Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aerial Lift Pre Use Inspection Checklist

Caricato da

Sigit Pratikno0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

2K visualizzazioni1 paginaThis document is an aerial lift pre-use inspection form. It contains two sections - the first lists 21 inspection items to check such as controls, safety lights, guardrails and platform condition. The second section lists safety precautions to have, look for or be aware of such as fall protection equipment, wind conditions, floor hazards and overhead obstructions. Any issues identified in the inspection require removing the key and reporting problems to a supervisor.

Descrizione originale:

Cheklist pemeriksaan Aerial Lift

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document is an aerial lift pre-use inspection form. It contains two sections - the first lists 21 inspection items to check such as controls, safety lights, guardrails and platform condition. The second section lists safety precautions to have, look for or be aware of such as fall protection equipment, wind conditions, floor hazards and overhead obstructions. Any issues identified in the inspection require removing the key and reporting problems to a supervisor.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

2K visualizzazioni1 paginaAerial Lift Pre Use Inspection Checklist

Caricato da

Sigit PratiknoThis document is an aerial lift pre-use inspection form. It contains two sections - the first lists 21 inspection items to check such as controls, safety lights, guardrails and platform condition. The second section lists safety precautions to have, look for or be aware of such as fall protection equipment, wind conditions, floor hazards and overhead obstructions. Any issues identified in the inspection require removing the key and reporting problems to a supervisor.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

AERIAL LIFT PRE-USE INSPECTION

FORM

AERIAL LIFT PRE- USE INSPECTION CHECKLIST

Operator Print Name and Sign Aerial or Scissor Lift ID#

Unit Type Scissor Lift Articulating Boom Man Lift Date Location of Use

Other _________________________________________________________________________

# Section 1: Inspection Item and Description: P/F/NA

1 Operating and emergency controls are in proper working condition, EMO button or Emergency Stop

Device

2 Functional upper drive control interlock (i.e. foot pedal, spring lock, or two hand controls)

3 Emergency Lowering function operates properly

4 Lower operating controls successfully over ride the upper controls

5 Both upper and lower controls are adequately protected from inadvertent operation.

6 Control panel is clean & all buttons/switches are clearly visible (no paint over spray, etc.)

7 All switch & mechanical guards are in good condition and properly installed

8 All Safety Indicator lights work

9 Drive controls function properly & accurately labeled (up, down, right, left, forward, back)

10 Motion alarms are functional

11 Safety decals are in place and readable

12 Guardrails and anchor points are in place, and in good condition

13 Work platform & extension slides are clean, dry, & clear of debris

14 Work platform extension slides in and out freely with safety locking pins in place to lock setting on

models with extension platforms.

15 Inspect for defects such as cracked welds, fuel leaks, hydraulic leaks, damaged control cables or wire

harness, etc.

16 Tires and wheels are in good condition, with adequate air pressure if pneumatic

17 Braking devices are operating properly

18 The manufacturer’s operations manual is stored on AWP (in all languages of the operators)

19 Oil level, Hydraulic Oil Level, Fuel Level, Coolant Level

20 Battery Charge

21 Outriggers in place or functioning. Associated alarms working

Section 2: Safety Precautions (Have, Look For, or be Aware of) Check to Confirm

Personal Fall Arrest and Protective Equipment. (Harness, lanyard, hardhat etc.)

In windy conditions see manufacturer guidelines or if not in guidelines then…if lift begins to rock

in the wind lower the lift

Floor conditions: Drop offs, holes, uneven surfaces, and sloped floors.

Housekeeping: Debris, floor obstructions, cords, construction material and supplies.

Electrical power cables or panels, (minimum 10 feet away). If larger lines or wet conditions contact

EH&S or the Electrical shop for guidance. Insolated small lines in dry conditions 3 feet away.

Chemical lines, gas lines, drain lines, and utilities.

Overhead obstructions

Loads (do not exceed capacity)

Watch for vehicular and pedestrian traffic. Set up barricades if necessary.

Comments

IF THE AERIAL LIFT FAILS ANY PART OF THIS INSPECTION, REMOVE THE KEY AND REPORT THE PROBLEM TO YOUR

SUPERVISOR. DO NOT ATTEMPT TO MAKE REPAIRS UNLESS YOU ARE A TRAINED AND AUTHORIZED SERVICE PERSON.

ALL SERVICE IS TO BE DOCUMENTED. IF ANYTHING HAS BEEN JERRY-RIGGED NOTIFY YOUR SUPERVISOR AT ONCE.

Page 1 of 1 6/14/2016

Potrebbero piacerti anche

- SAPI Working at Heights Training 2011Documento63 pagineSAPI Working at Heights Training 2011Suharto AriNessuna valutazione finora

- Skid Steer (Generic) : Job Safety AnalysisDocumento2 pagineSkid Steer (Generic) : Job Safety AnalysisNanthan GanesNessuna valutazione finora

- Aramco Heat IndexDocumento1 paginaAramco Heat IndexDLPS HSE0% (1)

- Mewp Inspection ChecklistDocumento4 pagineMewp Inspection ChecklistBiswajit BiswasNessuna valutazione finora

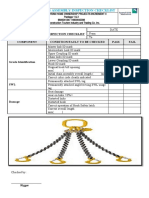

- FC 4.1.4 - Chain Sling Assembly Inspection Checklist FormDocumento2 pagineFC 4.1.4 - Chain Sling Assembly Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

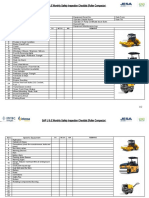

- Compactor Daily Inspection ChecklistDocumento1 paginaCompactor Daily Inspection ChecklistThandabantu Magengelele33% (3)

- 03 - Hydra Crane ChecklistDocumento1 pagina03 - Hydra Crane ChecklistAfzal Akhtar100% (5)

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDocumento1 pagina006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnNessuna valutazione finora

- Welding and Gas CuttingDocumento2 pagineWelding and Gas CuttingKrishna Patil100% (2)

- Mobile Crane Monthly ChecklistDocumento3 pagineMobile Crane Monthly ChecklistDAOUMY YOUNESSNessuna valutazione finora

- Concrete Pump Safety ChecklistDocumento15 pagineConcrete Pump Safety ChecklistHaleemUrRashidBangashNessuna valutazione finora

- Bar Cutting Machine HSE ChecklistDocumento2 pagineBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Crane Inspection ChecklistDocumento1 paginaCrane Inspection Checklistrig4Nessuna valutazione finora

- B.Lifting Equipment Selection 230119Documento98 pagineB.Lifting Equipment Selection 230119Sigit Pratikno100% (1)

- Crane Carry - in InspectionDocumento3 pagineCrane Carry - in InspectionAdhy Darmawan100% (1)

- Ladder Inspection ChecklistDocumento1 paginaLadder Inspection Checklistnib100% (2)

- Hydraulic Jack Inspection ChecklistDocumento1 paginaHydraulic Jack Inspection ChecklistHario Pramudito100% (2)

- SWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ADocumento1 paginaSWP-SF010A - 6 Daily Vibratory Roller Compactor Rev. ACliffordNessuna valutazione finora

- Asphalt Cutter ChecklistDocumento1 paginaAsphalt Cutter ChecklistDhanu Nikku100% (5)

- Method Statement For Cement Wall Plastering-1Documento8 pagineMethod Statement For Cement Wall Plastering-1md_rehan_2Nessuna valutazione finora

- Monthly Movable Tower Light Inspection ChecklistDocumento1 paginaMonthly Movable Tower Light Inspection Checklistshahid100% (2)

- 1326370398-HS6-54 Use of MEWP Risk AssessmentDocumento2 pagine1326370398-HS6-54 Use of MEWP Risk AssessmentJohn David Hoyos Marmolejo83% (6)

- Grout Checking ListDocumento1 paginaGrout Checking ListJennifer Damasco50% (2)

- Trowel Concrete Machine Pre-Use Inspection Checklist: ProjectDocumento2 pagineTrowel Concrete Machine Pre-Use Inspection Checklist: ProjectImam Ali100% (1)

- Roller Compactor Monthly ChecklistDocumento2 pagineRoller Compactor Monthly ChecklistDAOUMY YOUNESS100% (1)

- Tower Crane ChecklistDocumento1 paginaTower Crane ChecklistbeshoyNessuna valutazione finora

- Operation Manual JLG 600S-660SJ Global 06-05-08 (Int.) PDFDocumento132 pagineOperation Manual JLG 600S-660SJ Global 06-05-08 (Int.) PDFfater esmandarNessuna valutazione finora

- 19-F13 Vehicle Mounted Crane Inspection ChecklistDocumento2 pagine19-F13 Vehicle Mounted Crane Inspection ChecklistSn Ahsan100% (1)

- UtICO PTWDocumento1 paginaUtICO PTWsami gorsiNessuna valutazione finora

- Safety Checklist of Safety BeltDocumento1 paginaSafety Checklist of Safety BeltA S Yadav0% (1)

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocumento1 paginaJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- Jackhammer Inspection ChecklistDocumento1 paginaJackhammer Inspection Checklistmpho67% (6)

- Icorr BookDocumento984 pagineIcorr BookSuraj M SethuNessuna valutazione finora

- Boom Lift - Daily ChecklistDocumento1 paginaBoom Lift - Daily Checklistpawankumar100% (2)

- 022 - HSSE - Full Body Harness Inspection ChecklistDocumento1 pagina022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyNessuna valutazione finora

- JSA Machinal PipingDocumento7 pagineJSA Machinal PipingNaitik Desai48100% (1)

- Skyjack SJIII 4626Documento2 pagineSkyjack SJIII 4626AlmacarNessuna valutazione finora

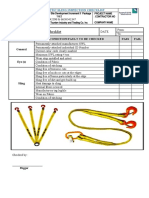

- FC 4.1.6 - Synthetic Sling Inspection Checklist FormDocumento2 pagineFC 4.1.6 - Synthetic Sling Inspection Checklist FormJosef Demner Tiu PaspeNessuna valutazione finora

- Load Chart Kato KR 50HDocumento2 pagineLoad Chart Kato KR 50HSigit Pratikno100% (2)

- Telehandler Forklift Pre-Use Inspection ChecklistDocumento1 paginaTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- Hydraulic Scissor Lift CatalogDocumento6 pagineHydraulic Scissor Lift CatalogSubramanian Periyanaina100% (1)

- Form-162-Scissor Lift Daily Inspection ChecklistDocumento1 paginaForm-162-Scissor Lift Daily Inspection Checklistshamroz khan100% (1)

- Checklist Pencil GrinderDocumento1 paginaChecklist Pencil Grinderrexivy100% (1)

- RS Concrete Pumping Risk AssessmentDocumento8 pagineRS Concrete Pumping Risk AssessmentLito PanchoNessuna valutazione finora

- Plate Compactor Inspection ChecklistDocumento1 paginaPlate Compactor Inspection ChecklistNair R RakeshNessuna valutazione finora

- Lifting Method Statement - SimplifiedDocumento3 pagineLifting Method Statement - Simplifiednitesh dayamaNessuna valutazione finora

- Form 071 HIAB Boom Truck Safety ChecklistDocumento2 pagineForm 071 HIAB Boom Truck Safety ChecklistJishad Nalakath100% (3)

- HSE-BMS-013 Color Coding and InspectionDocumento30 pagineHSE-BMS-013 Color Coding and InspectionSatya Naidu100% (1)

- 10 - Cherry Picker Inspection ChecklistDocumento1 pagina10 - Cherry Picker Inspection Checklistsanjeev kumarNessuna valutazione finora

- Daily Inspection Checklist For ManliftDocumento1 paginaDaily Inspection Checklist For ManliftFaris Wahed33% (3)

- Aluminium LadderDocumento1 paginaAluminium LadderVinay PandeyNessuna valutazione finora

- Form-068-Mobile Crane Daily Safety ChecklistDocumento1 paginaForm-068-Mobile Crane Daily Safety ChecklistJishad Nalakath75% (4)

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocumento1 paginaInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- Backhoe-Loader Daily Inspection ChecklistDocumento1 paginaBackhoe-Loader Daily Inspection ChecklistMartine OtienoNessuna valutazione finora

- Acceptance Criteria Radiography Test 2018 PDFDocumento7 pagineAcceptance Criteria Radiography Test 2018 PDFSigit Pratikno100% (1)

- Aerial Lift PreUse Inspection ChecklistDocumento1 paginaAerial Lift PreUse Inspection ChecklistMohamed KadryNessuna valutazione finora

- Transit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksDocumento1 paginaTransit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksRísês ÃfrözNessuna valutazione finora

- Grinder Checklist2Documento3 pagineGrinder Checklist2jovyNessuna valutazione finora

- Kalmar OPERATOR TRAININGDocumento40 pagineKalmar OPERATOR TRAININGWhite Tiger100% (7)

- Lorry Loader Crane ChecklistDocumento1 paginaLorry Loader Crane ChecklistSameer ParambathNessuna valutazione finora

- Grader Daily Inspection ChecklistDocumento2 pagineGrader Daily Inspection Checklistazer Azer100% (2)

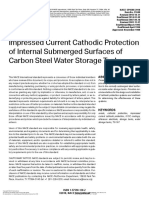

- NACE SP0388 Impressed Current CP Storage TanksDocumento24 pagineNACE SP0388 Impressed Current CP Storage TanksSigit PratiknoNessuna valutazione finora

- Working at HeightDocumento5 pagineWorking at HeightIKSPI HorizonNessuna valutazione finora

- Lift Elevator ReportDocumento49 pagineLift Elevator ReportdpgcNessuna valutazione finora

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocumento1 paginaChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (2)

- Hira-09 Copper Slag Blasting and Spray Penting WorkDocumento14 pagineHira-09 Copper Slag Blasting and Spray Penting WorkRaju100% (1)

- Laboratory Maintenace Checklist: Compression Machine For Concrete Cube TestingDocumento2 pagineLaboratory Maintenace Checklist: Compression Machine For Concrete Cube TestingQuality Control100% (1)

- SMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationDocumento7 pagineSMS - SF 4.4.6.6.1 Method Statement Glass Partition InstallationAli SahibzadaNessuna valutazione finora

- Daily Checklist Derrick Winch R.001Documento2 pagineDaily Checklist Derrick Winch R.001angger aminda noorcipta joharNessuna valutazione finora

- Cradle Check ListDocumento1 paginaCradle Check ListBineesh100% (3)

- Safety Violation Notice General Information: ST ND RDDocumento2 pagineSafety Violation Notice General Information: ST ND RDAsif Hussain100% (1)

- HIRA No. 02-Use of Access Scaffolding SBDDocumento2 pagineHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- Scissor Lift Inspection FormDocumento1 paginaScissor Lift Inspection Formfabs.png.2020Nessuna valutazione finora

- KWX Double Element ProbesDocumento1 paginaKWX Double Element ProbesSigit PratiknoNessuna valutazione finora

- EPV16ADocumento2 pagineEPV16AadanNessuna valutazione finora

- Lift Emergency RescueDocumento29 pagineLift Emergency RescuebugseNessuna valutazione finora

- Um0244 01 GBDocumento84 pagineUm0244 01 GBnetharafernando1Nessuna valutazione finora

- Telescopic Boom Lift: PerformanceDocumento2 pagineTelescopic Boom Lift: Performancewahyu widayatNessuna valutazione finora

- Manual de Operacion Manlift - HaulotteDocumento114 pagineManual de Operacion Manlift - Haulotteluis angel de la cruz olleroNessuna valutazione finora

- Liflux 80 SL Spec SheetDocumento6 pagineLiflux 80 SL Spec SheetForklift Systems IncorporatedNessuna valutazione finora

- Sitecraft 2012 Catalogue Handling PDFDocumento90 pagineSitecraft 2012 Catalogue Handling PDFlalit PatilNessuna valutazione finora

- User Manuel Service FronteqDocumento86 pagineUser Manuel Service FronteqDRYCON PERUNessuna valutazione finora

- ACF2T Datasheet enDocumento8 pagineACF2T Datasheet enPraveen RamNessuna valutazione finora

- Man Lifts: Trailer MountedDocumento4 pagineMan Lifts: Trailer MountedPelonky ManiaNessuna valutazione finora

- Safe Bucket Truck Operations: Edition IIDocumento23 pagineSafe Bucket Truck Operations: Edition IIchrisNessuna valutazione finora

- Airman Large Mobile Compressors PDFDocumento6 pagineAirman Large Mobile Compressors PDFAgus Suparna PutraNessuna valutazione finora

- 65002-0001 Terex Ta33Documento59 pagine65002-0001 Terex Ta33reman partsNessuna valutazione finora

- JLG-Toucan-12E - ENDocumento104 pagineJLG-Toucan-12E - ENSandun RajitaNessuna valutazione finora

- PDF PPT 3Documento71 paginePDF PPT 3RafiaNessuna valutazione finora

- X550AJ Operation and Safety Manual PDFDocumento136 pagineX550AJ Operation and Safety Manual PDFZenon Nuñonca ZapataNessuna valutazione finora

- ANSI Whitepaper Part 2019Documento8 pagineANSI Whitepaper Part 2019ameraldaherNessuna valutazione finora

- CatalogIA PDFDocumento74 pagineCatalogIA PDFOctavian TaviNessuna valutazione finora

- Genie Z45 22Documento4 pagineGenie Z45 22Jaime SuaNessuna valutazione finora

- Operators Manual LGMG Eu NL Idml enDocumento68 pagineOperators Manual LGMG Eu NL Idml enFernandoNessuna valutazione finora

- Feb 2017 Buildability SiteDocumento21 pagineFeb 2017 Buildability SiteTun Lin OoNessuna valutazione finora