Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

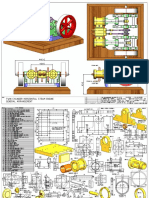

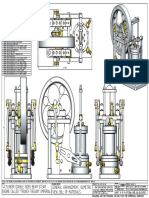

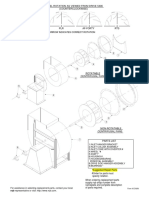

Notes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam Engine

Caricato da

Jayaramakrishna YakambariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Notes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam Engine

Caricato da

Jayaramakrishna YakambariCopyright:

Formati disponibili

NOTES: M4-4PL 5 5-2PL ALU/MS/BRS 5 3 5 MS/ALU/BRS 5 5 5 5

0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS 6-4PL

BRZ

7 7

1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH

16.5

14

REGARDS TO HOLE AND SHAFT TOLERANCES. 10

2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE DAA 19 19

HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER 18PF 7 50

1-05B

26

M3-4PL

28.5

THAN THE MATCHING TAPPED HOLE. 1-01A R 12 1-04A 4

25

3. PREFERABLY ALL TAPPED HOLES AND MATCHING 1-01B R4 1-04B 4 12CF

4 4

SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

6 6

ALU/MS/BRS D D

9.5PF

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE

23

INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN

20

23

28.5

12

25

14 1-03 12LPF

MATERIAL CHOICE.

26

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM M4 DAA 24 24

SCALE 1:2

R1

PRESSURE APPLIED TO IT SHALL BE SILVER/HARD 9 3 5 26.5 11 31.5

1.

R2

2 REQ.D SCALE 1:2

5

5

16.5

5 10

SOLDERED. 6

14

R TIMMING MARK DAA

R6

3

10HEX

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED 1-04B SCALE 1:1.5 SPOT DRILL

M8

STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 34 25 12 24 24 37 29 5 MS/ALU/BRS 7 7 4 1 4 1

2.5

9 9 DAA

60% LONGER THEN COMPRESSED STATE. MS

7 40 7 95-2PL M3 10-4PL

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS 1-05C 1-05A

14RM

18PF

OPPOSITE FACE EQUAL

4

CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER

7

7 7

BY USING EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR

14

28 28

SOLDER.

7

SCALE 1:1.5 7

16 19 50 19 16

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM CB 10-4PL 9.5 14 SCALE 1:2 10.5 12 12 10.5 4 5 4

4

AND/OR WATER SHOULD BE CONSTRUCTED USING NON- 1-05C

5

M5 M5 4PF 45 45 1-05B

FERROUS OR NON CORROSIVE MATERIAL SUCH AS BRASS,

7 7

HIDDEN LINES REMOVED 1-05C

5

BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR

M8

M8

7 7

MONEL. 1-02G FOR CLARITY

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE 4PF 24 24

12 38 1-08A SECTION D-D SCALE 1 : 1.5

MANUFACTURED AND THE MODEL IS ASSEMBLED IS 12 SCALE 1:1.5

7 7 1-02A 1-02H 1-06 3 3

ENTIRELY LEFT TO THE BUILDER/MODEL MAKER. 5 5 1-02A 1-08B 3-4PL M8 6 1-08B

25

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY A

LEFT UP TO THE MODEL MAKER. MS R5

7

7

1-02G

44

20

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE 1-02G

15

12 12 1-06

5

MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER. 9.5

30.5

R 19 19 M3 5 24

21.8

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS R15.7 1-02B R 5

1-08A

10

OR SURFACES, WERE DEEMED NECESSARY TO PREVENT 15°

10

° 1-02B 22.5 22.5

PARTS FROM LOOSENING. 15 R3 R3

10

5 11

14.5

11

2.5

E

9.5

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED A 4

6.5 6.5

4

M3

WHERE DEEMED NECESSARY. 4.5 4.5 20.5 20.5

M3

9 3

4.5 1-02C 5 5

9.5RM

9.5RM

SCALE 1:1.5

2.5

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE 4.5 SECTION A-A

DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT 4 SCALE 1 : 1.5 6 1-02C

2.5

1-02E .5 6.5

THE ERRORS/OMISSIONS CAN BE RECTIFIED. R2.5

9

R2.5-4PL R2.5 4PF 1-04

MATERIAL ABBREVIATIONS: 3 E 4 4

5

75

ALU = ALUMINIUM 7 7 14 24 14

°

HALU= HARD ALUMINIUM 14

10

BRS = BRASS R3.8 4 5 ° 3 SECTION E-E SCALE 1 : 1.5

9 SCALE 1:1.5 R2.5

19

R5

BRZ = BRONZE OR GUNMETAL (BRZ/GM) 1-02B 4PF R3 3

1

3.5 R

CI = CAST IRON

6.5 6.5

10

7.5

5

CU = COPPER

1

B 13 13 1-02F

14

GRA = GRAPHITE

4

10

MS = MILD STEEL/BRIGHT MILD STEEL 5 13 M6 1-02D 2.5

SS = SILVER STEEL OR STAINLESS STEEL MS/ALU/BRS 3 9

18.4 18.4 SECTION B-B

SPS = SPRING STEEL SCALE 1 : 1.5

5 5

PEEK= POLYETHER ETHER KETONE R2. 15° 15°

5

1-02H 1-02D

SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, 5

TEFLON OR RUBBER C

1

1-02H

5

IN GENERAL SYNTHETIC MATERIALS SOULD BE

R1

R2.5 R2.5

5

ABLE TO WITHSTAND THE HEAT AND 1-02E

20

25.3

PRESSURE(S) APPLIED TO THEM.

48.8

nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED R2.5 1-02E

123.3

OTHER ABBREVIATIONS

1-02

20

DP = DEEP 6 6

DAA= DRILL AFTER ASSEMBLY 3 1-02

51

D&TAA= DRILL AND TAP AFTER ASSEMBLY 5 3

R1

CF = CLOSE FIT (SIZE FOR SIZE)

PF = PRESS FIT

5 5

(145.5)

73

R2.5 1-03

PFAA= PRESS FIT AFTER ASSEMBLY

59.8

PCD = PITCH CIRCLE DIAMETER R 2 .5

5

R2.5 5 5

76

RM = REAM 5

HEX = HEXACON, 6SIDED M3

CP = COMPRESSED

1

1-02F

180

KNL = KNURLED

5 5

6

R4

13.3

CSK = COUNTERSINK

5

PL = PLACES 1-08

4PF

40.6

DWL= DOWEL 9.5 9.5

R1

R17

SPF= SPOTFACE 1-02C SCALE 1:1.5

7

R2.5 1-07

23

(T)HESOP=(TAPPED)HOLES EQUALLY SPACED ON PCD 1-01

(T)HESOC=(TAPPED)HOLES EQUALLY SPACED ON 1-03

CIRCUMFERENCE C SECTION C-C 1-05

SA-xxx = SUB ASSEMBLY-xxx 29 28.5 28.5 29 SCALE 1 : 2 MS SA-1-105 1-07

NOTES: THIS DESIGN IS BASED ON DRAWINGS WHICH WERE PUBLISHED ON THE M.E.M. WEBSITE. THIS ENGINE WAS DESIGNED AND BUILT BY Mr. CHUCK FELLOWS, ROUND ROCK TEXAS, USA. THIS ENGINE IS 1.5 TIMES LARGER THAN THE ORIGINAL

TITLE DRAWING CONTENTS PROJECT No 09A-25-00 PROJECTION

MODEL SCALE: 1:1

A MODEL OF A MAUDSLAY MARINE TYPE NOTES, PARTS AND ASSEMBLIES JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

JANUARY 2019 J.A.M. DE WAAL PAPAKURA NZ

VERTICAL STEAM ENGINE

Copyright ©

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA

2110. NEW ZEALAND. PHONE: OO64 09 2988815. MOB:

0211791000 E-MAIL: dewaal@xtra.co.nz. SHEET: 02 OF 04 A3 No: 09A-25-00-SHT02

DRAWINGS ARE FOR PERSONAL USE ONLY NOT FOR COMMERCIAL PURPOSSES

Potrebbero piacerti anche

- Single cylinder steam engine slide valveDocumento6 pagineSingle cylinder steam engine slide valveDanilo AlvarezNessuna valutazione finora

- Exp Pistons Oppos S 09 04 04 PDFDocumento4 pagineExp Pistons Oppos S 09 04 04 PDFHerbertCampanaSoteloNessuna valutazione finora

- Lanz A3 Sheet 05 PDFDocumento1 paginaLanz A3 Sheet 05 PDFsrihariNessuna valutazione finora

- Tandem Scotch Yoke Steam EngineDocumento4 pagineTandem Scotch Yoke Steam EngineAmar HairlahovicNessuna valutazione finora

- Double Block Bleed ValveDocumento18 pagineDouble Block Bleed ValveToty DzNessuna valutazione finora

- The Piping Guide Part 1Documento156 pagineThe Piping Guide Part 1Njoku StephenNessuna valutazione finora

- BP9763 A3 Sheet 03Documento1 paginaBP9763 A3 Sheet 03Miguel MotaNessuna valutazione finora

- Customer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaDocumento2 pagineCustomer: Ge Packaged Power PROJECT PO: 411513279 PROJECT NO.: 1370344 Project Name: Termoyopal Project Location: Yopal, ColombiaomarNessuna valutazione finora

- General Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEDocumento4 pagineGeneral Arrangement and Sections Locomotive Boiler For T3 "Badenia" For 5inch (127mm) GAUGEAracely Cárdenas100% (1)

- Sa-3-303 Sa-3-304 Sa-3-305 Sa-3-311 Sa-3-312 Sa-3-313Documento1 paginaSa-3-303 Sa-3-304 Sa-3-305 Sa-3-311 Sa-3-312 Sa-3-313सचिन पटेलNessuna valutazione finora

- Alloy and Material Specs for ValvesDocumento0 pagineAlloy and Material Specs for ValvesZoebairNessuna valutazione finora

- JDW Draughting Services Drawing Property and Contact DetailsDocumento1 paginaJDW Draughting Services Drawing Property and Contact DetailsShridhar ZambareNessuna valutazione finora

- 1chseaw JDW Complet PDFDocumento4 pagine1chseaw JDW Complet PDFOrlando Rojas PintoNessuna valutazione finora

- MAQUINADocumento2 pagineMAQUINAEnrique PinazoNessuna valutazione finora

- A Gas Fired Steam Locomotive of The Dush RailwaysDocumento15 pagineA Gas Fired Steam Locomotive of The Dush Railwaysing aprNessuna valutazione finora

- An 910 An 911 An 914Documento1 paginaAn 910 An 911 An 914blackhawkNessuna valutazione finora

- DVSSE-01 Twin Cylinder Horizontal Steam Engine General ArrangementDocumento4 pagineDVSSE-01 Twin Cylinder Horizontal Steam Engine General ArrangementJuan GabrielNessuna valutazione finora

- 54 Vertical Twin Cylinder Steam Engine PDFDocumento5 pagine54 Vertical Twin Cylinder Steam Engine PDFAlex NaranjoNessuna valutazione finora

- 09C-40-00-A3-SHEET-01 - Sheet1Documento1 pagina09C-40-00-A3-SHEET-01 - Sheet1Nam HoangNessuna valutazione finora

- BS 10 Flange Dimensions and Pressure Ratings for Stainless Steel FlangesDocumento6 pagineBS 10 Flange Dimensions and Pressure Ratings for Stainless Steel Flangesfarmanali07Nessuna valutazione finora

- Muncaster 11 A3 Sheet 04Documento1 paginaMuncaster 11 A3 Sheet 04Juan PastorNessuna valutazione finora

- Bicylindre en V PDFDocumento5 pagineBicylindre en V PDFOrlando Rojas PintoNessuna valutazione finora

- BGRHHDocumento3 pagineBGRHHShubham KalbhutNessuna valutazione finora

- General Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)Documento5 pagineGeneral Arrangement, Isometric 2X1 Cyl. Horizontal Steam Engines With View, Notes Rope Driven Generator (Rope Drive)adil jabaroNessuna valutazione finora

- Finish F 69: Aerospace CoatingsDocumento2 pagineFinish F 69: Aerospace CoatingsKentNessuna valutazione finora

- KR02-WQ00-S-8012-Rev D-Air Receiver GAD-Approved (06.05.2021)Documento5 pagineKR02-WQ00-S-8012-Rev D-Air Receiver GAD-Approved (06.05.2021)ABAID ULLAHNessuna valutazione finora

- Single cylinder steam engine general arrangementDocumento4 pagineSingle cylinder steam engine general arrangementJorge Luis Villegas ValdiviaNessuna valutazione finora

- Vapeur Flying Scotman 32mm 2015 PDFDocumento46 pagineVapeur Flying Scotman 32mm 2015 PDFfoyfauzi67100% (3)

- A3 Tcose Sheet 01 PDFDocumento1 paginaA3 Tcose Sheet 01 PDFसचिन पटेलNessuna valutazione finora

- Kertas A3 - Freight-Lorry-Jdw 2Documento3 pagineKertas A3 - Freight-Lorry-Jdw 2Pemesinan SMK Migas CepuNessuna valutazione finora

- 4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesDocumento2 pagine4-Cylinder Oscillating Steam Engine Called "Simple" G.A., Isometric View, Bom, Notes, Parts and AssembliesOrlando Rojas PintoNessuna valutazione finora

- Weigh Bridge Endevour (4950 X 5000 X 4950 X 3000 X 587 Pitless), 16X3 MTR, 100MT 8 LC, Patel Infr - Vadodara. - WBI - 164Documento1 paginaWeigh Bridge Endevour (4950 X 5000 X 4950 X 3000 X 587 Pitless), 16X3 MTR, 100MT 8 LC, Patel Infr - Vadodara. - WBI - 164abhibawaNessuna valutazione finora

- (Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangDocumento4 pagine(Hoccokhi - VN) Bai Tap Lap Rap Solidworks 2dongco NgangChien Dang VanNessuna valutazione finora

- ET200Documento354 pagineET200klippie_1Nessuna valutazione finora

- General Arrangement, Isometric Engine Called "Trunch Trojan" (Imperial) View, Bill of Materials 1-Cylinder Double Sided Beam SteamDocumento4 pagineGeneral Arrangement, Isometric Engine Called "Trunch Trojan" (Imperial) View, Bill of Materials 1-Cylinder Double Sided Beam SteamOscar OsornoNessuna valutazione finora

- Presentation For KOM Vendor-SubcontDocumento19 paginePresentation For KOM Vendor-Subcontahmad kusumaNessuna valutazione finora

- Top View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionDocumento4 pagineTop View: Rtefer To Modelbouwer Magazine (S) October and November 1987 For DescriptionLe TruongNessuna valutazione finora

- RS232, RS422, RS485 Standards ExplainedDocumento9 pagineRS232, RS422, RS485 Standards ExplainedGil Hale100% (1)

- VERTICAL CYLINDRICAL VESSEL WITH FLANGED FLAT TOP AND BOTTOMDocumento1 paginaVERTICAL CYLINDRICAL VESSEL WITH FLANGED FLAT TOP AND BOTTOMsandesh sadvilkarNessuna valutazione finora

- Muncaster 11 A3 Sheet 02Documento1 paginaMuncaster 11 A3 Sheet 02Juan PastorNessuna valutazione finora

- Jpb2cvse A3 Sheet 01Documento1 paginaJpb2cvse A3 Sheet 01Juan PastorNessuna valutazione finora

- Cabletec Metal Braids Bonding Leads CatalogDocumento28 pagineCabletec Metal Braids Bonding Leads CatalogРоман ДяченкоNessuna valutazione finora

- Ose 1 Vertical Ose Beginner 1 Ok PDFDocumento1 paginaOse 1 Vertical Ose Beginner 1 Ok PDFAnonymous MMLzZjbyNessuna valutazione finora

- Maudslay Marine Type Vertical Steam EngineDocumento3 pagineMaudslay Marine Type Vertical Steam EngineAxel DominiqueNessuna valutazione finora

- Nasm21250 (MS21250, Nas624 .. Nas644)Documento4 pagineNasm21250 (MS21250, Nas624 .. Nas644)Bogdan RusuNessuna valutazione finora

- 2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and NotesDocumento1 pagina2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and NotesMiguel MotaNessuna valutazione finora

- Creo SyllabusDocumento183 pagineCreo Syllabussonu thigleNessuna valutazione finora

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocumento1 paginaA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesSARGEN YOHAN LOZANO ARIASNessuna valutazione finora

- An3 Thru An20 Rev-12bDocumento2 pagineAn3 Thru An20 Rev-12bffontanaNessuna valutazione finora

- LISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsDocumento6 pagineLISI AEROSPACE - PULL-STEM™ and PULL-IN™ PinsLeandro González De CeccoNessuna valutazione finora

- Item Parts ListDocumento3 pagineItem Parts ListMiltongrimi GrimilNessuna valutazione finora

- August 16, 2021 Hardware Specifications Highlighted Updated Specification Rev. TitleDocumento8 pagineAugust 16, 2021 Hardware Specifications Highlighted Updated Specification Rev. TitleTony C.Nessuna valutazione finora

- 09C-40-00-A3-SHEET-03 - Sheet1Documento1 pagina09C-40-00-A3-SHEET-03 - Sheet1Abdul MannanNessuna valutazione finora

- Route-11kv Cable Route Sheet-1Documento1 paginaRoute-11kv Cable Route Sheet-1imranNessuna valutazione finora

- An optimized title for a PIC18F4431 microcontroller schematicDocumento1 paginaAn optimized title for a PIC18F4431 microcontroller schematicnguyendtk5Nessuna valutazione finora

- Roller Bracket AssemblyDocumento1 paginaRoller Bracket AssemblyRishikesh GunjalNessuna valutazione finora

- Jadwal KBM SMT GNP+P5PPRA-9 Januari SD 6 Februari 2023Documento1 paginaJadwal KBM SMT GNP+P5PPRA-9 Januari SD 6 Februari 2023Sapta Aji nugrahaNessuna valutazione finora

- Graphic Temp. RecorderDocumento1 paginaGraphic Temp. RecorderPoyaNessuna valutazione finora

- BOP Part Data PDFDocumento1 paginaBOP Part Data PDFBehnam NouroozpourNessuna valutazione finora

- ACF PLR Af-Forty RTS: Wheel Rotation As Viewed From Drive Side (Counterclockwise)Documento1 paginaACF PLR Af-Forty RTS: Wheel Rotation As Viewed From Drive Side (Counterclockwise)Isaias de la CruzNessuna valutazione finora

- Rendered Pictures A Model of A Maudslay Marine Type Vertical Steam EngineDocumento1 paginaRendered Pictures A Model of A Maudslay Marine Type Vertical Steam EngineJayaramakrishna YakambariNessuna valutazione finora

- Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineDocumento1 paginaParts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineJayaramakrishna YakambariNessuna valutazione finora

- Maudslay A3 Sheet 01Documento1 paginaMaudslay A3 Sheet 01Jayaramakrishna YakambariNessuna valutazione finora

- Catia Part DesignDocumento244 pagineCatia Part DesignNavaneeth KGNessuna valutazione finora

- Convener Office Address: CONVENER, APPOLYCET-2019Documento2 pagineConvener Office Address: CONVENER, APPOLYCET-2019Jayaramakrishna YakambariNessuna valutazione finora

- AR Adjustments: Details, Setup, Flow, Accounting and API: September 5th, 2008Documento5 pagineAR Adjustments: Details, Setup, Flow, Accounting and API: September 5th, 2008John SmithNessuna valutazione finora

- Lab 1 Handout Electrical MachinesDocumento23 pagineLab 1 Handout Electrical Machinesvishalsharma08Nessuna valutazione finora

- Design of Hydraulic Structures Seepage TheoryDocumento13 pagineDesign of Hydraulic Structures Seepage TheorySuleman FaisalNessuna valutazione finora

- 1136 E01-ML01DP5 Usermanual EN V1.2Documento11 pagine1136 E01-ML01DP5 Usermanual EN V1.2HectorNessuna valutazione finora

- Understanding Power Dynamics and Developing Political ExpertiseDocumento29 pagineUnderstanding Power Dynamics and Developing Political Expertisealessiacon100% (1)

- 7 C's of Business LetterDocumento3 pagine7 C's of Business LetterGladys Forte100% (2)

- Guimaras State CollegeDocumento5 pagineGuimaras State CollegeBabarianCocBermejoNessuna valutazione finora

- Campbell Soup Case-StudyDocumento3 pagineCampbell Soup Case-StudyraghudeepaNessuna valutazione finora

- 9-Lesson 5 Direct and Indirect SpeechDocumento8 pagine9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- Investigation of Twilight Using Sky Quality Meter For Isha' Prayer TimeDocumento1 paginaInvestigation of Twilight Using Sky Quality Meter For Isha' Prayer Timeresurgam52Nessuna valutazione finora

- Lesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersDocumento10 pagineLesson Element Baron-Cohen Et Al. (1997) : Instructions and Answers For TeachersSyed SumaiyahNessuna valutazione finora

- Whirlpool FL 5064 (ET)Documento8 pagineWhirlpool FL 5064 (ET)long_kongo100% (1)

- Lab 01 - HCV and LCV by Gas CalorimeterDocumento6 pagineLab 01 - HCV and LCV by Gas CalorimeterTakreem SindhuNessuna valutazione finora

- Brake System PDFDocumento9 pagineBrake System PDFdiego diaz100% (1)

- Scan & Pay Jio BillDocumento22 pagineScan & Pay Jio BillsumeetNessuna valutazione finora

- Super-Critical BoilerDocumento32 pagineSuper-Critical BoilerAshvani Shukla100% (2)

- Advanced Scan I21no2Documento29 pagineAdvanced Scan I21no2Jaiber SosaNessuna valutazione finora

- Operation 490BDocumento60 pagineOperation 490BYe Min Htike100% (1)

- Ninja's Guide To OnenoteDocumento13 pagineNinja's Guide To Onenotesunil100% (1)

- Margin Philosophy For Science Assessment Studies: EstecDocumento11 pagineMargin Philosophy For Science Assessment Studies: EstecFeyippNessuna valutazione finora

- U1L2 - Definitions of 21st Century LiteraciesDocumento19 pagineU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloNessuna valutazione finora

- Confirmation Form: Pillar Regional Conference (NCR)Documento1 paginaConfirmation Form: Pillar Regional Conference (NCR)Llano Multi-Purpose CooperativeNessuna valutazione finora

- Test Unit 7 m.2Documento6 pagineTest Unit 7 m.2Petchara SridakunNessuna valutazione finora

- ResumeDocumento5 pagineResumeSaeed SiriNessuna valutazione finora

- E Requisition SystemDocumento8 pagineE Requisition SystemWaNi AbidNessuna valutazione finora

- The Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaDocumento4 pagineThe Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaEry Arifullah100% (1)

- Writing A Spooky Setting DescriptionDocumento4 pagineWriting A Spooky Setting DescriptionAayan AnjumNessuna valutazione finora

- Daftar PustakaDocumento3 pagineDaftar PustakaNurha ZizahNessuna valutazione finora

- Siart, Et. Al (2018) Digital GeoarchaeologyDocumento272 pagineSiart, Et. Al (2018) Digital GeoarchaeologyPepe100% (2)

- A Sample of Directory or Instruction:: World Temperatures February 16Documento1 paginaA Sample of Directory or Instruction:: World Temperatures February 16eksaNessuna valutazione finora