Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FEA Study On LPG Bullets

Caricato da

Spyros DimakisDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FEA Study On LPG Bullets

Caricato da

Spyros DimakisCopyright:

Formati disponibili

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

Design of LPG mould billet using FEM

R. Datha Satyanarayana I. Satyanarayana

P.G Student, professor,

Department of Mechanical Engineering, Department of Mechanical Engineering,

Chaitanya College of Engineering. Chaitanya College of Engineering.

ABSTRACT: And according to role of process vessels are mainly

The significance of the title of the project comes to classified into four types:

front with designing structure of a 1000 mt capacity of

LPG mounded bullet pressure vessel for static loading, (a)Reaction pressure vessel.

is basically a project concerned with different design (b)Heat exchanger pressure vessel.

variables, thickness of shell, elliptical head, operating (c)Separation pressure vessel.

manhole and stiffners under load case of high pressure (d)Storage pressure vessel.

test and working fluid with standards of ASME codes

and its assessment is carried out in CATIAV5 for model- The objective of this project is to design a Horizontal

ing and analysis in HYPERMESH/ANSYS. it is employed storage pressure vessel which can store LPG (liquid pe-

on practical design of LPG pressure vessel as per re- troleum gases). In general storage pressure vessels are

quired by the industry. used to hold liquid or gaseous materials, storage media

or container to balance the pressure from the buffering

effect. In order to achieve better design results, ASME

INTRODUCTION: boiler codes were taken into consideration.

A pressure vessel is a closed container designed to hold

gases or liquids at a pressure substantially different

from the ambient pressure. They are used to store flu-

ids under pressure. The pressure vessels are designed

with great care because rupture of pressure vessels

means an explosion which may cause loss of life and

property. The material of pressure vessels may be brit-

tle such that cast iron or ductile such as mild steel. And

pressure vessels are classified mainly into two types,

(a) According to Dimensions (b) According to end

Construction.The pressure vessels, according to the

dimensions are classified as thin and thick shells. The

ratio of internal diameter and wall thickness is the fac-

tor which differentiates between thin and thick shells.

If the ratio d/t is more than 10, then it is called thin shell

Typical Horizontal LPG Storage Vessel Assembly.

and if this ratio is less than 10 it is said to be thick shell.

The examples of the thin shells are pipes, boilers and

storage tanks while the thick shells are used in pres- Objectives and Scope:

sure cylinders, Gun barrels, etc.The pressure vessels ac-

cording to end construction are classified as open end A Finite element model is developed to analyze the

and closed end. A simple cylinder whit a piston is an behavior of Horizontal mounded LPG Vessel subjected

example of closed end vessel. In case of open end ves- to Hydro test condition, and Operation Condition. In

sels the circumferential stress is induced in addition to Hydro Test condition, water is used to test the vessel

the circumferential stress. as its density is higher than the LPG. Following are the

loads considered in Hydro Test Condition:

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 705

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

-Pressure inside the vessel. 2.2 Types of Storage Vessels:

Hydro Test Pressure.

Pressure Due to Head (100 % head of water).

2.2.1 Selection of storage vessel type:

-External Pressure on the vessel.

-Self weight due to gravity.

In addition to mounded storage, other types of vessel

may also be used to store LPG under pressure at ambi-

In Operating Condition, LPG is used and the vessel is

ent temperature.

subjected to varying pressure at different heads as 25%,

50%, 75%, 90%. Following are the loads considered in

•Spheres

Operating Condition:

•Bullets (above ground)

-Internal Pressure

-Pressure due to head (25%, 50%, 75%, 90%)

•Submerged storage vessels

-External pressure

The principle of the design of the vessel is that the axi-

-Mound pressure at dome ends

symmetrical loads are carried by the shell plates, while

-Mound pressure on cylinder

bending stresses due to non-symmetrical loads are car-

-Self weight due to gravity.

ried by the shell plates, while bending stresses due to

non-axisymmetrical loads are carried by stiffening rings

The Primary Objective of this research is to build a pres-

(except for small diameter, unstiffened vessels).

sure vessel with design parameters and to validate the

results using finite element method. Scope of design-

ing a pressure vessel covers the design basis for follow-

ing equipment:

-Vessel

-Stiffeners

-Domes / Hemispherical D-ends

-Sand filling in differential settlements.

-Man-holes

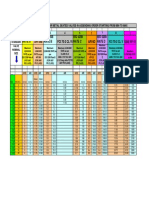

-Pad-Plates MINIMUM SHELL/HEAD THICKNESS

Design of Pressure Vessel

Minimum thickness shall be as given below

a) For carbon and low alloy steel vessels- 6mm (Includ-

2.1 Codes and Standards: ing corrosion allowance not exceeding 3.0mm), but

not less than that calculated as per following:

Following are the codes and standards had been used

For diameters less than 2400mm

to design the Horizontal pressure vessel:

Wall thickness = Dia/1000 +1.5 + Corrosion Allowance

ASME SEC. VIII DIV.1 /

For diameters 2400mm and above

For Pressure vessels

Wall thickness = Dia/1000 +2.5 + Corrosion Allowance

IS: 2825

All dimensions are in mm.

b) For stainless steel vessel and high alloy vessels -3

ASME SEC. VIII DIV.2

mm, but not less than that calculated as per following

For Pressure vessels (Selectively for high

for diameter more than 1500mm.

pressure / high thickness / critical service)

Wall thickness (mm) = Dia/1000 + 2.5

Corrosion Allowance, if any shall be added to minimum

ASME SEC. VIII DIV.2

thickness.

For Storage Spheres

c) Tangent to Tangent height (H) to Diameter (D) ratio

(H/D) greater than 5 shall be considered as column and

ASME SEC. VIII DIV.3

designed accordingly.

For Pressure vessels (Selectively for high pressure)

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 706

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

d) For carbon and low alloy steel columns / towers Boundary Conditions (Hydro Test Condition):

-8mm (including corrosion allowance not exceeding

3.0mm.

e) For stainless steel and high alloy columns / towers 4.2.1 Constraints:

-5mm. Corrosion allowance, if any, shall be added to

minimum thickness. Vessel is supported by the Sand fill, and sand fill is con-

structed on the ground, hence all the base nodes of

the mound are constrained in all degrees of freedom

2.3.2 Vessel sizing: (123456). The arrow marks detailed below represents

constraints on the base.

All Stiffeners

Based on inside diameter

All Clad/Lined Vessels

Based on inside diameter

Vessels (Thickness>50mm)

Based on inside diameter

All Other Vessels

Based on outside diameter

Tanks & Spheres

Based on inside diameter

FE Model Preparation / Results:

Fig: 4.4 Constraints (SPC loactions)

Since the vessel is installed on the ground, Gravity of

9810 mm /s2 has been considered over the entire mod-

el. Other Boundary conditions are loads applied inter-

nally and externally. Below are the details of other load

cases carried out to find the performance of the Vessel

Design.

Pressures inside the Vessel:

With regard to the stiffener design, the internal pres-

sure only affects the normal force N3 in the stiffening

ring, not the bending moment of the shear force. Part

Mesh is created using hypermesh, and an average ele- of the shell plates will act together with the ring to car-

ment size of 20 mm is used for modeling. Hexa / Penta ry the load to which the rings are subjected. This part,

element configurations are used in building this model. the working width w, is:

And to capture the surfaces stresses, we had extracted w = 2 x 0.78 x √(R x t)

skin as shell elements. The internal pressure, acting on the working width, will

cause a normal tensile load N3 which is carried by the

combination of stiffening ring and working width of

the shell plate.

N3 = p3 x w x R

Where p3 = the internal design pressure.

Hydro Test Pressure : 19.75 kg/cm2 or 1.93668 MPa

Pressure due to head : 0.75 kg/cm2 or 0.073575 MPa

(at 100% head of water)

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 707

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

4.2.3 Pressure outside the Vessel:

External Pressure : 1.856 kg/cm2 or 0.1819994 MPa

Gravity is considered to capture the self weight of the

vessel.

4.3 Boundary Conditions (internal pressure +

liquid weight + mound weight + load due to

thermal expansion with center soft) at Oper-

ating Conditions:

4.3.1 Pressures inside the Vessel (fig:

4.5):Internal Pressure: 14.5 kg/cm2 or 1.42187

MPa

4.3.2 Pressure due to head (LPG):

Fig: 4.6 Mound weight

Following are the Load-Cases Analyzed:

Hydro Test Condition :

Generally hydro test conditions are tested at 90% head

of the volume being filled in the vessel, so that it lets us

25% head: 0.103 kg/cm2 or 0.0101165 MPa

know the ability to sustain for high pressure.Below are

50% head: 0.103 kg/cm2 or 0.020233 MPa

the Load cases done for operating Conditions:

75% head: 0.103 kg/cm2 or 0.03034 MPa

4.3.3 Pressure Outside the Vessel:

External Pressure : 1.856 kg/cm2 or 0.1819994 MPa

Mound Pressure at Dome Ends: 0.1647 MPa

Mound Pressure on Cylinder:

The weight on the mound assumed to be in a radial

pressure q on the cylinder, as shown in the below fig-

ure (ψ0 = 90°): At angle ψ: qψ = q0 cos ψ,

Where q0 (kN/m2) is the maximum pressure at ψ = 0

q0*Cos = 0.035146 MPa

q10*Cos = 0.034612 MPa

q20*Cos = 0.033027 MPa

q30*Cos = 0.030438 MPa

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 708

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

SCL Plots at various junctions are defined below and

each SCL plot had been compared with the allowable

stress at those maximum points in the below locations

:

SCL-1 : Dome to Shell

SCL-2 : Shell to Nozzle

SCL-3 : Shell to stiffeners at ends

SCL-4 : Shell to Stiffeners-at center

SCL-5 : Shell to Dome-A

SCL Locations:

Fig:4.7a HydroTest Condition

Load Case-1: Internal Pressure + liquid weight +

mound weight + Load due to thermal expansion with

centre soft.

LoadCase-2: Internal pressure + liquid weight +

mound weight + Load due to thermal expansion with

end soft.

LoadCase-3: liquid weight + mound weight + Load

due to thermal expansion with centre soft.

LoadCase-4: liquid weight + mound weight + Load

due to thermal expansion with end soft.

Fig: 4.8 SCL Loacations

SCL’s had been plotted from the above some locations

where the stress are maximum. Hence the analyst has

to take SCL at all critical location near discontunity.

With experience and looking at geometry and stress

contour, and expert will be able to make out which SCL

gives maximum membrane or bending stress. In oth-

er words considering that SCL which gives maximum

membrane and bending stress to arrive at PL or Q as

the case may be helpful.

Fig: 4.7b LoadCases - 1 to 4 4.6 Results:

HYDRO –TEST Condition:

4.5 SCL: Stress Classification Lines:

This SCL information gives various details across the Displacement & Stress Contours at 90% LPG Head:

cross-sectional thickness, mainly these scl plots are de-

tailed in the welding regions. So that we can calculate

Z-Displacement at 100 % water filled condi-

the strength of the weld joint in the vessel to ensure

that there are no pressure leakages. These plots are tion:

defined by displacement in X-Dir and Stress in Y-Dir.

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 709

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

in red ranging from 345-639 MPa.

Fig: 4.10b Stresses between Domes(A&B) to Vessel

(Hydro Test Condition) with pad plates.

Above stress between Dome A to Vessel and Dome B

Fig: 4.9b Stress Plot (Hydro Test Condition) to Vessel. These are the locations where the stresses

are very high and above the yield limit, but below the

Overall Stress contour at Yield Strength (345 MPa): ultimate stress for the material being used. To reduce

the stresses over this region, pad plates are used.

Fig: 4.10a Overall Stress Plot (Hydro Test Condition)

The stresses above the allowable limit are

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 710

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

Fig: 4.11 Stresses between Domes to Vessel (Hydro 4.13 SCL plots for Hydro Test Condition.

Test Condition) without pad plates. Summary of SCL Data extracted for Hydro

Test Condition (Table 4.1):

A localized stress is formed below the pad plates. (Max

Stress: 639 MPa) Stress contour at allowable stress

(205 Mpa) for stiffeners:

4.12 Stress Plots in Stiffener locations

Stiffeners are in allowable range at 100%head+Hydro

Test Pressure. Except in the regions of stiffeners just

below the pad-plates. Thus there is a local stress which

is less than the minimum yield strength (< 345MPa).

SCL Info for Hydro Test Condition:

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 711

ISSN No: 2348-4845

International Journal & Magazine of Engineering,

Technology, Management and Research

A Monthly Peer Reviewed Open Access International e-Journal

5. CONCLUSION: 4. American Standard Pipe Diameters;

Finite element model is developed to analyze the be- 5. Stresses in Large Horizontal Cylindrical Pressure Ves-

havior of Horizontal mounded LPG Vessel subjected to sels on Two Saddle Supports by L. P. Zick.Original paper

Hydro test condition, and Operation Condition. Aim is published in September 1951 “THE WELDING JOURNAL

to design and validate a pressure vessel that can store RESEARCH SUPPLEMENT.”

1000 metric tons (MT) of LPG in it (either in gaseous

state or in liquid state). SA-537-cl1 material had been 6. Location of ‘reboiler return inlet nozzle’ and its ef-

used for all components in the model. This design has fect on Distillation Column article@processenggservic-

been validated for various conditions and passed suc- es.com, 005-2009 Process Engineering Services.

cessfully.

7. Optimal wall-thickness of the spherical pressure ves-

1.Hydro Test Condition: As briefed earlier any pressure sel with respect to criterion about minimal mass and

vessel constructed shall be tested for Hydro Test as a equivalent stressdražankozak, josipsertić. ANNALS OF

mandatory. In this test 90% of water will be filled in the THE FACULTY OF ENGINEERING HUNEDOARA – 2006

vessel and subjected to internal pressure of 19.75 kg/ TOME IV. Fascicole 2 Understanding How Changes in

cm2 and an external pressure of 1.85 kg/cm2 (obtained Pressure Vessel Codes May Impact Pressure Vessel

from design calculations) and also self weight due to Performance .Patrick J. Sullivan Highlander Engineer-

gravity. Below is the results summary (Table 4.6): ing Services 2008, PLLC Argyle, NY

SCL-1 : Dome to Vessel 8. Results of fea analyses at nozzle/shell junctions sub-

SCL-2 : Vessel to Nozzle jected to external loads steven R. Massey charlie S.

SCL-3 : Vessel to stiffeners at ends HsiehBlack & veatch pritchardInc-2009.

SCL-4 : Vessel to Stiffeners-at center

SCL-5 : Vessel to Dome-A/B ABOUT AUTHORS:

Whole model cannot be taken into considered for find- R.Datha Satyanarayana is a P.G student of Me-

ing stresses due to assumptions made to minimize the chanical Department of Chaitanya Engineering College.

model to main components of a vessel. Stress inten- He done his B.Tech from ADITYA Engineering College

sities are calculated in only the welded locations and affiliated to Jawaharlal Nehru Technological University

joints, where the bullet has to sustain for higher stress- Kakinada.

es. As per the above table, model is passed for all the

membrane and bending stresses ( ~280 MPa < Yield

strength 50000 psi / 345 MPa ). All the obtained stress- Prof[Dr]I.SATYANARAYANA,B.E.,M.E.,PGDAS.,FI

es for the design are less than the allowable stresses. E,FIIP,MISTE,C[ENGG],,born in West Godavari district,

Andhra Pradesh, INDIA. He received M.E. [machine de-

sign] from Andhra University, VISAKHAPATNAM. AP,

Refernces:

INDIA. He is CHAIRMAN of ‘’THE INSTITUTION OF EN-

GINEERS [INDIA] VISAKHAPATNAM, centre, He is also

1. Dennis Moss, “Pressure vessel design manual”

a council member of IEI. He has 35 years of industrial

experience and 10 years teaching experience as pro-

2. B.S.Thakkar, S.A.Thakkar; “DESIGN OF PRESSURE

fessor in Mech.Engg..presently he is working as pro-

VESSEL USING ASME CODE, SECTION VIII, IVISION

fessor in Mech Engg dept, CHAITANYA ENGG,COLLEGE

1”; International Journal of Advanced Engineering

VISAKHAPATNAM. INDIA

Research and Studies, Vol. I, Issue II, January-March,

2012.

3. ASME Boiler and Pressure Vessel Code 2007 Sec 8

Division 1 (2007).

Volume No: 1(2014), Issue No: 12 (December) December 2014

www.ijmetmr.com Page 712

Potrebbero piacerti anche

- Technical Bid No 1Documento235 pagineTechnical Bid No 1kaushalNessuna valutazione finora

- Essential Practices for Managing Chemical Reactivity HazardsDa EverandEssential Practices for Managing Chemical Reactivity HazardsNessuna valutazione finora

- Cryo Piping SystemsDocumento19 pagineCryo Piping SystemsaravindhcamNessuna valutazione finora

- COEN 13116 Duct Burner Solutions LR WebDocumento2 pagineCOEN 13116 Duct Burner Solutions LR WebscribdkhatnNessuna valutazione finora

- The Seven Rules of NegotiatingDocumento4 pagineThe Seven Rules of NegotiatingRyan HengNessuna valutazione finora

- EPE201008 - PT Badak NGL BlackOut Start Up SystemDocumento4 pagineEPE201008 - PT Badak NGL BlackOut Start Up SystemNasrulSyahruddinNessuna valutazione finora

- Floating Liquefaction Projects: Technical, Operational, Commercial and Legal ChallengesDocumento11 pagineFloating Liquefaction Projects: Technical, Operational, Commercial and Legal Challengessamriddh25Nessuna valutazione finora

- ReportDocumento19 pagineReportMainak Vk ChatterjeeNessuna valutazione finora

- CHART Cold Box Installation Operation and Maintenance PDFDocumento16 pagineCHART Cold Box Installation Operation and Maintenance PDFBrinto VargheseNessuna valutazione finora

- Coastal Ocean Observing SystemsDa EverandCoastal Ocean Observing SystemsYonggang LiuNessuna valutazione finora

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaDa EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNessuna valutazione finora

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988Da EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNessuna valutazione finora

- Permanent Mooring System Wire Rope, Sockets, Pins and Connectors For Deepwater Floating Structures (Based On Dnv-Os-E304)Documento18 paginePermanent Mooring System Wire Rope, Sockets, Pins and Connectors For Deepwater Floating Structures (Based On Dnv-Os-E304)yvNessuna valutazione finora

- Productie 16 - Curacao RFP - LNG Import and Trans-Shipment Terminal in CuracaoDocumento39 pagineProductie 16 - Curacao RFP - LNG Import and Trans-Shipment Terminal in Curacaobagusu_6Nessuna valutazione finora

- H P F L A R e (K - F X - 0 4 3 0 0 1)Documento16 pagineH P F L A R e (K - F X - 0 4 3 0 0 1)tariqNessuna valutazione finora

- A High Capacity Floating LNG Design by Barend - PekDocumento15 pagineA High Capacity Floating LNG Design by Barend - PekShaka Shalahuddin Shantika PutraNessuna valutazione finora

- 6580 - 67 - r0 - OWT Open DrainDocumento10 pagine6580 - 67 - r0 - OWT Open DrainMohammad MohseniNessuna valutazione finora

- Prsentation of Sub Station Equipment: Presented By:-Sh. B. R. Gulati Sr. Manager (Elect.)Documento17 paginePrsentation of Sub Station Equipment: Presented By:-Sh. B. R. Gulati Sr. Manager (Elect.)Ravinder SharmaNessuna valutazione finora

- Standard Specification: LPG Loading / Unloading ArmDocumento19 pagineStandard Specification: LPG Loading / Unloading ArmANIL KUMAR100% (1)

- Esquemas ShellDocumento15 pagineEsquemas Shelljanneth100% (1)

- Engineering FeeDocumento25 pagineEngineering FeetouchvikrantNessuna valutazione finora

- LNG RequirementsDocumento4 pagineLNG RequirementsManuel GuerreroNessuna valutazione finora

- GTL technology converts natural gas to liquid fuelsDocumento18 pagineGTL technology converts natural gas to liquid fuelsShashwat VatsaNessuna valutazione finora

- Sener Fsru EnglishDocumento33 pagineSener Fsru EnglishFrancisco J RodríguezNessuna valutazione finora

- ES Petroleum Energy GuideDocumento122 pagineES Petroleum Energy GuideRizkina Ika AryanaNessuna valutazione finora

- FEED Screen Whitepaper PlantDocumento10 pagineFEED Screen Whitepaper PlantazamshafiqNessuna valutazione finora

- Valve Leakage Class CompDocumento1 paginaValve Leakage Class CompSantoshi PriyaNessuna valutazione finora

- BBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFDocumento2 pagineBBS-10-W8-DS-011 - C - Glycol Surge Drum DS PDFAdianto RahmanNessuna valutazione finora

- WesPac Tilbury Marine Jetty Project Brochure 2014-09-02Documento4 pagineWesPac Tilbury Marine Jetty Project Brochure 2014-09-02Jeff NagelNessuna valutazione finora

- Plant LayoutDocumento8 paginePlant Layoutrsmallwood395895100% (1)

- TA-143-D00-G-TD005 - 0 - Employer's Requirements PDFDocumento78 pagineTA-143-D00-G-TD005 - 0 - Employer's Requirements PDFshareyhouNessuna valutazione finora

- GTG 1409sc Solart60 60hzDocumento21 pagineGTG 1409sc Solart60 60hzKhaldoon AlnashiNessuna valutazione finora

- 20samarat Annd1Documento35 pagine20samarat Annd1Prabhakar Tiwari100% (1)

- Onshore LNG Study - Rev - 2Documento68 pagineOnshore LNG Study - Rev - 2kaspersky2009Nessuna valutazione finora

- Gas Tech 2008 FLN G Business PresentationDocumento25 pagineGas Tech 2008 FLN G Business PresentationNirma Afrisanti KinasihNessuna valutazione finora

- Liquefied Natural Gas: Trust The Industry's Longest-Serving Turnkey ContractorDocumento12 pagineLiquefied Natural Gas: Trust The Industry's Longest-Serving Turnkey Contractorvignesh100% (1)

- LNG Tank FabricationDocumento1 paginaLNG Tank FabricationtndeshmukhNessuna valutazione finora

- Natural Gas Liquefaction Technology For Floating LNG FacilitiesDocumento12 pagineNatural Gas Liquefaction Technology For Floating LNG FacilitieshortalemosNessuna valutazione finora

- WikiLeaks - Sensitive Cables, GY Tag - PT 2Documento186 pagineWikiLeaks - Sensitive Cables, GY Tag - PT 2Brigadier David GrangerNessuna valutazione finora

- Finite Element Analysis Validation of Mounded LPG BulletsDocumento8 pagineFinite Element Analysis Validation of Mounded LPG BulletsMuhammed NoufalNessuna valutazione finora

- Intertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas CarriersDocumento19 pagineIntertanko Gas and Marine Seminar: Blending/Commingling of LPG Cargoes On Board Gas Carriersmouloud miloud100% (1)

- All To Know About IFR & EFRDocumento30 pagineAll To Know About IFR & EFRyazNessuna valutazione finora

- Planned Refinery Outages in The United States: Fourth-Quarter 2018Documento30 paginePlanned Refinery Outages in The United States: Fourth-Quarter 2018Euclides PrietoNessuna valutazione finora

- Linde Small Scale LNG Distribution OverviewDocumento17 pagineLinde Small Scale LNG Distribution OverviewPawan Chaturvedi100% (1)

- Experience Based Data For FPSO's Structural Design: Abs Technical Papers 2003Documento8 pagineExperience Based Data For FPSO's Structural Design: Abs Technical Papers 2003jworderNessuna valutazione finora

- Zeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaDocumento4 pagineZeepod Overview: Malaysia L Singapore L Indonesia L Sri LankaAmirah AqilahNessuna valutazione finora

- 1961spm OILandGAS PDFDocumento110 pagine1961spm OILandGAS PDFvesgacarlosNessuna valutazione finora

- Petroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsDocumento72 paginePetroleum Regeneration and Processing Facility - Phase Ii: Employer'S RequirementsChitradeep FalguniyaNessuna valutazione finora

- Bontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and ReliabilityDocumento25 pagineBontang Future 3rd LNG-LPG - A Design Which Achieves Very High Levels of Flexibility, Safety and Reliabilitywebwormcpt100% (1)

- Open Rack Vaporizer Mass and Energy BalanceDocumento12 pagineOpen Rack Vaporizer Mass and Energy BalanceMuhammad Nanda100% (1)

- Harbour InspectionDocumento92 pagineHarbour InspectionAgung Siswahyu100% (1)

- Methanol ProposalDocumento7 pagineMethanol Proposalapi-292477726Nessuna valutazione finora

- FPSO SystemsDocumento29 pagineFPSO Systemspraving76100% (1)

- EPC PricingDocumento4 pagineEPC PricingJohn GregNessuna valutazione finora

- Current Status of Mixed LNG Storage Technology Development: Back GroundDocumento5 pagineCurrent Status of Mixed LNG Storage Technology Development: Back GroundmimoNessuna valutazione finora

- TSG R0004 2009Documento76 pagineTSG R0004 2009bikobelloNessuna valutazione finora

- Hazards and Risk Assessment of Caltex Kurnell Refinery DemolitionDocumento60 pagineHazards and Risk Assessment of Caltex Kurnell Refinery DemolitionGILBERTO YOSHIDANessuna valutazione finora

- Effect of Base Isolation On Seismic Fragility of Aboveground LNG Storage TanksDocumento6 pagineEffect of Base Isolation On Seismic Fragility of Aboveground LNG Storage TanksciscoNessuna valutazione finora

- Vessels LDocumento34 pagineVessels LMohammed.abudi1996Nessuna valutazione finora

- Kinetic data and reaction orders for methane combustion reactionsDocumento8 pagineKinetic data and reaction orders for methane combustion reactionsSpyros DimakisNessuna valutazione finora

- Tank DesignDocumento100 pagineTank DesignSpyros DimakisNessuna valutazione finora

- Tank DesignDocumento100 pagineTank DesignSpyros DimakisNessuna valutazione finora

- MethaneCombustion PDFDocumento11 pagineMethaneCombustion PDFSpyros DimakisNessuna valutazione finora

- Tk-Okta Site Class BDocumento114 pagineTk-Okta Site Class BSpyros DimakisNessuna valutazione finora

- CH4 2 Welding Joint PreparationDocumento46 pagineCH4 2 Welding Joint PreparationMatija BušićNessuna valutazione finora

- IFR API IdeasDocumento1 paginaIFR API IdeasSpyros DimakisNessuna valutazione finora

- Domes Api IdeasDocumento1 paginaDomes Api IdeasSpyros DimakisNessuna valutazione finora

- S 614v18 12Documento66 pagineS 614v18 12Spyros Dimakis100% (1)

- Double Pipe Heat ExchangerDocumento5 pagineDouble Pipe Heat ExchangerSpyros DimakisNessuna valutazione finora

- Flare-Gas-Review in Oil and Gas IndustryDocumento19 pagineFlare-Gas-Review in Oil and Gas IndustrySpyros DimakisNessuna valutazione finora

- FrauDocumento1 paginaFrauSpyros DimakisNessuna valutazione finora

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalDocumento11 pagineStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalBryan Pérez PérezNessuna valutazione finora

- Bimetallic CorrosionDocumento20 pagineBimetallic CorrosionchristophedepaepeNessuna valutazione finora

- Diploma Thesis Numerical Modeling of Porous BurnersDocumento73 pagineDiploma Thesis Numerical Modeling of Porous BurnersSpyros DimakisNessuna valutazione finora

- Federico Garcia LorcaDocumento1 paginaFederico Garcia LorcaSpyros DimakisNessuna valutazione finora

- BrainDocumento1 paginaBrainSpyros DimakisNessuna valutazione finora

- History of Veterinary MedicineDocumento25 pagineHistory of Veterinary MedicineAli AsadullahNessuna valutazione finora

- Non Deterministic Finite AutomataDocumento30 pagineNon Deterministic Finite AutomataAnikNessuna valutazione finora

- Ultimate Guide To Construction SubmittalsDocumento10 pagineUltimate Guide To Construction SubmittalsDavid ConroyNessuna valutazione finora

- User Manual LCD Signature Pad Signotec SigmaDocumento15 pagineUser Manual LCD Signature Pad Signotec SigmaGael OmgbaNessuna valutazione finora

- C++ NotesDocumento129 pagineC++ NotesNikhil Kant Saxena100% (4)

- GEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1Documento73 pagineGEHC DICOM Conformance CentricityRadiologyRA600 V6 1 DCM 1030 001 Rev6 1 1mrzdravko15Nessuna valutazione finora

- Teaching TrigonometryDocumento20 pagineTeaching Trigonometryapi-21940065Nessuna valutazione finora

- Health Information SystemDocumento11 pagineHealth Information SystemVineeta Jose100% (1)

- Intelligent Transportation System SolutionsDocumento38 pagineIntelligent Transportation System SolutionsWisnu AjiNessuna valutazione finora

- War, Rivalry An State Building in Latin AmericaDocumento16 pagineWar, Rivalry An State Building in Latin AmericaPablo Andrés Garrido GonzálezNessuna valutazione finora

- Lab Report AcetaminophenDocumento5 pagineLab Report Acetaminophenapi-487596846Nessuna valutazione finora

- MBA 2020: Research on Online Shopping in IndiaDocumento4 pagineMBA 2020: Research on Online Shopping in Indiaprayas sarkarNessuna valutazione finora

- Intraoperative Nursing Care GuideDocumento12 pagineIntraoperative Nursing Care GuideDarlyn AmplayoNessuna valutazione finora

- De Thi HK 2 Tieng Anh 9 de 2Documento17 pagineDe Thi HK 2 Tieng Anh 9 de 2Lê Thu HiềnNessuna valutazione finora

- Product Manual 82434 (Revision C) : Generator Loading ControlDocumento26 pagineProduct Manual 82434 (Revision C) : Generator Loading ControlAUGUSTA WIBI ARDIKTANessuna valutazione finora

- OsmanabadDocumento5 pagineOsmanabadKirankumar MutnaliNessuna valutazione finora

- Process of Producting High Carbon Ferro ChromeDocumento5 pagineProcess of Producting High Carbon Ferro ChromeSantosh Kumar MahtoNessuna valutazione finora

- Assignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodDocumento4 pagineAssignment of A Glass Transition Temperature Using Thermomechanical Analysis: Tension MethodEric GozzerNessuna valutazione finora

- Assessment in Southeast AsiaDocumento17 pagineAssessment in Southeast AsiathuckhuyaNessuna valutazione finora

- Telegra Manual - DatasheetDocumento79 pagineTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- Samuel Vizcaino: Professional ProfileDocumento3 pagineSamuel Vizcaino: Professional ProfileVizcaíno SamuelNessuna valutazione finora

- CE ProblemDocumento5 pagineCE ProblemJho FNessuna valutazione finora

- DBIRS SyllabusDocumento2 pagineDBIRS SyllabusAshitosh KadamNessuna valutazione finora

- Salford Care Organisation Job Description & Person SpecificationDocumento14 pagineSalford Care Organisation Job Description & Person SpecificationAyesha EhsanNessuna valutazione finora

- Filler SlabDocumento4 pagineFiller Slabthusiyanthanp100% (1)

- Silicone Bonding BrochureDocumento4 pagineSilicone Bonding BrochureAmir ShahzadNessuna valutazione finora

- New ALS MADRASAH COMBINEDDocumento6 pagineNew ALS MADRASAH COMBINEDJane BaysaNessuna valutazione finora

- Canna DispensariesDocumento35 pagineCanna DispensariesWaf Etano100% (1)

- Financial Services : An OverviewDocumento15 pagineFinancial Services : An OverviewAnirudh JainNessuna valutazione finora

- MMADDocumento2 pagineMMADHariharan SNessuna valutazione finora