator Control Board in EgyptEhab Anwar Elnagdy100% (1)

- Manual de Instalación Escaleras Hosting-20141011Documento51 pagineManual de Instalación Escaleras Hosting-20141011Diego Fernando Carrion TorresNessuna valutazione finora

- HB As380 E20 PDFDocumento70 pagineHB As380 E20 PDFjonathanNessuna valutazione finora

- 201604201039062023Documento205 pagine201604201039062023younes100% (2)

- 13 - IRIS - NV - Error CodeDocumento53 pagine13 - IRIS - NV - Error Codesteve niereNessuna valutazione finora

- Testing-and-Commissioning NICE PARAMETERDocumento2 pagineTesting-and-Commissioning NICE PARAMETERGutmonarchNessuna valutazione finora

- Export Market Dairy Tariffs Guide 15 May 2020Documento184 pagineExport Market Dairy Tariffs Guide 15 May 2020GutmonarchNessuna valutazione finora

- Escalator C PDFDocumento1 paginaEscalator C PDFGutmonarchNessuna valutazione finora

- New 5396 Brown and Haley Compressed Air - Project Assessment Report Rev ADocumento17 pagineNew 5396 Brown and Haley Compressed Air - Project Assessment Report Rev AGutmonarchNessuna valutazione finora

- Wire Rope Lubricant PDFDocumento1 paginaWire Rope Lubricant PDFGutmonarchNessuna valutazione finora

- ASIO4ALL v2 Instruction ManualDocumento11 pagineASIO4ALL v2 Instruction ManualDanny_Grafix_1728Nessuna valutazione finora

- KRUGER FDA - Series Centrifugal FanDocumento51 pagineKRUGER FDA - Series Centrifugal FanSusan LamNessuna valutazione finora

- All About SharksDocumento3 pagineAll About SharksGutmonarchNessuna valutazione finora

- E1102m PDFDocumento283 pagineE1102m PDFBhawani Singh RajawatNessuna valutazione finora

- Magnetic Effect of Current 1Documento11 pagineMagnetic Effect of Current 1Radhika GargNessuna valutazione finora

- S Jozsef Viata in DiosigDocumento52 pagineS Jozsef Viata in Diosigunoradean2Nessuna valutazione finora

- APA CitationsDocumento9 pagineAPA CitationsIslamNessuna valutazione finora

- Adverbs Before AdjectivesDocumento2 pagineAdverbs Before AdjectivesJuan Sanchez PrietoNessuna valutazione finora

- Name: Kartikeya Thadani Reg No.: 19bma0029Documento4 pagineName: Kartikeya Thadani Reg No.: 19bma0029Kartikeya ThadaniNessuna valutazione finora

- CAP214 Web Devlopment PDFDocumento9 pagineCAP214 Web Devlopment PDFAlisha AgarwalNessuna valutazione finora

- Church A Rchitecture Abbey: Throne" Ecclesia Cathedralis (In Latin)Documento18 pagineChurch A Rchitecture Abbey: Throne" Ecclesia Cathedralis (In Latin)Pat GeronzNessuna valutazione finora

- Harbin Institute of TechnologyDocumento7 pagineHarbin Institute of TechnologyWei LeeNessuna valutazione finora

- Malate SynthaseDocumento8 pagineMalate SynthaseMinichNessuna valutazione finora

- LIM Gr7 Q4W3Documento9 pagineLIM Gr7 Q4W3Eto YoshimuraNessuna valutazione finora

- 2017 - The Science and Technology of Flexible PackagingDocumento1 pagina2017 - The Science and Technology of Flexible PackagingDaryl ChianNessuna valutazione finora

- Pre T&C Checklist (3 Language) - Updated - 2022 DavidDocumento1 paginaPre T&C Checklist (3 Language) - Updated - 2022 Davidmuhammad farisNessuna valutazione finora

- Weill Cornell Medicine International Tax QuestionaireDocumento2 pagineWeill Cornell Medicine International Tax QuestionaireboxeritoNessuna valutazione finora

- Conrad John's ResumeDocumento1 paginaConrad John's ResumeTraining & OD HRODNessuna valutazione finora

- PT - Science 5 - Q1Documento4 paginePT - Science 5 - Q1Jomelyn MaderaNessuna valutazione finora

- Information Security Policies & Procedures: Slide 4Documento33 pagineInformation Security Policies & Procedures: Slide 4jeypopNessuna valutazione finora

- Roman Roads in Southeast Wales Year 3Documento81 pagineRoman Roads in Southeast Wales Year 3The Glamorgan-Gwent Archaeological Trust LtdNessuna valutazione finora

- MSC in Healthcare Management (Top-Up) Degree From ARU - Delivered Online by LSBR, UKDocumento19 pagineMSC in Healthcare Management (Top-Up) Degree From ARU - Delivered Online by LSBR, UKLSBRNessuna valutazione finora

- DMemo For Project RBBDocumento28 pagineDMemo For Project RBBRiza Guste50% (8)

- Panera Bread Company: Case AnalysisDocumento9 paginePanera Bread Company: Case AnalysisJaclyn Novak FreemanNessuna valutazione finora

- Impact Grammar Book Foundation Unit 1Documento3 pagineImpact Grammar Book Foundation Unit 1Domingo Juan de LeónNessuna valutazione finora

- Michael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Documento55 pagineMichael M. Lombardo, Robert W. Eichinger - Preventing Derailmet - What To Do Before It's Too Late (Technical Report Series - No. 138g) - Center For Creative Leadership (1989)Sosa VelazquezNessuna valutazione finora

- Polymeric Nanoparticles - Recent Development in Synthesis and Application-2016Documento19 paginePolymeric Nanoparticles - Recent Development in Synthesis and Application-2016alex robayoNessuna valutazione finora

- B. Inggris Narrative TeksDocumento11 pagineB. Inggris Narrative TeksDew FitriNessuna valutazione finora