Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Anish A1 Colour

Caricato da

AnishTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Anish A1 Colour

Caricato da

AnishCopyright:

Formati disponibili

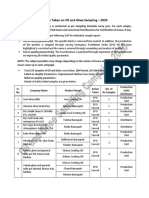

GFRG Panel Construction: A Building Technique For low cost construction

Glass fibre reinforced gypsum (GFRG) panel or Rapid wall is a modern building element for mass- Manufacture and Transportation of GFRG Panels

scale construction of houses in a very short span of time. A GFRG panel is basically calcined

gypsum plaster, reinforced with glass fibres which when filled with reinforced concrete in an 1.The manufacture of GFRG panels is done in a semi-automatic plant using the slurry obtained by heating the calcined raw gypsum.

appropriate proportion becomes strong enough to act as a load bearing and shear wall 2.The Calcined raw gypsum(plaster) is mixed with water, white cement and certain chemicals like D50(retarder) and BS94(water repellant) in a mixer.

3.Different layers of slurries are then spread over a table and are interspersed with glass fibres and aluminum plugs (for creating hollow cavities).

The typical dimension of a GFRG Advantages of Using GFRG Panels 4.After half an hour or so, the aluminum plugs are removed and the panels are sent to a dryer.

building panel is 12 x 3 x 0.127m

which weighs around 1.6 tons. 1) Quicker Construction

Buildings can be constructed in a month

with GFRG panels.

2) Economical

GFRG reduces the consumption of

cement by almost 50%, steel by 35% and

sand by an astonishing 76%.

3) Fire Resistant

In an event of fire, GFRG panels release A house project with low cost construction

15-20% moisture of its own weight which

largely reduces the surface temperature Plan of the house is given which is 2 BHK and the plot area is 150 sq.yard (1350sq.ft)

and fire damage. Following techniques is used for the low cost building construction

4) Earthquake Resistant

GFRG panels have been found to be Construction process with GFRG Panels

successful at resisting the impacts of

earthquakes in the fifth seismic zone as 1.The construction process up to the plinth level remains similar as in the conventional

their panels can be turned into shear method. No special foundation is required for the installation of GFRG panels.

walls as well.

5) Cooler than a Conventional building 2.Concrete belts are built at the plinth area with protruding iron rods which are meant to

When compared with the conventional strengthen the interlocking with the cells of the panel.

building materials, GFRG panels can keep

your building cooler by up to 4 degrees. 3.GFRG panels are placed at the appropriate positions using mechanical means, preferably a

crane, and external supports are provided to maintain the verticality. Necessary cuts for doors,

6) Strength and Durability

windows, sanitary fittings, vents etc. are made as per the design.

The strength and durability of GFRG

Most common use of GFRG panels is as a load bearing panels is five times that of the

walls. Cavities of walls can be unfilled or can be filled with 4.The hollow cavities are filled with concrete and reinforcement as per the requirement to

conventional construction materials.

concrete or reinforced concrete depending on the load strengthen the panels. Generally, concrete is filled in every third cavity of the panel and the

Besides, gypsum is known for its

coming on to the panels. Generally panels without filling remaining cavities can be filled with waste materials like quarry dust.

strength and offers excellent

might be sufficient to carry loads up to two storeys. For dimensional stability and durability.

additional floors, the wall panels have to be strengthened 5.Finally, waterproofing treatment is carried out for the roofs and floors of the building.

7) Water Resistant

with concrete infilling or with reinforced. Certain chemicals are added to the mix

during the manufacture of GFRG panels

which make them impervious to the

attack of water.

8) More Carpet Area

Since the thickness of the walls made

with GFRG panels is less (5 inches)

when compared with the conventional

walls (9 inches), a greater carpet area is

Uses of GFRG in India accessible in a GFRG building

This technology was introduced in India in 2003, using all Applications of GFRG Panels

kinds of gypsum. IIT Madras is carrying significant

research on the same in order to introduce affordable 1.As a light-weight bearing wall Ground floor plan

mass housing construction. 2.As high-capacity vertical and shear

Although the use of gypsum is limited, ''IIT Madras has load bearing wall

extended the use of panels as floor/roof slabs, staircase 3.As partition wall

waist, and landing slabs. A complete building system was 4.As roof slabs/horizontal floor Building Economics Submitted to: Ar.kapil Arora

thus proposed by IIT Madras, with the use of GFRG 5.As compound wall/Security wall

panels alone, with minimal use of concrete and steel, 6.As pitched roofing House project with Submitted by:Anish(15120005)

and avoiding entirely the use of bricks. 7.As cladding in industrial structures Low cost construction

Techniques

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- BR Interlock Pallet Racking System 2009 enDocumento8 pagineBR Interlock Pallet Racking System 2009 enMalik Rehan SyedNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocumento3 pagineCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclaireNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Biology Q PDFDocumento9 pagineBiology Q PDFsumon chowdhuryNessuna valutazione finora

- Chapter FourDocumento9 pagineChapter FourSayp dNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- STR Mpa-MpmDocumento8 pagineSTR Mpa-MpmBANGGANessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Aplikasi Metode Geomagnet Dalam Eksplorasi Panas BumiDocumento10 pagineAplikasi Metode Geomagnet Dalam Eksplorasi Panas Bumijalu sri nugrahaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Lecture 8 - ThermodynamicsDocumento65 pagineLecture 8 - ThermodynamicsHasmaye PintoNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Glycolysis Krebscycle Practice Questions SCDocumento2 pagineGlycolysis Krebscycle Practice Questions SCapi-323720899Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Fundamental Molecular Biology: GenomesDocumento45 pagineFundamental Molecular Biology: GenomesMoonHoLeeNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityDocumento3 pagine9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityAchraf BouraNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- EM2U60CLP 115-127 V 60 HZ 1Documento4 pagineEM2U60CLP 115-127 V 60 HZ 1armagedrumNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Energy Optimization of A Large Central Plant Chilled Water SystemDocumento24 pagineEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Nessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Hydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and EthanolDocumento11 pagineHydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and Ethanolkelly betancurNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- AA-036322-001 - Anchor Bolt DetailsDocumento1 paginaAA-036322-001 - Anchor Bolt DetailsGaurav BedseNessuna valutazione finora

- TM - 1 1520 237 10 - CHG 10Documento841 pagineTM - 1 1520 237 10 - CHG 10johnharmuNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Tiếng AnhDocumento250 pagineTiếng AnhĐinh TrangNessuna valutazione finora

- E-Kabin - O Series - Monoblock Enclosure - ENGDocumento12 pagineE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşNessuna valutazione finora

- ANATOMY 1 NILEM and Cat FISHDocumento19 pagineANATOMY 1 NILEM and Cat FISHAnisatul Khabibah ZaenNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Resume Massage Therapist NtewDocumento2 pagineResume Massage Therapist NtewPartheebanNessuna valutazione finora

- A Conceptual Framework For Characterizing M - 2019 - International Journal of MiDocumento7 pagineA Conceptual Framework For Characterizing M - 2019 - International Journal of MiKENNY BRANDON MAWODZWANessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Checklist For Surge Arrester Rev00Documento3 pagineChecklist For Surge Arrester Rev00Santhosh Kumar VinayagamNessuna valutazione finora

- Drawing Submssion Requirements - September - 2018Documento66 pagineDrawing Submssion Requirements - September - 2018Suratman Blanck MandhoNessuna valutazione finora

- Essay Type ExaminationDocumento11 pagineEssay Type ExaminationValarmathi83% (6)

- Tcu Module Pe1 Lesson 1Documento7 pagineTcu Module Pe1 Lesson 1Remerata, ArcelynNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Action Taken On Oil and Ghee Sampling - 2020Documento2 pagineAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNessuna valutazione finora

- Probni Test 1. Godina - Ina KlipaDocumento4 pagineProbni Test 1. Godina - Ina KlipaMickoNessuna valutazione finora

- 2015 12 17 - Parenting in America - FINALDocumento105 pagine2015 12 17 - Parenting in America - FINALKeaneNessuna valutazione finora

- Maya Mendez ResumeDocumento2 pagineMaya Mendez Resumeapi-520985654Nessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grand Hyatt Manila In-Room Dining MenuDocumento14 pagineGrand Hyatt Manila In-Room Dining MenuMetroStaycation100% (1)

- Essay 31 - Permissive ParentingDocumento2 pagineEssay 31 - Permissive Parentingqbich37Nessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)