Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inspection of Earth Wire

Caricato da

Nirmal WiresCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Inspection of Earth Wire

Caricato da

Nirmal WiresCopyright:

Formati disponibili

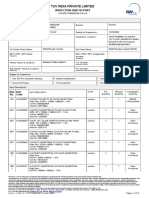

INSPECTION REPORT

Inspection Report Number 208877-011019-1 Rev: 0 Date: 01.10.2019

Contract code 401172

I. General

Client: M/s Tata Projects Limited Project: SPGVL 400 kV D/C Silchar

Misa T/L Pkg-I

Supplier: M/s Nirmal Wires Pvt. Ltd Location Deulti, Howrah

Sub- Supplier: NA Location NA

P.O. Number: SBU- T & D (Transmission Distribution)/ Rev. --- Date 03.09.2018

Silchar-Misa Package-I-200197/20451

Sub- Supplier P.O. NA Rev. --- Date ---

Number:

II. Visit Details:

NOI/E-mail Ref: Email From Mr. Rishi Rana-Sterlite Date: 25.09.2019

Inspection Location: Deulti, Howrah

Contact Details

Supplier Name Mr. S K Kedia Phone 9830017911

Sub Name NA Phone NA

Supplier

Visit Date(s) 01.10.2019

Inspection Stage Stage Final Pre Dispatch

P.O. Order Status Completed Partially Completed

III. a).Inspected Items ( Annexure may be prepared, if required)

Sr. No. / Description P.O. Qty. Inspected Accepted Rejected Hold

PO Item Qty. Qty. Qty. Qty.

No.

1 Earthwire, Galvanized steel, IS 398, 7/3.66 76300 68010 ---- ---- 68000

mm Meter Meter Meter

PO Item No.: 9507080008 (17 nos. (17 nos.

Drum Sl. No. TATA/EWD 24 to 40 drum)

drum)

b). Offered condition: Stranded Steel Earth Wire was offered in galvanized condition. Wire was wrapped on 17 nos.

Drum with drum no.- TATA / EWD 24 to 40.

IV. Summary of Inspection Activities Performed:

a) Reference Documents

Document No. Rev Title Approval Document

Status Supplied by

TPL/NOIDA/NERSS/SM/18- --- Inspection call Yes SPGVL

19/074, Dt-23.09.19

NWPL/SPGVL/MQP/EW/19- 00 MQP for GS Earth wire7/3.66mm Yes NWPL

20/01 issue No. 01

Page 1 of 4 Format No: 15.03.01/F-01/R4 Date: 01-04-2019

INSPECTION REPORT

SBU- T & D (Transmission --- PO copy Yes NWPL

Distribution)/ Silchar-Misa

Package-I-200197/20451, dt-

03.09.18

SPGVL/NERSS/S- 0 Guaranteed Technical Particulars of GI Earth Yes NWPL

M/ENGG/TPL/137, Dt- wire size 7/3.66mm

30.04.19

--- ---- Relevant Stds. ---- NWPL

b) Previous report reference, if any: NA

c) Inspection, Measuring and Test Equipment:

Sr. Description ID No Make Type Range Calibration Traceability

No. Validity to

NABL/NPL

1 Refer attached Calibration status Report. Yes

2

a) Accuracy of measurements ensured - Yes

b). NABL Approved Testing Laboratory - Yes No NA

If Yes, Verify and note the NABL certificate number and its validity.

If No, Verify the facilities as per check list: TQS-IS-CL-02**

**This is applicable for tests witnessed at unapproved Laboratories/manufacturing facility.

(Tick applicable clause)

d) ITP/QAP/MQP –Activities: (H-Hold, W- witness, R- Review, S- Surveillance)

ITP/QAP Inspection activity as per QAP/ITP. H/W/R/S Quantum of Check

Clause

D-I to VII Surface, check for oil treatment, Overall diameter, W One sample from 10 drums

Lay length, Performing & post forming, Direction of

lay, Diameter of individual wire

D-VIII to XII Tensile strength of individual wire, Elongation test, W One sample from 10 drums

DC Resistance test, Torsion test, Wrap test

D-XIII to Weight of zinc coating, Uniformity test, Joint, Length W One sample from 10 drums

XVI Measurement

D-XVII Sealing --- 100%

D-XVIII Wooden drum Dimension, Barrel battn strength, W One sample of lot

Marking

As per Documents review R 100%

MQP

Page 2 of 4 Format No: 15.03.01/F-01/R4 Date: 01-04-2019

INSPECTION REPORT

e) Inspection Activity Narrative Summation:

Scope of insp.: As per approved MQP, sampling done from drum No.-TATA/EWD 25 & 32 for Dimension,

Mech. & GI test. For Chemical test sample drawn from drum no. TATA/EWD 32 and rewinding done on drum

no- TATA/EWD 28 & 36.

1. Visual Inspection: Vendor offered the earth wire in 17 nos. drum with drum no.- TATA/EWD 24 to 40. Visual

insp. carried out on selected drum during rewinding for Surface defects, check for oil treatment, performing &

post forming, direction of lay, Joint etc. and found satisfactory.

2. Dimensional Check: Overall dia., Lay length, Dia. Of individual wire checked and found within tolerance limit.

Overall length checked during rewinding on selected drum and found satisfactory. Wooden drum dimension

checked on random selected sample and found within tolerance limit.

3. Material Identification: Drums were identified by Customer name- TATA / SPGVL, drum no., length, size,

weight, Mfg. Name marked by yellow paint on each wooden drum.

4. Acceptance Test: Acceptance test such as Tensile strength of composite wire & single wire, % Elongation,

torsion test of single strand, wrap test, DC Resistance test of earth wire checked and results found satisfactory.

Witnessed reports attached.

5. Chemical Test: Sample drawn from drum no. TATA/EWD 32 for Chemical testing at NABL accredited third

party lab. and report to be submitted to client for review. Sample packed in envelop duly signed & TPL stamp

was put on envelop for identification only.

6. Galvanizing Test: Mass & Uniformity of zinc coating witnessed on selected samples and results found

satisfactory. Witnessed reports attached.

7. Review: MTC, Routine test certificate for the offered material submitted by vendor was reviewed and found in

order Packing list submitted by vendor was verified found in order. -Reports attached. Calibration Status were

tallied with original TCs.

f). Record Notes/ Details of discussion with Client: RMTC for steel wire are from Electrosteel and the same has

been accepted by call originator.

g) Non-Conformance /Issues: yes

Sr. No. Description of Component Description of Non-Conformance / Issues

1 Earth wire, Galvanized Steel, 7/ 3.15 Chemical test results from third party lab.

mm.

h) Identification:

Location of Stamping: Specimen

Inspected drums were

sealed by ruber stamp & Metal Stamp Sticker Marking

Specimen: TPL/716

Page 3 of 4 Format No: 15.03.01/F-01/R4 Date: 01-04-2019

INSPECTION REPORT

signed at cut end for

identification only.

Note: TPL Stamping is done for identification purpose only.

V. Conclusion:

Based on above inspection observations, inspected items are kept under HOLD due to NC point (g-1).

VI. Attachments:

Sr. No. Descriptions No of Pages

1 Test witnessed Reports 02 Nos.

2 Packing list, MTC, Routine TC, Calibration status Reports. 07 Nos.

3 Photographs 02 Nos.

VII. Safety Compliance:

a). Safety PPE Used: Safety Shoe Helmet Goggles Ear Plugs Nose mask Hand Gloves

VIII. IRN Issued with this Report: Yes No

Supplier / Sub Supplier Tata Projects Ltd Client / Client Representative

Signature & date: 01.10.19 Signature & date: 01.10.19 Signature & date:

Name: Mr. Vineet Singh (8335079204) Name: N Nandi (9609618520) Name:

Liability: Client/vendor/supplier/manufacturer shall note that this inspection report is issued without prejudice to

contractual obligations of the vendor/supplier/manufacturer and does not relieve him from the guarantee and obligations

set forth in the purchase order and other contractual documents. It should also be noted that in all cases where the test

certificate/inspection reports issued by the vendor/supplier/laboratory are reviewed by the surveyor for conformity to the

requirements of the standard/specification, the responsibility for the accuracy and validity of the inspection/test results lies

with the issuer of the said certificate/report.

Page 4 of 4 Format No: 15.03.01/F-01/R4 Date: 01-04-2019

Potrebbero piacerti anche

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Fir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFDocumento3 pagineFir - 01 - Ioc Petronas - Cable Laying - 12.03 PDFgaladrialNessuna valutazione finora

- Irn 20.09.2019 Fl-Smidth VoltampDocumento2 pagineIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNessuna valutazione finora

- Alstom IRDocumento4 pagineAlstom IRkasi reddyNessuna valutazione finora

- 2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDocumento14 pagine2037-PL-PL-0058-FR-T-025 Dated 18.12.19 PDFDadaso Baburao JamdarNessuna valutazione finora

- Material Inspection Report 6219-1Documento2 pagineMaterial Inspection Report 6219-1คุณพ่อน้อง บิ๊กบอสNessuna valutazione finora

- GTP&DWG of - Earthing Pipe& Earth RodDocumento6 pagineGTP&DWG of - Earthing Pipe& Earth RodabhishekNessuna valutazione finora

- LTHE-BFCCU-TUV-00103-LHP-IRN 01 DT - 02.06.2018Documento1 paginaLTHE-BFCCU-TUV-00103-LHP-IRN 01 DT - 02.06.2018bappadittaNessuna valutazione finora

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocumento2 pagineDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNessuna valutazione finora

- Anish New Catalogue (Hardware)Documento13 pagineAnish New Catalogue (Hardware)Rajeeb MohammedNessuna valutazione finora

- Native Inspection - Report - CleanedDocumento6 pagineNative Inspection - Report - CleanedPrathamesh OmtechNessuna valutazione finora

- 120 PDFDocumento28 pagine120 PDFqczoomenNessuna valutazione finora

- Welding SAF2205 Tubes To CS TubesheetDocumento2 pagineWelding SAF2205 Tubes To CS Tubesheetmasterdol1983Nessuna valutazione finora

- Aerial Bundled Conductor Solutions: Product CatalogDocumento44 pagineAerial Bundled Conductor Solutions: Product CatalogNimish TaterhNessuna valutazione finora

- WOWLibrary Preheating of Materials ConsumablesDocumento4 pagineWOWLibrary Preheating of Materials ConsumableshreerNessuna valutazione finora

- Ir 5073 Ppa 005Documento6 pagineIr 5073 Ppa 005ValiNessuna valutazione finora

- Technip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFDocumento18 pagineTechnip - IVR - 8116970849 - Sr. No.01 - R00 - 077015C002-PO-1310-0012-02-O9833 PDFAbhay KarandeNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsDocumento7 pagineCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocumento5 pagineQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Nessuna valutazione finora

- Sample Wps Carbon Steel GTAW SMAW PDFDocumento2 pagineSample Wps Carbon Steel GTAW SMAW PDFirwanNessuna valutazione finora

- Bis-Dk-Ut 1152 - 1200-24-VC01Documento6 pagineBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNessuna valutazione finora

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocumento4 pagineWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanNessuna valutazione finora

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocumento4 pagineL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNessuna valutazione finora

- Welding Process Related DefectsDocumento1 paginaWelding Process Related DefectskapsarcNessuna valutazione finora

- L&T Construction: Sno Desription Frequency of Updation Date of UpdationDocumento2 pagineL&T Construction: Sno Desription Frequency of Updation Date of UpdationANILNessuna valutazione finora

- Corrosion Behavior of Welded Stainless Steel PDFDocumento20 pagineCorrosion Behavior of Welded Stainless Steel PDFLanang Dian NugrohoNessuna valutazione finora

- 1.2 Resistance and Special WeldingDocumento14 pagine1.2 Resistance and Special WeldingnikhilbathamNessuna valutazione finora

- Kou2003 PDFDocumento6 pagineKou2003 PDFGe EffgenNessuna valutazione finora

- Purchase Spec. For Tubes (Sa789 S31803)Documento6 paginePurchase Spec. For Tubes (Sa789 S31803)Daison PaulNessuna valutazione finora

- Spec Sheet - Handler 187Documento4 pagineSpec Sheet - Handler 187Hobart Welding ProductsNessuna valutazione finora

- To-101175 OspDocumento5 pagineTo-101175 OspSIVANessuna valutazione finora

- WPS - 004Documento12 pagineWPS - 004MAT-LIONNessuna valutazione finora

- Minimizing Weld Defects in SAWDocumento3 pagineMinimizing Weld Defects in SAWNalla Gane100% (1)

- RTCC Manual WPS Approval WE-WPS-001Documento7 pagineRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNessuna valutazione finora

- TC - ASTM 517 GR FDocumento1 paginaTC - ASTM 517 GR FPremnath YadavNessuna valutazione finora

- WPS - 006Documento13 pagineWPS - 006MAT-LIONNessuna valutazione finora

- 2020-8002-Rep-1046 0Documento8 pagine2020-8002-Rep-1046 0nor fazmi rozikinNessuna valutazione finora

- Material Product Data SheetDocumento4 pagineMaterial Product Data SheethungNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- How To Choose Electrodes For Joining High-Strength SteelsDocumento3 pagineHow To Choose Electrodes For Joining High-Strength SteelsmakcodetechNessuna valutazione finora

- Adea Company BroucherDocumento15 pagineAdea Company BroucherVelu SamyNessuna valutazione finora

- R0607-Cm-Itr-08-606 321a PDFDocumento13 pagineR0607-Cm-Itr-08-606 321a PDFShelton S S SheltonNessuna valutazione finora

- Duplex Stainless Steel - Part 2 - TWIDocumento6 pagineDuplex Stainless Steel - Part 2 - TWItuanNessuna valutazione finora

- Po 00028 1Documento3 paginePo 00028 1Ferry AwanNessuna valutazione finora

- Purchase Order: Number: 14 - SOODocumento4 paginePurchase Order: Number: 14 - SOOLê Đức ThiệnNessuna valutazione finora

- Sa-Dar-Cv-W O74-004Documento6 pagineSa-Dar-Cv-W O74-004Divakar PanigrahiNessuna valutazione finora

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento1 paginaQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNessuna valutazione finora

- IVR 050112009522 - 95 2 Rev.0Documento6 pagineIVR 050112009522 - 95 2 Rev.0Vinay YadavNessuna valutazione finora

- Bluewater MIR Roc Master CPP IR 003 (Jun.20 PDFDocumento8 pagineBluewater MIR Roc Master CPP IR 003 (Jun.20 PDFANIL PLAMOOTTIL100% (1)

- ASTM A36 DatasheetDocumento4 pagineASTM A36 DatasheetRene D. ArrietaNessuna valutazione finora

- QAP Seamless PipeDocumento2 pagineQAP Seamless PipeashokkahirwarNessuna valutazione finora

- TVL-Shielded Metal Arc Welding 12 Third: PanimulaDocumento3 pagineTVL-Shielded Metal Arc Welding 12 Third: PanimulaFlorinda Gagasa100% (1)

- PQR - PipeDocumento3 paginePQR - PipeAdvanced Quality Centre AQC100% (1)

- SMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFDocumento11 pagineSMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFbiancogallazziNessuna valutazione finora

- Template BUTTDocumento1 paginaTemplate BUTTDylan TriggNessuna valutazione finora

- Cert Piping W54.5Documento2 pagineCert Piping W54.5SANU0% (1)

- Flange Material TCDocumento1 paginaFlange Material TCSACHIN PATELNessuna valutazione finora

- Ir 0703Documento3 pagineIr 0703sheikmoinNessuna valutazione finora

- Inspection Report: Page 1 of 2 Vendor P.O. NODocumento4 pagineInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNessuna valutazione finora

- 410 CTDocumento2 pagine410 CTSARAVANAN ANessuna valutazione finora

- Product List - Alu and Steel ConductorDocumento1 paginaProduct List - Alu and Steel ConductorNirmal WiresNessuna valutazione finora

- RMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedDocumento3 pagineRMS - UHS - Misch Metal Steel - 19x2.49mm - 24MAR22 - SignedNirmal WiresNessuna valutazione finora

- Asl TLDocumento9 pagineAsl TLNirmal WiresNessuna valutazione finora

- SLS 7 Sri LankaDocumento14 pagineSLS 7 Sri LankaNirmal WiresNessuna valutazione finora

- Is 2599 1983Documento13 pagineIs 2599 1983Nirmal WiresNessuna valutazione finora

- RRVPNL - Latest SpecificationDocumento6 pagineRRVPNL - Latest SpecificationNirmal WiresNessuna valutazione finora

- Mill Test Certificates: TSN Wires Co., LTDDocumento1 paginaMill Test Certificates: TSN Wires Co., LTDNirmal WiresNessuna valutazione finora

- Astm 856Documento3 pagineAstm 856Nirmal Wires100% (1)

- Packing List For GI Plant Packing Details For ACSRDocumento2 paginePacking List For GI Plant Packing Details For ACSRNirmal WiresNessuna valutazione finora

- Norma ASTM-A641Documento5 pagineNorma ASTM-A641Dilmer CV100% (2)

- CIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Documento3 pagineCIN: U28909WB1981PTC034204: Head (Works) Head (Q.A.)Nirmal WiresNessuna valutazione finora

- BS 5896Documento33 pagineBS 5896Nirmal WiresNessuna valutazione finora

- % Moisture : CIN: U28909WB1981PTC034204Documento3 pagine% Moisture : CIN: U28909WB1981PTC034204Nirmal WiresNessuna valutazione finora

- Standard Operating Procedure: Tools RequiredDocumento3 pagineStandard Operating Procedure: Tools RequiredNirmal WiresNessuna valutazione finora

- CESC - ESG Supplier Performance & Evaluation QuestionnaireDocumento31 pagineCESC - ESG Supplier Performance & Evaluation QuestionnaireNirmal WiresNessuna valutazione finora

- 003 SOP of Phosphate BathDocumento1 pagina003 SOP of Phosphate BathNirmal WiresNessuna valutazione finora

- Astm B 498Documento5 pagineAstm B 498Nirmal WiresNessuna valutazione finora

- ASTM B 232 (ACSR Conductor)Documento16 pagineASTM B 232 (ACSR Conductor)Nirmal WiresNessuna valutazione finora

- Pgcil SpecsDocumento90 paginePgcil SpecsNirmal Wires100% (1)

- Pest of Field Crops and Management PracticalDocumento44 paginePest of Field Crops and Management PracticalNirmala RameshNessuna valutazione finora

- Mode of Action of Vancomycin: L D D D D DDocumento8 pagineMode of Action of Vancomycin: L D D D D DNolanNessuna valutazione finora

- Amp DC, OaDocumento4 pagineAmp DC, OaFantastic KiaNessuna valutazione finora

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Documento3 pagineTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngNessuna valutazione finora

- Bushcraft Knife AnatomyDocumento2 pagineBushcraft Knife AnatomyCristian BotozisNessuna valutazione finora

- Vedic Maths Edited 2Documento9 pagineVedic Maths Edited 2sriram ANessuna valutazione finora

- Benko Gambit-Jacobs and Kinsman, 1999Documento163 pagineBenko Gambit-Jacobs and Kinsman, 1999johnson Greker100% (3)

- Docsity Detailed Lesson Plan 5Documento4 pagineDocsity Detailed Lesson Plan 5Sydie MoredoNessuna valutazione finora

- Product Specifications Product Specifications: LLPX411F LLPX411F - 00 - V1 V1Documento4 pagineProduct Specifications Product Specifications: LLPX411F LLPX411F - 00 - V1 V1David MooneyNessuna valutazione finora

- Broiler ProductionDocumento13 pagineBroiler ProductionAlexa Khrystal Eve Gorgod100% (1)

- Manual: Functional SafetyDocumento24 pagineManual: Functional SafetymhaioocNessuna valutazione finora

- MCQs - Chapters 31 - 32Documento9 pagineMCQs - Chapters 31 - 32Lâm Tú HânNessuna valutazione finora

- Unit 4Documento15 pagineUnit 4David Lopez LaraNessuna valutazione finora

- Manual Ares-G2 2Documento78 pagineManual Ares-G2 2CarolDiasNessuna valutazione finora

- Adime 2Documento10 pagineAdime 2api-307103979Nessuna valutazione finora

- Mark Magazine#65Documento196 pagineMark Magazine#65AndrewKanischevNessuna valutazione finora

- Specification Sheet: Case I Case Ii Operating ConditionsDocumento1 paginaSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNessuna valutazione finora

- Daikin FUW Cabinet Fan Coil UnitDocumento29 pagineDaikin FUW Cabinet Fan Coil UnitPaul Mendoza100% (1)

- #Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)Documento4 pagine#Angles Are in Degrees: EGR2313 HW SOLUTIONS (2021)SolomonNessuna valutazione finora

- Tetra IntroductionDocumento65 pagineTetra Introductionuniversidaddistrital100% (2)

- Acampamento 2010Documento47 pagineAcampamento 2010Salete MendezNessuna valutazione finora

- Ds-Module 5 Lecture NotesDocumento12 pagineDs-Module 5 Lecture NotesLeela Krishna MNessuna valutazione finora

- Ac1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTDocumento50 pagineAc1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTHung Faat ChengNessuna valutazione finora

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Documento293 pagineChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaNessuna valutazione finora

- DISCHARGE PLAN CuyosDocumento6 pagineDISCHARGE PLAN CuyosShaweeyah Mariano BabaoNessuna valutazione finora

- Addition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Documento1 paginaAddition Color by Code: Yellow 1, 2, Blue 3, 4, Pink 5, 6 Peach 7, 8 Light Green 9, 10, Black 11Noor NadhirahNessuna valutazione finora

- Morse Potential CurveDocumento9 pagineMorse Potential Curvejagabandhu_patraNessuna valutazione finora

- List of The Legend of Korra Episodes - Wikipedia PDFDocumento27 pagineList of The Legend of Korra Episodes - Wikipedia PDFEmmanuel NocheNessuna valutazione finora

- F5 Chem Rusting ExperimentDocumento9 pagineF5 Chem Rusting ExperimentPrashanthini JanardananNessuna valutazione finora

- Redirection & PipingDocumento16 pagineRedirection & PipingPraveen PatelNessuna valutazione finora