Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cheap and Easy Satellite 70cm Downlink Antenna

Caricato da

Benjamin DoverCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

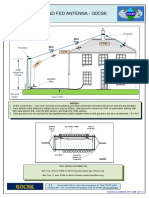

Cheap and Easy Satellite 70cm Downlink Antenna

Caricato da

Benjamin DoverCopyright:

Formati disponibili

Cheap Yagi for 70 cm

Build this Cheap and Easy Satellite Downlink Antenna

by Richard F. Crow, N2SPI, n2spi@amsat.org

Author’s Note: You’ve never seen an hamfest. Also, it makes an excellent school, (Low Earth Orbit) satellite is only 250 to

antenna constructed like this. You’ve never club or Boy Scout project. 500 milliwatts. With satellite to earth station

seen an antenna presented like this either. Virtually no ham antenna article today lists distances of 400 to 2000 miles, receiving

What follows is a revised copy of a free all the materials, tools and specific building these kinds of signals adequately requires

handout I developed for the AMSAT booth instructions so that a beginner can build it. a gain antenna. So, I downlink the FM

at the 2006 Rochester (NY) hamfest. It is As a result, only a well-equipped, skilled and LEOs (AO-27, SO-50 and AO-51) with a

intended to enable non-satellite hams to experienced ham can hope to replicate those homemade, handheld 440 MHz Yagi antenna.

painlessly acquire the 440 MHz downlink designs. In addition, many hams today don’t The electrical design for this antenna is from

antenna needed to actually hear and work have a machine shop or even a basement Cheap Yagi Antennas for VHF/UHF by Kent

a satellite. I also had companion handouts workshop or even power tools. So, after the Britain, WA5VJB, (Google Cheap Yagi). I

for my designs of easy-to-build 2m uplink 2005 Rochester hamfest, I put many months re-engineered the mechanical design to be

antennas. These handouts will be published of thought into the design and presentation super lightweight and super easy to build.

later. For more background on how these of an inexpensive, build-it-yourself satellite I did this by inventing a foam board boom

handouts got started, see my article in the antenna which would remedy these issues. laminated with double-sided tape, aluminum

May/June 2005 issue of The AMSAT Journal What emerged is presented here. wire antenna elements and no solder coax

titled “AMSAT at the Rochester Hamfest”. connections. Only a few simple hand tools

Feel free to copy this handout and give it Introduction are required. No power tools are required.

away at your next AMSAT presentation or Typical transmit power for an FM LEO And, I list all the tools and materials needed

Figure 1: The N2SPI Cheap and Easy Satellite Downlink Antenna.

30 The AMSAT Journal July/August 2006 www.amsat.org

head of the combination square against

the factory edge and with the rule lying

flat against the foam board, make two

pencil marks, one at 2-1/4 inches up the

left side, and one 2-1/4 inches up the

right side, from the factory edge. Use

the straight edge to draw a 30 inch line

between the two marks. This general

measuring procedure is hereafter called

“using previous measuring methods”.

8) Now, place the first pine board under the

line on the foam board so as to act as

a cutting board. Place the second pine

board so the foam board lies flat and

steady.

9) Be sure the X-Acto knife has a fresh,

sharp blade. Now, carefully and

patiently (take your time), trace along

the line with the tip of the X-Acto knife.

At first, just penetrate the surface paper.

Repeat, cutting a little deeper each time,

and as you can, gently bend back the

foam board to expose the cut. Finally,

cut through to make a foam board

strip (hereafter called a strip). Write

“bottom” on the factory edge to make

Figure 2: Terminal strip in various stages of disassembly. it the bottom edge. This general cutting

procedure is hereafter called “using

previous cutting methods”.

and give detailed step-by-step instructions secret to the “N2SPI No-Solder Connection

so that anyone can build this antenna. And Method”. 10) Repeat steps 7 through 9 to make a

finally, not only does this antenna receive the second 2-1/4 inch by 30 inch strip which

4) Select a terminal on the Euro-style

satellite signal from horizon to horizon; it’s includes the other factory edge. These

terminal strip and, using the flat 1/8”

also light as a feather making it very easy to two particular strips are hereafter called

blade screwdriver, screw both screws

hold. See Figure 1. “side panels”.

in the terminal all the way in. Now, use

Step-by-Step Instructions the diagonal cutters to clip off the tops In the next step, make three 1-1/4 inch by

1) Read these instructions all the way of both plastic screw towers just above 30 inch foam board strips for the inner core

through to get an idea of what’s involved. the screw heads. of the antenna boom.

Pay particular attention to how tools are 5) Unscrew both screws until they fall out. 11) Using previous measuring and cutting

used in case you don’t have one and Now, push the terminal’s metal barrel methods make three 1-1/4 inch by 30

can make a substitution with a tool you out of the plastic housing. inch strips. Note: (1) there are no more

have. factory edges to locate, and (2) after

6) Now, re-install both screws into the

2) Referring to the list of materials in Table each strip is cut, write “bottom” on

barrel to complete the first wire-to-wire

1, acquire the necessary materials if you its better, 30 inch edge to make it the

connector, hereafter called a connector.

don’t have some of them already. bottom edge.

Repeat Steps 4 through 6 to obtain a

3) Referring to the List of Tools in Table 2, second connector. See Figure 2. In the next three steps, laminate the three 1-

make sure you have the necessary tools 1/4 inch wide by 30 inch long strips to make

In the next four steps, make two 2-1/4 inch

or suitable substitutes. If you aren’t the inner core of the boom.

by 30 inch foam board strips for the side

familiar with a particular tool look it up panels on the antenna boom. 12) From one end of a 1-1/4 inch by 30 inch

at www.sears.com or other tool supplier strip, lay down a first piece of double-

Web sites. The Sears tools shown are 7) Position the foam board so a 30 inch

side tape near the top edge for the first

excellent but pricey. You may find less factory edge, hereafter called a factory

15 inches. Then cut neatly with the X-

expensive equivalent tools at Home edge, faces you. Place the two pine

Acto knife. In a similar way, lay down

Depot, Wal-Mart, etc. boards under the foam board so it is

the remaining 15 inches of double-sided

elevated and lies flat and steady. Adjust

In the next three steps, liberate two wire-to- tape. Using the same procedure lay

the combination square so 2-1/4 inches

wire connectors from the Euro-style terminal down a two pieces of double-side tape

of the rule (metal ruler part) is sticking

strip. The wire-to-wire connector is the near the bottom edge.

out of the attached head. Then, place the

The AMSAT Journal July/August 2006 www.amsat.org 31

Figure 3: Side panel with element positions marked (markings made very dark for illustrative purposes).

13) Take a second 1-1/4 inch by 30 inch panels to show where the elements will pass Then, wrap the handle with one layer of

strip, line up the bottom edges and one through. clear packing tape.

end of the two strips. Starting at the one 20) Refer to Table 3. Use the combination 26) Re-push the skewer through the reflector

end, progressively press the second strip square to measure and mark on the top element hole until it just touches the

onto the first, keeping the bottom edges edge (non-factory edge) 1/4 inch in from associated cross-mark on the second

lined-up until you’re done. If the strips the wide end. Now, use the tape measure side panel. Use the combination square

are slightly warped combine the warp to mark the remaining element positions to verify the skewer is perpendicular

of one strip with an opposite warp from along the top edge. with respect to the boom. If not, adjust

the other strip, so they cancel out. the actual new puncture point so the

21) Now, at each marked element position,

14) Repeat Steps 12 and 13, hereafter called use the combination square to draw a skewer is perpendicular to the boom,

“using previous laminating methods”, to line perpendicular to the factory edge and using the method in Step 23, make

laminate the third 1-1/4 inch by 30 inch (bottom edge) and across the side panel. the hole. Repeat this until all seven

strip together with the first two. Then, re-adjust the combination square element holes in the second side panel

In the next five steps, cut a handle out of one to measure and place a cross-mark on are made.

end of each side panel. each line at a point 1-3/8 inches up from In the next four steps, fabricate the antenna

15) Using previous measuring methods, the factory edge. At the driven element driven element out of #8 AWG aluminum

from the bottom left corner of a side line only, make a second cross-mark wire.

panel, measure 5 inches to the right 1-7/8 inches up from the factory edge. 27) Straighten out a 24 inch length

along the factory edge and make a See Figure 3. (hereafter called a wire) from the #8

first mark. Then, at this first mark, use 22) Repeat Steps 20 and 21 to mark the AWG aluminum ground wire. Use the

the combination square to draw a line second side panel the same way as the combination square to measure and

perpendicular to the factory edge across first, EXCEPT on the opposite side than mark (with the permanent marker)

the panel. the first (i.e., the second side panel’s 8 inches in from a wire-end. At the

16) Now, again from the left corner, measure markings are a mirror image of the first mark, bend the wire around a 3/8

and make a second mark 1-1/4 inches side panel’s markings). inch diameter drill bit (if nothing else,

up the left side. In the next step, make holes for the elements remove the blade and use the X-Acto

in one side panel only. knife handle) until the short segment

17) Now, from the factory edge, measure is parallel with the long segment and

and make a third mark 1-1/4 inches 23) Place the first side panel on a pine the two segments are spaced 1/2 inch

up the perpendicular line made in step board and push the shish-kebab skewer apart. If the aluminum wire dirties your

15. Then, use a straight edge to draw partway through at an element location hands, wipe it down with paper towels

a 5 inch line from the second to third until it just barely pokes through. dampened with a spray cleaner such as

mark. Wiggle the skewer, if it helps. Then turn Windex.

18) Place the 45 degree surface of the panel over and poke the skewer back

through all the way to complete the hole. 28) Use the combination square to measure

combination square’s head against the 13 inches along the long segment

factory edge and extend and position the Do this for all seven element holes.

starting from the bend. Mark and final

rule so you can draw a 45 degree line In the next three steps, laminate the side cut the wire here as follows: With the

from the third mark to the right and up panels to the inner core, wrap the handle and diagonal cutters, cut the wire halfway,

to the top edge. Using previous cutting finish making the element holes. rotate the wire 90 degrees, and cut

methods cut along the 5 inch and 45 24) Position the first side panel so the halfway again. Bend the wire back

degree lines making a curved transition element position markings are facing and forth until it snaps in two. Use the

at their junction. See Figure 3. one side of the inner core. Now, using mill file to bevel and smooth over the

19) Repeat steps 15 through 18 to cut a previous laminating methods laminate remaining rough and sharp edges. Use

handle in the second side panel. Note the first side panel to the inner core. this method to get a smooth, rounded

that both side panels now have a 2-1/4 25) Using previous laminating methods wire-end when a final cut is called for.

inch wide end and a 1-1/4 inch narrow laminate the second side panel to the 29) Find the halfway point, or center, of

end. other side of the inner core, after lining- the long segment. This should be at 13

In the next three steps, mark both side up the wide end(s) of both side panels. inches/2 = 6-1/2 inches from either end.

32 The AMSAT Journal July/August 2006 www.amsat.org

1-1/2 inches of bare, clockwise-twisted

wire.

In the next three steps, install the driven

element and attach the coaxial cable using the

“N2SPI No-Solder Connection Method”.

35) Use the flat 1/8” blade screwdriver to

back-off the screws in both connectors,

if necessary, until no screws are entering

the wire chamber. Then, slide one

connector over the coaxial cable shield

conductor. Locate the pair of holes in the

side panel for the driven element’s long

segment. Place the connector installed

on the shield wire between these holes

with its screws facing forward and tilted

up. The coax shield should come out

of the side of the connector opposite

the first hole which the driven element

will pass through. Then, push the long

element segment through the hole in the

side panel and into the connector. As

you’re doing this, use the 4” long nose

pliers, as needed, to position and hold

things in place. See Figure 4.

36) Slide the other connector over the coax

center conductor. Locate the pair of

holes in the side panel to be used by the

driven element’s short segment. Place

the connector installed on the center

conductor between these holes with its

Figure 4: Driven element detail. screws facing up. The center conductor

Now, get ready to make two marks, the at the mark. Gently bend the jacket back should be on the same side as the shield.

first 5/8 inches to the left, and the second to examine, and promote, the depth of Push the short segment through the side

5/8 inches to the right, of the center. the cut. Use a similar technique to slit panel into the connector, while moving

Do this by adjusting the combination the jacket from here up to the cable end, more of the long segment. Keep pushing

square to 6-1/2 - 5/8 = 5-7/8 inches. cutting all the way through the jacket the short segment through the connector

Now, measure and mark 5-7/8 inches only as you near the end. Now, pull the until a little bit of it passes into the other

in from the bend and also 5-7/8 inches rest of the jacket apart and remove it. side panel but doesn’t extend beyond

from the cut end. These marks will help it. Having the short segment, as well

33) Unbraid the shield wires until stopped as the long, held by both side panels

you to center the element later. by the new jacket end point. Trim considerably strengthens the attachment

30) In a way similar to Step 28, final cut off half the shield wires and twist the of the driven element to the boom. See

the short wire segment to 7-1/16 inches remaining wires clockwise to form a 3 Figure 4.

measured from the bend. inch long 18 AWG size bare stranded

wire shield conductor. 37) When the driven element is centered,

In the next four steps, prepare the coaxial and its hairpin is straight and not twisted,

cable which will be the antenna’s feed line. 34) Cut the center conductor to a 1-3/4 inch and the pigtails between the coax and

31) Take the RG-58 coaxial cable assembly length. In a way similar to Step 32 cut connector are 3/8 inch in length, tighten

(hereafter called the cable) and use the the center conductor insulation halfway, all screws. Apply a couple of dabs of hot

diagonal cutters to cut off one of the all the way around, 1/2 inch down melt glue to hold the driven element in

BNC connectors. Measure and mark the from the wire-end. Twist the insulation place. Then trim away the excess wire

cable jacket 3 inches down from the cut clockwise to complete the cut, then with the X-Acto knife.

end. twist and pull it off. Similarly, remove

another 1/2 inch, and then another. Use In the last five assembly steps, cut the

32) Be sure the X-Acto knife has a fresh, the 4” long nose pliers, as needed, to remaining antenna elements out of the #8

sharp blade. Place the cable on a pine twist and pull-off the center insulation. AWG aluminum wire and install them.

board and gently roll it back and forth In the end, the visible center conductor 38) Final cut five, 14 inch straightened

under the X-Acto knife to cut halfway should have 1/4 inch of insulation lengths out of the #8 AWG aluminum

through the jacket, all the way around, remaining, and from there to wire-end, wire.

The AMSAT Journal July/August 2006 www.amsat.org 33

to tell time accurately. Verify your outside to a location where you can aim

wristwatch, or other timepiece, against your antenna by hand toward AO-51

the official United States time, which when it will be in unobstructed sky at, or

you’ll find at http://tf.nist.gov. near, a maximum altitude of 30 degrees

c) To determine if AO-51 is in a suitable or more. Wave the antenna around in

mode, go to www.amsat.org, click on general direction of the satellite and

Amateur Satellite Status and then click rotate it around the boom axis until you

on the AO-51 Schedule to make sure the hear the strongest signal.

U downlink (435.300 MHz) is active. f) And finally, you will hear AO-51 at

d) To receive AO-51, connect your new exactly 435.300 MHz when it is at, or

antenna to a UHF narrow band FM near, maximum altitude. But at other

Figure 5: The N2SPI Cheap and Easy Satellite

receiver, preferably with tuning steps times in the pass, because of Doppler

Downlink Antenna in action.

of 5 KHz or less, and tune it to 435.300 frequency shift, you’ll have to tune

MHz. This receiver can be most any somewhere between 435.290 to 435.310

39) Refer to Table 3. From the final cut end MHz to find the clearest reception.

of a 14 inch wire, use the combination Amateur Radio 440 MHz HT, 440

square to carefully measure and mark MHz mobile transceiver, wide band g) Other satellites to listen for are AO-27

the specified length and then final receiver or police scanner. Personally, and SO-50 (a.k.a. SAUDISAT 1C),

cut each element, i.e., both wire ends I use an Alinco DJ-S40T pocket sized which both downlink on 436.795 MHz.

receive the final cut treatment. UHF HT for my FM downlink receiver Check www.amsat.org for their status

($90 at www.aesham.com). Also, a and characteristics. Also, if you prefer,

40) Similar to Step 29, find each element low noise 440 MHz receive preamp you can use the online satellite pass

center. Make two marks +/- 5/8 inch can improve reception considerably. predictions at www.amsat.org.

from the center of each element. I use a Hamtronics LNK-450 preamp In Conclusion ...

41) Locate the pair of holes for each ($60 at www.hamtronics.com). I rig up If you need assistance building or using

remaining antenna element in the side two 9 volt battery clips in series (Radio this satellite downlink antenna or have

panels. Push each element through Shack #274-324) to power the LNK-450 other questions or comments, contact

their pair of holes and then center them. from two 9 volt batteries. Also, full cup me at: n2spi@amsat.org. Please put the

Rotate the element wire while you push, headphones will help you hear AO-51’s phrase “Satellite Downlink Antenna, v2.0”

if it helps. signal more clearly and will be a must somewhere on the email subject line.

42) Apply a dab of hot melt glue to the when you transmit on the uplink. I use

middle of each element to hold it in Vanco HF-24RS scanner headphones

place. When done, use some clear ($20 at www.aesham.com).

packing tape to secure the coaxial cable e) Initially, take your antenna and receiver

to the top of the handle part of the boom.

See Figure 4.

And finally, test your new satellite downlink

antenna. Table 1: List of Materials

43) Test your new antenna by using it to Quantity Used Material Description * Example Source Item No. **

actually receive a satellite’s signal, say

AMSAT’s AO-51 downlink. See Figure 1 "Elmer's" 20 inch x 30 inch Foam Board Staples 245555

5. To do this:

a) Determine when AO-51 is in line-of- 240" "Scotch 665" Permanent Double Sided Tape Staples 130500

sight range of your location. For example,

go to www.heavens-above.com, select 36" Clear Wide Cellophane Packing Tape Staples 490802

your location under Anonymous Users,

and navigate to radio amateur satellites.

94" #8 AWG Aluminum Ground Wire Radio Shack 15-035

Then look for start and end times for

AO-Echo (AO-51) passes. After a start

time, AO-51 will rise in the sky until it 1 Euro-style 12 mm Terminal Strip Radio Shack 274-677

reaches a maximum altitude and then

start to fall. Note that Heavens Above 1 RG-58 Coax Jumper Cable, BNC to BNC, 6 ft. Radio Shack 278-964

gives you the “time”, “Alt.” and “Az.”

for the maximum altitude. Click on * Name in quotes is the brand of product I used. Equivalents should be OK.

these terms for an explanation. ** Some Example Item Numbers come packaged in higher quantities than Qty Used.

b) To use the time based pass information

successfully, you’ll need to be able

34 The AMSAT Journal July/August 2006 www.amsat.org

Table 2: List of Tools

Item Number

Tool Description Source

16" Combination Square Sears 00939681000

Small Tape Measure Sears 00939697000

Flat 1/8" Blade Screwdriver Sears 00941421000

6" Diagonal Cutters Sears 00945075000

4" Long Nose Pliers Sears 00945698000

Mill File Sears 00931300000

"Sharpie" Ultra Fine Point Permanent Marker Staples 498386

"X-Acto" Knife with #11 Blade Staples 506998

"X-Acto" #11 Blade Refills Staples 428300

Hot Melt Glue Gun with Glue Stick Staples 508701

36" Straight Edge (Metal Yardstick) Wal-Mart

1/16" Square Shish-Kebab Skewer Supermarket

36" long Pine Boards,

Lumberyard

Qty = 2 (see Steps 7 and 8)

Sharpened Pencil

Table 3: Element positions and element lengths for the 440 MHz antenna.

Element

Position Element

Antenna Element Name from the Length *

Wide End (in inches)

(in inches)

Director 4 (D4) 1/4 11

Director 3 (D3) 6-3/4 12

Director 2 (D2) 13 12

Director 1 (D1) 18-3/4 12-3/8

Driven Element (DE) 21-3/4 13

Reflector (REF) 24-1/4 13-3/8

* Try to cut the element length to within +/- 1/32 of an inch.

The AMSAT Journal July/August 2006 www.amsat.org 35

Potrebbero piacerti anche

- Shop-Tested Router Techniques and Projects From The Editors of Wood Magazine by Ben AllenDocumento96 pagineShop-Tested Router Techniques and Projects From The Editors of Wood Magazine by Ben AllenGabrielNessuna valutazione finora

- DIY BroadbandAbsorber by AaronYoungDocumento2 pagineDIY BroadbandAbsorber by AaronYoungBryan AnthonyNessuna valutazione finora

- Build It! Wind TurbineDocumento23 pagineBuild It! Wind TurbineGanesh Korore100% (1)

- Scanning For Time 2Documento6 pagineScanning For Time 2Lenard KavaiNessuna valutazione finora

- 7 DB For 7 Bucks - Text PDFDocumento2 pagine7 DB For 7 Bucks - Text PDFΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNessuna valutazione finora

- TV TableDocumento4 pagineTV TableSergioNessuna valutazione finora

- All-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalDocumento7 pagineAll-Star Router Jigs: Make Your Tool A Multi-Tasker With This Problem-Solving ArsenalFernando AgudeloNessuna valutazione finora

- Mitersawstation PDFDocumento9 pagineMitersawstation PDFJose Amenta100% (1)

- NS-10M - The 1978 Original, Bob Clearmountain VersionDocumento1 paginaNS-10M - The 1978 Original, Bob Clearmountain VersionDemetrius BrazNessuna valutazione finora

- Make a Ribbon ControllerDocumento16 pagineMake a Ribbon ControllerVaclav MullerNessuna valutazione finora

- 220 MHZ All-Mode Transverter PDFDocumento6 pagine220 MHZ All-Mode Transverter PDFvu2ttp0% (1)

- Notice Cellule KetkDocumento2 pagineNotice Cellule KetkVIELMASNessuna valutazione finora

- Solutions: Gluing-Up A Mitered CornerDocumento2 pagineSolutions: Gluing-Up A Mitered CornerHomerSimsonnakisNessuna valutazione finora

- Manual Brother P-ToUCH PT-65Documento4 pagineManual Brother P-ToUCH PT-65wiltrud.heinzelNessuna valutazione finora

- Flying 3D Paper Airplane Construction Manual (Cutout Nets Included!)Documento12 pagineFlying 3D Paper Airplane Construction Manual (Cutout Nets Included!)danylomalyuta67% (3)

- Part 6: An Arm For Megabot: Step 1 - Add A Second DeckDocumento6 paginePart 6: An Arm For Megabot: Step 1 - Add A Second DeckOmar FranciaNessuna valutazione finora

- Step Attenuator DIYDocumento3 pagineStep Attenuator DIYfred osterNessuna valutazione finora

- Arca de NoeDocumento12 pagineArca de NoeEduardo H. HernandezNessuna valutazione finora

- Planking PrimerDocumento8 paginePlanking PrimermouradNessuna valutazione finora

- GuidesDocumento7 pagineGuidesALCHY IGNNessuna valutazione finora

- Plywood From Technology: PotentialDocumento8 paginePlywood From Technology: PotentialAkash GoyalNessuna valutazione finora

- With Breadboard Ends: Trestle TableDocumento9 pagineWith Breadboard Ends: Trestle TableBenjamin BeckerNessuna valutazione finora

- ZUIKO 90mm F2 Papercraft ManualDocumento5 pagineZUIKO 90mm F2 Papercraft Manualmixer5056Nessuna valutazione finora

- MTM-18 DesignDocumento8 pagineMTM-18 DesignfulgenNessuna valutazione finora

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityDa EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNessuna valutazione finora

- 200 Projetosde MarcenariaDocumento1.080 pagine200 Projetosde MarcenariaJosevaldo InacioNessuna valutazione finora

- Gran Piramide de Khufu - DesbloqueadoDocumento6 pagineGran Piramide de Khufu - DesbloqueadoZu CisneNessuna valutazione finora

- 200 Personal Woodworking Plans and Projects PDFDocumento985 pagine200 Personal Woodworking Plans and Projects PDFAlexsandro Pereira Dos Reis100% (5)

- MAKING PRINTED CIRCUIT BOARDS PHOTOGRAPHICALLYDocumento4 pagineMAKING PRINTED CIRCUIT BOARDS PHOTOGRAPHICALLYbongoloidNessuna valutazione finora

- CuttingDocumento28 pagineCuttingburakNessuna valutazione finora

- Fiberwall: More Color, More ChoiceDocumento1 paginaFiberwall: More Color, More Choiceمحمد عزتNessuna valutazione finora

- 6500 Woodworking ProjectsDocumento99 pagine6500 Woodworking Projectswhimpy chahyadi0% (1)

- 5 Shop Made Clamps - SSCDocumento1 pagina5 Shop Made Clamps - SSCjuan olivaNessuna valutazione finora

- Tango The Plywood Automata1Documento25 pagineTango The Plywood Automata1Igor BettarelloNessuna valutazione finora

- HG Manhat2 PDFDocumento11 pagineHG Manhat2 PDFNikola DulgiarovNessuna valutazione finora

- 160 80 40 M End Fed Antenna g0csk PDFDocumento5 pagine160 80 40 M End Fed Antenna g0csk PDFPeter MulderNessuna valutazione finora

- Frankenstein Laser Engraver: InstructablesDocumento38 pagineFrankenstein Laser Engraver: InstructablesKon ArvaNessuna valutazione finora

- Ludwig Phase II CloneDocumento15 pagineLudwig Phase II CloneEmmanuel SanzNessuna valutazione finora

- AG AFLX 1500 01 Splice REV5 0108Documento2 pagineAG AFLX 1500 01 Splice REV5 0108kisan singh100% (1)

- Building Tips and Tricks PDFDocumento16 pagineBuilding Tips and Tricks PDFcodeethylNessuna valutazione finora

- Stereo Cutterhead EngrBriefDocumento10 pagineStereo Cutterhead EngrBriefvaultKNessuna valutazione finora

- FermiDocumento7 pagineFermiAna MoraisNessuna valutazione finora

- John Becker: Win A Digital MultimeterDocumento5 pagineJohn Becker: Win A Digital Multimetersuperser123465Nessuna valutazione finora

- 160-20m LOG Loop-On-Ground Page 11 RadioReference - Com ForumsDocumento7 pagine160-20m LOG Loop-On-Ground Page 11 RadioReference - Com ForumstlebrykNessuna valutazione finora

- Build An Infra-Red SnooperscopeDocumento8 pagineBuild An Infra-Red SnooperscopeJOHNNessuna valutazione finora

- One-Masted SloopDocumento3 pagineOne-Masted Sloopbearbullride10Nessuna valutazione finora

- 2 Meter Phased Vert AntDocumento6 pagine2 Meter Phased Vert AntBenny SNessuna valutazione finora

- p.31 Flower-Pattern Clock: Enlarge To 180%Documento2 paginep.31 Flower-Pattern Clock: Enlarge To 180%Rafael SchneidewindNessuna valutazione finora

- Eubanks Secrets To A Better ReedDocumento5 pagineEubanks Secrets To A Better ReedCaylaNessuna valutazione finora

- Antena LoopDocumento4 pagineAntena Loopalexcivi100% (1)

- Three Great Ways to Make Loose-Tenon JointsDocumento6 pagineThree Great Ways to Make Loose-Tenon JointsFausto Martin Vicente MoralesNessuna valutazione finora

- Build A Lattice TowerDocumento4 pagineBuild A Lattice TowerrascedNessuna valutazione finora

- Anvil Cutter Length Gauge: Tool Tip..Documento2 pagineAnvil Cutter Length Gauge: Tool Tip..NidhiNessuna valutazione finora

- Manual: Tools Needed For Installation Speaker WireDocumento2 pagineManual: Tools Needed For Installation Speaker WireMohammad FamuNessuna valutazione finora

- Microwave Building Blocks-The Doubly-Balanced MixerDocumento3 pagineMicrowave Building Blocks-The Doubly-Balanced MixerNickEglezosNessuna valutazione finora

- Nine Motor Boats and How To Build ThemDocumento136 pagineNine Motor Boats and How To Build ThemMaxi Sie100% (1)

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocumento2 pagine"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNessuna valutazione finora

- Pianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsDa EverandPianos: Their Construction, Tuning, And Repair - With Numerous Engravings And DiagramsValutazione: 5 su 5 stelle5/5 (2)

- TV Rptrs RPTR 120revDocumento12 pagineTV Rptrs RPTR 120revBenjamin DoverNessuna valutazione finora

- Bogen Amplifier - Gs-SeriesDocumento20 pagineBogen Amplifier - Gs-SeriesBenjamin DoverNessuna valutazione finora

- Battleship IOWA EventDocumento1 paginaBattleship IOWA EventBenjamin DoverNessuna valutazione finora

- Merci Train Box CarsDocumento2 pagineMerci Train Box CarsBenjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 135Documento11 pagineTV Rptrs RPTR 135Benjamin DoverNessuna valutazione finora

- M Audio Fast Track Pro ManualDocumento17 pagineM Audio Fast Track Pro Manualandre2771Nessuna valutazione finora

- TV Rptrs RPTR 122Documento10 pagineTV Rptrs RPTR 122Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 118Documento10 pagineTV Rptrs RPTR 118Benjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 121 1Documento12 pagineTV Rptrs RPTR 121 1Benjamin DoverNessuna valutazione finora

- Camera Lens Sizes, Mounts & AdaptersDocumento11 pagineCamera Lens Sizes, Mounts & AdaptersBenjamin DoverNessuna valutazione finora

- Nature Power 110 Watt Solar Panel KitDocumento10 pagineNature Power 110 Watt Solar Panel KitBenjamin DoverNessuna valutazione finora

- Radio Shack Pro-2040Documento44 pagineRadio Shack Pro-2040Benjamin DoverNessuna valutazione finora

- HR9670 Amateur Radio Emergency Preparedness ActDocumento14 pagineHR9670 Amateur Radio Emergency Preparedness ActBenjamin DoverNessuna valutazione finora

- ZyXEL - NAS326 - V5.21 - Ed4Documento341 pagineZyXEL - NAS326 - V5.21 - Ed4Benjamin DoverNessuna valutazione finora

- Rca Remote Rcr412s - OmDocumento21 pagineRca Remote Rcr412s - OmBenjamin DoverNessuna valutazione finora

- ZyXEL - NAS326 - 6Documento6 pagineZyXEL - NAS326 - 6Benjamin DoverNessuna valutazione finora

- LamOmegAlph OriginalDocumento2 pagineLamOmegAlph OriginalJohn Derick Bojo Hugo SabioNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-106-2Documento13 pagineBoulder Amateur TV Repeater's Newsletter-106-2Benjamin DoverNessuna valutazione finora

- Hoshizaki IM-500SAA Icemaker Service ManualDocumento39 pagineHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-111revDocumento9 pagineBoulder Amateur TV Repeater's Newsletter-111revBenjamin DoverNessuna valutazione finora

- TV Rptrs RPTR 113Documento11 pagineTV Rptrs RPTR 113Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-112Documento13 pagineBoulder Amateur TV Repeater's Newsletter-112Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-108Documento9 pagineBoulder Amateur TV Repeater's Newsletter-108Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-110Documento11 pagineBoulder Amateur TV Repeater's Newsletter-110Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-107Documento11 pagineBoulder Amateur TV Repeater's Newsletter-107Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-105Documento10 pagineBoulder Amateur TV Repeater's Newsletter-105Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-109Documento9 pagineBoulder Amateur TV Repeater's Newsletter-109Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-104Documento14 pagineBoulder Amateur TV Repeater's Newsletter-104Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-102Documento10 pagineBoulder Amateur TV Repeater's Newsletter-102Benjamin DoverNessuna valutazione finora

- Boulder Amateur TV Repeater's Newsletter-103Documento9 pagineBoulder Amateur TV Repeater's Newsletter-103Benjamin DoverNessuna valutazione finora

- CATV Reference GuideDocumento320 pagineCATV Reference Guidesciocoveanu100% (1)

- Chapter 9: Transport Layer and Security Protocols For Ad Hoc Wireless NetworksDocumento14 pagineChapter 9: Transport Layer and Security Protocols For Ad Hoc Wireless NetworksPoornimaNessuna valutazione finora

- The Following Text Is For Number 1-5! How Do Seasons Happen?Documento2 pagineThe Following Text Is For Number 1-5! How Do Seasons Happen?arjuna sanjayaNessuna valutazione finora

- Manitoba Association of Native Firefighters Inc.: Regional Firefighter'S Competition Team Registration FormDocumento1 paginaManitoba Association of Native Firefighters Inc.: Regional Firefighter'S Competition Team Registration FormKrissy PaulNessuna valutazione finora

- Mobicents SS7Stack User GuideDocumento136 pagineMobicents SS7Stack User GuideLandry YelomeNessuna valutazione finora

- EC8701 Antennas and Microwave Engineering PDFDocumento42 pagineEC8701 Antennas and Microwave Engineering PDFpriya dharshini0% (1)

- Azure Single Vnet Dedicated Inbound Deployment Guide PDFDocumento201 pagineAzure Single Vnet Dedicated Inbound Deployment Guide PDFGary TownsendNessuna valutazione finora

- G450 CLI CommandDocumento1.334 pagineG450 CLI CommandBrandon Paulse100% (2)

- The Salafi Methodology and Its Reformist Call by Sheikh Muhammad BazmoolDocumento1.920 pagineThe Salafi Methodology and Its Reformist Call by Sheikh Muhammad BazmoolSöliou Salafi Salafi ContéNessuna valutazione finora

- Profibus DP Overview and Eurotherm ImplementationDocumento23 pagineProfibus DP Overview and Eurotherm Implementationsina20795100% (2)

- BR SPG1700 PDFDocumento2 pagineBR SPG1700 PDFricardo garavitoNessuna valutazione finora

- Field CommunicationsDocumento7 pagineField CommunicationsSameer NaeemNessuna valutazione finora

- PTP 550 User Guide v4.1.2Documento249 paginePTP 550 User Guide v4.1.2Fábio CabralNessuna valutazione finora

- Evolution of Packet SwitchingDocumento9 pagineEvolution of Packet Switchingdaerie1661Nessuna valutazione finora

- Secret Code SamsungDocumento3 pagineSecret Code SamsungMuizz Rasani100% (11)

- A DUAL CAPACITIVELY FED Broadband Patch - Motl - 2000Documento3 pagineA DUAL CAPACITIVELY FED Broadband Patch - Motl - 2000Saikat Ch BakshiNessuna valutazione finora

- Core v5.0Documento2.822 pagineCore v5.0Ion JardelNessuna valutazione finora

- rs900g DatasheetDocumento8 paginers900g DatasheetAe FnNessuna valutazione finora

- The Need for Free Public Wi-FiDocumento2 pagineThe Need for Free Public Wi-FiAmsyar HaikalNessuna valutazione finora

- BRKSEC-3020 Advanced FirewallsDocumento200 pagineBRKSEC-3020 Advanced FirewallsJin ParkNessuna valutazione finora

- Hardening ProCurve Switches White PaperDocumento10 pagineHardening ProCurve Switches White PaperBlertin Haruni100% (2)

- Tilgin HG1500 090830-CDocumento2 pagineTilgin HG1500 090830-CAndrii DutkoNessuna valutazione finora

- GMDSSDocumento1 paginaGMDSSRahul rajeshNessuna valutazione finora

- Software-Defined Vanets: Benefits, Challenges, and Future DirectionsDocumento17 pagineSoftware-Defined Vanets: Benefits, Challenges, and Future DirectionsAdnan AliNessuna valutazione finora

- 1 - Fieldbus Layers: OundationDocumento11 pagine1 - Fieldbus Layers: OundationSandeep Kumar KrishnarajNessuna valutazione finora

- Stellar AP SeriesDocumento72 pagineStellar AP SeriesDani FirdausNessuna valutazione finora

- MIMO 4T4R - Site Solution - V1Documento37 pagineMIMO 4T4R - Site Solution - V1HoudaNessuna valutazione finora

- Wireless TOA Wa-1822 - SpecDocumento2 pagineWireless TOA Wa-1822 - SpeckonkowNessuna valutazione finora

- Lab ManualDocumento26 pagineLab ManualsgsggsgsNessuna valutazione finora

- Resource Allocation With Frequency Reuse Using MatlabDocumento31 pagineResource Allocation With Frequency Reuse Using Matlabnandakishore.nallaNessuna valutazione finora