Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Visual Inspection of Crimped Connections PDF

Caricato da

vinay gayateTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Visual Inspection of Crimped Connections PDF

Caricato da

vinay gayateCopyright:

Formati disponibili

Visual inspection of crimped connections

Insulation crimping Wire crimping

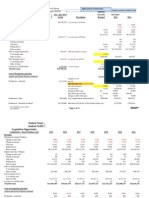

B or F-Crimp Contact twisted 0.03 – 0.56 mm2 (AWG 32 –20) 0.25 +/- 0.15 mm

Crimp flanks hit upon the

0.30 – 0.81 mm2 (AWG 22 –18) 0.25 +/- 0.15 mm crimp contact base

0.50 – 2.50 mm2 0.40 +/- 0.20 mm

Mismatch Insulation 2.50 – 6.00 mm2 0.60 +/- 0.30 mm

10°

Cross-section contact pierced

Insert slope Individual strands are not enclosed in wire crimp – Mismatch: conductor cross-section contact

(trumpet, bell mouth) must be visible! insertion error

Insulation is enclosed and fixed

The crimp flanks are closed

Note: In case of double crimping with differing

cross-sections and/or outer diameters, the smaller Crimp too Iso-crimp Insulation The twisting between the crimp zone and the contact Position deviation

cable is ALWAYS at the bottom! high overfilled pierced body must be a maximum of 10°! Insulation crimp Crimp not closed

Crimp flank bent 3° 5° Insertion slope allowed Crimp not filled

Overlapping crimp

Crimp is overpressed

Crimp too low Crimp too high

Mismatch

Mismatch Insulation

Cross-section contact pierced Cracks in crimp base and severe burr formation

Dividing tab must be present! (max. 0.5 mm)

Insulation is enclosed and fixed

The crimp flanks “overlap”

Insulation damaged Crimp flanks are closed, support each other and are Wire crimp is not closed and is overfilled Crimp flanks curl unevenly

Note: In case of double crimping with differing uniformly curledt

cross-sections and/or outer diameters, the smaller Crimp too Insulation

cable is ALWAYS at the bottom! high pierced

Note: The same quality standards Asymmetry:

apply for processing single wire seals Max. material Min. half

O or enclosed crimp thickness material thickness

Burr height

less than material Mismatch: conductor cross-section contact Mismatch: conductor Contact is not

thickness cross-section contact centred to the tool

Insulation is enclosed and fixed. Iso-crimp is Iso-crimp too large No damage to the insulation permissible! Burr height

The crimp flanks “overlap” one another “overpressed” Insulation not enclosed Pressure marks must be visible! less than half material thickness

Position of the conductor in the crimp contact Strands cut off or broken Functional zone of crimp contacts

Conductor and insulation Dividing tab too long and deformed Contact functional zone damaged and deformed

must be visible! End of the conductor must be visible!

Transition

damaged

Horizontal

± max. 3° Axial shift

Cable inserted too short

Cable stripped too short

Vertical

± max. 5°

Cable inserted too far Strands are broken in

the wire crimp

Note: Note: Crimp contacts with damaged, bent and deformed

Cable stripped too long Divider tab must be visible. functional zones (snap locks etc.) must NOT be “straight-

Length max. 0.5 mm ened out” and must always be disposed of as “bad parts”!

Definition of insulation crimp height in accordance with DIN 41 611 Part 3 Extraction force in accordance with DIN 46 249 Part 1, SEN 245010 and EN 60352-2: 2006 Measuring crimping dimensions

The insulation is not stripped, but only inserted Always perform extraction tests with insulation crimp open! Pull-Out Force of Crimp Connections Crimp height

in the insulation crimp zone and crimped. Nominal conductor Nominal size Extraction force (N) min. Crimp dimensions and tolerances for the crimp

cross-section (plug width) Testing has to be in accordance with Test 16d of IEC 60512. contact under test are to be taken from the relevant

The 30° deflection is applied without extraction force. Nominal size Nominal size

mm2 2.8 4.8–9.5 processing specification!

0.14 2.8 20 20 Wire Gauge Pull-Out Wire Gauge Pull-Out

Individual wires break off irregularly beyond the insert slope = Test OK! 0.25 2.8 40 40 Force Force Anvil Measuring tip

Crimp width

The cable must not fall out! 0.50 2.8 4.8 6.3 60 80 mm 2

AWG N mm 2

AWG N

0.75 2.8 4.8 6.3 70 120 0.05 30 6 1.3 16 135

1.00 2.8 4.8 6.3 80 160 0.08 28 11 1.5 150

1.50 4.8 6.3 200 0.12 26 15 2.1 14 200

Individual wires break irregularly beyond the insert slope = Crimp too low! 2.50 4.8 6.3 250 0.14 18 2.5 230

4.00 6.3 9.5 350 0.22 24 28 3.3 12 275

6.00 6.3 9.5 500 0.25 32 4.0 310

Wire crimp without cable

For different conductor cross sections the lower extraction force is definitive 0.32 22 40 5.3 10 355

in each case.The extraction forces for the nominal size 2.8 arise from the 0.5 20 60 6.0 360

lower material thickness. Excerpt: DIN 46 249 Part 1. 0.75 85 8.4 8 370

Crimp too high! Extraction forces in accordance with Cross-section Extraction for 0.82 18 90 10.0 380

Copyright by KabelForum –

DIE NECKARPRINZEN 999927. 0912.1‘.DD

Note: It is not sufficient to simply measure the conductor extraction SEN 245010: The SEN 245010 standard 0,75–50 mm2 150 N per mm2 1.0 108

force, as it could have the same value for different compression levels!

applies the most stringent QA requirements

for a crimp connection in international –95 mm2 120 N per mm2 IEC 60760, Section 17 and IEC 61210, table 9, show the same All rights reserved!

Inspection of the crimp dimensions is required! comparison. over 95 mm2 100 N per mm2 values for validation of crimp connections. www.kabelforum.de

www.we-online.com

Potrebbero piacerti anche

- Google Analytics Certification Test QuestionsDocumento36 pagineGoogle Analytics Certification Test QuestionsRoberto Delgato100% (1)

- Bias & LinearityDocumento8 pagineBias & LinearityVbaluyoNessuna valutazione finora

- Control and On-Off Valves GuideDocumento87 pagineControl and On-Off Valves Guidebaishakhi_b90100% (3)

- BQ Mechanical (Sirim)Documento7 pagineBQ Mechanical (Sirim)mohd farhan ariff zaitonNessuna valutazione finora

- Hughes Brothers PDFDocumento52 pagineHughes Brothers PDFJavier MaldonadoNessuna valutazione finora

- Eaton Tb09500001e PDFDocumento62 pagineEaton Tb09500001e PDFJuan E Torres MNessuna valutazione finora

- Tutorial Ip 2 Win EnglishDocumento25 pagineTutorial Ip 2 Win EnglishGarry Zein0% (1)

- KET Catalog Electronic ConnectorDocumento40 pagineKET Catalog Electronic ConnectorAraceli OrtizNessuna valutazione finora

- Styron 686E: High Heat Crystal PolystyreneDocumento2 pagineStyron 686E: High Heat Crystal PolystyreneMarwin PilayNessuna valutazione finora

- List of Internal Auditors & Competency - Qms Auditor: Updation Freq - YearlyDocumento1 paginaList of Internal Auditors & Competency - Qms Auditor: Updation Freq - YearlyShaili SharmaNessuna valutazione finora

- Forecast AnalysisDocumento15 pagineForecast AnalysisscotthnguyenNessuna valutazione finora

- Initialization : Fails Fails Fails Fails Fails FailsDocumento4 pagineInitialization : Fails Fails Fails Fails Fails FailsLuis SanchezNessuna valutazione finora

- 20160316162112020Documento2 pagine20160316162112020ahmedNessuna valutazione finora

- Dinse Dix-Sas-100-Dinse-Gmbh-DeDocumento42 pagineDinse Dix-Sas-100-Dinse-Gmbh-DeMNessuna valutazione finora

- Netstal Hourly Production Monitoring Sheet 08-08-2018Documento1 paginaNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456Nessuna valutazione finora

- Control Chart Analysis for Seaming OperationDocumento6 pagineControl Chart Analysis for Seaming Operationsudar1477Nessuna valutazione finora

- Set Up w2213 Maq 12-04 SiemensDocumento10 pagineSet Up w2213 Maq 12-04 SiemensCarlos EscobedoNessuna valutazione finora

- Properties of Common ThermoplasticsDocumento326 pagineProperties of Common ThermoplasticsjaithilagarajNessuna valutazione finora

- Transfopower Industries (PVT.) Limited: Forms & Formats SR# Form Name Form Reference NoDocumento6 pagineTransfopower Industries (PVT.) Limited: Forms & Formats SR# Form Name Form Reference NoUsman TirmiziNessuna valutazione finora

- Control Plan m6 Flange NutDocumento8 pagineControl Plan m6 Flange NutRANANessuna valutazione finora

- Up6 Manipulator System Manual PDFDocumento656 pagineUp6 Manipulator System Manual PDFrapeisl100% (2)

- US CrimpposterDocumento1 paginaUS CrimpposterGábor SulyokNessuna valutazione finora

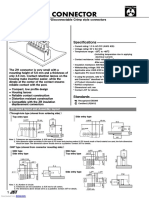

- Connector Connector: ZH Connector ZH ConnectorDocumento3 pagineConnector Connector: ZH Connector ZH ConnectorGreenoceanNessuna valutazione finora

- Chapter 5Documento5 pagineChapter 5Tan Mei QianNessuna valutazione finora

- Sub Miniature Power Relay: Specifications How To Order Coil DataDocumento1 paginaSub Miniature Power Relay: Specifications How To Order Coil DataShyam LalNessuna valutazione finora

- Instruction Sheet iC60NDocumento1 paginaInstruction Sheet iC60NFarhan YassarNessuna valutazione finora

- Fiber Reinforced Polymers in Civil Engineering: Harbin Institute of TechnologyDocumento49 pagineFiber Reinforced Polymers in Civil Engineering: Harbin Institute of TechnologyEngr Muhammad AbidNessuna valutazione finora

- Magnetic Sensors SMC-SMP Series and MagnetsDocumento2 pagineMagnetic Sensors SMC-SMP Series and MagnetsleandroNessuna valutazione finora

- Acs - Catálogo InglêsDocumento3 pagineAcs - Catálogo InglêsPaulo SergioNessuna valutazione finora

- 39 M Deck Type Truss Bridge - ConnectionDocumento1 pagina39 M Deck Type Truss Bridge - Connectionvibishnan100% (1)

- TEMA 1 MCBDocumento2 pagineTEMA 1 MCBEddy MusicNessuna valutazione finora

- Emboss Tape and Radial Tape Connector SpecsDocumento5 pagineEmboss Tape and Radial Tape Connector SpecspaulpuscasuNessuna valutazione finora

- Product Family: "Fuses Offer Unique Advantages Compared To Other Protective Devices."Documento18 pagineProduct Family: "Fuses Offer Unique Advantages Compared To Other Protective Devices."Mihaela AntonNessuna valutazione finora

- Turck Round Conector Bs5133-0Documento1 paginaTurck Round Conector Bs5133-0RAFAEL CARDOSONessuna valutazione finora

- Li9Yc (ST) 11Y 4X2X0.15 GN: Leoni Special Cables GMBHDocumento2 pagineLi9Yc (ST) 11Y 4X2X0.15 GN: Leoni Special Cables GMBHLeodoletaNessuna valutazione finora

- 2006-8035 Eng TdsDocumento6 pagine2006-8035 Eng TdsAPNessuna valutazione finora

- Safety Standard Recognized, 900 Series, Radial Disc, Encapsulated, AC Type, X1 440 VAC/Y2 300 VAC (Industrial Grade)Documento19 pagineSafety Standard Recognized, 900 Series, Radial Disc, Encapsulated, AC Type, X1 440 VAC/Y2 300 VAC (Industrial Grade)Luis OjedaNessuna valutazione finora

- Minimum Bending Radii For Cables: Solid Conductor Solid ConductorDocumento1 paginaMinimum Bending Radii For Cables: Solid Conductor Solid ConductorRinodhNessuna valutazione finora

- Brosur Nyaf 1 X 4 mm2 Biru 100 Meterrol JemboDocumento1 paginaBrosur Nyaf 1 X 4 mm2 Biru 100 Meterrol Jembom4l4ik4tny4w4Nessuna valutazione finora

- Installation and specifications for Autonics AFS terminal block seriesDocumento1 paginaInstallation and specifications for Autonics AFS terminal block seriesPaulo SergioNessuna valutazione finora

- Connector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocumento3 pagineConnector: 5.0mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsЕвгений ИвановNessuna valutazione finora

- doc2Documento10 paginedoc2Michael MitchellNessuna valutazione finora

- 7TKK000108 High-Tech Fuse Catalogue US DGTDocumento76 pagine7TKK000108 High-Tech Fuse Catalogue US DGTjrvvfNessuna valutazione finora

- (Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394Documento2 pagine(Material Number Old: 95353308) : Ex Solenoid Interlock Ex STM 295 1Ö1S/1Ö1S-R-FE Material Number: 1186394RD 88Nessuna valutazione finora

- AXE340124Documento9 pagineAXE340124jenny flyerNessuna valutazione finora

- WAGO 2006-1681 1000-449enDocumento9 pagineWAGO 2006-1681 1000-449ennhất phạmNessuna valutazione finora

- Eng SS 114-16008 PDocumento11 pagineEng SS 114-16008 PMuhammad SyafiiNessuna valutazione finora

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocumento5 pagineConnector: 2.5mm Pitch/disconnectable Crimp Style Connectorssaiful rizalNessuna valutazione finora

- Push-Pull Connectors Cable Mounted Plug CCA3 Series: CCA3P1/A12 1 2 P o L eDocumento1 paginaPush-Pull Connectors Cable Mounted Plug CCA3 Series: CCA3P1/A12 1 2 P o L eĦøÐâNessuna valutazione finora

- 20 - Anchor Bolt PERI 14-20 X 130Documento2 pagine20 - Anchor Bolt PERI 14-20 X 130Gaetano ScorsoneNessuna valutazione finora

- Toyo VCSDocumento12 pagineToyo VCSdony ramdhaniNessuna valutazione finora

- 67SPECTBDocumento22 pagine67SPECTBNishanth Navaneetha GopalakrishnanNessuna valutazione finora

- QP ReactorsDocumento17 pagineQP ReactorssaravanakumarpalaniNessuna valutazione finora

- Sub-D Feedthroughs: Three Versions For Different Technical RequirementsDocumento2 pagineSub-D Feedthroughs: Three Versions For Different Technical RequirementsDeaNessuna valutazione finora

- Connector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDocumento6 pagineConnector: 2.5mm Pitch/disconnectable Crimp Style ConnectorsDragos-Iulian NeacsuNessuna valutazione finora

- 7TKK000108 - High-Tech Fuse - Catalogue - US - DGTDocumento76 pagine7TKK000108 - High-Tech Fuse - Catalogue - US - DGTadrian garciaNessuna valutazione finora

- UNI - Z241 - 17 - 5 - 600x300 ModifiedDocumento23 pagineUNI - Z241 - 17 - 5 - 600x300 ModifiedpaulaNessuna valutazione finora

- Coaxial Connectors: Rohs CompliantDocumento9 pagineCoaxial Connectors: Rohs CompliantYounes AlzyoudNessuna valutazione finora

- Waterproof Toggle: Dual SealDocumento4 pagineWaterproof Toggle: Dual Sealvendry vidiantoroNessuna valutazione finora

- TL2201 3Documento3 pagineTL2201 3rakibul hasanNessuna valutazione finora

- TL2201 2065763Documento4 pagineTL2201 2065763rakibul hasanNessuna valutazione finora

- Drawings of FittingsDocumento2 pagineDrawings of FittingsAdoniyas Abayneh NegashNessuna valutazione finora

- 16 MMDocumento1 pagina16 MMThomas RisingNessuna valutazione finora

- 165AS3SpecsDocumento2 pagine165AS3SpecsCruz ArangoNessuna valutazione finora

- SEO-OPTIMIZED TITLE FOR SHEAR CALCULATIONSDocumento1 paginaSEO-OPTIMIZED TITLE FOR SHEAR CALCULATIONSRAJKUMARNessuna valutazione finora

- CM10 Series 10-Contact Plug SpecsDocumento1 paginaCM10 Series 10-Contact Plug Specsjroyal692974Nessuna valutazione finora

- Visual Inspection of Crimped ConnectionsDocumento1 paginaVisual Inspection of Crimped Connectionsvinay gayateNessuna valutazione finora

- Polycab Solar InverterDocumento2 paginePolycab Solar Invertervinay gayateNessuna valutazione finora

- Iec PCB 60194 STDDocumento17 pagineIec PCB 60194 STDvinay gayateNessuna valutazione finora

- IEC 61810-1 PreviewDocumento21 pagineIEC 61810-1 Previewvinay gayate0% (1)

- International Standard: Electromechanical Elementary Relays - Test and Measurement ProceduresDocumento9 pagineInternational Standard: Electromechanical Elementary Relays - Test and Measurement Proceduresvinay gayate100% (1)

- Textbook of Veterinary Homeopathy by DR MadrewarDocumento3 pagineTextbook of Veterinary Homeopathy by DR Madrewarvinay gayate0% (1)

- Textbook of Veterinary Homeopathy by J Saxton andDocumento1 paginaTextbook of Veterinary Homeopathy by J Saxton andनीरज आर्य वेदपथिकNessuna valutazione finora

- Milenium BypassDocumento1 paginaMilenium BypassdinotecNessuna valutazione finora

- I) CentrifugesDocumento46 pagineI) Centrifugesiahim87Nessuna valutazione finora

- 3P61 Service Manual PDFDocumento17 pagine3P61 Service Manual PDFgulaab786Nessuna valutazione finora

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Documento37 pagineQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarNessuna valutazione finora

- Tur C PDFDocumento86 pagineTur C PDFWilliam LambNessuna valutazione finora

- RefrigerationDocumento11 pagineRefrigerationBroAmirNessuna valutazione finora

- Phase Locked LoopDocumento4 paginePhase Locked LoopsagarduttaNessuna valutazione finora

- Suparco+ KRL Test Ques For Electrical EngrzDocumento5 pagineSuparco+ KRL Test Ques For Electrical Engrzمحمد فصیح آفتابNessuna valutazione finora

- College Report of Optical Burst SwitchingDocumento21 pagineCollege Report of Optical Burst Switchingimcoolsha999Nessuna valutazione finora

- YEZ-Conical Brake MotorDocumento3 pagineYEZ-Conical Brake MotorMech MallNessuna valutazione finora

- TN 46Documento23 pagineTN 46Khalil AhmadNessuna valutazione finora

- CAT775GDocumento32 pagineCAT775GAndy Chan100% (1)

- Strategic Information Systems Planning: Course OverviewDocumento18 pagineStrategic Information Systems Planning: Course OverviewEmmy W. RosyidiNessuna valutazione finora

- Applying The Haar Wavelet Transform To Time Series InformationDocumento27 pagineApplying The Haar Wavelet Transform To Time Series InformationJohn LemonNessuna valutazione finora

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDocumento12 pagineGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainNessuna valutazione finora

- OceanPixel Abundo Marine Renewable Energy An Emerging OptionDocumento96 pagineOceanPixel Abundo Marine Renewable Energy An Emerging OptionjopaypagasNessuna valutazione finora

- Scrap NFL PanipatDocumento9 pagineScrap NFL PanipatJitenderSinghNessuna valutazione finora

- Process Sizing CriteriaDocumento91 pagineProcess Sizing CriteriaMohammad BadakhshanNessuna valutazione finora

- Breaking Water Protection Paradigms: RTM Composite DomesDocumento52 pagineBreaking Water Protection Paradigms: RTM Composite DomesaerostressNessuna valutazione finora

- Load-Modulated Arrays Emerging MIMO TechnologyDocumento83 pagineLoad-Modulated Arrays Emerging MIMO TechnologysmkraliNessuna valutazione finora

- Microstructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic DeformationDocumento10 pagineMicrostructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic Deformationsoni180Nessuna valutazione finora

- AOE - FormDocumento8 pagineAOE - FormBimal GuptaNessuna valutazione finora

- 4PL Supply Chain Transformation SolutionsDocumento2 pagine4PL Supply Chain Transformation SolutionsGourav HegdeNessuna valutazione finora

- Piping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Documento3 paginePiping Class Sdxp10 - 1.4410 - (2507 Superduplex SS)Lucian GrigorasNessuna valutazione finora