Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3.2.9 Process Flowchart

Caricato da

Glennizze GalvezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3.2.9 Process Flowchart

Caricato da

Glennizze GalvezCopyright:

Formati disponibili

3.2.

9 Process Flowchart

3.2.10 Detailed Process Procedure of Making a bottled laing:

1. Gathering and Preparation Raw Materials

1.1 Gathering of Raw Materials

1.1.1 Recognize the raw materials needed for the production.

After which, identify the possible source options that is

available nearby. In order to determine the optimum

solution, the researchers applied assignment method to

know the lowest possible cost of acquiring quality raw

materials.

1.1.2 Place purchase order to chosen supplier. Upon delivery,

the quality of raw materials shall be inspected first before

acceptance. All the raw materials that didn’t pass that

quality freshness standard requirement will be returned to

the supplier. While those raw materials that guarantees

freshness will be accepted and put in the storage.

1.2 Preparation of Raw Materials

1.2.1 The garlic, ginger, peanut and chili will be washed

thoroughly. Then, it will be peeled first. The peeled raw

materials will be put in the mincing machine. The

machine has a capacity of 500g per cycle and it will only

take 10 minutes to complete the cycle. The minced

materials will be weighed appropriately depending on the

desired number of output.

1.2.2 Prepare the coconut fruit from the storage first. Then,

crack the coconut shell into two using the back of a

sontaku. Make sure to drain the water from the fruit.

1.2.3 Before extracting the coconut milk, you shall first prepare

the coconut meat. The coconut flesh will be put against

the machine and it will be moved back and forth manually

until all the flesh are grated.

1.2.4 The grated coconut meat will be put on a coconut milk

extractor to mechanically squeeze it to extract the meat.

The machine can extract 20kgs to 35kgs of coconut meat

per hour. After the extraction, the coconut milk will be set

aside for the production.

1.2.5 Lastly, the ground meat and taro leaves will be prepared

and weighed. The quantity will depend upon the planned

output of production.

2. Cooking the Product

2.1 Initial Preparation

2.1.1 Prepare the wide casserole pan. Wash it thoroughly and

secure that it is free from any harmful microorganisms.

2.1.2 Be sure to secure that all the necessary condiments are

available before the actual cooking.

2.1.3 The person-in-charge must double check the raw materials

that were previously prepared and see to it that its quantity is

enough for the planned production.

2.2 Actual Cooking

2.2.1 Arrange the taro leaves evenly in the wide large casserole

pan.

2.2.2 Spread the meat, garlic, and ginger on the top of the taro

leaves.

2.2.3 Season it with salt and pepper to taste.

2.2.4 Put on the pure coconut milk. Make sure that the amount of

the coconut milk is sufficient to cook the leaves.

2.2.5 Then, cook it over low heat. Let it boil until it dry up.

2.2.6 Add chili and other spices when desired.

2.2.7 Let it sit on the table for an hour to cool down.

2.3 Preliminary Food Inspection

2.3.1 Get a sample from the product. Check the texture of the taro

leaves. Make sure that it passed the quality standard

required.

2.3.2 Secure that the itchiness of the taro leaves didn’t spread on

the dish or else it will cause an itchy feeling when the

product is consumed.

2.3.3 If it turns out that the product do not meet the acceptable

quality required, the cooked product will be set aside. It will

no longer be rework because recooking it might cause

contamination and other health risk.

3. Packaging

3.1 Primary Packaging

3.1.1 The glass jar will be prepared and cleaned first before

setting up the filling machine. The laing product that met the

acceptable quality required will be put on the filling machine.

An employee-in-charge will manually operate the lever to fill

the bottle.

3.1.2 After filling it, the assigned employee must see to it that the

bottle is capped strongly. Before it proceed to the next

station.

3.1.3 The capped bottle will now be placed on the sealing machine

to prevent it from spilling.

3.2 Final Quality Inspection

3.2.1 The sealed product will be thoroughly inspected and a rug

will be used to wipe the outside part of the bottle before

putting it in the boxes.

3.2.2 The bottled product that do not pass the final quality required

because of its defective packaging will be set aside and

further use as a product sample.

3.2.3 After the final quality inspection, all the products will be

stored and prepared for the actual selling.

Potrebbero piacerti anche

- Section 7Documento25 pagineSection 7FarahSyazwaniNessuna valutazione finora

- Assessment Guidelines: SITHCCC007 Assessment Tasks and InstructionsDocumento19 pagineAssessment Guidelines: SITHCCC007 Assessment Tasks and InstructionsDipeshNessuna valutazione finora

- Melcs CookeryDocumento11 pagineMelcs CookeryCATHERINE BARNEDONessuna valutazione finora

- TLESelf TestsDocumento6 pagineTLESelf TestsmayetteNessuna valutazione finora

- Learner Evidence SeafoodDocumento14 pagineLearner Evidence SeafoodpriyaNessuna valutazione finora

- Melcs CookeryDocumento11 pagineMelcs CookeryMarj P. Malalay GablinezNessuna valutazione finora

- M-02 Injera ProcessingxDocumento98 pagineM-02 Injera ProcessingxGadisaNessuna valutazione finora

- Desserts Evidence DessertDocumento17 pagineDesserts Evidence Dessertpriya0% (1)

- Effectiveness Evaluation of Vacuum Pressure As Contributing Factor To Lightweight Seasoning Packets Distribution System - RevisionDocumento7 pagineEffectiveness Evaluation of Vacuum Pressure As Contributing Factor To Lightweight Seasoning Packets Distribution System - RevisionTu DuongNessuna valutazione finora

- I Design & Facilities of My Premise: S.No. Checklist Item WeightageDocumento3 pagineI Design & Facilities of My Premise: S.No. Checklist Item WeightageMAHESH SHAWNessuna valutazione finora

- Section IiDocumento14 pagineSection IiJociel BurneaNessuna valutazione finora

- Quarter 1 - Module 2: CookeryDocumento11 pagineQuarter 1 - Module 2: Cookeryroderic v. perezNessuna valutazione finora

- Kitchen Session 3a Workplan AssessmentDocumento54 pagineKitchen Session 3a Workplan AssessmentDuncan SunNessuna valutazione finora

- Abc Meat CompanyDocumento7 pagineAbc Meat CompanyMichaelTrumanjayaNessuna valutazione finora

- Grade Level: Grade 9 Subject: TLE (Cookery NC II)Documento8 pagineGrade Level: Grade 9 Subject: TLE (Cookery NC II)Rhea Alo100% (3)

- CG NotesDocumento4 pagineCG Notesvictormallosa28Nessuna valutazione finora

- Core Competencies Unit of Competency: Prepare Vegetables DishesDocumento4 pagineCore Competencies Unit of Competency: Prepare Vegetables DishesScarlet Elgamo GalantoNessuna valutazione finora

- Kitchen Session 1a: Prepare Seafood DishesDocumento31 pagineKitchen Session 1a: Prepare Seafood DishesAMAN MIGLANINessuna valutazione finora

- Core CompetencyDocumento9 pagineCore CompetencyLeanne DaluddongNessuna valutazione finora

- CBLM SWBL JoeyDocumento8 pagineCBLM SWBL Joeymariedyl marcoNessuna valutazione finora

- 4 3Documento2 pagine4 3arlene gayaresNessuna valutazione finora

- Grade 10 - Food Processing - Mod 1Documento12 pagineGrade 10 - Food Processing - Mod 1Winnie joy m. torresNessuna valutazione finora

- Sample Budget of Work COOKERY IDocumento6 pagineSample Budget of Work COOKERY IFelixVergara100% (1)

- G7 Las Bpp-Week5Documento4 pagineG7 Las Bpp-Week5MJay Cabarles BbinhsNessuna valutazione finora

- Processing and EquipmentDocumento49 pagineProcessing and Equipmentnumantabassum3Nessuna valutazione finora

- Form 4.3 - Summary of Current CompetenciesDocumento4 pagineForm 4.3 - Summary of Current CompetenciesvayaNessuna valutazione finora

- Vegetable That Can Be Planted in TropicsDocumento7 pagineVegetable That Can Be Planted in TropicsindongparNessuna valutazione finora

- Clean and StorDocumento4 pagineClean and Storccdnuez01829Nessuna valutazione finora

- Training Needs (Learning Outcomes) Module Title/Module of InstructionDocumento2 pagineTraining Needs (Learning Outcomes) Module Title/Module of InstructionMagdalena Sanjuan FavorNessuna valutazione finora

- Mkath Foodprocessing (Housekeeping) Week2 - 4Documento41 pagineMkath Foodprocessing (Housekeeping) Week2 - 4Ma Katherine Reyes VictoriaNessuna valutazione finora

- Emil Eldho MOOC Project ReportDocumento31 pagineEmil Eldho MOOC Project Reportebby joseph100% (3)

- Cuisinart Microware Popcorn MakerDocumento8 pagineCuisinart Microware Popcorn MakerFredNessuna valutazione finora

- Tle 10 Cookery Q4 Module 3Documento8 pagineTle 10 Cookery Q4 Module 3Danica DaniotNessuna valutazione finora

- 1.) Purefoods Tender Juicy Hotdogs 2.) Raw Materials: Meat ProcessingDocumento2 pagine1.) Purefoods Tender Juicy Hotdogs 2.) Raw Materials: Meat Processingjoshstrike21Nessuna valutazione finora

- Mushroom Preservation: An Assignment OnDocumento6 pagineMushroom Preservation: An Assignment OnRamindra SuwalNessuna valutazione finora

- Budgetted Plan in Tle Vi: Home EconomicsDocumento8 pagineBudgetted Plan in Tle Vi: Home EconomicsPrecilla HalagoNessuna valutazione finora

- Cookery ExamDocumento6 pagineCookery ExamSherwin D. SungcalangNessuna valutazione finora

- 7 8 Tle Caregiving W2 RevalidatedDocumento10 pagine7 8 Tle Caregiving W2 RevalidatedKen KetekNessuna valutazione finora

- Tabel Hazard Dan Critical Control Steak 2Documento2 pagineTabel Hazard Dan Critical Control Steak 2Allyscia Melinda AllysciamelindaNessuna valutazione finora

- LEARNING MATERIAL Group 3 Tocino MakingDocumento10 pagineLEARNING MATERIAL Group 3 Tocino MakingRogelito D. BallonNessuna valutazione finora

- Cookery9 Q2 Mod1 Lesson1-2 PrepareSaladandDressing V4-2Documento52 pagineCookery9 Q2 Mod1 Lesson1-2 PrepareSaladandDressing V4-2Ian Grace Dolar FabianiaNessuna valutazione finora

- Bioplastic: Year 2Documento19 pagineBioplastic: Year 2SHAL NeyNessuna valutazione finora

- Exp 4 Heat Sterilization of Canned Chicken in Prepared SauceDocumento4 pagineExp 4 Heat Sterilization of Canned Chicken in Prepared SauceNurul Syafiqah0% (1)

- Mango Juice PRDCTN TRNGDocumento10 pagineMango Juice PRDCTN TRNGsaleekha shamsudheenNessuna valutazione finora

- 9 TLE COOKERY Q1 W2 ValidatedDocumento11 pagine9 TLE COOKERY Q1 W2 ValidatedGilbert MalicdemNessuna valutazione finora

- Bow TleDocumento2 pagineBow Tlekeren rose100% (4)

- New Module TLE 7 WEEK 5Documento6 pagineNew Module TLE 7 WEEK 5Cathlyn RanarioNessuna valutazione finora

- Pre Assessment ChecklistDocumento7 paginePre Assessment ChecklistJosh Kane Langam100% (1)

- REGUNAYAN - Assesment, Recipe, DocumenationDocumento5 pagineREGUNAYAN - Assesment, Recipe, DocumenationMarco RegunayanNessuna valutazione finora

- Hazard Analysis Critical Control Point Plan: La Salle University School of Tourism & Hospitality ManagementDocumento71 pagineHazard Analysis Critical Control Point Plan: La Salle University School of Tourism & Hospitality ManagementJiezel ChiNessuna valutazione finora

- Tleeeeeeeee Lesson 3333333Documento15 pagineTleeeeeeeee Lesson 3333333Cal GonzalesNessuna valutazione finora

- FST528 Lab ManualDocumento31 pagineFST528 Lab ManualNurSyazaHani100% (2)

- Microbiological Culture Media DR Ibrahim HashimDocumento13 pagineMicrobiological Culture Media DR Ibrahim HashimIBRAHIMHASHIMNessuna valutazione finora

- HAFT LESSON 2 TLE 8 CAREGIVING Maintain ToolsJ EquipmentJ AndG ParaphernaliaDocumento13 pagineHAFT LESSON 2 TLE 8 CAREGIVING Maintain ToolsJ EquipmentJ AndG ParaphernaliaeciladlgdNessuna valutazione finora

- Hericel Chapter 3Documento7 pagineHericel Chapter 3Mariel Garcia PajelmarianoNessuna valutazione finora

- Health & Hygiene Inspection RIG 215 17 April 2018Documento8 pagineHealth & Hygiene Inspection RIG 215 17 April 2018shahzad sultanNessuna valutazione finora

- SITHCCC007 Assessment 1 - PortfolioDocumento15 pagineSITHCCC007 Assessment 1 - Portfoliopriya rajaniNessuna valutazione finora

- Sithccc006 Short QuestionDocumento21 pagineSithccc006 Short QuestionMukta AktherNessuna valutazione finora

- A Processing Manual of Individual Quick Frozen Green Peas from Raw Material to Cold Storage.Da EverandA Processing Manual of Individual Quick Frozen Green Peas from Raw Material to Cold Storage.Nessuna valutazione finora

- Entrep 4 Week: What I KnowDocumento9 pagineEntrep 4 Week: What I KnowGlennizze GalvezNessuna valutazione finora

- Accountancy Student: Froilan Arlando BandulaDocumento5 pagineAccountancy Student: Froilan Arlando BandulaGlennizze GalvezNessuna valutazione finora

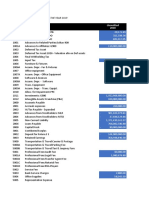

- Assets: Balance Sheet As of September 31, 2020Documento91 pagineAssets: Balance Sheet As of September 31, 2020Glennizze GalvezNessuna valutazione finora

- Unaudited Trial Balance For The Year 2019: Sultan 900 Capital, IncDocumento18 pagineUnaudited Trial Balance For The Year 2019: Sultan 900 Capital, IncGlennizze GalvezNessuna valutazione finora

- Chapter 14 - Bus Com Part 1 - Afar Part 2-1Documento4 pagineChapter 14 - Bus Com Part 1 - Afar Part 2-1Glennizze GalvezNessuna valutazione finora

- Body Composition: BenefitsDocumento8 pagineBody Composition: BenefitsGlennizze GalvezNessuna valutazione finora

- January 2019: Sun Mon Tue Wed Thu Fri SatDocumento12 pagineJanuary 2019: Sun Mon Tue Wed Thu Fri SatGlennizze GalvezNessuna valutazione finora

- Fun BoothDocumento2 pagineFun BoothGlennizze GalvezNessuna valutazione finora

- SynthesisDocumento2 pagineSynthesisGlennizze GalvezNessuna valutazione finora

- PurposiveDocumento1 paginaPurposiveGlennizze GalvezNessuna valutazione finora

- Maxims of CommunicationDocumento1 paginaMaxims of CommunicationGlennizze GalvezNessuna valutazione finora

- Chapter 16 - Bus Com Part 3 - Afar Part 2-1Documento5 pagineChapter 16 - Bus Com Part 3 - Afar Part 2-1Glennizze GalvezNessuna valutazione finora

- Accountancy Student: Froilan Arlando BandulaDocumento5 pagineAccountancy Student: Froilan Arlando BandulaGlennizze GalvezNessuna valutazione finora

- Accountants National Capital Region (NFJPIA-NCR) Is A Duly: Ngarap Tungo SA Kilang LaDocumento4 pagineAccountants National Capital Region (NFJPIA-NCR) Is A Duly: Ngarap Tungo SA Kilang LaGlennizze GalvezNessuna valutazione finora

- Systems Analysis and Design: Course DescriptionDocumento3 pagineSystems Analysis and Design: Course DescriptionGlennizze GalvezNessuna valutazione finora

- Bio Plants SurveyDocumento1 paginaBio Plants SurveyGlennizze GalvezNessuna valutazione finora

- University of Perpetual Help System DALTA: Las Piñas CampusDocumento65 pagineUniversity of Perpetual Help System DALTA: Las Piñas CampusGlennizze Galvez100% (1)

- Accountancy Student: Froilan Arlando BandulaDocumento5 pagineAccountancy Student: Froilan Arlando BandulaGlennizze GalvezNessuna valutazione finora

- As A Temporary Investment of Excess Cash As Part of A Long-Term Risk-Adjusted Portfolio As A Strategic InvestmentDocumento41 pagineAs A Temporary Investment of Excess Cash As Part of A Long-Term Risk-Adjusted Portfolio As A Strategic InvestmentGlennizze GalvezNessuna valutazione finora

- Chapter 25 - Acctg For Derivatives & Hedging Transactions Part 2 - ADocumento10 pagineChapter 25 - Acctg For Derivatives & Hedging Transactions Part 2 - AGlennizze Galvez100% (3)

- Critical Questions: 1. What Is More Potent Strategy To Use? Customer Driven or Customer Driving Market?Documento2 pagineCritical Questions: 1. What Is More Potent Strategy To Use? Customer Driven or Customer Driving Market?Glennizze GalvezNessuna valutazione finora

- CV For Internship PDFDocumento5 pagineCV For Internship PDFGlennizze GalvezNessuna valutazione finora

- Draft PDFDocumento166 pagineDraft PDFashwaq000111Nessuna valutazione finora

- Hydraulic Mining ExcavatorDocumento8 pagineHydraulic Mining Excavatorasditia_07100% (1)

- ENT 300 Individual Assessment-Personal Entrepreneurial CompetenciesDocumento8 pagineENT 300 Individual Assessment-Personal Entrepreneurial CompetenciesAbu Ammar Al-hakimNessuna valutazione finora

- E-Versuri Ro - Rihana - UmbrelaDocumento2 pagineE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- Bank Danamon Organization ChartDocumento4 pagineBank Danamon Organization ChartFaisal Agus NugrahaNessuna valutazione finora

- Logiq v12 SM PDFDocumento267 pagineLogiq v12 SM PDFpriyaNessuna valutazione finora

- Understanding and Teaching Fractions: Sybilla BeckmannDocumento26 pagineUnderstanding and Teaching Fractions: Sybilla Beckmannjhicks_mathNessuna valutazione finora

- Understanding PTS Security PDFDocumento37 pagineUnderstanding PTS Security PDFNeon LogicNessuna valutazione finora

- IcarosDesktop ManualDocumento151 pagineIcarosDesktop ManualAsztal TavoliNessuna valutazione finora

- Project Management TY BSC ITDocumento57 pagineProject Management TY BSC ITdarshan130275% (12)

- General Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveDocumento19 pagineGeneral Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveJolo Allexice R. PinedaNessuna valutazione finora

- Introduction - Livspace - RenoDocumento12 pagineIntroduction - Livspace - RenoMêghnâ BîswâsNessuna valutazione finora

- Phylogeny Practice ProblemsDocumento3 paginePhylogeny Practice ProblemsSusan Johnson100% (1)

- Predator U7135 ManualDocumento36 paginePredator U7135 Manualr17g100% (1)

- A Medium-Rise Residential Building: A B C E D F G HDocumento3 pagineA Medium-Rise Residential Building: A B C E D F G HBabyjhaneTanItmanNessuna valutazione finora

- Agency Canvas Ing PresentationDocumento27 pagineAgency Canvas Ing Presentationkhushi jaiswalNessuna valutazione finora

- Binary OptionsDocumento24 pagineBinary Optionssamsa7Nessuna valutazione finora

- Speed, Velocity & Acceleration (Physics Report)Documento66 pagineSpeed, Velocity & Acceleration (Physics Report)Kristian Dave DivaNessuna valutazione finora

- Top Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersDocumento8 pagineTop Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersBassignotNessuna valutazione finora

- Facebook: Daisy BuchananDocumento5 pagineFacebook: Daisy BuchananbelenrichardiNessuna valutazione finora

- Ducted Split ACsDocumento31 pagineDucted Split ACsHammadZaman100% (1)

- M. Ircham Mansyur 07224005 Microprocessor-2 (H13)Documento7 pagineM. Ircham Mansyur 07224005 Microprocessor-2 (H13)emiierNessuna valutazione finora

- Final WMS2023 HairdressingDocumento15 pagineFinal WMS2023 HairdressingMIRAWATI SAHIBNessuna valutazione finora

- COURTESY Reception Good MannersDocumento1 paginaCOURTESY Reception Good MannersGulzina ZhumashevaNessuna valutazione finora

- Upes School of Law Lac & Adr Association: PresentsDocumento7 pagineUpes School of Law Lac & Adr Association: PresentsSuvedhya ReddyNessuna valutazione finora

- 19c Upgrade Oracle Database Manually From 12C To 19CDocumento26 pagine19c Upgrade Oracle Database Manually From 12C To 19Cjanmarkowski23Nessuna valutazione finora

- HFE0106 TraskPart2Documento5 pagineHFE0106 TraskPart2arunkr1Nessuna valutazione finora

- 24 DPC-422 Maintenance ManualDocumento26 pagine24 DPC-422 Maintenance ManualalternativblueNessuna valutazione finora

- How To Launch Remix OS For PCDocumento2 pagineHow To Launch Remix OS For PCfloapaaNessuna valutazione finora

- I I I I: Peroxid.Q!Documento2 pagineI I I I: Peroxid.Q!Diego PradelNessuna valutazione finora