Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Char

Caricato da

Biju_PottayilCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Char

Caricato da

Biju_PottayilCopyright:

Formati disponibili

Technical Data Sheet

Approved 22740;22741 1 22740 epoxy ^(ValidationDate) 1

Jotachar JF750

Product description

This is a two component solvent free amine cured epoxy intumescent coating. Specially designed as intumescent

coating to provide fire protection for steel in hydrocarbon pool and jet fires for different types of structures and

equipment. No additional reinforcing mesh is required. To be used as mid coat as part of a complete system in

atmospheric environments. Suitable on approved primers on carbon steel, aluminium, hot dipped galvanized

steel and stainless steel substrates.

Typical use

Typically used in the oil, gas and energy industries. Suitable for both offshore and onshore environments.

In line with all epoxy intumescent technologies, the product is suitable for use on pipe work, vessels or

equipment operating up to 80 °C. Should it be necessary to install on substrates operating at higher

temperatures, please contact your local Jotun office for more information.

Other

Approvals and certificates

BS 476 Part 21 Hydrocarbon Pool Fire curve for structural and divisional fire protection

ISO 22899 Jet Fire Standard for structural and divisional fire protection

NORSOK M-501, System 5A, Rev. 6

ISO 20340 Cyclic Durability Testing

Resistance to Blast Over Pressure

Certified and approved by Lloyds Register of Shipping

Det Norske Veritas Type Approval

ANSI/UL 1709

Additional certificates and approvals may be available on request.

Colours

grey

Product data

Property Test/Standard Description

Solids by volume ISO 3233 100 %

Flash point ISO 3679 Method 1 100 °C

VOC-US/Hong Kong US EPA method 24 (tested) 0 g/l

The provided data is typical for factory produced products, subject to slight variation depending on colour.

All data is valid for mixed paint.

Film thickness per coat

Dry Film Thickness is in the range of 1 to 35 mm dependent upon the fire case and project specific requirements.

Typical Maximum Thickness per coat is 10 mm.

Higher film build can be achieved dependent upon steelwork configuration, geometry, ambient conditions, pump

type and set up as well as primer used.

Absolute maximum DFT is the thickness at which the system can be applied without sagging or slumping.

Date of issue: 6 June 2016 Page: 1/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotachar JF750

Surface preparation

To secure lasting adhesion to the subsequent product all surfaces shall be clean, dry and free from any

contamination.

Surface preparation summary table

Surface preparation

Substrate Minimum Recommended

Coated surfaces Clean, dry and undamaged compatible Clean, dry and undamaged compatible

coating (ISO 12944-4 6.1) coating (ISO 12944-4 6.1)

Application

Application methods

The product can be applied by

Spray: Use two component heated plural spray unit or modified airless spray (with heating

equipment). Refer to the Application Guide (AG) for additional information.

Note: All pumps used for the application of this product must be certified by Jotun.

Trowel: Refer to the Application Guide (AG) for additional information.

Product mixing ratio (by weight)

Jotachar JF750 Comp A 1 part(s)

Jotachar JF750 Comp B 1 part(s)

Individual components must have been stored for minimum 12 hours at 25 to 30 °C (77 to 86 °F). Stir/mix

thoroughly with a power agitator before application.

Thinner/Cleaning solvent

Thinner: Jotun Thinner No. 29

Thinning max.: 5 %

Thinning is typically 5 % by volume for modified airless spray and manual application.

Cleaning solvent: Jotun Thinner No. 7

Guiding data for airless spray

Nozzle tip (inch/1000): 31-41

Pressure at nozzle (minimum): 200 bar/2900 psi

Date of issue: 6 June 2016 Page: 2/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotachar JF750

Drying and Curing time

Substrate temperature 5 °C 15 °C 23 °C 40 °C

Surface (touch) dry 6h 3h 1 h 1 h

Walk-on-dry 24 h 12 h 6 h 3 h

Dry to over coat, minimum 6h 3h 2 h 1 h

Dried/cured for service 24 h 12 h 6 h 3 h

Drying and curing times are determined under controlled temperatures and relative humidity below 85 %, and

at average of the DFT range for the product.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Walk-on-dry: Minimum time before the coating can tolerate normal foot traffic without permanent marks,

imprints or other physical damage.

Dry to over coat, minimum: The shortest time allowed before the next coat can be applied.

Dried/cured for service: Minimum time before the coating can be permanently exposed to the intended

environment/medium.

Induction time and Pot life

Paint temperature 15 °C 23 °C

Pot life 45 min 40 min

Product compatibility

Depending on the actual exposure of the coating system, various primers and topcoats can be used in

combination with this product. Some examples are shown below. Contact Jotun for specific system

recommendation.

Previous coat: zinc epoxy, inorganic zinc silicate, epoxy, epoxy mastic

Subsequent coat: crosslinked acrylic, polyurethane, polysiloxane, epoxy

Primers used under this product must be approved by Jotun. For the list of approved primers, please consult

Jotun.

See Application Guide.

Packaging (typical)

Weight Size of containers

(litres)

Jotachar JF750 Comp A 20 kg / 10 kg / 20 /

2.5 kg 10

Jotachar JF750 Comp B 20 kg / 10 kg / 20 / 10 /

2.5 kg 5

The volume stated is for factory made colours. Note that local variants in pack size and filled volumes can vary

due to local regulations.

Date of issue: 6 June 2016 Page: 3/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotachar JF750

Storage

The product must be stored in accordance with national regulations. Keep the containers in a dry, cool, well

ventilated space and away from sources of heat and ignition. Containers must be kept tightly closed. Handle

with care.

Storage temperature not to exceed 35 °C.

Shelf life at 23 °C

Jotachar JF750 Comp A 12 month(s)

Jotachar JF750 Comp B 12 month(s)

In some markets commercial shelf life can be dictated shorter by local legislation. The above is minimum shelf

life, thereafter the paint quality is subject to re-inspection.

Caution

This product is for professional use only. The applicators and operators shall be trained, experienced and have

the capability and equipment to mix/stir and apply the coatings correctly and according to Jotun's technical

documentation. Applicators and operators shall use appropriate personal protection equipment when using this

product. This guideline is given based on the current knowledge of the product. Any suggested deviation to suit

the site conditions shall be forwarded to the responsible Jotun representative for approval before commencing

the work.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do

not inhale spray mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable

cleanser, soap and water. Eyes should be well flushed with water and medical attention sought immediately.

Colour variation

When applicable, products primarily meant for use as primers or antifoulings may have slight colour variations

from batch to batch. Such products may fade and chalk when exposed to sunlight and weathering.

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are often

used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product

itself. Minor product variations may be implemented in order to comply with local requirements. Jotun reserves

the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs

and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom)

version will prevail.

Date of issue: 6 June 2016 Page: 4/4

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Quantar RSS Manual PDFDocumento362 pagineQuantar RSS Manual PDFFrancisco NarvaezNessuna valutazione finora

- Creating Security Standards - Context, Structure and Must-Have ContentDocumento59 pagineCreating Security Standards - Context, Structure and Must-Have ContentBrayanNessuna valutazione finora

- ASME B17.2-1967 (2013) ScanDocumento12 pagineASME B17.2-1967 (2013) Scanvijay pawar100% (2)

- Huawei Optix 155 (622h) (Metro 1000) Description PDFDocumento7 pagineHuawei Optix 155 (622h) (Metro 1000) Description PDFTeddy100% (1)

- Designs Guide To en 1994-2, Eurocode 4Documento184 pagineDesigns Guide To en 1994-2, Eurocode 4Viet Duc Dang100% (3)

- List of Hazards Control MeasuresDocumento29 pagineList of Hazards Control Measuresテレブリコ ジェファーソン0% (1)

- Jotachar 1709 PDFDocumento5 pagineJotachar 1709 PDFBiju_PottayilNessuna valutazione finora

- H-046-006478-00 (2.0) HyLED Series Service Manual (En)Documento230 pagineH-046-006478-00 (2.0) HyLED Series Service Manual (En)Jose Ivan Carvajal Cortizos67% (3)

- AirConditioning & Ventilation TCX Methodology Rev# 1.1Documento12 pagineAirConditioning & Ventilation TCX Methodology Rev# 1.1Non Etabas GadnatamNessuna valutazione finora

- Identification Cards: Kingdom of Saudi Arabia Ministry of Interior High Commission For Industrial SecurityDocumento12 pagineIdentification Cards: Kingdom of Saudi Arabia Ministry of Interior High Commission For Industrial SecurityTalha AltafNessuna valutazione finora

- JOTUN Jotamastic 80Documento5 pagineJOTUN Jotamastic 80Hafiz KamalNessuna valutazione finora

- Pilot ACR: Technical Data SheetDocumento4 paginePilot ACR: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Tankguard StorageDocumento5 pagineTankguard StorageBiju_PottayilNessuna valutazione finora

- Penguard PrimerDocumento5 paginePenguard PrimerPutroedidohNessuna valutazione finora

- StyreneDocumento2 pagineStyreneBiju_PottayilNessuna valutazione finora

- Jotrun TDSDocumento4 pagineJotrun TDSBiju_PottayilNessuna valutazione finora

- Jotrun TDSDocumento4 pagineJotrun TDSBiju_PottayilNessuna valutazione finora

- Se LettDocumento4 pagineSe LettBiju_PottayilNessuna valutazione finora

- Solvalitt MidthermDocumento5 pagineSolvalitt MidthermBiju_PottayilNessuna valutazione finora

- Pioner PrimerDocumento4 paginePioner PrimerBiju_PottayilNessuna valutazione finora

- Jotun TDSDocumento2 pagineJotun TDSBiju_PottayilNessuna valutazione finora

- Jotun Malathon TDSDocumento5 pagineJotun Malathon TDSBiju_PottayilNessuna valutazione finora

- Muki EPSDocumento5 pagineMuki EPSBiju_PottayilNessuna valutazione finora

- Corro-Coat PE Series 50: Technical Data SheetDocumento3 pagineCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Pilot QD Primer: Technical Data SheetDocumento4 paginePilot QD Primer: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Jotun Siloxane Acrylic PrimerDocumento3 pagineJotun Siloxane Acrylic PrimerBiju_PottayilNessuna valutazione finora

- Jotamastic SF Alu: Technical Data SheetDocumento5 pagineJotamastic SF Alu: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Jotamastic 87 MIO50Documento5 pagineJotamastic 87 MIO50Biju_PottayilNessuna valutazione finora

- Jotatemp 1000 CeramicDocumento5 pagineJotatemp 1000 CeramicBiju_PottayilNessuna valutazione finora

- Jotatherm TB550Documento5 pagineJotatherm TB550Biju_PottayilNessuna valutazione finora

- Jotamastic Plus: Technical Data SheetDocumento5 pagineJotamastic Plus: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Jotamastic 87 GFDocumento5 pagineJotamastic 87 GFBiju_PottayilNessuna valutazione finora

- Jotamastic 87 AluminiumDocumento5 pagineJotamastic 87 AluminiumBiju_PottayilNessuna valutazione finora

- Penguard Special: Technical Data SheetDocumento5 paginePenguard Special: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Jotamastic 80 MIODocumento5 pagineJotamastic 80 MIOBiju_PottayilNessuna valutazione finora

- Jotun TDSDocumento2 pagineJotun TDSBiju_PottayilNessuna valutazione finora

- ArmourDocumento5 pagineArmourBiju_PottayilNessuna valutazione finora

- Imperite 300: Technical Data SheetDocumento4 pagineImperite 300: Technical Data SheetBiju_PottayilNessuna valutazione finora

- Mastervolt ManualDocumento2 pagineMastervolt ManualJimy HendrixNessuna valutazione finora

- FCT307 Machines Directive Quick GuideCDocumento7 pagineFCT307 Machines Directive Quick GuideCvarolomerNessuna valutazione finora

- AsmDocumento2 pagineAsmChristopher Nicolas A. Illanes FernandezNessuna valutazione finora

- Asme Sec V Art 6 Ed 2004Documento10 pagineAsme Sec V Art 6 Ed 2004Anonymous fnVTzv9XlNessuna valutazione finora

- Grundfosliterature 5235944 PDFDocumento324 pagineGrundfosliterature 5235944 PDFĐạt TrầnNessuna valutazione finora

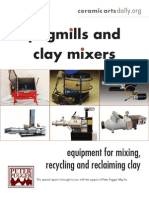

- Pug Mills MixersDocumento6 paginePug Mills MixersStefan Van CleemputNessuna valutazione finora

- IP HeaderDocumento1 paginaIP HeaderbajjiboyNessuna valutazione finora

- Dual WAN Connection On Cisco With Policy-Based Routing (PBR) Pierky's BlogDocumento9 pagineDual WAN Connection On Cisco With Policy-Based Routing (PBR) Pierky's BlogeciscoNessuna valutazione finora

- Oam 101430 bp04 DocDocumento44 pagineOam 101430 bp04 DocAshok ThiyagarajanNessuna valutazione finora

- GA1A2S100Documento10 pagineGA1A2S100Cedric BodinNessuna valutazione finora

- Principled PerformanceDocumento5 paginePrincipled PerformanceAbdul SyukurNessuna valutazione finora

- Inlocuire Dist k4m PDFDocumento7 pagineInlocuire Dist k4m PDFMugur AchiteiNessuna valutazione finora

- The ISO 30401 Knowledge Management Systems: A New Frame For Managing Knowledge. Conceptualisation and PracticeDocumento14 pagineThe ISO 30401 Knowledge Management Systems: A New Frame For Managing Knowledge. Conceptualisation and PracticeGANIMEDES TRIMEGISTRO ROSALES REYESNessuna valutazione finora

- VidyadhariDocumento5 pagineVidyadharividyadhari12Nessuna valutazione finora

- CDRB PresentationDocumento36 pagineCDRB PresentationZohaib Alam WarraichNessuna valutazione finora

- 651R 2 Matrix DetailsDocumento9 pagine651R 2 Matrix DetailsRaulNessuna valutazione finora

- Ferroli DOMIcondensF28 Boiler ManualDocumento12 pagineFerroli DOMIcondensF28 Boiler ManualLau454100% (1)

- PCR T465 ManualDocumento92 paginePCR T465 ManualpesotacosNessuna valutazione finora

- Solid State Digital Hourmeters & Counters 700 Series: FeaturesDocumento6 pagineSolid State Digital Hourmeters & Counters 700 Series: FeaturesEwerton BianchiNessuna valutazione finora

- Socomec Ups Netys - RT - 1100-3000-Operating - ManualDocumento28 pagineSocomec Ups Netys - RT - 1100-3000-Operating - ManualalvinkertNessuna valutazione finora

- Ole Op at orDocumento42 pagineOle Op at orVagelis AntoniouNessuna valutazione finora