Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ir - L1904-32 17apr19-Mt (Sfjt-E)

Caricato da

Alleyson Akin100%(1)Il 100% ha trovato utile questo documento (1 voto)

167 visualizzazioni5 pagineToolbox description

Titolo originale

IR_L1904-32 17APR19-MT (SFJT-E)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoToolbox description

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

167 visualizzazioni5 pagineIr - L1904-32 17apr19-Mt (Sfjt-E)

Caricato da

Alleyson AkinToolbox description

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

ITS Inspection Technical Solution Sdn Bhd

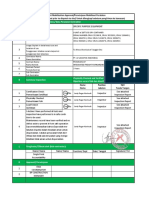

MAGNETIC PARTICLE ITS-OP-MPI-F02 REV02

REPORT NO:

EXAMINATION REPORT IR/DB/L1904-32/MT-08

Client: DIMENSION BID (M) SDN BHD Location: SFJT-E

Project: OFFSHORE CONTAINER ANNUAL PO/Sales Order No: -

PERIODIC INSPECTION Client Time Sheet No: 1421

Procedure No: ITS.OP.MPI.002 REV1 Code & Standards ASTM E 709

Client Procedure: - Acceptance Criteria: -

Examination Method C Dry Wet Visible Flourescent

Current Type AC (Yoke Only) DC N/A (Permanent Yoke)

Sensitivity Check Pie Gage Castrol Strip Direction Longitudinal Circular

Equipment Model Manufacturer Serial No. Cal. Due Consumables

AC Yoke Y-1 MAGNAFLUX 2010007 29-May-19 Medium Model Manufacturer

Permanent Black Ink BO-1 SHERWIN

Others White Contrast CP-2 SHERWIN

Cleaning Method Wire Brush Solvent Cleaning Paint Remover Dry rag wiping

Light Intensity DAYLIGHT VIEW Lighting Equipment: N/A

Material : CARBON STEEL Temperature AMBIENT

Surface Condition AS WELDED Welding Process: SMAW

SSPC-WIRELINE

Serial

Item Description WIRELINE TOOL CONTAINER CONTAINER-03

No:

Areas Inspected 100 % MPI ON ACCESSABLE WELDMENT AREA OF 4 NOS PADEYE

Findings NO SIGNIFICANT DEFECT DETECTED RESULT ACCEPTED

INSPECTION DATE: 17/04/2019 PROPOSED NEXT INSPECTION DATE: 16/04/2020

Inspected By Report Reviewed By Client's Rep / Third Party

Name: MOHD NORULHSAN Name: RAMLI BIN LAMIN

Qualification: NDT LEVEL II Position: OPERATION EXECUTIVE

Date: 17/04/2019 Date: 17/04/2019

This reports with interpretation and results are based on time of inspection are confidential and intended solely for the use of to whom they

are addressed.This reports shall not to reproduce/amend any substantial part without permission from company.The company accepts no

liability for any damage caused by any related to the part tested.

HQ - No 10-1, Jalan Ungu C, U9/C, Sunway Kayangan, 40150, Shah Alam, Selangor. Tel: +60378323464 Fax: +60378327464

www.its-inspection.com

ITS Inspection Technical Solution Sdn Bhd

MAGNETIC PARTICLE ITS-OP-MPI-F02 REV02

REPORT NO:

EXAMINATION REPORT IR/DB/L1904-32/MT-09

Client: DIMENSION BID (M) SDN BHD Location: SFJT-E

Project: OFFSHORE CONTAINER ANNUAL PO/Sales Order No: -

PERIODIC INSPECTION Client Time Sheet No: 1421

Procedure No: ITS.OP.MPI.002 REV1 Code & Standards ASTM E 709

Client Procedure: - Acceptance Criteria: -

Examination Method C Dry Wet Visible Flourescent

Current Type AC (Yoke Only) DC N/A (Permanent Yoke)

Sensitivity Check Pie Gage Castrol Strip Direction Longitudinal Circular

Equipment Model Manufacturer Serial No. Cal. Due Consumables

AC Yoke Y-1 MAGNAFLUX 2010007 29-May-19 Medium Model Manufacturer

Permanent Black Ink BO-1 SHERWIN

Others White Contrast CP-2 SHERWIN

Cleaning Method Wire Brush Solvent Cleaning Paint Remover Dry rag wiping

Light Intensity DAYLIGHT VIEW Lighting Equipment: N/A

Material : CARBON STEEL Temperature AMBIENT

Surface Condition AS WELDED Welding Process: SMAW

Serial

Item Description WIRELINE TOOL CONTAINER No:

TB-DB-01

Areas Inspected 100 % MPI ON ACCESSABLE WELDMENT AREA OF 4 NOS PADEYE

Findings NO SIGNIFICANT DEFECT DETECTED RESULT ACCEPTED

INSPECTION DATE: 17/04/2019 PROPOSED NEXT INSPECTION DATE: 16/04/2020

Inspected By Report Reviewed By Client's Rep / Third Party

Name: MOHD NORULHSAN Name: RAMLI BIN LAMIN

Qualification: NDT LEVEL II Position: OPERATION EXECUTIVE

Date: 17/04/2019 Date: 17/04/2019

This reports with interpretation and results are based on time of inspection are confidential and intended solely for the use of to whom they

are addressed.This reports shall not to reproduce/amend any substantial part without permission from company.The company accepts no

liability for any damage caused by any related to the part tested.

HQ - No 10-1, Jalan Ungu C, U9/C, Sunway Kayangan, 40150, Shah Alam, Selangor. Tel: +60378323464 Fax: +60378327464

www.its-inspection.com

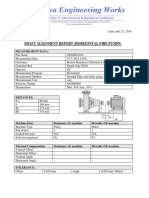

ITS Inspection Technical Solution Sdn Bhd

MAGNETIC PARTICLE ITS-OP-MPI-F02 REV02

REPORT NO:

EXAMINATION REPORT IR/DB/L1904-32/MT-10

Client: DIMENSION BID (M) SDN BHD Location: SFJT-E

Project: LIFTING SET ANNUAL PO/Sales Order No:

PERIODIC EXAMINATION Client Time Sheet No: 1421

Procedure No: ITS.OP.MPI.002 REV1 Code & Standards ASTM E 709

Client Procedure: - Acceptance Criteria: -

Examination Method C Dry Wet Visible Flourescent

Current Type AC (Yoke Only) DC N/A (Permanent Yoke)

Sensitivity Check Pie Gage Castrol Strip Direction Longitudinal Circular

Equipment Model Manufacturer Serial No. Cal. Due Consumables

AC Yoke Y-1 MAGNAFLUX 2010007 29/05/2019 Medium Model Manufacturer

Permanent Black Ink BO-1 SHERWIN

Others White Contrast CP-2 SHERWIN

Cleaning Method Wire Brush Solvent Cleaning Paint Remover Dry rag wiping

Light Intensity DAYLIGHT VIEW Lighting Equipment: N/A

Material : CARBON STEEL Temperature AMBIENT

Surface Condition AS WELDED Welding Process: SMAW

Serial 9427/4 , 9733/1

Item Description WIRE CLAMP No: & 9552/1

Areas Inspected FULL BODY ON CLAMP

Findings NO SIGNIFICANT DEFECT DETECTED RESULT ACCEPTED

INSPECTION DATE: 17/04/2019 PROPOSED NEXT INSPECTION DATE: 16/04/2020

Inspected By Report Reviewed By Client's Rep / Third Party

Name: MOHD NORULHSAN Name: RAMLI BIN LAMIN

Qualification: NDT LEVEL II Position: OPERATION EXECUTIVE

Date: 17/04/2019 Date: 17/04/2019

This reports with interpretation and results are based on time of inspection are confidential and intended solely for the use of to whom they

are addressed.This reports shall not to reproduce/amend any substantial part without permission from company.The company accepts no

liability for any damage caused by any related to the part tested.

HQ - No 10-1, Jalan Ungu C, U9/C, Sunway Kayangan, 40150, Shah Alam, Selangor. Tel: +60378323464 Fax: +60378327464

www.its-inspection.com

ITS Inspection Technical Solution Sdn Bhd

MAGNETIC PARTICLE ITS-OP-MPI-F02 REV02

REPORT NO:

EXAMINATION REPORT IR/DB/L1904-32/MT-11

Client: DIMENSION BID (M) SDN BHD Location: SFJT-E

Project: LIFTING SET ANNUAL PO/Sales Order No:

PERIODIC EXAMINATION Client Time Sheet No: 1421

Procedure No: ITS.OP.MPI.002 REV1 Code & Standards ASTM E 709

Client Procedure: - Acceptance Criteria: -

Examination Method C Dry Wet Visible Flourescent

Current Type AC (Yoke Only) DC N/A (Permanent Yoke)

Sensitivity Check Pie Gage Castrol Strip Direction Longitudinal Circular

Equipment Model Manufacturer Serial No. Cal. Due Consumables

AC Yoke Y-1 MAGNAFLUX 2010007 29/05/2019 Medium Model Manufacturer

Permanent Black Ink BO-1 SHERWIN

Others White Contrast CP-2 SHERWIN

Cleaning Method Wire Brush Solvent Cleaning Paint Remover Dry rag wiping

Light Intensity DAYLIGHT VIEW Lighting Equipment: N/A

Material : CARBON STEEL Temperature AMBIENT

Surface Condition AS WELDED Welding Process: SMAW

Serial

Item Description WIRE LOOPER No:

DB EL 1

Areas Inspected FULL BODY ON LOOPER

Findings NO SIGNIFICANT DEFECT DETECTED RESULT ACCEPTED

INSPECTION DATE: 17/04/2019 PROPOSED NEXT INSPECTION DATE: 16/04/2020

Inspected By Report Reviewed By Client's Rep / Third Party

Name: MOHD NORULHSAN Name: RAMLI BIN LAMIN

Qualification: NDT LEVEL II Position: OPERATION EXECUTIVE

Date: 17/04/2019 Date: 17/04/2019

This reports with interpretation and results are based on time of inspection are confidential and intended solely for the use of to whom they

are addressed.This reports shall not to reproduce/amend any substantial part without permission from company.The company accepts no

liability for any damage caused by any related to the part tested.

HQ - No 10-1, Jalan Ungu C, U9/C, Sunway Kayangan, 40150, Shah Alam, Selangor. Tel: +60378323464 Fax: +60378327464

www.its-inspection.com

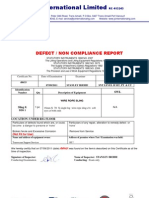

ITS Inspection Technical Solution Sdn Bhd

MAGNETIC PARTICLE ITS-OP-MPI-F02 REV02

REPORT NO:

EXAMINATION REPORT IR/DB/L1904-32/MT-12

Client: DIMENSION BID (M) SDN BHD Location: SFJT-E

Project: LIFTING SET ANNUAL PO/Sales Order No:

PERIODIC EXAMINATION Client Time Sheet No: 1421

Procedure No: ITS.OP.MPI.002 REV1 Code & Standards ASTM E 709

Client Procedure: - Acceptance Criteria: -

Examination Method C Dry Wet Visible Flourescent

Current Type AC (Yoke Only) DC N/A (Permanent Yoke)

Sensitivity Check Pie Gage Castrol Strip Direction Longitudinal Circular

Equipment Model Manufacturer Serial No. Cal. Due Consumables

AC Yoke Y-1 MAGNAFLUX 2010007 29/05/2019 Medium Model Manufacturer

Permanent Black Ink BO-1 SHERWIN

Others White Contrast CP-2 SHERWIN

Cleaning Method Wire Brush Solvent Cleaning Paint Remover Dry rag wiping

Light Intensity DAYLIGHT VIEW Lighting Equipment: N/A

Material : CARBON STEEL Temperature AMBIENT

Surface Condition AS WELDED Welding Process: SMAW

SHACKLES 4.75 TON , 3.25 TON Serial

Item Description N/A

& 2 TON CROSBY No:

Areas Inspected FULL BODY ON 3 PC SHACKLE WITH BOLT

Findings NO SIGNIFICANT DEFECT DETECTED RESULT ACCEPTED

INSPECTION DATE: 17/04/2019 PROPOSED NEXT INSPECTION DATE: 16/04/2020

Inspected By Report Reviewed By Client's Rep / Third Party

Name: MOHD NORULHSAN Name: RAMLI BIN LAMIN

Qualification: NDT LEVEL II Position: OPERATION EXECUTIVE

Date: 17/04/2019 Date: 17/04/2019

This reports with interpretation and results are based on time of inspection are confidential and intended solely for the use of to whom they

are addressed.This reports shall not to reproduce/amend any substantial part without permission from company.The company accepts no

liability for any damage caused by any related to the part tested.

HQ - No 10-1, Jalan Ungu C, U9/C, Sunway Kayangan, 40150, Shah Alam, Selangor. Tel: +60378323464 Fax: +60378327464

www.its-inspection.com

Potrebbero piacerti anche

- R1118111-S30002-COL-C00000-20019-H03-Rev.C QCDocumento37 pagineR1118111-S30002-COL-C00000-20019-H03-Rev.C QCDIBYENDU BERA100% (1)

- Dokumen - Tips Wqt-FormatDocumento2 pagineDokumen - Tips Wqt-FormatMr Pie100% (1)

- MI Barite Tank 2 Mpi RepDocumento7 pagineMI Barite Tank 2 Mpi RepChristopher Jones100% (1)

- Fcaw 16 THKDocumento5 pagineFcaw 16 THKparesh2387Nessuna valutazione finora

- Handling ToolsDocumento21 pagineHandling ToolsMehmet SoysalNessuna valutazione finora

- Ultrasonic Test Report: Before AfterDocumento7 pagineUltrasonic Test Report: Before AfterMenad SalahNessuna valutazione finora

- WPQR No. 2016 02Documento14 pagineWPQR No. 2016 02GANESH ANessuna valutazione finora

- Table 5: Requirements For Drill Pipe Inspection ReportingDocumento1 paginaTable 5: Requirements For Drill Pipe Inspection ReportingJosue FishNessuna valutazione finora

- Flash Report #01: Industry & Facilities DivisionDocumento4 pagineFlash Report #01: Industry & Facilities DivisionEduard GadzhievNessuna valutazione finora

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Documento2 pagineMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNessuna valutazione finora

- Result of Inspection: ConclusionDocumento5 pagineResult of Inspection: ConclusionBayu Aringga putraNessuna valutazione finora

- WPS FormatDocumento2 pagineWPS FormatAmit SarkarNessuna valutazione finora

- Ut ReportDocumento6 pagineUt ReportVijay PandeyNessuna valutazione finora

- Utoc Preliminary Wps Shell Project 270807 PDFDocumento55 pagineUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNessuna valutazione finora

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Documento2 paginePrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNessuna valutazione finora

- Wps Model 2 PDFDocumento17 pagineWps Model 2 PDFbeyNessuna valutazione finora

- Bis-Dk-Ut 1152 - 1200-24-VC01Documento6 pagineBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNessuna valutazione finora

- WPS PQR-02Documento8 pagineWPS PQR-02Ranjan Kumar100% (1)

- Paharpur Cooling Towers LTD: Magnetic Particle Testing ReportDocumento1 paginaPaharpur Cooling Towers LTD: Magnetic Particle Testing ReportGoutam Kumar DebNessuna valutazione finora

- Weld Test Checklist: Welder (S) DetailsDocumento2 pagineWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- B H e L Limited RTDocumento13 pagineB H e L Limited RTbhavin17850% (2)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Documento7 pagineBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNessuna valutazione finora

- WPQT FormatDocumento176 pagineWPQT FormatRafiqKu50% (2)

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocumento219 pagineSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529Nessuna valutazione finora

- Shaft Alignment Report (Horizontal Fire Pumps) : Measurement DataDocumento2 pagineShaft Alignment Report (Horizontal Fire Pumps) : Measurement DataSaad KhNessuna valutazione finora

- Report NDT r1Documento23 pagineReport NDT r1Trinh Thai100% (1)

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Documento17 pagineWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNessuna valutazione finora

- Welder Performace Qualification Report 2014..Documento132 pagineWelder Performace Qualification Report 2014..Kayra Riri ChirulNessuna valutazione finora

- Brazing BPS 107-1 PDocumento5 pagineBrazing BPS 107-1 Pmbe josephNessuna valutazione finora

- WPS - 2Documento3 pagineWPS - 2aleventNessuna valutazione finora

- Inspection Report Radiographic TestingDocumento1 paginaInspection Report Radiographic TestingJindarat Kasemsooksakul0% (1)

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocumento2 pagineName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNessuna valutazione finora

- Defect / Non Compliance ReportDocumento12 pagineDefect / Non Compliance ReportMichael OkwuwaNessuna valutazione finora

- Rp-20-Ut-011-Tcr-Saudi CementDocumento1 paginaRp-20-Ut-011-Tcr-Saudi CementRonel John Rodriguez CustodioNessuna valutazione finora

- Welding Report For Tank 1Documento1 paginaWelding Report For Tank 1Rifki HasyaNessuna valutazione finora

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocumento2 pagineAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNessuna valutazione finora

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 pagineCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNessuna valutazione finora

- WPS Format For AWS D1.1 - WPS - FCAWDocumento1 paginaWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNessuna valutazione finora

- Val Caraig WPQTDocumento1 paginaVal Caraig WPQTMark Jason M. BrualNessuna valutazione finora

- IPBD Instruction Manual PDFDocumento41 pagineIPBD Instruction Manual PDFrobinknit2009Nessuna valutazione finora

- Cargo Net InspectionDocumento0 pagineCargo Net Inspectionriazhosein77Nessuna valutazione finora

- UT Report FormDocumento1 paginaUT Report FormElisha NguyenNessuna valutazione finora

- Welder IdentificationDocumento9 pagineWelder Identificationdandiar1Nessuna valutazione finora

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- Electrode Selection ChartDocumento4 pagineElectrode Selection Chartsunitbhaumik100% (2)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Documento19 pagineHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-2)Mohamed AtefNessuna valutazione finora

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocumento2 pagineWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNessuna valutazione finora

- Reports - QAQC - R0Documento10 pagineReports - QAQC - R0talupurumNessuna valutazione finora

- Welding Procedure Specification: ST NDDocumento1 paginaWelding Procedure Specification: ST NDMaung SleeperNessuna valutazione finora

- Magnetic Particle Examination: DateDocumento2 pagineMagnetic Particle Examination: DateAbhishek SharmaNessuna valutazione finora

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocumento1 paginaWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- SS Pipe Welding ProcedureDocumento5 pagineSS Pipe Welding Procedureamit rajputNessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- LPT ReportDocumento2 pagineLPT ReportAnonymous OEUUoKHYR100% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocumento1 paginaPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNessuna valutazione finora

- RT Procedure 10.09.16Documento9 pagineRT Procedure 10.09.16mukeshsingh6Nessuna valutazione finora

- ET NDT Sample Test Report FormatDocumento1 paginaET NDT Sample Test Report Formatanas dwiNessuna valutazione finora

- Content 20240115185834Documento2 pagineContent 20240115185834BLY YEDEKPA NOEL BENITONessuna valutazione finora

- MPI Report SWL 5 Ton BoxDocumento2 pagineMPI Report SWL 5 Ton BoxYusuf bagewadiNessuna valutazione finora

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Documento1 pagina75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNessuna valutazione finora

- Daily Report Management Apprentice: Time From Time To Hours DescriptionDocumento1 paginaDaily Report Management Apprentice: Time From Time To Hours DescriptionAlleyson AkinNessuna valutazione finora

- Daily Report Management Apprentice: Time From Time To Hours DescriptionDocumento1 paginaDaily Report Management Apprentice: Time From Time To Hours DescriptionAlleyson AkinNessuna valutazione finora

- Daily Report Management Apprentice: Time From Time To Hours DescriptionDocumento1 paginaDaily Report Management Apprentice: Time From Time To Hours DescriptionAlleyson AkinNessuna valutazione finora

- Daily Report Management Apprentice: Time From Time To Hours DescriptionDocumento1 paginaDaily Report Management Apprentice: Time From Time To Hours DescriptionAlleyson AkinNessuna valutazione finora

- Rotary Cutters PDFDocumento3 pagineRotary Cutters PDFAlleyson AkinNessuna valutazione finora

- Figure 1 Tile CrackDocumento5 pagineFigure 1 Tile CrackAlleyson AkinNessuna valutazione finora

- Pergi Devils PDFDocumento1 paginaPergi Devils PDFAlleyson AkinNessuna valutazione finora

- Go Devils PDFDocumento1 paginaGo Devils PDFAlleyson AkinNessuna valutazione finora

- Go Devils PDFDocumento1 paginaGo Devils PDFAlleyson AkinNessuna valutazione finora

- However, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To PrescriptionDocumento7 pagineHowever, A Review of The Factual Antecedents of The Case Shows That Respondents' Action For Reconveyance Was Not Even Subject To Prescriptionkemsue1224Nessuna valutazione finora

- HboDocumento126 pagineHboKunal ChaudhryNessuna valutazione finora

- 1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderDocumento18 pagine1.0 Design Andheri Khola Bridge, 1x25m 8.4m 3 GirderManoj ChaudharyNessuna valutazione finora

- Cost Justifying HRIS InvestmentsDocumento21 pagineCost Justifying HRIS InvestmentsNilesh MandlikNessuna valutazione finora

- Job Schedule Sheet: 'Lead Time Monitoring GraphDocumento48 pagineJob Schedule Sheet: 'Lead Time Monitoring GraphEndraNessuna valutazione finora

- Coreapb3: Nivin PaulDocumento19 pagineCoreapb3: Nivin PaulNivin PaulNessuna valutazione finora

- CV: LT Col MD Rakibul Hassan, Raqueeb HassanDocumento14 pagineCV: LT Col MD Rakibul Hassan, Raqueeb HassanRakibul Hassan100% (26)

- Holiday Activity UploadDocumento6 pagineHoliday Activity UploadmiloNessuna valutazione finora

- Strategic Role of Operations ManagementDocumento2 pagineStrategic Role of Operations ManagementEashan JindalNessuna valutazione finora

- Acctg 14 - MidtermDocumento5 pagineAcctg 14 - MidtermRannah Raymundo100% (1)

- Mystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Documento80 pagineMystique-1 Shark Bay Block Diagram: Project Code: 91.4LY01.001 PCB (Raw Card) : 12298-2Ion PetruscaNessuna valutazione finora

- 20-21 Ipads Shopping GuideDocumento1 pagina20-21 Ipads Shopping Guideapi-348013334Nessuna valutazione finora

- 42 Investors Awareness Towards Mutual FundsDocumento8 pagine42 Investors Awareness Towards Mutual FundsFathimaNessuna valutazione finora

- Text-Book P3Documento147 pagineText-Book P3Nat SuphattrachaiphisitNessuna valutazione finora

- Want To Buy & Sell Expired Domain Names-Follow These 3 StepsDocumento6 pagineWant To Buy & Sell Expired Domain Names-Follow These 3 StepsEmiemNessuna valutazione finora

- Topic: Matrix Addition and SubtractionDocumento6 pagineTopic: Matrix Addition and SubtractionAnonyNessuna valutazione finora

- QuickRide LogcatDocumento53 pagineQuickRide LogcatAthira OSNessuna valutazione finora

- Mathswatch Student GuideDocumento8 pagineMathswatch Student Guideolamideidowu021Nessuna valutazione finora

- COEN 252 Computer Forensics: Incident ResponseDocumento39 pagineCOEN 252 Computer Forensics: Incident ResponseDudeviswaNessuna valutazione finora

- 007 G.R. No. 162523 November 25, 2009 Norton Vs All Asia BankDocumento5 pagine007 G.R. No. 162523 November 25, 2009 Norton Vs All Asia BankrodolfoverdidajrNessuna valutazione finora

- Contribution of Science and Technology To National DevelopmentDocumento2 pagineContribution of Science and Technology To National DevelopmentAllan James DaumarNessuna valutazione finora

- CH03 HKM Law Investigation and EthicsDocumento32 pagineCH03 HKM Law Investigation and Ethicsmilkikoo shiferaNessuna valutazione finora

- LabVIEW Core 3 2013 - Course ManualDocumento135 pagineLabVIEW Core 3 2013 - Course Manualtalaindio100% (2)

- SD HospitalDocumento2 pagineSD HospitalSam PowelNessuna valutazione finora

- Boat, Time Speed and DistanceDocumento5 pagineBoat, Time Speed and DistanceAnmol AswalNessuna valutazione finora

- Operating Instruction PMD55Documento218 pagineOperating Instruction PMD55Dilip ARNessuna valutazione finora

- Types of TrianglesDocumento5 pagineTypes of Trianglesguru198319Nessuna valutazione finora

- Uy & Roxas vs. CADocumento19 pagineUy & Roxas vs. CAThea P PorrasNessuna valutazione finora

- Abstract 2 TonesDocumento8 pagineAbstract 2 TonesFilip FilipovicNessuna valutazione finora

- Automated Parking SystemDocumento48 pagineAutomated Parking SystemRiya SinghNessuna valutazione finora