Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Operation Principal of Screw Compressor

Caricato da

narayan46Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Operation Principal of Screw Compressor

Caricato da

narayan46Copyright:

Formati disponibili

OPERATION PRINCIPLE OF SCREW COMPRESSORS

Ambient air is sucked through the filter

1 and then it flows through the suction

regulator equipped with the variable control 7

1

valve adapting to instantaneous demand for

compressed air. 6 9

The suction regulator operation is controlled 8

by the electrical unit connected to the pressure 10

sensor.

5

Oil previously treated in the filter 2 is injected

into the air compressed in the screw air end 3 . 2

3

The oil injection ensures lubrication, sealing

and cooling of the screw air end. The oil and 4

air mixture is compressed in spaces between

the screw impellers and then flows into the

oil separator tank 4 , where most of the oil

is precipitated from the mixture.

The oil collected in the oil separator is carried away with

From the separator tank, air flows through

the pipe 8 to the screw air end. The oil flow through

the fine filter 5 , minimum pressure valve

the cooler 9 is controlled by the thermostat 10 .

6 , to the aftercooler 7 , where it is cooled

to a temperature 10ºC higher than the ambient The suction and oil filters are equipped with the

temperature. pollution sensors.

Construction of screw air end

6 1 Drive shaft

2

2 Impeller with external teeth

5 3 Impeller with internal teeth

4 Bearing cap

5 Shaft sealing

6 Bearings

4

1 3

Potrebbero piacerti anche

- Rotary Screw CompressorDocumento4 pagineRotary Screw CompressorNAYEEMNessuna valutazione finora

- Advantages of Oil-Free Screw CompressorsDocumento4 pagineAdvantages of Oil-Free Screw CompressorsMANIU RADU-GEORGIANNessuna valutazione finora

- Rotary Screw CompressorDocumento8 pagineRotary Screw Compressormanpreetsodhi08100% (2)

- How To Select and Service A Turbine OilDocumento8 pagineHow To Select and Service A Turbine Oildaniel adam100% (1)

- Centrifugal Damper CatDocumento8 pagineCentrifugal Damper CatAdil Shahzad100% (2)

- SKF Handbook Bearings in Twin CompressorsDocumento60 pagineSKF Handbook Bearings in Twin CompressorsAlvaro Munoz100% (2)

- Bearings in Twin Screw CompressorsDocumento108 pagineBearings in Twin Screw Compressorsa_salehi100% (1)

- The Flooded Rotary Srew CompressorDocumento35 pagineThe Flooded Rotary Srew Compressoranhhung80Nessuna valutazione finora

- Ufn3 Treinamento e ManutençãoDocumento62 pagineUfn3 Treinamento e ManutençãoRodneiNessuna valutazione finora

- Vacuum PumpDocumento10 pagineVacuum Pumptutuli1990Nessuna valutazione finora

- Failure Analysis John CraneDocumento83 pagineFailure Analysis John CraneIulian Luncan96% (23)

- Understanding BlowersDocumento11 pagineUnderstanding BlowersJam BabNessuna valutazione finora

- Brochure Fans Axial Variax AftermarketDocumento8 pagineBrochure Fans Axial Variax Aftermarketkarlos1407Nessuna valutazione finora

- Balance LineDocumento0 pagineBalance Linewsjouri2510Nessuna valutazione finora

- Rotary Screw AIREND Manual 2003 PDFDocumento41 pagineRotary Screw AIREND Manual 2003 PDFManh Pham100% (1)

- Mechanical Seal InstructionsDocumento25 pagineMechanical Seal Instructionsjack-bcNessuna valutazione finora

- Mechanical SealsDocumento54 pagineMechanical Sealsajitkk79100% (2)

- LSP LowSpeedHighPressurePumps E00522Documento7 pagineLSP LowSpeedHighPressurePumps E00522Sigit PramonoNessuna valutazione finora

- Waste Heat Recapture From Supermarket Refrigeration Systems 01Documento76 pagineWaste Heat Recapture From Supermarket Refrigeration Systems 01evrimkNessuna valutazione finora

- CentrifugalDocumento616 pagineCentrifugalNicolas Petruselli100% (1)

- OHC Canned Motor Pump: Sulzer PumpsDocumento17 pagineOHC Canned Motor Pump: Sulzer Pumpsshashank_kakade100% (1)

- Understanding Lobe Blowers Roots Blower PDFDocumento9 pagineUnderstanding Lobe Blowers Roots Blower PDFEduardoPomarMakthonNessuna valutazione finora

- Compressor Lubrication Best PracticesDocumento22 pagineCompressor Lubrication Best Practicesengrsurif100% (1)

- Oil Analysis Handbook PDFDocumento35 pagineOil Analysis Handbook PDFAbass BILA100% (1)

- Rotary Twin Scew Brochure UK HRDocumento20 pagineRotary Twin Scew Brochure UK HRNguyễn Hữu DũngNessuna valutazione finora

- CompressorsDocumento49 pagineCompressorsashishdane100% (1)

- A Practical Guide To Compressor TechnologyDocumento27 pagineA Practical Guide To Compressor TechnologyOliver Froment0% (1)

- Reciprocating Compressor Valve DesignDocumento15 pagineReciprocating Compressor Valve Designsaikatchoudhuri100% (1)

- Oil-Free Screw Compressor 2Documento18 pagineOil-Free Screw Compressor 2shyam_anupNessuna valutazione finora

- Raven 3800 MixerDocumento3 pagineRaven 3800 Mixersantosh kumar100% (1)

- Sundyne High Speed Pump (OH6)Documento40 pagineSundyne High Speed Pump (OH6)Angga Deri Saputra100% (2)

- Hibon PD BlowerDocumento3 pagineHibon PD BlowerAbhinav SaiNessuna valutazione finora

- 1 - SealbasicsDocumento72 pagine1 - SealbasicsdhasdjNessuna valutazione finora

- Fan Engineering Guide - Twin City FansDocumento12 pagineFan Engineering Guide - Twin City FansHafiz KamalNessuna valutazione finora

- Lobe and Gear PumpsDocumento17 pagineLobe and Gear PumpsCarl Angelo A. LiwanagNessuna valutazione finora

- Fundamentals of Compressed Air and Reciprocating CompressorsDocumento115 pagineFundamentals of Compressed Air and Reciprocating CompressorsAmit Kumar JaiswalNessuna valutazione finora

- Oil Mist Lubrication TrainingDocumento70 pagineOil Mist Lubrication TrainingDelfinsh100% (3)

- BlowerDocumento32 pagineBlowerajaysharma_1009Nessuna valutazione finora

- Course Material On Compressor & PumpDocumento59 pagineCourse Material On Compressor & PumpKumar Gaurav SinghNessuna valutazione finora

- Instructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeDocumento30 pagineInstructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeSai RamNessuna valutazione finora

- Kirloskar Ebara Pumps Limited: A Presentation byDocumento11 pagineKirloskar Ebara Pumps Limited: A Presentation bypsshnkr100% (1)

- Preventing Cavitation Damage in Liquid Ring PumpsDocumento6 paginePreventing Cavitation Damage in Liquid Ring Pumpshimadri.banerji60Nessuna valutazione finora

- Elliott Single Stage CompressorsDocumento8 pagineElliott Single Stage CompressorsEdson França RodriguesNessuna valutazione finora

- The Axial Flow Compressor CompromiseDocumento8 pagineThe Axial Flow Compressor Compromisekincandia100% (4)

- Mechanical SealsDocumento107 pagineMechanical Sealsseaqu3st100% (2)

- Fluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYDa EverandFluid Film Lubrication - Osborne Reynolds Centenary: FLUID FILM LUBRICATION - OSBORNE REYNessuna valutazione finora

- Hydrocarbon Turbo ExpandersDocumento20 pagineHydrocarbon Turbo ExpandersPakde NdokNessuna valutazione finora

- Pumps & Systems - August 2015Documento116 paginePumps & Systems - August 2015Dragan Belcovski100% (1)

- Mag Drive PumpsDocumento5 pagineMag Drive PumpsakkineniNessuna valutazione finora

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDa EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineValutazione: 5 su 5 stelle5/5 (1)

- Forsthoffer’s Component Condition MonitoringDa EverandForsthoffer’s Component Condition MonitoringValutazione: 4 su 5 stelle4/5 (2)

- Design and Analysis of Centrifugal CompressorsDa EverandDesign and Analysis of Centrifugal CompressorsNessuna valutazione finora

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionDa EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNessuna valutazione finora

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsDa Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsValutazione: 1 su 5 stelle1/5 (1)

- Grooming Leaders at Home - LinkedInDocumento7 pagineGrooming Leaders at Home - LinkedInnarayan46Nessuna valutazione finora

- Productdatasheet Babsl 72 NBR 902Documento2 pagineProductdatasheet Babsl 72 NBR 902narayan46Nessuna valutazione finora

- Broschure Shipping en WebDocumento12 pagineBroschure Shipping en Webnarayan46Nessuna valutazione finora

- Spec Sheet Flange Dots+TagsDocumento1 paginaSpec Sheet Flange Dots+Tagsnarayan46Nessuna valutazione finora

- Spec Sheet MultiNutsDocumento1 paginaSpec Sheet MultiNutsnarayan46Nessuna valutazione finora

- flangeDOTS+VCI AnnouncementDocumento1 paginaflangeDOTS+VCI Announcementnarayan46Nessuna valutazione finora

- Tirupati Tirumala Guidelines PDFDocumento35 pagineTirupati Tirumala Guidelines PDFnarayan46Nessuna valutazione finora

- Spec Sheet Flange BumpersDocumento1 paginaSpec Sheet Flange Bumpersnarayan46Nessuna valutazione finora

- Engineering & Upgrade Workshop & Field Service Compressor ComponentsDocumento1 paginaEngineering & Upgrade Workshop & Field Service Compressor Componentsnarayan46Nessuna valutazione finora

- J.P. SAUER & SOHN WP150L Manual PDFDocumento60 pagineJ.P. SAUER & SOHN WP150L Manual PDFmail4ksn60% (5)

- KPC Loco Model 3HC55Documento4 pagineKPC Loco Model 3HC55narayan46100% (1)

- Shielding Gases Selection Chart 2013Documento1 paginaShielding Gases Selection Chart 2013Lachie TaylorNessuna valutazione finora

- Breaker KOM PDFDocumento50 pagineBreaker KOM PDFnamduong368100% (5)

- Turbine Meter Data SheetDocumento24 pagineTurbine Meter Data SheetehsanelahimirzaNessuna valutazione finora

- Avelair Refrigerant Dryers PDFDocumento2 pagineAvelair Refrigerant Dryers PDFNuno PaivaNessuna valutazione finora

- Centrifugal Compressors 2 How It WorksDocumento20 pagineCentrifugal Compressors 2 How It WorksRavi Kumar Talikota100% (1)

- Dr. Mohamed A. Qassem: Heat Transfer BranchDocumento24 pagineDr. Mohamed A. Qassem: Heat Transfer BranchMohamed ElfekyNessuna valutazione finora

- Ledeen Actuator General Catalogue - Entire LineDocumento24 pagineLedeen Actuator General Catalogue - Entire LineJair LamasNessuna valutazione finora

- Next Generation OnShore LNG Plant DesignsDocumento18 pagineNext Generation OnShore LNG Plant Designsdigeca50% (2)

- B08401000 Discharge Regulator - 027630016aDocumento1 paginaB08401000 Discharge Regulator - 027630016aLeandro MagriNessuna valutazione finora

- Aerodynamic Design Schemes of The Inlet Guide VaneDocumento9 pagineAerodynamic Design Schemes of The Inlet Guide VanedbNessuna valutazione finora

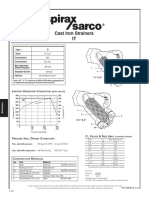

- Filtro It Spirax Sarco PDFDocumento2 pagineFiltro It Spirax Sarco PDFLina GarciaNessuna valutazione finora

- (1976-1) Minimum Thickness of A Liquid Film Flowing Vertically Down A Solid SurfaceDocumento6 pagine(1976-1) Minimum Thickness of A Liquid Film Flowing Vertically Down A Solid SurfaceClarissa OlivierNessuna valutazione finora

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUDocumento216 pagineSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) APUAnonymous 298xlo3uUNessuna valutazione finora

- BOMBA WILDEN P1500 PlasticDocumento24 pagineBOMBA WILDEN P1500 PlasticHiroaki HamadaNessuna valutazione finora

- Turbine Lube Oil System AND GENERATOR SealingDocumento32 pagineTurbine Lube Oil System AND GENERATOR SealingNishant ChaudharyNessuna valutazione finora

- v322C and 325C Excavator Hydraulic System (Attachment) Medium Pressure Circuit PDFDocumento2 paginev322C and 325C Excavator Hydraulic System (Attachment) Medium Pressure Circuit PDFMohamed RashedNessuna valutazione finora

- Gas LawsDocumento2 pagineGas LawsRaleen GenerNessuna valutazione finora

- Hydraulics FormulaDocumento1 paginaHydraulics FormulalifeadventureNessuna valutazione finora

- HGV Power Box SC Data Sheet v1 0Documento8 pagineHGV Power Box SC Data Sheet v1 0Miguel CNessuna valutazione finora

- SINOPEC PartnersEngDocumento42 pagineSINOPEC PartnersEngHamed GeramiNessuna valutazione finora

- Safety ValvesDocumento66 pagineSafety ValvesMuhammad Afiq Mohd ZaidNessuna valutazione finora

- Q4 Science 7 - Module 3Documento18 pagineQ4 Science 7 - Module 3Maria Conxedes GudesNessuna valutazione finora

- 300+ TOP Thermodynamics Multiple Choice Questions and AnswersDocumento1 pagina300+ TOP Thermodynamics Multiple Choice Questions and AnswersBhutto WaqarNessuna valutazione finora

- Panduan Pengoperasian TurbineDocumento60 paginePanduan Pengoperasian TurbineIfdal SalmaNessuna valutazione finora

- Elgi Sauer WP66L - 3 Stage Air Cooled Compressor (PassatSeries) 30 To 80 BarDocumento3 pagineElgi Sauer WP66L - 3 Stage Air Cooled Compressor (PassatSeries) 30 To 80 BarpmlmkpNessuna valutazione finora

- G.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationDocumento2 pagineG.R. Engineering Pvt. LTD.: Hydrotest Pressure Test Stress CalculationTushar Mangrati100% (2)

- Oillab 715 Reid Vapour Pressure: Automatic Analysers: Oillab RangeDocumento1 paginaOillab 715 Reid Vapour Pressure: Automatic Analysers: Oillab RangeOmar SaaedNessuna valutazione finora

- Venturi Type Flow Meter: SubmittalDocumento1 paginaVenturi Type Flow Meter: SubmittalrajuNessuna valutazione finora

- Bernoulli's EquationDocumento26 pagineBernoulli's EquationGabriela Montero100% (1)

- Hydrotest Procedure For Pressure VesselDocumento6 pagineHydrotest Procedure For Pressure VesselAbdul Kharis100% (1)