Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Advanced Welding Using Oxyacetylene PDF

Caricato da

tereveTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Advanced Welding Using Oxyacetylene PDF

Caricato da

tereveCopyright:

Formati disponibili

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

LEARNER GUIDE

PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Published by

HEART TRUST/NATIONAL TRAINING AGENCY

Produced by

Learning Management Services Department

Gordon Town Road

Kingston 7

Jamaica W.I.

This material is protected by copyright. Copying this material or any part of it by any means,

including digital or in any form is prohibited unless prior written permission is obtained from

the HEART Trust/NTA.

*** 2006 ***

Version 1 LRDU – JUN. 06

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

TABLE OF CONTENTS

PAGE

Introduction................................................................................................................................... 1

Welcome ............................................................................................................................. 1

This Competency Unit ........................................................................................................ 1

Before You Start ................................................................................................................. 2

Planning Your Learning Programme .................................................................................. 2

Self-Assessment Checklist.................................................................................................. 3

How To Use This Learner Guide........................................................................................ 5

Using The Computer And Other Resources ....................................................................... 6

Method Of Assessment ....................................................................................................... 6

Quality Assurance............................................................................................................... 7

Element 1: Select Welding Equipment and Consumables................................................ 8

Self Assessment Checklist ................................................................................................ 11

Element 2: Assemble Welding Equipment....................................................................... 12

Self Assessment Checklist ................................................................................................ 15

Element 3: Weld Joint to Standards or Equivalent ........................................................ 16

Self Assessment Checklist ................................................................................................ 28

Element 4: Inspect Welds .................................................................................................. 29

Self Assessment Checklist ................................................................................................ 32

Element 5: Correct Defects................................................................................................ 33

Self Assessment Checklist ................................................................................................ 35

Version 1 LRDU – JUN. 06

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Element 6: Maintain Weld Records.................................................................................. 36

Self Assessment Checklist ................................................................................................ 37

Element 7: Clean Up .......................................................................................................... 38

Self Assessment Checklist ................................................................................................ 41

Version 1 LRDU – JUN. 06

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

LG-MEMFAB0072A:

PERFORM ADVANCED WELDING

USING OXYACETYLENE WELDING

PROCESS (OAW)

INTRODUCTION

Welcome

Welcome to the Learner Guide for Unit of Competency “Perform Advanced Welding Using

Oxyacetylene Welding Process (OAW)”. This is just one of a number of Learner Guides

produced for the maintenance stream of the Metal, Engineering and Maintenance Industry, and it

is designed to guide you, the learner, through a series of learning processes and activities that

will enable you to achieve the specified learning outcomes for the competency unit.

The content of this guide was developed from the Competency Standard LG-MEMFAB0072A,

which is one of the basic building blocks for the National Vocational Qualification of Jamaica

(NVQ-J) certification within the industry. Please refer to your Learner’s Handbook for a

thorough explanation of standards and competencies, and how these relate to the NVQ-J

certification.

You are also advised to consult the Competency Standard and assessment instrument for a better

understanding of what is required to master the competency.

This Competency Unit

“Perform Advanced Welding Using Oxyacetylene Welding Process” addresses the

knowledge and skills requirements to effectively perform advanced welding using oxyacetylene

welding process. There are seven main areas or elements:

Element 1: Select welding equipment and consumables

Element 2: Assemble welding equipment

Element 3: Weld joints to standards or equivalent

Element 4: Inspect welds

Element 5: Correct faults

Element 6: Maintain weld records

Version 1 LRDU – JUN. 06 1

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Element 7: Clean up

As you go through each element, you will find critical information relating to each one. You are

advised to study them carefully so that you will be able to develop the necessary knowledge,

skills and attitudes for performing advanced welding using oxyacetylene welding process.

Before you start

Before you start this Learner Guide, you need to:

a. Obtain a Learner’s Logbook. You will use it to record evidence of your new

skills/competence. As you demonstrate your new skills, record your activities and have your

learning facilitator sign off on them. This will allow you to provide evidence of your

competence when you are being assessed against the competency standard.

b. Ensure that you have access to the facilities and equipment necessary for learning.

c. Ensure that your learning resources are available.

d. Ensure that you are wearing suitable clothing, that tools and equipment are safe, and that the

correct safety equipment is used.

e. Plan your learning programme (see below)

f. Understand how to use this Learner Guide (see below)

Planning your learning programme

The self-assessment checklist on the following pages will assist you in planning your training

programme and it will help you to think about the knowledge and skills needed to demonstrate

competency in this unit. As you go through each one you will be able to find out which aspects

of the elements you have already mastered and which ones you already have and which you will

need to pay more attention to as you go through the learning process.

To complete the self-assessment checklist, simply read the statements and tick the ‘Yes’ or ‘No’

box. You should do this exercise now.

Version 1 LRDU – JUN. 06 2

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Self-Assessment Checklist

Perform Advanced Welding Using Oxyacetylene Welding

Process (OAW)

Element 1 Select welding equipment and consumables Yes No

1. I can select correct welding equipment and consumables

from weld procedure specifications ( ) ( )

Element 2 Assemble welding equipment Yes No

1. I can assemble and set up welding equipment, including

cylinders, regulators, hoses, torches and tips safely in

accordance with standard operating procedures ( ) ( )

Element 3 Weld joints to standards or equivalent Yes No

1. I can weld material to standards or equivalent specifications

in the overhead position ( ) ( )

2. I can interpret instruction, symbols, specifications including

bead size, bead placement, reinforcement etc correctly and

in accordance with weld procedure ( ) ( )

Element 4 Inspect welds Yes No

1. I can inspect weld joints visually against specifications ( ) ( )

2. I can identify weld defects ( ) ( )

Version 1 LRDU – JUN. 06 3

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Element 5 Correct faults Yes No

1. I can remove defects with minimum loss of sound metal

using correct application and appropriate techniques ( ) ( )

Element 6. Maintain weld records Yes No

1. I can maintain weld records in accordance with specifications

and standard operating procedures ( ) ( )

Element 7 Clean up Yes No

1. I can clean area around work activity ( ) ( )

2. I can safely dispose of waste and unwanted materials ( ) ( )

3. I can clean, maintain and store tools and equipment ( ) ( )

How did you do?

If you ticked all or most of the ‘Yes’ boxes, then you might not need to go through the entire

guide. Ask your learning facilitator to assist you in determining the most appropriate action you

should take.

If you ticked a few of the ‘Yes’ boxes or none at all then you should work through all of the

guide, even though some of the material may be familiar to you.

Plan your learning based on your answers. Be sure to involve your learning facilitator in the

planning process.

Version 1 LRDU – JUN. 06 4

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

How to use this Learner Guide

This Learner Guide is designed to assist you to work and learn at your own pace.

We suggest that you:

• Go through the sections/elements as they are presented (starting at Section 1)

• Check your progress at each checkpoint to ensure that you have understood the material

• Observe the icons and special graphics used throughout this guide to remind you of what you

have to do and to enhance your learning. The icons and their meanings are as follows:

Complete Assessment Exercise

This exercise requires you to think about the knowledge and skills

that you have or will develop in this competency unit.

Definition Box

Words/phrases are defined or explained in this box. The

words/phrases being explained are in bold print.

Checkpoint

This denotes a brain teaser and is used to check your

understanding of the materials presented. No answers are

provided for the questions asked.

Activity

This denotes something for you to do either alone or with

the assistance of your trainer/supervisor.

Reference

Points you to the reference materials and other support

documents or resources used in compiling the unit content.

Version 1 LRDU – JUN. 06 5

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

• Ask your learning facilitator for help if you have any problems with the interpretation of the

contents, the procedures, or the availability of resources.

• Complete each activity as you come to it. If the activity requires you perform an actual task,

be sure to tell your learning facilitator when you get to that activity so that he/she can make

any arrangements, if necessary.

• Get your learning facilitator to sign and date the Learner Logbook when you have completed

an activity.

• Complete the self-assessment checklist at the end of each section or element.

When you have worked through all elements of the guide, and when you can tick every ‘Yes’

box, you are ready for assessment and should ask your learning facilitator to assist you in making

the arrangements to have your performance assessed.

Using the Computer and Other Resources

Where your activities refer you to the library, computer and Internet resources, ask your learning

facilitator to assist you with locating these resources. If you are getting your training in an

institution, there may be a library and a computer laboratory. If this is not the case, visit the local

library and find out what resources are available.

If you are new to the computer and the Internet, someone in the computer room should be able to

show you how to use these resources.

Please note that in many of your activities you have been referred to information on the Internet.

This is because the Internet has a vast amount of information that can help you in acquiring the

particular competencies. We would like to advise you, however, that we cannot guarantee that

all the sites will be available when you need them. If this happens, ask your learning facilitator

to assist you with locating other sites that have the information you require.

Method of Assessment

Competency will be assessed while you are actually performing the tasks related to this

competency. This may be in a real workplace or a simulated situation that accurately relates to

the work situation. You are advised to consult the associated competency standard for further

details relating to the assessment strategies.

Version 1 LRDU – JUN. 06 6

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Quality Assurance

A feedback form is included at the back of each learner guide, so all users are afforded the

opportunity to document their concerns pertinent to the various aspects of the guide. Such

concerns will assist in the review process of the learner guides. Users are encouraged to cut out

the form, complete and submit same to the address provided.

You may now start your learning. Have fun while you work!

Version 1 LRDU – JUN. 06 7

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 1: SELECT WELDING EQUIPMENT AND CONSUMABLES

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills and attitudes required to

select welding equipment and consumables. Your learning facilitator is there to assist you with

the various activities, so that on completion you should be able to:

1. Select correct welding equipment and consumables from weld procedure specifications.

SELECT CORRECT WELDING EQUIPMENT AND CONSUMABLES

Any job that is done in an established industry such as welding must conform to established

practices to ensure uniformity of quality. National and international codes and regulations must

be adhered to in order to ensure that welding practices are of the highest quality and standard.

Whenever you engage in any type of project, there are some key factors which should be noted:

• The quality of work produced should be in accordance with engineering drawings,

specifications and standards

• Proper inventory management of material and spare parts should be done

• Follow guidelines while working

• Adhere to guidelines for completing job

• Preparation of steel

• Welding machine selection

• Set up welding plant

• Proper welding process should be carried out

• The welds should be inspected

Acetylene and Oxygen Cylinders

Acetylene is a fuel gas and should be referred to by its proper name and not by the word gas.

Always use a regulator with the cylinder. Use cylinder upright and store in dry places. Always

test for leaks.

Oxygen should be referred to by its proper name, “oxygen”, and not by the word “air”. Care

should be taken when using an oxygen cylinder. Oxygen by itself cannot burn; it supports

burning. Never use oxygen as a substitute for air. The care for valves required on the oxygen

cylinder is almost the same as for acetylene cylinders.

It is very important to have the correct hose for the required gas. The colours are red for the

acetylene and other fuel-gases, green for oxygen, and black for inert gas and air. Hoses must be

in good condition to prevent fires and explosions. Keep all hoses away from hot objects, and

Version 1 LRDU – JUN. 06 8

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

avoid oil and grease, which will cause the rubber to deteriorate and increase the risk of fire. Do

not repair hose with tape. Hose connections should conform to regulations and standards of the

International Acetylene Association.

Pressure reducing regulators must be used for the gas and pressure intended for.

General Safety Precautions

When toxic gases, fumes, and dust are generated, proper protection are required. Welding fumes

can originate from fluxes, the coating or the flux and material being welded. The space in which

the welder operates is very important, such as height of the ceiling. When welding in a confined

space such as a tank, boiler or small compartment, good ventilation is necessary. When welding

on high-rise building, special precautions are required such as railings, safety belts, lifelines or

other safeguards.

Faulty storage can be dangerous especially when storing materials such as steel pipes, sheet steel,

and plates. Proper slacking is of great importance. Faulty or electrical wiring can cause fire and

electric shock. Trained electricians should be used to service electrical equipment. Good

housekeeping is important on welding job. Tools or other objects should be safely stocked away

to prevent hazards.

Handling cylinders

The mixture of flammable gases and air, which is highly explosive, is used in the application of

oxyacetylene welding and cutting. The following precautions are required when using cylinders:

• When lifting cylinders with a crane use a cradle on platform. Never use a sling to lift

cylinder. Never drop cylinders or allow them to strike each other violently

• To move cylinders tilt and roll them on their bottom edges. Never drag or slide them. If

transferred in a carrier, they should be fastened securely

• Cylinders should be fastened securely while in use

• Never move unattached cylinders with the regulators on. Cylinder valves must be closed

and capped before being moved. Close valve of empty cylinders, and replace the valve

protection caps, and mark MT (empty) on them

• Close cylinder valves when work is completed

• Keep cylinders away from welding and cutting operations so that hot slag, sparks, and

flame cannot reach them

• Never tamper with the number stamped on the cylinders; this is illegal. Never tamper

with the valves on safety devices or valves on cylinders

• Never attempt to refill a cylinder

Version 1 LRDU – JUN. 06 9

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Tools and Equipment

You should observe and familiarize yourself with the types of tools and equipment used in the

welding trade. It is important to thoroughly check all tools for any faults and report to your

immediate supervisor. Defective tools should not be used because this will cause injury to

yourself and others. Various types of tools and equipment are used in welding process. Proper

care must be taken in maintaining and using these tools and equipment. Tools and equipment

used in the welding industry include:

• Ball peen hammer

• Hacksaw

• Weld gauges

• Combination- square

• Marking out tools

• Weld – cleaning hammer

• Measuring tape

• Scriber and center punch

• Chisel

• Pliers

• Files of all cross-sectional shape and types

• Screw drivers

• Arc welding equipment

• Safety equipment

• Chipping hammer

• Wire brush

• Oxyacetylene welding and cutting equipment

• Work benches

• Vices

• Spirit level

• Letter stamp

Power Tools

• Hand and drill press

• Angle grinders, pedestal- grinders, surface grinders, rotary

• Wire brush

• Shear and nibbler

• Beveling-machine

It is very important to select the right tools for the particular job. Using the wrong tools for the

job can cause injury to yourself and others. When using tools make sure the tools and your hands

are free of oil and grease; this will help to prevent the hand from slipping and causing any injury

to yourself.

Version 1 LRDU – JUN. 06 10

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Refer to: Learners Guide LG- MEMCOR0141A – Apply Principles of

Occupational Health and Safety (OH&S) in work

Welding Electrodes available at :

www.metalwebnews.com/howto/weldrod.html Accessed 22/07/06. This

website will show you a wide range of arc welding electrodes from which

you can make your selection

CHECKPOINT

What factors should you bear in mind when you are

selecting a welding machine? What are the types to choose

from and what are the attachments?

ACTIVITY

Visit the nearest welding shop with permission from the

owner and examine the equipment. Compare the different

types of equipment to the institution’s. Share your

information with your colleagues and learning facilitator.

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element, see if you have fully grasped all the components by

doing the following Self-Assessment:

Checklist 1 Yes No

1. I know how to select correct welding equipment and

consumables from weld procedure specifications ( ) ( )

Checklist 2 Yes No

1. Correct welding equipment and consumables are selected

from weld procedure specifications ( ) ( )

Version 1 LRDU – JUN. 06 11

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 2: ASSEMBLE WELDING EQUIPMENT

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills, and attitude required to

assemble welding equipment. Your learning facilitator is there to assist you with the various

activities, so that on completion you should be able to:

1. Assemble and set up welding equipment, including cylinders, regulators, hoses, torches

and tips safely in accordance with standard operating procedures

Assembling and setting up your oxy-acetylene equipment is important for a successful operation.

The oxy-acetylene welding equipment should include:

• Acetylene cylinder

• Oxygen cylinder

• A means of securing the cylinders in an upright position.

• Acetylene and oxygen regulators and gauges

• Acetylene and oxygen hoses

• Welding torch

• Spark lighter

• Safety equipment

Before you use the welding equipment you should:

• Check to see if the cylinders are in good condition.

• Fasten cylinders to hand truck to prevent them from falling.

• Blow out the cylinder opening by opening the valve slightly to blow away any dirt

particles that might be there before attaching regulator to cylinder.

• Inspect sealing surfaces and fittings. Avoid using worn or damaged parts.

• Attach regulator to cylinder. Be sure that the regulator nut fits the cylinder valve fittings

properly.

• Connect hoses to regulators. Hoses should not be twisted, around each other.

• Allow high-pressure oxygen or acetylene to pass through the respective hoses, connect

hoses to torch before connecting the torch to hoses

• Check for leaks. Use soapy solution on outside joints where leaks are suspected; bubbles

will indicate if any leak exists.

Version 1 LRDU – JUN. 06 12

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ACTIVITY

With the help of your learning facilitator, assemble and set

up oxy-acetylene welding equipment. Ensure that when you

do a test run, your facilitator is present to address all safety

concerns.

Quality Assurance Requirements

Any job that is done in an established industry such as welding must conform to established

practices to ensure uniformity of quality. National and international codes and regulations must

be adhered to in order to ensure that welding and practices are of the highest quality and

standards.

Whenever you engage in any type of project, there are some key factors, which should be noted:

• The quality of work produced should be in accordance with engineering drawings,

specifications and standards

• Proper inventory management of material and spare parts

• Follow guidelines while working

• Adhering to guidelines for completing job

• Preparation of steel

• Welding machine selection Quality Assurance charges

• Set up welding plant the maker of the product or

• Proper welding process the supplier of a service with

• Weld inspection the responsibility for assuring

the customer that the

Quality Assurance requirements may include: appropriate quality has been

achieved.

• Workplace operations and procedures

• Quality of materials

• Control of handling procedures

• Use and maintenance of equipment

• Attention to specification of work

In order for you to maintain a high level of quality you should practise the following:

• Listen carefully to instructions if given verbally by the learning facilitator.

• Always have a notebook on hand to write instructions.

• Check materials, tools and other required equipment. If there is any doubt about any

piece of equipment, report to the supervisor immediately.

Version 1 LRDU – JUN. 06 13

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

CHECKPOINT

What are some of the activities you can do to ensure quality

assurance?

ACTIVITY

• Discuss with your learning facilitator about producing quality

work and how it motivates others to aim at the highest level.

• Research types of quality systems and how you would

implement the one that is most appropriate in a welding shop

environment which also addresses occupational health and

safety issues.

Refer to: William A. Bowditch and Kevin E. Bowditch, (1997), Welding

Technology Fundamentals, The Goodyear/Willcox Company

Incorporation Page 36.

HEART Trust/ NTA (2000), Welding, (3rd Ed) Level 1

MEMFAB0111A – Weld using manual metal arc welding process

Walker, John R. (1986), Arc Welding, Basic Fundamentals, The

Goodheart-Willcox Co. Inc.

Version 1 LRDU – JUN. 06 14

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

CHECKPOINT

Why is it important for you to be familiar with the different parts

of the welding equipment?

ACTIVITY

Visit a welding workshop nearest to you with permission from the

owner and observe the assembling procedures. If welding equipment

is at your location, ask your learning facilitator to assist you with

assembling the parts. Assess your colleagues and vise versa in the

assembling process.

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element, see if you have fully grasped all the components by

doing the following Self-Assessment:

Checklist 1 Yes No

1. I know how to select correct welding equipment and

consumables from weld procedure specifications ( ) ( )

Checklist 2 Yes No

1. Correct welding equipment and consumables are selected

from weld procedure specifications ( ) ( )

Version 1 LRDU – JUN. 06 15

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 3: WELD JOINT TO STANDARDS OR EQUIVALENT

LEARNING OUT COMES

As you go through this element, you will acquire the knowledge, skills, and attitudes to weld

joint to standards or equivalent. Your learning facilitator is there to assist you with the various

activities, so that on completion you should be able to:

1. Weld materials to standards or equivalent specifications in the overhead position

2. Interpret correctly symbols, bead size, bead placement and reinforcement.

INTERPRET SYMBOLS CORRECTLY

You should be familiar with the symbols used in welding as these will guide you to the type of

welding required for a specific job. The interpretation from the drawing/blueprint of these

symbols is important to the reduction of defects.

When there are symbols on a drawing you should note the location of the arrow with regard to

the joint. When the weld is to be made on the arrow side of the joint the weld symbol is placed

on the reference line.

When the weld is on the other side of the joint this is specified by placing the weld symbol on the

reference line away from the joint as shown on the illustration below:

Fig. 1

Weld symbol on a reference line

Groove Weld Symbols available at : www.unified-eng.com/scitech/weld/groove.html Accessed

22/07/06

Version 1 LRDU – JUN. 06 16

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Look at the figures below on the left and the right to help you read the eight elements of a weld:

Fig. 2

Elements of a welding symbol

Integrated Publishing available at :www.tpub.com/.../14040/css/14040_111.htm Accessed

22/07/06

Each element is numbered and illustrated separately and explained in the following:

• (1) This shows the reference line, or base, for the other symbols

• (2) This shows the arrow. The arrow points to the location of the weld

• (3) This shows the basic weld symbols. In this case it should be a fillet weld located on

the arrow side of the object to be welded

• (4) This shows the dimensions and other data. The 1/2 means the weld should be 1.27 cm

(1/2 inch) thick

• (5) The 2-4 means the weld should be 5.08cm (2 inches) long (L) with a center spacing or

pitch (P) of 4 inches

• (6) This shows the supplementary symbols. This supplementary symbol means the weld

should be convex

• (7) This shows the finish symbol, G, which means the weld should be finished by

grinding. Note that the finish markings that show the degree of finish are different.

This also shows the tail. It is used to set off symbols that order the machinist to use a

certain process or to follow certain specifications or other references; in this case,

specification A-1. The tail will be omitted if it is not needed for this purpose

• (8) This shows the specifications, process, or other reference explained in item 7. In this

example, the tail of the symbol indicates the abbreviation of a process-oxyacetylene

welding (OAW)

Once you have a full understanding of the different symbols your interpretation of the different

welds, such as bead, groove, fillet and plug should be easier.

Use the diagram above to guide you with the different bead welds.

Version 1 LRDU – JUN. 06 17

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Fig.3

Standard location of elements and types of welding symbols.

Integrated Publishing available at : www.tpub.com/.../14250/css/14250_67.htm Accessed

22/07/06

Version 1 LRDU – JUN. 06 18

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Fig. 4

Integrated Publishing available at :www.infodotinc.com/blueprintreading/38.htm Accessed

22/07/06

Version 1 LRDU – JUN. 06 19

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

CHECKPOINT

Why are welding symbols important?

ACTIVITY

Examine the weldings in your workshop in groups of twos and

make drawings to interpret six different welding symbols and

present to your peers as well as your learning facilitator.

WELD MATERIALS TO STANDARDS

Bead Weld is composed of a narrow layer or layers of metal

deposit in an unbroken string on the surface of the metal.

Plug Weld is a weld made through one piece of metal to join it

to another metal surface.

Fillet Weld is triangular in shape and used for joining two

surfaces at an angle.

Groove Weld is a weld made between the two pieces of metal to

the joint.

You should follow the sequence below to make any of the above welds:

• Make sure that all personal protective equipment (PPE) is being used

• Remove all flammable materials and solvents from the welding area

• Position the metal, using clamps if needed

Version 1 LRDU – JUN. 06 20

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Joint Weld

Joint Weld is an area Joints are classified into four welds:

where two or more pieces • Lap joint

of metals are assembled • Vee joint

together. • Butt joint

• Tee joint

Fig. 5

Five basic types of Joints

Fortune City available at :www.fortunecity.com/.../247/weld_book/ILLUS.htm Accessed

22/07/06

You should interpret the type of joint from the symbols on the drawing.

You should follow the following procedures to achieve the specific joint weld.

• Make your usual preparations to weld

• Position the plates on worktable with two edges in close contact

• Tack weld the plates together. (Tack weld is a short weld)

• Move the electrode along the surface of the plate

• Allow to dry and remove slag

Version 1 LRDU – JUN. 06 21

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

This procedure should be used for all joints with emphasis on the location of the joint.

Fig. 6

Tee joint- single pass fillet weld, Lap Joints and Butt joints in heavy sections

Fortune City available at : www.fortunecity.com/.../247/weld_book/ILLUS.htm Accessed

22/07/06

Version 1 LRDU – JUN. 06 22

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Weld positions

You should weld in a flat or down hand position as much as possible. This position is standard

and the simplest way to do a weld.

You may be required to weld in different positions according to the job.

The other positions are:

• Vertical

• Horizontal

• Overhead

Vertical position is welding in an You should use this technique on thin metal because

upward or downward position on a penetration is shallow and reduces the possibility of

surface burn through.

The axis of the weld is approximately vertical in vertical position welding.

The molten metal has a tendency to run downward and pile up when welding is done on a

vertical surface. A joint with excessive reinforcement at the lower end will result and some

undercutting on the surface of the plates if a weld that is not carefully made.

The manipulation of the torch and the filler rod keeps the metal from sagging or falling and

ensures good penetration and fusion at the joint. The flew of metal can be controlled by pointing

the flame upward at a 45 degree angle to the plate, and holding the rod between the flame and the

molten puddle . Both the torch and the welding rod should be moved back and forth to deposit a

uniform bead. The welding rod should be held slightly above the center line of the joint, and the

welding flame should sweep the molten metal across.

Refer to: Fortune City available at :

www.fortunecity.com/.../247/weld_book/Ch11.htm

Accessed 22/07/06

Version 1 LRDU – JUN. 06 23

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Horizontal position is

welding metal in straight-

line direction.

Welding at times must be done in the position in which the part will be used hence welding

cannot always be done in the most desirable position.. Often that may be on the ceiling, in the

corner, or on the floor. Proper description and definition is necessary since welding procedures

must indicate the welding position to be performed, and welding process selection is necessary

since some have all-position capabilities whereas others may be used in only one or two

positions.

Refer to: Fortune City available at :

www.fortunecity.com/.../247/weld_book/Ch11.htm

Accessed 22/07/06

Fig. 7

Horizontal welding

Fortune City available at :www.fortunecity.com/.../247/weld_book/Ch11.htm Accessed

22/07/06

You can use this technique to weld v-groove butt.

Refer to: Machinist www.machinist.org/army_welding/fig11-10.gif Accessed 06/07/06

Version 1 LRDU – JUN. 06 24

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Overhead position is welding From the underside of a joint overhead welding is

surface above your head against performed.

gravity

The metal deposited tends to drop or sag on the plate in

overhead welding, causing the bead to have a high

crown. The molten puddle should be kept small and enough filler metal should be added to

obtain good fusion with some reinforcement at the bead to overcome this difficulty. The flame

should be removed for an instant to permit the weld metal to freeze if the puddle becomes too

large. When welding light sheets, the puddle size can be controlled by applying the heat equally

to the base metal and filler rod.

You should be aware of the torch and welding rod position for welding overhead butt joints. The

flame should be directed so as to melt both edges of the joint. To maintain an adequate puddle

with enough reinforcement, sufficient filler metal should be added. To avoid burning the

welding flame should support the molten metal and small welding. Only a small puddle is

required, so a rod should be used. Care should be taken to control the heat through the plates.

This is particularly important when welding is side only

Refer to: Fortune City available at :

www.fortunecity.com/.../247/weld_book/Ch11.htm

Accessed 22/07/06

Fig. 9

Welding a butt joint in the overhead position

Fortune City available at :www.fortunecity.com/.../weld_book/fig11-15.gif Accessed 22/07/06

Version 1 LRDU – JUN. 06 25

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

CHECKPOINT

Why is the angle important when welding in a vertical position?

ACTIVITY

Work in groups of twos and practise these welding positions. Ask

your learning facilitator to assist you as you perform the different

techniques to ensure that the element of safety is practised and

upheld throughout the activity. However if you are unsure of your

self, discontinue and request assistance!

Welding different types of material

You may be required to work on different types of metal using your arc welding skills. The

different metals require different approaches. You can use the following procedures:

High Carbon steel

You should have some knowledge of the kind of work the metal will perform as this will assist in

your selection of electrodes. Once you have selected your electrodes using the procedures

explained in element 1, you then need to prepare the surface for welding:

• Remove all rust with a wire brush, grease and other foreign matter by grinding

• Deposit string beads parallel (with flow of abrasive material that is used on heavy rocks

and perpendicular on material that are used on sand and soil).

Aluminium

You should remember that aluminum is a nonferrous metal that has no iron and as such has high

heat conducting properties. Aluminum alloys have an approximate melting range from 482 to

660°C (900 to 1220°F).

• Prepare the surface for welding

• Keep the rod in a vertical position

• Move in a straight line

• On completion remove slag

Version 1 LRDU – JUN. 06 26

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Galvanised

You should note the thickness of the galvanized metal as the incorrect temperature may result in

burn through. If you select the incorrect rod fusion will be incomplete.

• Heat the end of a 3.2 mm (1/8 in.) low carbon welding rod until approximately 12.7 mm

(1/2 in.) of the rod is molten.

• Hold the rod so that the molten end is above the joint to be welded

Pipe

You will require using all the techniques that were outlined above as pipes are made from high

carbon, aluminum, and galvanised steel.

The most common welding that you will require to do is to weld the circumference.

• Prepare the surface for welding

• Select your rod in accordance with the material

• Mark the circumference with chalk

• Run the bead around the pipe until a satisfactory weld is produced

Refer to: Fortune City available at:

www.fortunecity.com/.../247/weld_book/Ch11.htm

Accessed 22/07/06

CHECKPOINT

Why is it important to choose the correct electrode and what should

you do before you start welding?

ACTIVITY

Select two pieces of pipe metals of the same diameter and

circumference and perform a joint weld. Choose the type of rod that

you would use depending of course on the type of metals that you

have to weld. Ensure that you take into consideration occupational

health and safety precautions. Ask your learning facilitator to assist

you if necessary.

Version 1 LRDU – JUN. 06 27

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element check if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I know how to weld materials to standards or equivalent

specifications in the overhead position ( ) ( )

2. I can explain how to interpret instructions, symbols,

specifications correctly including bead size, bead placement,

reinforcement etc. and in accordance with weld procedure ( ) ( )

Checklist 2 Yes No

1. Materials are welded to standards or equivalent specifications

in the overhead position ( ) ( )

2. Instructions, symbols, specifications are interpreted correctly

including bead size, bead placement, reinforcement etc. and

in accordance with weld procedure ( ) ( )

Version 1 LRDU – JUN. 06 28

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 4: INSPECT WELDS

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills and attitude required to

inspect welds. Your Learning Facilitator is there to assist you with the various activities, so that

on completion you should be able to:

1. Visually inspect weld against specification

2. Identify weld defects

Weld inspection can be classified as destructive or nondestructive. The former method is very

costly so therefore you should do a nondestructive inspection.

You should use the drawings to assist you on your inspection, as the symbols will guide you to

identify the correct specifications. You should also look for faulty welding. Here are some of the

things to look for in your inspection:

• Oversized and undersized welds

• Poor fusion

• Cracked weld

• Distortion

Oversized and undersized welds

• Weld has excessive or insufficient reinforcement

Poor fusion

• Faulty preparation

• Improper welding techniques

• Wrong speed

• Improper choice of rod size

• Wrong temperature

It may be corrected when you:

• Clean materials before welding

• Keep pressure and fanning motion constant

• Take more time by welding at lower temperatures

• Use small rod at root and large rods at top-practice proper sequence

• Preheat materials when necessary

• Clamp parts securely

Fig. 10

Version 1 LRDU – JUN. 06 29

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Poor Fusion

Fig. 11

Crack weld

Fig. 12

Distortion

ATIA available at :www.adtdl.army.mil/cgi-bin/adtdl.dll/tc/9-273/figC-7.gif

Accessed 15/06/06

Version 1 LRDU – JUN. 06 30

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

IDENTIFY WELD DEFECTS

Your should look for the following defects on your inspection:

• Excessive spatter- weld deposit placed all over the joint and away from the joint

• Poor fusion- the connection between the two surfaces is weak and in some cases burn

• through.

• Cracked weld- the bead is not smooth, there are lines running through the weld deposit.

• Distortion- one side of the metal is out of shape or bent (angular or longitudinal)

You should inspect the entire joint for any of these defects with the use of a wire brush or

chipping hammer. These tools will help you to remove any material that may prevent you from

seeing the weld properly.

Once you have seen the weld, you can use Weld Fillet Gauge to check and measure the undercut,

mismatch and groove weld height. This you can do by placing the gauge on the weld. When the

pointer is placed on the edge of the weld leg the height of the arrow will indicate weld leg size.

Refer to: The Five Essential Variables of Smaw (Stick) Welding available at

:http://deltaschooloftrades.com/stick%20essentials.htm Accessed

15/06/06

CHECKPOINT

• What are some of the signs of excessive spatter and poor fusion?

• Why do they occur and how can they be prevented?

ACTIVITY

• Examine all the welds that you have done and four other welds in

the workshop and do a visual inspection for defects.

• Develop a checklist to determine all the areas to consider when

carrying out an inspection and submit to your learning facilitator.

• List the defects and share them with colleagues and your learning

facilitator.

Version 1 LRDU – JUN. 06 31

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element check if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I know how to inspect weld joints visually against specifications ( ) ( )

2. I can explain how to identify weld defects ( ) ( )

Checklist 2 Yes No

1. Welded joints are visually inspected against specifications ( ) ( )

2. Weld defects are identified ( ) ( )

Version 1 LRDU – JUN. 06 32

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 5: CORRECT DEFECTS

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills and attitude required to

correct defects. Your learning facilitator is there to assist you through the various activities, so

that on completion you should be able to:

1. Remove and correct defect with minimal loss of sound metal, applying correct and

appropriate techniques.

You may reduce the defects of your weld by ensuring that you follow the proper techniques and

procedures. You should however remember that not all defects are based on the skill of the

welder but also the machine that you work with. The machine controls the amperage.

You should know how to correct and remove these defects:

• Excessive spatter is corrected by using the wire brush to rub off the excessive weld. To

remove the heavier deposit you should use a small chisel and hammer and gently chip the

deposit off the surface. To prevent this from happening again, change your angle of the

arc when welding

• Poor fusion is corrected by chiseling off the weld at the joint and doing over the weld.

Change your angle and reduce your pass over speed

• Cracks are corrected by using a wiring with a lower tensile strength or a different

chemistry. Increase the joint by preheating to slow weld cooling rate, allowing the joint to

expand and contract during heat or increase the size of the weld

• Distortion is your most difficult defect to correct with minimal loss of sound metal. You

will reheat the metal and use a hammer to reshape the metal so that its shape will change

when the metal cools

You should be able to prevent some of these defects when welding joints again. You can

prevent:

Poor fusion by:

• Correcting weld temperature

• Adjusingt weld speed to ensure melting of both sides of joint

• Using proper rod

• Holding at correct angle

• Making sure joint is clean. (“V” or groove joint if necessary)

Crack Weld by:

• Use proper rod. Cool work slowly

Version 1 LRDU – JUN. 06 33

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

• Design work to eliminate rigid joints

• Heat parts before welding and cool after welding

Distortion by:

• Clamping parts properly

• Allow for cooling between welds.

• Adjust pieces so that they wrap into position

• Use proper bead placement and welding sequence. Keep weld deposit to a minimal.

Remember: You should be able to inspect, identify and correct defects and reduce the loss of

metal by doing the correct procedures.

Refer to: Minnick, William H. (1996), Gas Metal Arc Welding Handbook,

The Goodheart- Willcox Co., Inc.

CHECKPOINT

What are five different ways that you can prevent defects caused

by excessive spatter?

ACTIVITY

Using the joint that you have been working with in the previous

elements, classify the defects. Use the technique learnt to correct

the defects under the supervision of your learning facilitator. You

should take into consideration occupational health and safety

issues.

Version 1 LRDU – JUN. 06 34

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element check if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I know how to remove defects with minimum loss of sound

metal applying correct and appropriate techniques ( ) ( )

Checklist 2 Yes No

1. Defects are removed with minimum loss of sound metal

applying correct and appropriate techniques ( ) ( )

Version 1 LRDU – JUN. 06 35

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

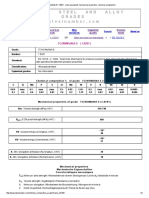

ELEMENT 6: MAINTAIN WELD RECORDS

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills and attitude required to

maintain weld records. Your learning facilitator is there to assist you with the various activities,

so that on completion you should be able to:

1. Maintain weld records according to specification and standard procedure

You should record the entire details specific to your welding job. This is required so that anyone

checking your work will be able to determine the following:

• Machine

• Amps

• Position

• Shop/site

• Joint location

• Metal electrodes

• Date

You should complete the standard form available and should also include tests done to meet

quality assurance. Your test should be either non-destructive or destructive. On the following

page there is a standard form used by welders.

CHECKPOINT

• Why is it recommended that you record welds?

• What are the benefits?

ACTIVITY

Check all the welds that you have done from the start of the

learner guide and record all the information on the form above

and discuss with your learning facilitator.

Do a comparison with your peers regarding how well you

followed the process of completing the form and allow your

facilitator to evaluate and correct if necessary.

Version 1 LRDU – JUN. 06 36

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element, see if you have fully grasped all the components by

doing the following Self-Assessment:

Checklist 1 Yes No

1. I know how to maintain weld records in accordance with

specifications and standard operating procedures ( ) ( )

Checklist 2 Yes No

1. Weld records are maintained in accordance with specifications

and standard operating procedures ( ) ( )

Version 1 LRDU – JUN. 06 37

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ELEMENT 7: CLEAN UP

LEARNING OUTCOMES

As you go through this element, you will acquire the knowledge, skills, and attitude required to

clean up after completion of work. Your learning facilitator is there to assist you with the

various activities, so that on completion you should be able to:

1. Clean work area

2. Dispose of waste and unwanted material safely

3. Clean, maintain and store tools and equipment

CLEAN WORK AREA

Cleaning up the worksite is very important. You should pay attention to this part of the job. As

you complete the task of cleaning up, there are a few things to bear in mind.

If you do not practise cleanliness you could end up doing the job again or causing additional

expense. By removing debris and other waste you can decrease the potential for danger on a site.

In the event that you will be leaving the work area for a short time, take nothing for granted, try

to leave it as safe as possible especially if an authorized personnel will not be present.

Weld residue should be placed in a wheelbarrow and removed from work area. Chisel off the dry

weld deposit and used electrodes.

DISPOSE OF WASTE AND UNWANTED MATERIAL SAFELY

You should remove the electrodes and metal from the work area. The excess material should be

placed in an area away from the work so that it can be disposed of properly.

All other material should be placed in an area that is easily accessible to the workmen. The area

for the unwanted material should be dry and properly ventilated.

CLEAN EQUIPMENT

Since your equipment plays a very important role in your efficiency, it is definitely a good idea

to properly secure the equipment to prevent theft or injury to persons who are ignorant as to

their operating procedures. Some of these pieces of equipment include:

• Wrench

• Chipping hammer

• Wire brush

Version 1 LRDU – JUN. 06 38

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

Wash the area with a power machine to remove grease and dust.

The Occupational Health & Safety requirements should also be adhered to upon completion of

the job. You should protect your equipment, clear and replace parking area and lock properly

when they are not needed.

There are steps to take before you clean the tools and equipment you have been using. Make

sure of the following:

• Unplug electrical equipment

• You should read instructions or manufacturer’s guide for immobilizing, cleaning and

storing the tools and equipment you use

• Immobilize all moving parts on equipment and tools

NB: Follow the manufacturer’s instructions with regard to the respective equipment, or seek

advice on how to make this equipment safe. Secure the best liquid for cleaning them.

When storing, edges should be covered to ensure protection of cutting edge and your safety. If

any defects whatsoever are detected, the equipment must be immediately repaired, removed from

the site for repairs or if irreparable, disposed of. Equipment that is not in use should be stacked

and stored neatly out of the weather or working environment.

CHECKPOINT

Why is it necessary to maintain and store equipment in a safe place?

Give at least three reasons.

ACTIVITY

Ask your learning facilitator to take you to a welding site after

obtaining permission. Observe the cleaning up procedure among

other things such as the site requirements, location of the welding

activity and how this would impact on occupational health and safety

issues. What recommendations would you make? Write a report and

submit to your learning facilitator

Version 1 LRDU – JUN. 06 39

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

A Safe and Secure Job Site

Make sure that you and your colleagues agree on safety issues, on the job conduct (no alcohol,

for example), storage, cleanup of construction materials, and disposal of hazardous substances.

Know the rules and abide by them for your own safety.

A Clean Finish

A safe working condition can quickly deteriorate when you, your colleagues or a contractor does

not clean up post-welding mess. Spattering in work areas should be picked up daily and cleaned

when the project is finished. You may want to include a provision for professional janitorial

services.

You can refer to the website:

Detail Dynamics available at:http://www.detaildynamicsinc.com/construction.htm

Accessed 13/07/06

ACTIVITY

You and your colleagues have been given a welding job. You notice

that your colleagues have not been giving special attention to the

cleaning up process. There are consequences for not cleaning your

worksite after completion of a job. What advice would you give your

colleagues about cleaning up?

Version 1 LRDU – JUN. 06 40

LG-MEMFAB0072A PERFORM ADVANCED WELDING USING OXYACETYLENE

WELDING PROCESS (OAW)

ARE YOU READY TO PROVE YOUR COMPETENCE?

Now that you have completed this element check if you have fully grasped all the components by

doing the following self-assessment.

Checklist 1 Yes No

1. I know how to clean area around work activity ( ) ( )

2. I know how to dispose of waste and unwanted materials of

safely ( ) ( )

3. I know how to clean, maintain and store tools and

equipment ( ) ( )

Checklist 2 Yes No

1. Area around work activity is cleaned ( ) ( )

2. Waste and unwanted materials are disposed of safely ( ) ( )

3. Tools and equipment are cleaned, maintained and stored ( ) ( )

Version 1 LRDU – JUN. 06 41

Learning Management Services Department

Learning Resources Development Unit

Learner Guide Feedback Form

Your feedback on the Learner Guides is important to us. Please complete the

form below to indicate areas for review as you see necessary. For each

component tick [√ ] the appropriate column.

Learner Guide Title:

Learner Guide Code:

LEARNER GUIDE INVESTIGATION

Area of Concern Good Fair Weak Element/Page

[ ] Self Assessment Checklist [ ] [ ] [ ]

[ ] Content [ ] [ ] [ ]

[ ] Activities [ ] [ ] [ ]

[ ] Checkpoints [ ] [ ] [ ]

[ ] Element Checklists [ ] [ ] [ ]

[ ] Graphics [ ] [ ] [ ]

[ ] References [ ] [ ] [ ]

Details of Concern:

Other Issues:

Your contact details:

[ ] Learner [ ] Instructor Institution: _______

Telephone #: E-mail:

Please cut along the dotted line and submit to:

Learning Resources Development Unit, Learning Management Services Department

Gordon Town Road, Kingston 6. Tel: 977-1700-5; Fax: 977-1115/977-1707

Version Control 1

Version 1 LRDU – JUN. 06

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Technical Drawing Unit PlanDocumento46 pagineTechnical Drawing Unit PlantereveNessuna valutazione finora

- Perform Brazing-Silver Soldering PDFDocumento33 paginePerform Brazing-Silver Soldering PDFtereve100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The BEST Floating ShelvesDocumento10 pagineThe BEST Floating ShelvesLiban M XujaleNessuna valutazione finora

- Mark Off OutDocumento38 pagineMark Off OuttereveNessuna valutazione finora

- Perform Housekeeping DutiesDocumento33 paginePerform Housekeeping DutiestereveNessuna valutazione finora

- Perform Housekeeping DutiesDocumento33 paginePerform Housekeeping DutiestereveNessuna valutazione finora

- ShopNotes Issue 62 PDFDocumento39 pagineShopNotes Issue 62 PDFSawk Puppit100% (2)

- M2 - U2 - Introduction To Oxy-Acetylene WeldingDocumento26 pagineM2 - U2 - Introduction To Oxy-Acetylene WeldingAravind Phoenix100% (2)

- Ultimaker 2+ - Repair Manual - Hot End IsolatorDocumento11 pagineUltimaker 2+ - Repair Manual - Hot End Isolatormiruna apostolNessuna valutazione finora

- Graduated Measuring DevicesDocumento21 pagineGraduated Measuring DevicestereveNessuna valutazione finora

- Suzuki Vitara XL7 Timing Chain ReplacementDocumento9 pagineSuzuki Vitara XL7 Timing Chain ReplacementtereveNessuna valutazione finora

- (D) Basic: Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsDocumento31 pagine(D) Basic: Cswip 3.1 (Welding Inspector) Multiple Choice QuestionsJigar Prajapati100% (1)

- Perform Brazing-Silver SolderingDocumento33 paginePerform Brazing-Silver Solderingtereve50% (2)

- Undertake A Routine TaskDocumento16 pagineUndertake A Routine Tasktereve100% (2)

- Engineering DrawingDocumento30 pagineEngineering DrawingDeepak MmechNessuna valutazione finora

- Positive Discipline Brochure Inside - 0Documento2 paginePositive Discipline Brochure Inside - 0tereveNessuna valutazione finora

- Coating Types and SystemsDocumento11 pagineCoating Types and Systemstereve100% (1)

- 2.2 Gravure Printing: 2.2.1 ProcessDocumento39 pagine2.2 Gravure Printing: 2.2.1 ProcessDang Thi Ngoc LieuNessuna valutazione finora

- Learner'S Guide: Heart Trust/National Training AgencyDocumento21 pagineLearner'S Guide: Heart Trust/National Training AgencytereveNessuna valutazione finora

- Grade 316 316LDocumento9 pagineGrade 316 316LvsajuNessuna valutazione finora

- Mill ScaleDocumento7 pagineMill ScaletereveNessuna valutazione finora

- Training Manual For Election Day Workers-Revised 2015 PDFDocumento65 pagineTraining Manual For Election Day Workers-Revised 2015 PDFtereveNessuna valutazione finora

- Blast CleaningDocumento8 pagineBlast CleaningtereveNessuna valutazione finora

- (OAW) - Fuel Gas WeldingDocumento39 pagine(OAW) - Fuel Gas WeldingtereveNessuna valutazione finora

- 320102b Oxy FuelDocumento64 pagine320102b Oxy FueltereveNessuna valutazione finora

- Advanced Welding Using Oxyacetylene PDFDocumento45 pagineAdvanced Welding Using Oxyacetylene PDFtereveNessuna valutazione finora

- OAW SafetyDocumento19 pagineOAW SafetytereveNessuna valutazione finora

- Learner Guide: Heart Trust/National Training AgencyDocumento28 pagineLearner Guide: Heart Trust/National Training AgencytereveNessuna valutazione finora

- OH&SDocumento25 pagineOH&Stereve100% (2)

- Secondary Teacher Get Started Guide - FINAL - 25sept2014 PDFDocumento19 pagineSecondary Teacher Get Started Guide - FINAL - 25sept2014 PDFtereveNessuna valutazione finora

- Carry Out Mechanical Cutting Operations - (Basic) PDFDocumento33 pagineCarry Out Mechanical Cutting Operations - (Basic) PDFtereve100% (2)

- Light Metal Fabrication Level 1Documento149 pagineLight Metal Fabrication Level 1tereveNessuna valutazione finora

- VMBS 2017-2018 FEE GUIDE - Members - 1 August 2017 - Post June 16 RevDocumento5 pagineVMBS 2017-2018 FEE GUIDE - Members - 1 August 2017 - Post June 16 RevtereveNessuna valutazione finora

- Product Design Analysis - HandoutDocumento2 pagineProduct Design Analysis - HandouttereveNessuna valutazione finora

- Firearms ActDocumento57 pagineFirearms ActtereveNessuna valutazione finora

- Standard Mechanical Seals Pusher Seals: Product Description Technical FeaturesDocumento2 pagineStandard Mechanical Seals Pusher Seals: Product Description Technical FeaturesabasakNessuna valutazione finora

- Corr-Con Inspection Services: Coating Procedure Test (CPT) ReportDocumento4 pagineCorr-Con Inspection Services: Coating Procedure Test (CPT) ReportArun Prasad100% (1)

- RMA-223 User GuideDocumento2 pagineRMA-223 User Guidemarc_2ice@yahoo.comNessuna valutazione finora

- Paint EstimationDocumento2 paginePaint EstimationomersonNessuna valutazione finora

- Welding FundamentalsDocumento6 pagineWelding FundamentalsChinmay Das100% (1)

- Methacrylate Structural Adhesives: Plexus MA422 Plexus MA832Documento1 paginaMethacrylate Structural Adhesives: Plexus MA422 Plexus MA832johnNessuna valutazione finora

- 200ml-Tetra-pack-Specification - U-StrawDocumento6 pagine200ml-Tetra-pack-Specification - U-StrawMostafa AlakhliNessuna valutazione finora

- Pds - Floor Hardener NMDocumento2 paginePds - Floor Hardener NMkasivisanadhNessuna valutazione finora

- Ferritic Malleable Iron Castings: Standard Specification ForDocumento5 pagineFerritic Malleable Iron Castings: Standard Specification ForVIKAS DAHIYANessuna valutazione finora

- Gaskets: Frame Plate End Plate II Channel Plates End Plate I Pressure PlateDocumento3 pagineGaskets: Frame Plate End Plate II Channel Plates End Plate I Pressure PlateSergei KurpishNessuna valutazione finora

- Course Plan WORKSHOP MANUFACTURING PROCESSES MD SARFARAZ ALAMDocumento3 pagineCourse Plan WORKSHOP MANUFACTURING PROCESSES MD SARFARAZ ALAMsarfaraz023Nessuna valutazione finora

- Casting DefectsDocumento8 pagineCasting DefectsJavier Escalante VillanuevaNessuna valutazione finora

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Documento8 pagineAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNessuna valutazione finora

- Kenna MetalDocumento80 pagineKenna MetalJ Ferreyra LibanoNessuna valutazione finora

- Shielded Metal Arc Welding NC II CGDocumento13 pagineShielded Metal Arc Welding NC II CGMarilyn odtujanNessuna valutazione finora

- Silica FiltersDocumento4 pagineSilica FiltersAndres AvNessuna valutazione finora

- Pva Bonding Agent ADocumento2 paginePva Bonding Agent ANovaArieNessuna valutazione finora

- Unit II Primary TreatmentDocumento48 pagineUnit II Primary TreatmentAmit AryanNessuna valutazione finora

- European Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)Documento2 pagineEuropean Steel and Alloy Grades: 7crwvmonb9-6 (1.8201)farshid KarpasandNessuna valutazione finora

- Zinfos 340 Ws Brushing and SprayingDocumento2 pagineZinfos 340 Ws Brushing and SprayingjNessuna valutazione finora

- Filtration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterDocumento6 pagineFiltration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterseinthaiserNessuna valutazione finora

- Interfill 830 ENDocumento2 pagineInterfill 830 ENPCNessuna valutazione finora

- Unit-5 PTDocumento136 pagineUnit-5 PTTanay NaikNessuna valutazione finora

- Woodshop Tools: Open End SpannerDocumento9 pagineWoodshop Tools: Open End SpannerAliNessuna valutazione finora