Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

(The Grinding Balls Bulk Weight in Fully Unloaded Mill

Caricato da

habibi1328Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

(The Grinding Balls Bulk Weight in Fully Unloaded Mill

Caricato da

habibi1328Copyright:

Formati disponibili

The enterprises consumers grinding media have a question about right choice the

grinding ball size (diameter) for the mill in order to achieve the required grinding quality.

We noted earlier, this information can be obtained from several sources:

– Technical documentation. It attached to the milling equipment (mill). Each mill

manufacturer recommends certain grinding media type for mill operation under certain

conditions: the crushed material parameters, the mill’s performance, the raw materials

particle size in the mill’s “feed”, and the required grinding fineness (finished class

content).

– Past experience of a ball mill. It is possible to calculate the grinding media average

diameter formed in the mill operation, during grinding media unload from m ill (the

grinding balls bulk weight in fully unloaded mill).

– Other enterprises. It is possible to obtain the necessary data on a grinding media

granulometric composition from other enterprises with a similar grinding process,

including similar requirements to the grinding quality.

Sometimes, the above sources use is impossible.

There is a mathematical solution to this problem – the Bond formula. It uses to help

determine the grinding media optimal size must be loaded into the ball mill for proper

operation ensure. The calculation formula is below:

B – the grinding balls diameter, mm;

A – the correction factor (for grinding balls A = 20,17; for cilpence A = 18,15);

F – the feedstock grain size in 80% of the material, μm;

K – the grinding correction coefficient (for wet grinding – 350; for dry grinding – 355);

S – the grind material bulk mass, g/cc. It is a tabulated value.

Wi – specific energy consumption, kW*h/ton;

C – the mill drum rotational speed,% of the critical speed;

D – the mill internal diameter, m.

At result B = 25mm or less necessary to use the correction factor 1.3, i.e. the grinding

balls average diameter should be 32.5 mm in the feed mixture. We draw your attention,

a larger grinding balls need to use for future loads. As practice shows, the difference

between the grinding balls average diameter in mill and loaded grinding balls diameter

is 10-15 mm. In our example, the grinding balls diameter needed to load into the mill

must be equal to 40-50 mm.

Let’s sum up. The grinding balls diameter determined by the Bond formula has a

recommendatory character and serves as a starting point for calculating the necessary

proportion grinding media feeding a new mill. More precisely adjust the ball load in the

mill can only by industrial test performing. During the industrial tests necessary to

accurately monitor the grinding quality, mill productivity and other technological

parameters adopted at the enterprise.

Potrebbero piacerti anche

- Optimised Ball Size DistributionDocumento4 pagineOptimised Ball Size DistributionSubhransu Sekhar Sahoo100% (1)

- Ball Milling ThesisDocumento6 pagineBall Milling Thesislaurenheardjackson100% (1)

- Process Train Ball MillDocumento28 pagineProcess Train Ball MillvvijaybhanNessuna valutazione finora

- Design of Injection Mould Tool For Rubber Seal Used in Water HeaterDocumento7 pagineDesign of Injection Mould Tool For Rubber Seal Used in Water HeaterAgonafirNessuna valutazione finora

- Ball Mill SizingDocumento10 pagineBall Mill Sizingvvananth100% (1)

- Machine Selection ProcessDocumento4 pagineMachine Selection ProcessSyed Mujtaba Ali BukhariNessuna valutazione finora

- Optimization of Continuous Ball MillsDocumento9 pagineOptimization of Continuous Ball MillsSubhransu Sekhar SahooNessuna valutazione finora

- Ball MillDocumento8 pagineBall MillHumbulaniNessuna valutazione finora

- Performance Evaluation of Shredder For AgriculturalDocumento7 paginePerformance Evaluation of Shredder For AgriculturalDanica Joyce DayritNessuna valutazione finora

- Design of Three-Chamber Ball MillDocumento7 pagineDesign of Three-Chamber Ball MillkrishnabijuNessuna valutazione finora

- 04 MillingDocumento21 pagine04 MillingMKPashaPasha100% (1)

- Hammer MillsDocumento56 pagineHammer MillskokiskoNessuna valutazione finora

- Fundamentals of Mould DesignDocumento60 pagineFundamentals of Mould DesignShubham ChaudharyNessuna valutazione finora

- Optimization of Ball Mill Lifter Profiles and Determination of Top Ball SizeDocumento15 pagineOptimization of Ball Mill Lifter Profiles and Determination of Top Ball SizePortia ShilengeNessuna valutazione finora

- Manual Freze WirtgenDocumento52 pagineManual Freze WirtgenOvidiu Ciobanu83% (6)

- Chapter IDocumento36 pagineChapter Ihùng nguyễnNessuna valutazione finora

- Ball Mill CalculationsDocumento2 pagineBall Mill CalculationsGanesh.MahendraNessuna valutazione finora

- Tube Mill NoteDocumento6 pagineTube Mill Notevvijaybhan100% (1)

- Liner Technical Information HP ConeDocumento6 pagineLiner Technical Information HP ConeDavid GarciaNessuna valutazione finora

- Design of a Micro Injection Moulding Machine for Thermosetting MaterialsDocumento3 pagineDesign of a Micro Injection Moulding Machine for Thermosetting Materialsregil01Nessuna valutazione finora

- Cement Separator & Ball Mill OptimizationDocumento29 pagineCement Separator & Ball Mill OptimizationAdelezzat OmranNessuna valutazione finora

- Pamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentDocumento12 paginePamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (3)

- A Method To Determine The Ball Filling, in Miduk Copper Concentrator SAG MillDocumento5 pagineA Method To Determine The Ball Filling, in Miduk Copper Concentrator SAG MillGilberto RodriguesNessuna valutazione finora

- Tool Design For Plastic Injection Molding.1Documento14 pagineTool Design For Plastic Injection Molding.1Shreekant GurlakattiNessuna valutazione finora

- Cement Mill NotebookDocumento32 pagineCement Mill Notebookhamedmustafa093100% (1)

- Grindability TestsDocumento6 pagineGrindability TestskidcatNessuna valutazione finora

- Morgardshammar Grinding MillsDocumento16 pagineMorgardshammar Grinding MillsTsakalakis G. Konstantinos100% (2)

- Bracket-Casting Design Tutorial by Using SimulationDocumento4 pagineBracket-Casting Design Tutorial by Using SimulationPeeka Prabhakara RaoNessuna valutazione finora

- Ball MillDocumento14 pagineBall MillISLAM I. Fekry95% (20)

- Ece TutorialDocumento7 pagineEce TutorialShreeji EnggNessuna valutazione finora

- Grinding MediaDocumento4 pagineGrinding Mediasempatik721Nessuna valutazione finora

- CMI Metal Pile Cushion Case StudyDocumento7 pagineCMI Metal Pile Cushion Case StudyRabia JavaidNessuna valutazione finora

- Parametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture UseDocumento14 pagineParametric Design Analysis and Fea Simulation of A Chisel Plow For An Agriculture UseAnonymous pKuPK3zUNessuna valutazione finora

- Exercises Chapter 3Documento7 pagineExercises Chapter 3Pdijk 007Nessuna valutazione finora

- 16july02 OkDocumento9 pagine16july02 OkJimmy Gifson SimanjuntakNessuna valutazione finora

- Cement Mill NotebookDocumento32 pagineCement Mill NotebookNael92% (50)

- Chap 10CDocumento10 pagineChap 10CToat SumohandoyoNessuna valutazione finora

- 05-46 Blocking Die Impression Shape Design For WebDocumento4 pagine05-46 Blocking Die Impression Shape Design For WebLungani SibindiNessuna valutazione finora

- A Report On The Winter Internship at Apollo Tyre1Documento17 pagineA Report On The Winter Internship at Apollo Tyre1Krishnakumar ErattemparambilNessuna valutazione finora

- Grinding in Ball MillsDocumento18 pagineGrinding in Ball MillsEnoque MatheNessuna valutazione finora

- Mold-Cooling ConveyorDocumento1 paginaMold-Cooling Conveyordon1239Nessuna valutazione finora

- Optimize crusher performance with the right liner selectionDocumento42 pagineOptimize crusher performance with the right liner selectionJoel Pacheco Diaz100% (1)

- Efficient Flashless ForgingDocumento6 pagineEfficient Flashless ForgingAzfarFaizNessuna valutazione finora

- Static Analysis of Alloy WheelDocumento21 pagineStatic Analysis of Alloy WheelDr NallusamyNessuna valutazione finora

- Modeling and control of ball mill grindingDocumento19 pagineModeling and control of ball mill grindingDarwin HendriNessuna valutazione finora

- How To Spec A Mill GearDocumento8 pagineHow To Spec A Mill GearawfahaddadinNessuna valutazione finora

- Transfer Pump BrochureDocumento12 pagineTransfer Pump BrochureRafert RamNessuna valutazione finora

- ME-352 CEP Taha Mahmood - 2017472Documento24 pagineME-352 CEP Taha Mahmood - 2017472Muneer AhmedNessuna valutazione finora

- Simulation Crushing Assignment1Documento15 pagineSimulation Crushing Assignment1Asif KhanNessuna valutazione finora

- Prompting Science and Engineering Students in Practical TrigonometryDa EverandPrompting Science and Engineering Students in Practical TrigonometryNessuna valutazione finora

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDa EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreValutazione: 4.5 su 5 stelle4.5/5 (11)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Da EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Nessuna valutazione finora

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Da EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Nessuna valutazione finora

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallDa EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallValutazione: 4 su 5 stelle4/5 (8)

- 4-Movazi Kardan Transe 3 PhazDocumento14 pagine4-Movazi Kardan Transe 3 Phazhabibi1328Nessuna valutazione finora

- Haarla - MiningMetal Flyer Part 1Documento1 paginaHaarla - MiningMetal Flyer Part 1habibi1328Nessuna valutazione finora

- 1SKC902019B0201PDF, MNSDocumento14 pagine1SKC902019B0201PDF, MNShabibi1328Nessuna valutazione finora

- Start Your Day, Your Way!: Wake Up With Radio or BuzzerDocumento3 pagineStart Your Day, Your Way!: Wake Up With Radio or Buzzerhabibi1328Nessuna valutazione finora

- Bafttechnical Proposal-Revb PDFDocumento57 pagineBafttechnical Proposal-Revb PDFhabibi1328Nessuna valutazione finora

- Poyry in Brief 2016 - ENG - Global - CropDocumento2 paginePoyry in Brief 2016 - ENG - Global - Crophabibi1328Nessuna valutazione finora

- Ote Outotec Pelletizing Technologies Eng WebDocumento8 pagineOte Outotec Pelletizing Technologies Eng WebSatyanarayana LalamNessuna valutazione finora

- Mathematical Relations Between Vectors and Their Components in 3D Coordinate SystemsDocumento8 pagineMathematical Relations Between Vectors and Their Components in 3D Coordinate Systemshabibi1328Nessuna valutazione finora

- Italian MANUFACTURING & ENGINEERING COMPANIES-Natarajan For IndiaDocumento3 pagineItalian MANUFACTURING & ENGINEERING COMPANIES-Natarajan For Indiahabibi1328Nessuna valutazione finora

- Delegation List Iran 6 2Documento2 pagineDelegation List Iran 6 2habibi1328Nessuna valutazione finora

- OTE Outotec Pallet Cars For Sintering and PelletizDocumento4 pagineOTE Outotec Pallet Cars For Sintering and PelletizShukla SuyashNessuna valutazione finora

- RH0294002 PR113PD-M User Manual (EN)Documento13 pagineRH0294002 PR113PD-M User Manual (EN)habibi1328Nessuna valutazione finora

- Original OTE Outotec Pellet Size Measurement System Eng WebDocumento2 pagineOriginal OTE Outotec Pellet Size Measurement System Eng Webhabibi1328Nessuna valutazione finora

- Outotec Mineral Processing Solutions: BenefitsDocumento12 pagineOutotec Mineral Processing Solutions: BenefitsAndi FaesalNessuna valutazione finora

- Contact Information Focus Areas Geological Survey of FinlandDocumento2 pagineContact Information Focus Areas Geological Survey of Finlandhabibi1328Nessuna valutazione finora

- Haarla - MiningMetal Flyer Part 2Documento1 paginaHaarla - MiningMetal Flyer Part 2habibi1328Nessuna valutazione finora

- 08 LV Systems DivisionDocumento1 pagina08 LV Systems Divisionhabibi1328Nessuna valutazione finora

- Bond Formula For The Grinding Balls Size CalculationDocumento2 pagineBond Formula For The Grinding Balls Size Calculationhabibi1328Nessuna valutazione finora

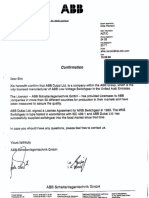

- 10 Letter From ABB GermanyDocumento1 pagina10 Letter From ABB Germanyhabibi1328Nessuna valutazione finora

- Rs2577sl ManualDocumento60 pagineRs2577sl Manualhabibi1328Nessuna valutazione finora

- GTK - Areas of Expertize - Summary Document - 1 10 2015Documento13 pagineGTK - Areas of Expertize - Summary Document - 1 10 2015habibi1328Nessuna valutazione finora

- Bahay ShesmshDocumento1 paginaBahay Shesmshhabibi1328Nessuna valutazione finora

- Bond Formula For The Grinding Balls Size CalculationDocumento2 pagineBond Formula For The Grinding Balls Size Calculationhabibi1328Nessuna valutazione finora

- Descripcion UMC100Documento158 pagineDescripcion UMC100José RamosNessuna valutazione finora

- Umc100-Fbp (2CDC135011B0202)Documento16 pagineUmc100-Fbp (2CDC135011B0202)SajuVijayaNessuna valutazione finora

- Moshaver1396 3 10 2591 1157563Documento7 pagineMoshaver1396 3 10 2591 1157563habibi1328Nessuna valutazione finora

- Latest Technology of Mill DiaphragmsDocumento17 pagineLatest Technology of Mill DiaphragmsISLAM I. Fekry100% (5)

- Latest Technology of Mill DiaphragmsDocumento17 pagineLatest Technology of Mill DiaphragmsISLAM I. Fekry100% (5)

- Latest Technology of Mill DiaphragmsDocumento17 pagineLatest Technology of Mill DiaphragmsISLAM I. Fekry100% (5)

- North American Indians - A Very Short IntroductionDocumento147 pagineNorth American Indians - A Very Short IntroductionsiesmannNessuna valutazione finora

- Mpeg-1 11172-1Documento46 pagineMpeg-1 11172-1Hana HoubaNessuna valutazione finora

- Giles. Saint Bede, The Complete Works of Venerable Bede. 1843. Vol. 8.Documento471 pagineGiles. Saint Bede, The Complete Works of Venerable Bede. 1843. Vol. 8.Patrologia Latina, Graeca et Orientalis100% (1)

- Assignment Brief Starting A Small BusinessDocumento3 pagineAssignment Brief Starting A Small BusinessFaraz0% (1)

- (123doc) - Internship-Report-Improving-Marketing-Strategies-At-Telecommunication-Service-Corporation-Company-VinaphoneDocumento35 pagine(123doc) - Internship-Report-Improving-Marketing-Strategies-At-Telecommunication-Service-Corporation-Company-VinaphoneK59 PHAN HA PHUONGNessuna valutazione finora

- HexaflexDocumento10 pagineHexaflexCharlie Williams100% (1)

- ML Performance Improvement CheatsheetDocumento11 pagineML Performance Improvement Cheatsheetrahulsukhija100% (1)

- People v. De Joya dying declaration incompleteDocumento1 paginaPeople v. De Joya dying declaration incompletelividNessuna valutazione finora

- Germ TheoryDocumento15 pagineGerm TheoryjackjugNessuna valutazione finora

- 1000 Electronic Devices & Circuits MCQsDocumento467 pagine1000 Electronic Devices & Circuits MCQskibrom atsbha67% (3)

- Movie Recommendation System-1Documento25 pagineMovie Recommendation System-1Singi TejaswiniNessuna valutazione finora

- Analyzing Evidence of College Readiness: A Tri-Level Empirical & Conceptual FrameworkDocumento66 pagineAnalyzing Evidence of College Readiness: A Tri-Level Empirical & Conceptual FrameworkJinky RegonayNessuna valutazione finora

- Novel anti-tuberculosis strategies and nanotechnology-based therapies exploredDocumento16 pagineNovel anti-tuberculosis strategies and nanotechnology-based therapies exploredArshia NazirNessuna valutazione finora

- Business Policy FormulationDocumento21 pagineBusiness Policy FormulationWachee Mbugua50% (2)

- Lesson Plan 3Documento6 pagineLesson Plan 3api-370683519Nessuna valutazione finora

- Net Ionic EquationsDocumento8 pagineNet Ionic EquationsCarl Agape DavisNessuna valutazione finora

- Hannah Money Resume 2Documento2 pagineHannah Money Resume 2api-289276737Nessuna valutazione finora

- Bluetooth Mobile Based College CampusDocumento12 pagineBluetooth Mobile Based College CampusPruthviraj NayakNessuna valutazione finora

- NWABSD Lesson PlansDocumento5 pagineNWABSD Lesson Plansapi-379699844Nessuna valutazione finora

- FortiMail Log Message Reference v300Documento92 pagineFortiMail Log Message Reference v300Ronald Vega VilchezNessuna valutazione finora

- Metabical Positioning and CommunicationDocumento15 pagineMetabical Positioning and CommunicationJSheikh100% (2)

- New Titles List 2014, Issue 1Documento52 pagineNew Titles List 2014, Issue 1Worldwide Books CorporationNessuna valutazione finora

- Linux OS MyanmarDocumento75 pagineLinux OS Myanmarweenyin100% (15)

- ReportDocumento7 pagineReportapi-482961632Nessuna valutazione finora

- BRM 6Documento48 pagineBRM 6Tanu GuptaNessuna valutazione finora

- 11 Recurrent Aphthous Stomatitis Caused by Food AllergyDocumento6 pagine11 Recurrent Aphthous Stomatitis Caused by Food AllergyramaNessuna valutazione finora

- Enterprise Information Management (EIM) : by Katlego LeballoDocumento9 pagineEnterprise Information Management (EIM) : by Katlego LeballoKatlego LeballoNessuna valutazione finora

- Listening LP1Documento6 pagineListening LP1Zee KimNessuna valutazione finora

- Health EconomicsDocumento114 pagineHealth EconomicsGeneva Ruz BinuyaNessuna valutazione finora

- Introduction To Tensors: Contravariant and Covariant VectorsDocumento18 pagineIntroduction To Tensors: Contravariant and Covariant VectorslilaNessuna valutazione finora