Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Risk Assessment - 002 PDF

Caricato da

채종언0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

223 visualizzazioni5 pagineTitolo originale

risk assessment - 002.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

223 visualizzazioni5 pagineRisk Assessment - 002 PDF

Caricato da

채종언Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

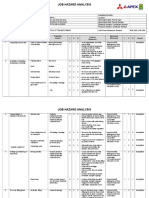

Risk Assessment Title HRSG Erection work

R/A Number: - Revision: A Risk Assessment

Current Risk Final Risk

Item Task Potential Hazard Potential Incident Existing Control Additional Control Remarks

Seve Freq. Risk Seve Freq. Risk

Ensure employee use proper Lifting Break the Job Down

Techniques.i.e. Lift with their Legs into Manageable

not their back. Portions

Use the "Buddy System" get help.

Ergonomic Injury

Lift the Heavy Material by

back, Muscke 1 2 2 1 1 1

Hands Provisions for Mechanical

Strains Sprains

Equipment i.e. Trolley, Fork lift etc.

Ensure that crane operator is Rigger shall be 100%

Cerfified by Third party, Valid visible & clearly relay

Certificates and Driver's Licenses. the information to the

crane operator.

Third party crane Inspections.

Lifting plan shall be

Unloading of

1 Competent Riggers who has Third prepared based con

Materials at Site

Party Certificates. SC&T HSE plan &

Procedures.

Daily Crane Inspections

Hit by Falling Object while Load shall be

Unloading Checking the conformity of the Consideered with

Hit by the Equipment Major Single Injury Floor. 2 2 4 crane specification 2 1 2

Crush between the Crane & All Kinds of lifting

Equipment accessories shall be inspected and Tag Lines are to be

color-coded by competent person used to Control Loads.

Barricade and secure the working

area with sign boards indicating

crane lifting is in progress to

prevent unauthorized entry.

Area shall be properly Maintained to place safety sign

all Equipment and materials must work place

be properly stored and picked up.

remove any

Housekeeping shall be on going unnecessary materials

Slip Minor Injury and picked up at the end of the 1 2 2 from job site. 1 1 1

day.

Materials shall be properlu stack

piled.

Follw the preplanned safe route for Ensure supervise by

access and egress as designated foreman or supervisor

by the Client

Platfoem provide safe

Hit the Fallen Material Major Single Injury Suitable & Sufficient PPE is to 2 2 4 access to the basin. 2 1 2

provided and worn by all There must be safe

operatives. access to and from the

platform

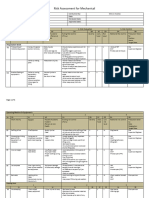

Ensure employee use proper Lifting Break the jpb down

Techniques.i.e. Lift with their Legs into manageable

not their back. portions.

Ergonomic Injury Use the "Buddy System" get help.

Lift the Heavy Material by

back, Muscle 1 2 2 1 1 1

hands

Strains Sprains Provisions for Mechanical

Equipment i.e. Trolley, Fork lift etc.

Erection of HRSG

2

Casing

All scaffolding must have handrails Supervisor is to

safety rails and toe boards fitted. undertake examination

of structual members

Only certified scaffolds are allowed prior to placement of

Fall from unstable Major multiple to design, erect alter unspect and scaffold boards.

dismantle scaffolding. 3 2 6 3 1 3

scaffold Injuries

Wooden plate must be used after

inspection with SAMSUNG.

Personne; must wear full body Ensure supercise by

harnesses and double lanyards foreman or supervisor

when working at height.

Personnel are required

They must correctly engage lifrlines to wear gloves at all

to structural members. times while handling

components.

Severe Bodily Temporary haorizontal rails and toe

Fall from height 4 2 8 4 1 4

Injury Single Death boards must be fixed to the

columns to act as hanfrails/edge

protection. Toe boards fastened to

columns.

Wooden plate must be used after

inspection with SAMSUNG.

Rigger must control the rigging Ensure supervise by

area. foreman or supervisor

Nobody must be under the lifted Check the ground

materials condition under the

2 2 4 Equipment outrigger 2 1 2

Hit the Fallen material Major single Injury

Check the lifting accessories before

lifting work

Always check the rigging materials Workers check the

when lifting work working situation and

check each other's

Rigger must control the rigging safety.

Jammed between pipe Hand & Finger area.

3 Piping work 1 3 3 1 2 2

and Structure Injuries-Bruising

Personnel must wear full body Ensure supervise by

harnesses and double lanyards foreman or supervisor

when working at height. (Especially, damaged

plate must be

They must correctly engage changed.)

Severe Bodily lifelines to structual members.

Fall from Height 4 2 8 4 1 4

Injury Single Death When working at

Wooden plate must be used after height must be up-

inspection with SAMSUNG. looking posture

Rigger must control the rigging Ensure supervise by

area. foreman or supervisor

Nobody must be under the lifted Check the ground

materials condition under the

2 2 4 Equipment outrigger 2 1 2

Hit the Fallen material Major single Injury

Check the lifting accessories before

lifting work

Always check the rigging materials Workers check the

when lifting work working situation and

check each other's

Rigger must control the rigging safety.

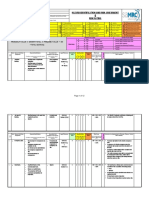

Erection of HRSG Jammed between pipe Hand & Finger area.

4 1 3 3 1 2 2

Modular and Structure Injuries-Bruising

Personnel must wear full body Ensure supervise by

harnesses and double lanyards foreman or supervisor

when working at height. (Especially, damaged

plate must be

They must correctly engage changed.)

Severe Bodily lifelines to structual members.

Fall from Height 4 2 8 4 1 4

Injury Single Death When working at

Wooden plate must be used after height must be up-

inspection with SAMSUNG. looking posture

Obtain proper confined space work Ensure supervise by

permit. foreman or supervisor

Ensure that whole watchers is Tag board at the point

aware of resure procedure. of entry of the pipe be

difficulty of discharge in

3 2 6 viable and all entries 3 1 3

case of emergency Personnel Injury

Correct TBM and explain to follow are to be noted

(Confined space)

emergency plan. correctly

Ensure that a trained hole watcher

is present at all times.

Measure concentration of oxygen Ensure supervise by

and harmful gases. foreman or supervisor

Check of ventilation facilites Prepare respirator and

Heat stress, rescue kits.

Poisonings, fire, fainting 3 2 6 3 1 3

Suffocation Check explosion-proof device when

handling flammable / combustible

materials"

Check equipment load chart and Confirm access to work

load weight (whether lifting plan area is restricted

was delivered or not) (Assignment of

signalman and

Check operation of over;oad banksman and zoning)

Multiple major prevention devcies and see if limit

Overtum 5 2 10 5 1 5

Mechnical parts injuries/ death is lifted. Check the ground

5 condition. If no good

Installation

If wind is more than 10m/s. It must condition, Need to do

be stopped to do lifting work. compacting work.

Ensure that the vehicles have Obeying the traffic plan

reverse back alam. and general traffic

rules wearing highly

All the people not directly involved visible working vests.

in the work of the operating cehcle

Hit/Struck by the mobile shall maintain a safety distnace of Flag man should

Major single injury 2 2 4 3 1 3

crane at least 2 meters from the vehicle. control the euipment.

Do

daily/Monthly.equipemt

n inspection

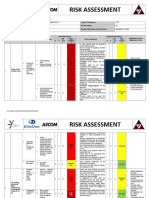

Personnnel must wear full body Ensure supervise by

harnesses and double lanyards foreman or supervisor

when working at height. (Especially, damaged

plate must be

They must correctly engage changed.)

severe bodily injury lifelines to structural members.

Fall from height 4 3 8 4 1 4

single death When working at

Wooden plate must be used after height must be up-

inspection with SAMSUNG. looking posture.

Put the hook on the

fixed structure.

Check the ground condition. Before rainy seasons,

It must prepare

If no sufficient to equipment setting, reinforcing.

need to reinforce the ground

condition. Stop the work if the

Working at rainy Multiple major ground condition is not

6 Overtum 5 2 10 5 1 5

conditions injuries/death Put the steel plate under the possible to support the

outrigger support area weight of equipment

and materials

Pour the concrete under the rigging

area.

Ensure that all the employees have Ensure that the

valid health check report. following trainings are

held.

Ensuring that all the the employees

have valid vocational training Occupational health

Preparation certificate. and safety training

Employing Personal disease (Safety induction)

7 unexperienced Health problem Flu. Heat stress 5 2 10 5 1 5

personnel unsafe heart disease Providing proper PPE

work environment SAMSUNG E&T

Discipline policy shall

be established and

applied.

Remove all the obstacles on the Certificated first aider

walking way of working area. shall be dispatched at

working area 1/10 ratio.

Excavation and open points shall

be closed with hard barriers. Workers shall work in

the daytime once in

Nesessary warning signs shall be two weeks and during

provided. shift change they shall

Slips and trips Fall on Minor & Major work in the daytime

2 2 4 2 1 2

same level single injury There shall be sufficient number of after minimum 11

paramedics. In emergency cases hours resting.

there shall be an ambulance and a

person who is responsible for the

medical room.

8 Night Shift works

Work permission shall be received Work permit for night

for night work. work shall be received.

If not none of the night

Related governmental authorized shift activities including

Hit by the equipment

severe bodily injury shall be notified for the night work. lifting/rigging is

Crush between the 4 2 8 allowed. 4 1 4

Single death

equipment Working area shall be illuminated

according to indonesia standard.

Ensure only competent personnel Ensure supervise by

are to use electrical tools and all foreman or supervisor

cables are prevented from trailing

access and ingess routes floor.

Keep all equipemnt away from 2 2 4 2 1 2

Electrical shock Personnel injury

moisture.

Operatives must wear goggles and

respiratory protective face masks

and suitable PPE.

Ensure all employees use proper Ensure supervise by

PE i.e. helmet, safety glasses, foreman or supervisor

gloves, safety shoes,

Ensure TBM is executed &

Hand & Finger monitored.

Jammed Pinched by tool injuries-Bruising 1 3 3 1 2 2

Cuts

Electrical hand

9

tools

The working with ewuipmet rules Ensure supervise by

ared defined this risk accessment foreman or supervisor

shall ne strictly folllowed

Device shall be

The grinder has to be gas guard operated through

and it shall be cjecked periodically reverse direction.

and before using it.

Otherwise it may be

The diskes shall be suitable for out of control.

Cut Personnel injury grinder. 2 2 4 2 1 2

The grinder shall be in

The damahed disk shall not be good condition and has

used. color code.

direction for cuttinf is important. Only authorized and

trained people shall be

involved the operation.

Potrebbero piacerti anche

- Daily JSA - Back Filling, Levelling and ComapactionDocumento3 pagineDaily JSA - Back Filling, Levelling and Comapactionshoaib akhtarNessuna valutazione finora

- PPE Lssuance RecordDocumento1 paginaPPE Lssuance RecordMd Rahmat100% (1)

- Safety Behavior Observation Checklist: Observe Quietly. Mark Each Observation ItemDocumento1 paginaSafety Behavior Observation Checklist: Observe Quietly. Mark Each Observation Itemkhrayzie bhone100% (2)

- Sharjah Waterfront City-Sector 2 & Sun IslandDocumento2 pagineSharjah Waterfront City-Sector 2 & Sun IslandCaptainNessuna valutazione finora

- OCP For Welding Gas CuttingDocumento2 pagineOCP For Welding Gas CuttingManu Sharma0% (1)

- HIRAC - Work - at - Height - Template PDFDocumento8 pagineHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariNessuna valutazione finora

- IM-WI-20-D Monthly Activity Plan - February - 2023Documento2 pagineIM-WI-20-D Monthly Activity Plan - February - 2023BalasubramaniamkamarajNessuna valutazione finora

- Hirarc Assignment and DiscussionDocumento11 pagineHirarc Assignment and DiscussionNur IzzahNessuna valutazione finora

- Schedule For Inspection Feb 2020Documento2 pagineSchedule For Inspection Feb 2020Siddharth RanaNessuna valutazione finora

- Cleaning Window Risk AssessmentDocumento3 pagineCleaning Window Risk AssessmentFrancis Enriquez TanNessuna valutazione finora

- Confined Space - RA-R9-01-002-01Documento1 paginaConfined Space - RA-R9-01-002-01cmrig74Nessuna valutazione finora

- Risk Assessment For Production and ErectionDocumento14 pagineRisk Assessment For Production and ErectionFurqan FarrukhNessuna valutazione finora

- Welding Works JSA HSE ProfessionalsDocumento1 paginaWelding Works JSA HSE ProfessionalsAli Kazi100% (1)

- Bison Kit MSDSDocumento10 pagineBison Kit MSDSeliNessuna valutazione finora

- Wireless and Driving ChecklistDocumento3 pagineWireless and Driving ChecklistAqeel AbbasiNessuna valutazione finora

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocumento2 pagineProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohnNessuna valutazione finora

- RISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeDocumento10 pagineRISK ASSESSMENT REPORT - George Municipality - Tender ENG0042016 Installation of Perimeter Concrete Palisade FeemmyNessuna valutazione finora

- Mie Hse Jha 004 Installation of TransformerDocumento5 pagineMie Hse Jha 004 Installation of TransformerMd Gulam SafiNessuna valutazione finora

- Risk Assessment-Maintance of Tanks, VesselsDocumento5 pagineRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNessuna valutazione finora

- Risk Assessment For Mechanical: Preparation WorkDocumento3 pagineRisk Assessment For Mechanical: Preparation Workahmedalderbi801Nessuna valutazione finora

- WAH - Working On Roofs - 0Documento13 pagineWAH - Working On Roofs - 0Rizki DarmawanNessuna valutazione finora

- Waste Treatment Plant HiraDocumento5 pagineWaste Treatment Plant HiraBharath KumarNessuna valutazione finora

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocumento13 pagineJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNessuna valutazione finora

- Waste Management PolicyDocumento16 pagineWaste Management PolicyImran MahmudNessuna valutazione finora

- HIRA-Assignment 2Documento4 pagineHIRA-Assignment 2Naveen PrakashNessuna valutazione finora

- Example Risk Assessment For Food Preparation, Cooking and ServiceDocumento5 pagineExample Risk Assessment For Food Preparation, Cooking and ServiceSiva Prasad100% (1)

- HIRAC B224 Najarul On 20.11Documento33 pagineHIRAC B224 Najarul On 20.11Surendra JangidNessuna valutazione finora

- Task Risk AssesmentDocumento3 pagineTask Risk Assesmentafsalkareem100% (1)

- Safety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0ADocumento8 pagineSafety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0AAnonymous kRIjqBLkNessuna valutazione finora

- Hot Work Permit 2Documento3 pagineHot Work Permit 2prabu lingamNessuna valutazione finora

- High Risk Job Safety Analysis: Contractor ArgonneDocumento13 pagineHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNessuna valutazione finora

- 5 First Aid Box Inventory (Old) 2018Documento1 pagina5 First Aid Box Inventory (Old) 2018lez2100% (1)

- C&C-EHS-F-002 HIRARC Biological Hazard at Site PDFDocumento3 pagineC&C-EHS-F-002 HIRARC Biological Hazard at Site PDFNajman HamdiNessuna valutazione finora

- Injury Statistics SheetDocumento4 pagineInjury Statistics SheetEslam IsmaeelNessuna valutazione finora

- Hirarc 2023Documento2 pagineHirarc 2023Ariff ZakariaNessuna valutazione finora

- Risk Assessment-Pnuematic Test. DraftDocumento3 pagineRisk Assessment-Pnuematic Test. DraftKono Nor AtanNessuna valutazione finora

- Scaffold Erection & Dismantling Rev: 00: Task Risk AssessmentDocumento9 pagineScaffold Erection & Dismantling Rev: 00: Task Risk Assessmentibrahim100% (1)

- Discharge Rod 11kv 3phaseDocumento1 paginaDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Hazard Identification and Risk Assessment & Risk RatingDocumento12 pagineHazard Identification and Risk Assessment & Risk RatingMuhammad Syauqi ShaidanNessuna valutazione finora

- Forklift Operations - Risk Assessment & Hazard IdentificationDocumento5 pagineForklift Operations - Risk Assessment & Hazard IdentificationSiyadarakkalmajeed ArakkalmajeedNessuna valutazione finora

- Jsa ConcretingDocumento4 pagineJsa ConcretingRavi thokalNessuna valutazione finora

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationDocumento3 pagineHazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationYasHie PwincsZaNessuna valutazione finora

- Erction and Dismantle ScaffoldingDocumento4 pagineErction and Dismantle Scaffoldingdownload dokumenNessuna valutazione finora

- Job Safety Assessment (Jsa)Documento19 pagineJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- 2.8c Risk AssessmentDocumento40 pagine2.8c Risk AssessmentSn AhsanNessuna valutazione finora

- Purpose:: Method StatementDocumento10 paginePurpose:: Method StatementIrfan ashrafNessuna valutazione finora

- Cooling Tower HiracDocumento4 pagineCooling Tower HiracblackyNessuna valutazione finora

- RISK ASSESSMENT (Backfilling of Excavated Area)Documento2 pagineRISK ASSESSMENT (Backfilling of Excavated Area)Raza Muhammad SoomroNessuna valutazione finora

- Risk Assessment: CCTV Inspection - Al MerifDocumento9 pagineRisk Assessment: CCTV Inspection - Al MerifSaim AliNessuna valutazione finora

- HSE RA 032 Diesel Storage Rev 0Documento11 pagineHSE RA 032 Diesel Storage Rev 0عمروNessuna valutazione finora

- HIRARCDocumento7 pagineHIRARCWong TonyNessuna valutazione finora

- 023 Ladder UseDocumento3 pagine023 Ladder Useraathi_cdiNessuna valutazione finora

- Storage of Chemical Risk AssessmentsDocumento1 paginaStorage of Chemical Risk AssessmentsMohammed Amer PashaNessuna valutazione finora

- EHS Calendar For October 2019: SUN MON TUE WED THU FRI SATDocumento1 paginaEHS Calendar For October 2019: SUN MON TUE WED THU FRI SATSiddharth RanaNessuna valutazione finora

- Fire Extinguisher Record SheetDocumento2 pagineFire Extinguisher Record SheetNarendraNessuna valutazione finora

- Fire Extinguisher Inspection Record Jan-2021Documento12 pagineFire Extinguisher Inspection Record Jan-2021Sarmad HussainNessuna valutazione finora

- Fire Prevention PolicyDocumento4 pagineFire Prevention PolicymuhammadkashikNessuna valutazione finora

- Safety Award ApplicationDocumento7 pagineSafety Award ApplicationJason Smith100% (1)

- Risk Assessment of Heavy LiftingDocumento5 pagineRisk Assessment of Heavy Lifting채종언100% (3)

- Extracted Pages From 1NHDA15-RUDN-08-CCC-ST-MES-00004-A-METHOD STATEMENT FOR INSTALLING OF SKI - SEGMENT.01Documento21 pagineExtracted Pages From 1NHDA15-RUDN-08-CCC-ST-MES-00004-A-METHOD STATEMENT FOR INSTALLING OF SKI - SEGMENT.01Sreejith SureshNessuna valutazione finora

- Risk Assessment - Lifting OperationsDocumento6 pagineRisk Assessment - Lifting OperationsJishad Nalakath83% (87)

- Risk Assessment of Heavy LiftingDocumento5 pagineRisk Assessment of Heavy Lifting채종언100% (3)

- Wps PQR p918908091328904 PDFDocumento7 pagineWps PQR p918908091328904 PDF채종언Nessuna valutazione finora

- P91 WPS: Welding Procedure Specification (WPS)Documento7 pagineP91 WPS: Welding Procedure Specification (WPS)채종언Nessuna valutazione finora

- SM A Review Full Report FINALDocumento100 pagineSM A Review Full Report FINALsamylkNessuna valutazione finora

- Danger of Smoking in The MorningDocumento2 pagineDanger of Smoking in The MorningAndi Intan AuliaNessuna valutazione finora

- Origin and Importance of GeneticsDocumento12 pagineOrigin and Importance of Geneticshuyenthanh1807100% (1)

- Alkaloids - Biosynthesis Biological Roles and HealthDocumento285 pagineAlkaloids - Biosynthesis Biological Roles and HealthPrakash PatelNessuna valutazione finora

- 2 Thrombosed HemorrhoidsDocumento5 pagine2 Thrombosed HemorrhoidsMarko LovrićNessuna valutazione finora

- Santosh DevDocumento45 pagineSantosh Devdevdsantosh100% (1)

- Posted by Ned Haluzan, 0 Comments Labels:: Air PollutionDocumento7 paginePosted by Ned Haluzan, 0 Comments Labels:: Air PollutionPei Jue TanNessuna valutazione finora

- Shafers Textbook of Oral Pathology 9Th Edition William G Shafer All ChapterDocumento67 pagineShafers Textbook of Oral Pathology 9Th Edition William G Shafer All Chaptermary.graham20483% (6)

- The Benefits of Cider VinegarDocumento15 pagineThe Benefits of Cider VinegarAldoSolsaNessuna valutazione finora

- Ophtha Quiz - Refractive ErrorsDocumento3 pagineOphtha Quiz - Refractive Errorsadi100% (1)

- Revalida 1Documento3 pagineRevalida 1herrabiel solisNessuna valutazione finora

- WSN 78 (2017) 193-198Documento6 pagineWSN 78 (2017) 193-198Santiago López BuitragoNessuna valutazione finora

- Tog 12228Documento7 pagineTog 12228Avanie PalNessuna valutazione finora

- Glossary of Commonly Used Dental Terms: 14212 Ambaum Boulevard Southwest Suite #101, Burien, WA 98166Documento10 pagineGlossary of Commonly Used Dental Terms: 14212 Ambaum Boulevard Southwest Suite #101, Burien, WA 98166Mayra RojasNessuna valutazione finora

- Physical Education and Health 4: Grade 12Documento39 paginePhysical Education and Health 4: Grade 12Dio Emmanuel SadangNessuna valutazione finora

- Radiologi Intervensi Di IndiaDocumento3 pagineRadiologi Intervensi Di IndiaPutu Adi SusantaNessuna valutazione finora

- Examinatin in Intensive CareDocumento731 pagineExaminatin in Intensive Careyankee1111100% (1)

- Mouse DissectionDocumento6 pagineMouse DissectionMauricio F. VillamarNessuna valutazione finora

- Ncbi Selulitis BulosaDocumento3 pagineNcbi Selulitis BulosaHarefa TirtaNessuna valutazione finora

- Drug Study GabapentinDocumento3 pagineDrug Study Gabapentinbridget.badiang001Nessuna valutazione finora

- Childhood and Adolescence Voyages in Development 6th Edition Rathus Solutions ManualDocumento12 pagineChildhood and Adolescence Voyages in Development 6th Edition Rathus Solutions ManualJenniferAguilarrfiax100% (10)

- (1913) List of Licensed EmbalmersDocumento96 pagine(1913) List of Licensed EmbalmersHerbert Hillary Booker 2nd0% (1)

- US SchubertDocumento21 pagineUS SchubertNirmayi HomkarNessuna valutazione finora

- Persuasive LetterDocumento2 paginePersuasive Letterapi-341527188Nessuna valutazione finora

- Soil Contamination With Cadmium, Consequences and Remediation UsingDocumento15 pagineSoil Contamination With Cadmium, Consequences and Remediation UsingsalmanNessuna valutazione finora

- One Health ConceptDocumento2 pagineOne Health ConceptYume AkamaiNessuna valutazione finora

- Inflammation. Etiology. Vascular Changes. Cellular Events in Inflammation. Acute Inflammation. Morphologic PatternsDocumento57 pagineInflammation. Etiology. Vascular Changes. Cellular Events in Inflammation. Acute Inflammation. Morphologic PatternsZauzaNessuna valutazione finora

- 02 - Recalibrating Gavi 5.0 in Light of COVID-19 and Successful Replenis..Documento19 pagine02 - Recalibrating Gavi 5.0 in Light of COVID-19 and Successful Replenis..aman_sasanNessuna valutazione finora

- Heart Reviewer 1Documento6 pagineHeart Reviewer 1tokzzNessuna valutazione finora

- Active Fluid De-Resuscitacion in Crtiticalli III Patients Whitj ShockDocumento8 pagineActive Fluid De-Resuscitacion in Crtiticalli III Patients Whitj ShockMartha Isabel BurgosNessuna valutazione finora