Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tenalloy 125: LOW ALLOY STEEL (High Strength)

Caricato da

satnamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tenalloy 125: LOW ALLOY STEEL (High Strength)

Caricato da

satnamCopyright:

Formati disponibili

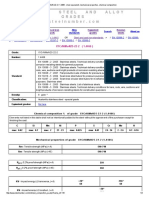

TENALLOY 125

LOW ALLOY STEEL (High Strength)

Low alloy steel Welding Electrode for joining Cr-Mo-V type cast steel.

CLASSIFICATION : DIN 8575 EN ISO 3580-A

E CrMoV 1 B E 1Cr Mo V B 22 H5

KEY FEATURES :

• Basic coated electrode • The deposit is heat treatable

• Cr-Mo-V type low alloy weld deposit • All position capability

• Suitable for welding similar composition • Radiographic quality weld

cast steels

WELDING POSITION : DCEP

TYPICAL APPLICATIONS :

• Welding similar composition low alloy cast • Suitable for steel casting with

steels e.g. (GS-17CrMoV5-10) comparable hardening characteristics

• Suitable for material 1.7706

REDRYING CONDITION : 250-300OC for minimum 1 hr. (Also available in vacuum packed condition)

CHEMICAL COMPOSITION OF UNDILUTED WELD METAL, Wt % :

C Mn Si Cr Mo

Typical 0.14 0.6 0.4 1.3 1.2

Specification 0.12-0.15 1.0 max 0.40-0.50 1.20-1.50 1.0-1.30

V Ni S P

Typical 0.2 0.2 0.01 0.01

Specification 0.20-0.30 0.40 max 0.02 max 0.02 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

YS at 0.2% CVN Impact

Condition UTS, MPa EL%

offset, MPa at 20°C, J

Typical 715 620 20 82

PWHT

Specification 630 min 500 min 16 min 27 min

PWHT : SR at 690°C for 2 hrs followed by water quenching after soaking at 940°C for 1 hr and

tempering at 720°C.

PARAMETERS - PACKING DATA :

Ø x L, mm Amperage, A Wt./Carton, Kg Carton/Box Net wt./Box, Kg

2.5 x 350 60-90 5 4 20

3.15 x 450 90-130 5 4 20

4.0 x 450 140-180 5 4 20

5.0 x 450 190-230 5 4 20

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

81

Potrebbero piacerti anche

- Electrode Booklet F Web 24Documento1 paginaElectrode Booklet F Web 24satnamNessuna valutazione finora

- Low alloy steel electrode for high strength weldingDocumento1 paginaLow alloy steel electrode for high strength weldingsatnamNessuna valutazione finora

- Electrode Booklet F Web 23Documento1 paginaElectrode Booklet F Web 23satnamNessuna valutazione finora

- Electrode Booklet F Web 14Documento1 paginaElectrode Booklet F Web 14satnamNessuna valutazione finora

- Mild Steel Electrode for General Purpose Structural ApplicationsDocumento1 paginaMild Steel Electrode for General Purpose Structural ApplicationssatnamNessuna valutazione finora

- Electrode Booklet F Web 85Documento1 paginaElectrode Booklet F Web 85satnamNessuna valutazione finora

- Tenalloy Z PlusDocumento1 paginaTenalloy Z Plushemal ChauhanNessuna valutazione finora

- Ebondm: Mild Steel General Purpose (MSGP)Documento1 paginaEbondm: Mild Steel General Purpose (MSGP)satnamNessuna valutazione finora

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Documento1 paginaNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Electrode Booklet F Web 18Documento1 paginaElectrode Booklet F Web 18satnamNessuna valutazione finora

- Electrode Booklet F Web 20Documento1 paginaElectrode Booklet F Web 20satnamNessuna valutazione finora

- Electrode Booklet F Web 21Documento1 paginaElectrode Booklet F Web 21satnamNessuna valutazione finora

- Nimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)Documento1 paginaNimoten Plus 535: LOW ALLOY STEEL (Nimoten Series)satnamNessuna valutazione finora

- Electrode Booklet F Web 13Documento1 paginaElectrode Booklet F Web 13satnamNessuna valutazione finora

- Bohler Fox N CM 2 KBDocumento1 paginaBohler Fox N CM 2 KBkamals55Nessuna valutazione finora

- Electrode Booklet F Web 9Documento1 paginaElectrode Booklet F Web 9satnamNessuna valutazione finora

- Celwel - 60 (Adore Electrodes)Documento1 paginaCelwel - 60 (Adore Electrodes)Harish KandollaNessuna valutazione finora

- Electrode Booklet F Web 22Documento1 paginaElectrode Booklet F Web 22satnamNessuna valutazione finora

- Low alloy electrodes for welding high-strength steels with OK 75.75Documento1 paginaLow alloy electrodes for welding high-strength steels with OK 75.75corsini999Nessuna valutazione finora

- Datasheet Sanicro 69Documento1 paginaDatasheet Sanicro 69Agustin CesanNessuna valutazione finora

- Tenalloy 70D11Documento1 paginaTenalloy 70D11pach-thNessuna valutazione finora

- Electrode Booklet F Web 121Documento1 paginaElectrode Booklet F Web 121satnamNessuna valutazione finora

- Supabase-X-Plus AdorDocumento1 paginaSupabase-X-Plus AdorJagan TnNessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Raj RajeshNessuna valutazione finora

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocumento1 paginaEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136Nessuna valutazione finora

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Documento1 paginaTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNessuna valutazione finora

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocumento1 paginaCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- X Bond: Welding Electrode For Structural Welding ApplicationDocumento1 paginaX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNessuna valutazione finora

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocumento1 paginaSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNessuna valutazione finora

- Product Data Sheet: S 'Submerged Arc Welding'Documento1 paginaProduct Data Sheet: S 'Submerged Arc Welding'adanmeneses1Nessuna valutazione finora

- ESABDocumento1 paginaESABXQNessuna valutazione finora

- Ficha Tecnica Esab Electrodos EspecialesDocumento1 paginaFicha Tecnica Esab Electrodos EspecialesStanley RamirezNessuna valutazione finora

- Raffmetal: UNI EN 1676 and 1706Documento2 pagineRaffmetal: UNI EN 1676 and 1706Martin DuarteNessuna valutazione finora

- Celwel - 70P (Ador Electrodes)Documento1 paginaCelwel - 70P (Ador Electrodes)Harish KandollaNessuna valutazione finora

- Nicalloy Mo-12: NON FERROUS (Ni Alloys)Documento1 paginaNicalloy Mo-12: NON FERROUS (Ni Alloys)krupesh patelNessuna valutazione finora

- Stainless steel electrode for welding martensitic and martensitic-ferritic steelsDocumento1 paginaStainless steel electrode for welding martensitic and martensitic-ferritic steelstarun kaushalNessuna valutazione finora

- Datasheet Sandvik Saf 2205 en PDFDocumento12 pagineDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNessuna valutazione finora

- Electrode Booklet F Web 93Documento1 paginaElectrode Booklet F Web 93satnamNessuna valutazione finora

- Mild Steel Electrode for Radiographic Quality WeldingDocumento1 paginaMild Steel Electrode for Radiographic Quality WeldingsatnamNessuna valutazione finora

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocumento1 paginaCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNessuna valutazione finora

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocumento1 paginaF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNessuna valutazione finora

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocumento1 paginaTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNessuna valutazione finora

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocumento1 paginaCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNessuna valutazione finora

- Kingbond Mild Steel Electrode for General Purpose Structural FabricationDocumento1 paginaKingbond Mild Steel Electrode for General Purpose Structural FabricationsatnamNessuna valutazione finora

- Join & Repair High-Carbon Steels with NiCr HLSDocumento1 paginaJoin & Repair High-Carbon Steels with NiCr HLSwalter091011Nessuna valutazione finora

- CM-9CB TG-S9Cb US-9CbDocumento3 pagineCM-9CB TG-S9Cb US-9Cbamit singhNessuna valutazione finora

- All-position stainless steel electrode for difficult weldsDocumento1 paginaAll-position stainless steel electrode for difficult weldscwiksjNessuna valutazione finora

- Electrode Booklet F Web 120Documento1 paginaElectrode Booklet F Web 120satnamNessuna valutazione finora

- Bohler S EMK 6Documento1 paginaBohler S EMK 6Enaam AtaallahNessuna valutazione finora

- Electrode Booklet F Web 105Documento1 paginaElectrode Booklet F Web 105satnamNessuna valutazione finora

- Electrode Booklet F Web 101Documento1 paginaElectrode Booklet F Web 101satnamNessuna valutazione finora

- Datasheet Sanicro 72hpDocumento2 pagineDatasheet Sanicro 72hpphillipskincaidNessuna valutazione finora

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocumento1 paginaHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuNessuna valutazione finora

- M.M.A. welding electrode for Martensitic stainless steelsDocumento1 paginaM.M.A. welding electrode for Martensitic stainless steelscwiksjNessuna valutazione finora

- Datasheet Sandvik 2212htDocumento2 pagineDatasheet Sandvik 2212htDarryl007Nessuna valutazione finora

- WB35S welding electrodeDocumento1 paginaWB35S welding electrodelathasri78Nessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Documento1 paginaAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNessuna valutazione finora

- CWC-BookletF1 59Documento1 paginaCWC-BookletF1 59satnamNessuna valutazione finora

- GTAW TIGFIL CuNi solid filler rod for welding copper nickel alloysDocumento1 paginaGTAW TIGFIL CuNi solid filler rod for welding copper nickel alloyssatnamNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- CWC-BookletF1 36 PDFDocumento1 paginaCWC-BookletF1 36 PDFJagannath SahuNessuna valutazione finora

- GMAW Solid Wire for Welding Copper AlloysDocumento1 paginaGMAW Solid Wire for Welding Copper AlloyssatnamNessuna valutazione finora

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocumento1 paginaAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNessuna valutazione finora

- NiCu-7 solid wire for welding nickel-copper alloysDocumento1 paginaNiCu-7 solid wire for welding nickel-copper alloyssatnamNessuna valutazione finora

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocumento1 paginaAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNessuna valutazione finora

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocumento1 paginaAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNessuna valutazione finora

- GMAW/GTAW Welding of Aluminium Alloys with ER1100 WireDocumento1 paginaGMAW/GTAW Welding of Aluminium Alloys with ER1100 WiresatnamNessuna valutazione finora

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDocumento1 paginaGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Documento1 paginaAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNessuna valutazione finora

- CWC-BookletF1 38 PDFDocumento1 paginaCWC-BookletF1 38 PDFsatnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 10Documento1 paginaCWC-BookletF1 10satnamNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocumento1 paginaTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNessuna valutazione finora

- CWC-BookletF1 17Documento1 paginaCWC-BookletF1 17satnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- CWC-BookletF1 12Documento1 paginaCWC-BookletF1 12satnamNessuna valutazione finora

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocumento1 paginaTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNessuna valutazione finora

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Documento1 paginaTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNessuna valutazione finora

- CWC-BookletF1 9Documento1 paginaCWC-BookletF1 9satnamNessuna valutazione finora

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Documento1 paginaAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNessuna valutazione finora

- Heavy-Duty Lubricant: FeaturesDocumento2 pagineHeavy-Duty Lubricant: Featuresarjun vsNessuna valutazione finora

- Thermo-Lag 3000-P PDS PDFDocumento7 pagineThermo-Lag 3000-P PDS PDFskNessuna valutazione finora

- Pressure Molding & Vacuum Forming Processes ExplainedDocumento22 paginePressure Molding & Vacuum Forming Processes ExplainedRik PtlNessuna valutazione finora

- Carboguard 890 PDSDocumento2 pagineCarboguard 890 PDSLinnie McleodNessuna valutazione finora

- CHE 310 Conversion / Degree of Completion: DefinitionDocumento30 pagineCHE 310 Conversion / Degree of Completion: DefinitionNelsonNessuna valutazione finora

- Swell and Swelling Potential Pressure TestDocumento21 pagineSwell and Swelling Potential Pressure TesthamefNessuna valutazione finora

- Ams 5667Documento8 pagineAms 5667Shankar ManoNessuna valutazione finora

- Pneumatic StructuresDocumento9 paginePneumatic StructuresMaitreyi YellapragadaNessuna valutazione finora

- Unit 1 Question Bank Welding EngineeringDocumento5 pagineUnit 1 Question Bank Welding EngineeringSayiram GNessuna valutazione finora

- Chemistry NotesDocumento115 pagineChemistry NotesGaddam RangaNessuna valutazione finora

- Niir Complete Technology Book On Dyes Dye IntermediatesDocumento9 pagineNiir Complete Technology Book On Dyes Dye IntermediatesAmit Kanani100% (1)

- Ketone Solvent Dewaxing ProcessDocumento14 pagineKetone Solvent Dewaxing Processابوالحروف العربي ابوالحروفNessuna valutazione finora

- Sepuran® N Module 4": in NM /H at 7 Barg 25°CDocumento2 pagineSepuran® N Module 4": in NM /H at 7 Barg 25°CsanjaigNessuna valutazione finora

- Mcqs For Hardness of Water Competitive Exams: Answer: CDocumento9 pagineMcqs For Hardness of Water Competitive Exams: Answer: Csalman100% (3)

- Flooring: Sika® Technology and Concepts For Flooring and CoatingDocumento56 pagineFlooring: Sika® Technology and Concepts For Flooring and Coatingsattar12345Nessuna valutazione finora

- Self Healing Concrete PDFDocumento10 pagineSelf Healing Concrete PDFBilal Akhundzada100% (1)

- Ceilcote 6650 Ceilcrete+ds+engDocumento4 pagineCeilcote 6650 Ceilcrete+ds+engMohamed NouzerNessuna valutazione finora

- GTW Indicators - Zhejiang Charming Dyeing and Finishing Co. LTDDocumento2 pagineGTW Indicators - Zhejiang Charming Dyeing and Finishing Co. LTDGhazanfar GulNessuna valutazione finora

- EPAPROOF FPCS 08.EN - Rev.11.060917Documento8 pagineEPAPROOF FPCS 08.EN - Rev.11.060917Ali HashemiNessuna valutazione finora

- Foundation Isolation ExDocumento2 pagineFoundation Isolation ExKrishna KumarNessuna valutazione finora

- E80dc1b2 01e9 4aee b425 C074a3d3649c Bukango Seed School Mid Term ExamsDocumento38 pagineE80dc1b2 01e9 4aee b425 C074a3d3649c Bukango Seed School Mid Term ExamsDaniel MarkNessuna valutazione finora

- Palpadores M2 RENISHAWDocumento8 paginePalpadores M2 RENISHAWJosevi Jiménez MerinoNessuna valutazione finora

- Ficha SWEP M10 - 2Documento2 pagineFicha SWEP M10 - 2lilymaulenNessuna valutazione finora

- Training Activity Matrix SMAW NC I-COREDocumento52 pagineTraining Activity Matrix SMAW NC I-COREEugenio Mates Jr.Nessuna valutazione finora

- Activity 3 - Oceña, Margarito Jr. o - Forensic Chemistry Laboratory - BS Crim - 3deltaDocumento4 pagineActivity 3 - Oceña, Margarito Jr. o - Forensic Chemistry Laboratory - BS Crim - 3deltaMARGARITO JR. OCEÑANessuna valutazione finora

- SN2651Documento20 pagineSN2651phaniraj.kNessuna valutazione finora

- Cracking AlkanesDocumento2 pagineCracking Alkaneskadek_windyNessuna valutazione finora

- Tennis Court Acrylic Cushion System SurfaceDocumento4 pagineTennis Court Acrylic Cushion System SurfaceOmair Akhtar KhanNessuna valutazione finora

- European Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)Documento3 pagineEuropean Steel and Alloy Grades: X1Crnimon25-22-2 (1.4466)farshid KarpasandNessuna valutazione finora

- Sarnacol®-2170: Product Data SheetDocumento3 pagineSarnacol®-2170: Product Data SheetAhmed MontashNessuna valutazione finora