Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 4, Design of Slab Revised

Caricato da

zeru3261172Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 4, Design of Slab Revised

Caricato da

zeru3261172Copyright:

Formati disponibili

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Reinforced Concrete Slab

A slab is a two dimensional structure, it carries load primary by bending action and transfers the load to

the supporting beams or walls and sometimes directly to columns. A structural section to be considered as a

slab, the minimum span shall not be less than four times the overall slab thickness. Slab is used to from a

variety of building elements like floors, roof, stair cases etc...

Classification of slabs

I. Based on support condition

Edge supported:-each corner of the slab is supported by beams

Edge unsupported:-the corner of the slab is free from beam support; the slab is rest

on columns (Flat Slab).

II. Based on structural section

Solid:- A slab that is uniform in section

Ribbed:- A slab that has a variation in section or hole in the slab.

Surafel T. Date:-November 29, 2017 Page 1

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

III. Based on structural action

One way slabs

They transfer load in one direction

(In the short direction)

-Long dimension

-Short dimension

≥2

Two way slabs

They transfer load in two directions.

-Long dimension

-Short dimension

<2

EBCS-2 recommendation on designing of slabs

Thickness

The following minimum thicknesses shall be adopted in design:

60 mm for slabs not exposed to concentrated loads (e.g. inaccessible roofs)

80 mm for slabs exposed mainly to distributed loads.

100 mm for slabs exposed to light moving concentrated loads (e.g. slabs accessible to light

motor vehicles)

120 mm for slabs exposed to heavy dynamic moving loads (e.g. slabs accessible to heavy

vehicles)

150 mm for slabs on point supports (e.g. flat slabs)

Flexural Reinforcement

The ratio of the secondary reinforcement to the main reinforcement shall be at least equal

to 0.2.

The geometrical ratio of main reinforcement in a slab shall not be less than

0.5

=

The spacing between main bars for slabs shall not exceed the smaller of 2D or 350 mm.

The spacing between secondary bars shall not exceed 400 mm.

Surafel T. Date:-November 29, 2017 Page 2

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Analysis and design of one-way solid slabs

If a slab is said to be one way then the ratio of the larger dimension to the short one is greater

than or equal to 2. This means the main reinforcement runs in one direction only.

The analysis carried out by assuming a beam of unit width (shaded area of 1m width in the

above picture) with a depth equal to the thickness of the slab and effective span length equal to the

distance between the supports. The strip of unit width may be analyzed in the same way as singly

reinforced rectangular section beam.

As the loads being transmitted to the supported beam, all reinforcement shall be placed at right

angles to these beams. However some additional bars may be placed in the other direction to carry

temperature and shrinkage stresses.

Generally, the design consists of selecting a slab thickness for deflection requirements and

flexural design carried out by considering the slab as a series of rectangular beams side by side.

To calculate spacing between bars, by selecting the diameter of the bar, as

1000

=

The maximum spacing between bars is

2 , ℎ ℎ

=

350

Minimum area of steel

0.5

≥

Surafel T. Date:-November 29, 2017 Page 3

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Design Example

Design the floor system of an Exhibition room which consists of one-way solid slab supported by beams. It

also subjected to a uniform load of 3KN/m2 for partition wall. Use concrete C25 and steel S300 class I

works and the floor finish is ceramic tile.

Solution

Design constant

25

= = = 20

1.25 1.25

0.85 0.85 × 20

= = = 11.33

ϒ 1.5

300

= = = 260.87

ϒ 1.15

260.87

= = = 28.78

0.8 0.8 × 11.33

= =

= 0.0035 = 200,000

11.33 0.0035

= 0.8 = 0.8 = 0.0253

+ 260.87 260.87

+ 0.0035

200000

To assure ductility

= 0.75 = 0.019

Check of one-way structural action

Panel Lx (m) Ly (m)

≥2

1 3 7 2.33>2 ,one-way

2 3 7 2.33>2 ,one-way

3 3.5 7 2 =2 ,one-way

Depth for deflection

= 0.4 + 0.6

400

Panel Le (mm) d(mm)

1 3000 24 106.25

2 3000 24 106.25

3 3500 24 123.96

Surafel T. Date:-November 29, 2017 Page 4

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Take the maximum value d=123.96mm

Overall depth D will be

Using

15mm concrete cover

Using ϕ10 reinforcement bar bottom

Using ϕ8 reinforcement bar transverse direction

D=123.96 + 15 + 10/2 =143.96mm, use 150mm

d=150-15-10/2=130mm

d1=150-15-10-8/2=121mm

Design Load

Dead load

From EBCS-1, Table 2.8 Flooring and Walling, for PVC covering (Ceramic

tile) the density is 16kN/m3 and its thickness=20mm

The density of the cement screed form EBCS-1 Table 2.1 =23kN/m3 and its

thickness=30mm

The density of C25 concrete is =25kN/m3

Self-weight of the slab = 0.15 × 25 / = 3.75 /

Cement screed= 0.03 × 23 / = 0.69 /

Ceramic tile = 0.02 × 16 / = 0.32 /

Partition load = 3 /

-------------------------------------

Total dead load DL=3.75 + 0.69 + 0.32 + 3 = 7.76kN/m2

Live load

Form EBCS-1, Table 2.9 category B C3, and form Table 2.10 we get the value

LL=5kN/m2

By considering one meter strip the design load will be

= 1.3 + 1.6 = 1.35 × 7.76 + 1.5 × 5 = (10.476 + 7.5) /

= Design dead load + Design Live load = (10.476 + 7.5)kN/m

Surafel T. Date:-November 29, 2017 Page 5

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Analysis

The variations in live load in different panels will result different bending moment values.

We use a Structural Analysis program called SAP2000 to do the analysis.

Surafel T. Date:-November 29, 2017 Page 6

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Surafel T. Date:-November 29, 2017 Page 7

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Summarizing the values

Loading Span AB Span BC Span CD

type Moment(KN.m) Moment(KN.m) Moment(KN.m)

Span(Field) Support Support Span(Field) Support Support Span(Field)

1 13.605 13.236 13.236 0 11.017 11.017 10.993

2 6.406 12.211 12.211 6.548 15.140 15.140 9.225

3 8.125 7.142 7.142 0 18.590 18.590 18.997

4 12.417 16.667 16.667 4.827 14.115 14.115 9.645

5 6.949 10.583 10.583 4.088 21.688 21.688 17.669

6 12.960 15.049 15.049 2.367 20.663 20.663 18.108

Maximum 13.605 16.667 16.667 6.548 21.668 21.688 18.997

Design the section for flexure (moment)

Mmax=21.688kN.m, b=1000mm, = 260.87

= 0.75 = 0.019

21.688 × 10

= = = 79.80 < 130 …. !

0.2952 0.2952 1000 11.33

Reinforcement

d=130mm, d1=121mm, b=1000mm, = 11.33 , = 260.87

The maximum spacing between bars is

2 , ℎ ℎ 2 × 150 = 300

= = =300mm

350 350

Minimum area of steel

0.5 0.5 × 1000 × 130

≥ = = 216.67

300

= 1− 1− , = , = ,

× 10

= = 78.54

4

Minimum reinforcements is needed in transverse direction; using ϕ8 reinforcement bar

d1=121mm

0.5 0.5 × 1000 × 121

= = = 201.67

300

× × .

= = 50.27 , = = .

= 249.27 , = 400

Use ϕ8 C/C 240

Surafel T. Date:-November 29, 2017 Page 8

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

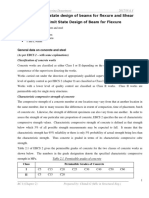

Location Moment ≤ 0.019 = Spacing S ≤ Actual S

(KN.m) ≥ (mm) (mm)

(mm2)

Field-AB 13.605 0.003204 416.54 188.55 180

Support-B 16.667 0.003961 514.94 152.52 150

Field-BC 6.548 0.001512 196.5 ≅216.67 399.69≅300 300

Support-C 21.668 0.005230 679.86 115.53 110

Field-CD 18.997 0.004547 591.11 132.87 130

Reinforcement detail

Surafel T. Date:-November 29, 2017 Page 9

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Analysis and Design of Two-Way Solid Slabs

Tow-way slab are a floor system whose individual panel are rectangular and the ratio of the larger to

smaller span is less than 2. They are composed of rectangular panels, supported at all four edges by beams

or walls stiff enough to be treated as unyielding.

The general procedure to design two-way slabs

1. Depth determination

The minimum effective depth for deflection can be calculated as

≥ 0.4 + 0.6

400

The overall depth D can be calculated

Longitudinal reinforcement

= + concrete cover +

2

Note that the reinforcement is in both directions

2. Design load calculation

Base on the limit state design method, the design load Pd is computed as follows

= 1.35 + 1.5

Where

DL is dead load including self-weight of the slab, partition wall, finishing etc…

LL live load

3. Analysis of individual panels (Moment)

The first step is to determine support and span moments for all panels. The support

and span moments are calculated as follows

=

= is the design moment per unit width at the point of reference.

= is a uniformly distributed design load

= the coefficient given in EBCS-2 Table A-1 as a function of (Ly/Lx) and support

condition of the panel.

= Longer span of the panel

= Shorter span of the panel

The subscript (i) has the following meaning

S=support

f=field (span)

x=direction of shorter span

y=direction of longer span

In table A-1 of EBCS-1 if the value of the aspect ratio (Ly/Lx) is between two values then use

linear interpolation.

This method is intended for slabs with uniformly distributed loads. If a slab is subjected to

a concentrated or line loads, in addition to a uniform load, these can generally be treated by

considering them as equivalent uniform loads using Reynould’s method, provided that the sum

of the non-uniform loads on panel does not exceed 20% of the total load.

4. Adjustments of support and span moment

I. Support Moment Adjustment

Let MR > ML

If (MR - ML)/ MR * 100 < 20% then the design moment Md

Md = (MR+ML)/2

If (MR- ML)/ MR * 100 ≥ 20% then distribute using their relative stiffness.

Surafel T. Date:-November 29, 2017 Page 10

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

1

= − ∆ = − ∆ , >

+ 1 1

+

1

= − ∆ = − ∆ , <

+ 1 1

+

= ℎ ℎ

∆ = − > ∆ = − >

II. Span Moment Adjustment

If the support moment is decreased, the span moment Mxf and Myf are then

increased to allow for changes of support moments.

= + ∆

= + ∆

Where

∆ = , −

, = coefficients for adjusting span moments given in EBCS-2 Table A-2

If the support moment is increased, no adjustment shall be made to the span

moment.

Surafel T. Date:-November 29, 2017 Page 11

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

5. Check the depth for flexure

≥

0.2952

If not satisfy, revise the design with a new depth calculated using the above equation.

6. Reinforcement design for flexure

We can calculate the reinforcement area using equation or design chart.

For a given and calculated data of

Material data C- and S-

Effective depth(d) ,Width(b=1000mm) and Design moment(Md)

I. Using equation

2

= 1− 1−

=

II. Using design chart

= →

=

To calculate spacing between bars, by selecting the diameter of the bar, as

1000

=

Compare the above design spacing S, with the minimum provision given by our code.

0.5

=

= 2

350

7. Reinforcement detail

The reinforcement bars can be detailed in such a way that at least 50% of the positive

bars is extended into the support. The negative bars may be terminated at a distance of Lx/4

to Lx/3 from the respective centerline point of the support.

8. Load transfer to frames

The design load on beams supporting solid slabs spanning into two direction at right angles

supporting distributed load may be assessed from the following equations.

=

=

EBCS-2 Table A-3 gives a value of load transfer coefficient , and the assumed

distribution of this loading is shown below.

Surafel T. Date:-November 29, 2017 Page 12

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Design Example

Design the floor system of an office building. Load form partition 2kN/m2, from floor finishing and screed

1kN/m2 .Using C25 and S300 class I works.

Solution

Design constant

25

= = = 20

1.25 1.25

0.85 0.85 × 20

= = = 11.33

ϒ 1.5

300

= = = 260.87

ϒ 1.15

= =

= 0.0035 = 200,000

11.33 0.0035

= 0.8 = 0.8 = 0.0253

+ 260.87 260.87

+ 0.0035

200000

To assure ductility

= . = .

Step 1 :- Depth determination

= 0.4 + 0.6

400

panel Lx Ly Ly/Lx<2 d(mm)

1 4000 4000 1 40 85

2 4000 6000 1.5 35 97.143

3 4000 5000 1.25 37.5 90.67

4 5000 6000 1.2 38 111.84

Maximum 111.84

Overall depth D will be using

15mm concrete cover

Using ϕ10 reinforcement bar bottom (it run perpendicular to the Longer span)

Using ϕ10 reinforcement bar transverse direction (above the bars that runs

perpendicular to the longer span, which runs parallel to the longer span.)

Longitudinal reinforcement

= + concrete cover +

2

10

= 111.84 + 15 + = 131.84

2

Let provide a minimum thickness for slab with concentrated load D=150mm

d=150-15-10/2=130mm d1=150-15-10-10/2=120mm

Surafel T. Date:-November 29, 2017 Page 13

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Step 2 :- Design load calculation

Dead load

The density of C25 concrete is =25kN/m3

Self-weight of the slab = 0.15m × 25KN/m = 3.75kN/m

Floor finishing and screed= 1kN/m

Partition load = 2 /

-------------------------------------

Total dead load DL=3.75 + 1+ 2 = 6.75kN/m2

Live load

Form EBCS-1, Table 2.9 category B C1, and form Table 2.10 we get the value

LL=3kN/m2

= 1.35 + 1.5 = 1.35 × 6.75 + 1.5 × 3 = 13.6125 N/m

Step 3 :- Analysis of individual panels (Moment)

Pd=13.6125kN/m2 =

Support Lx2 Mxs Mxf Mys Myf

Panel Ly/Lx αxs αxf αys αyf

Condition m kN.m kN.m kN.m kN.m

1 7 1 16 0.058 0.044 0 0.044 12.632 9.583 0 9.583

2 6 1.5 16 0 0.078 0.045 0.034 0 16.988 9.801 7.405

3 4 1.25 16 0.066 0.049 0.047 0.036 14.375 10.672 10.237 7.841

4 8 1.2 25 0 0.063 0.058 0.044 0 21.440 19.738 14.974

Surafel T. Date:-November 29, 2017 Page 14

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Step 4 :- Adjustments of support and span moment

I. Support Moment Adjustment

Adjustment between panel 1 and panel 2

ML=12.632kN.m

MR=9.801kN.m

− 12.632 − 9.801

100% = × 100% = 22.41% > 20%

12.632

1 1

= − ∆ = 12.632 − 4 × (12.632 − 9.801)

1 1 1 1

+ 4+4

= 11.217 .

Adjustment between panel 2 and panel 3

ML=9.801kN.m

MR=10.237kN.m

− 10.237 − 9.801

100% = × 100% = 4.26% < 20%

10.237

10.237 + 9.801

= = 10.019 .

2

Adjustment between panel 3 and panel 4

ML=14.375kN.m

MR=19.738kN.m

− 19.738 − 14.375

100% = × 100% = 27.17% > 20%

19.738

1 1

= − ∆ = 19.738 − 5 (19.738 − 14.375)

1 1 1 1

+ +

5 4

= 17.514 .

II. Span Moment Adjustment

Panel 1

∆ = − = 12.632 − 11.2165 = 1.4185

= 0.280

= 0.380

= + ∆ = 9.583 + 0.28 × 1.4185 = 9.980 .

= + ∆ = 9.583 + 0.38 × 1.4185 = 10.080 .

Panel 3

∆ = − = 10.237 − 10.019 = 0.218

= 0.332

= 0.154

= + ∆ = 10.672 + 0.332 × 0.218 = 10.744

= + ∆ = 7.841 + 0.154 × 0.218 = 7.875

Surafel T. Date:-November 29, 2017 Page 15

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Panel 4

∆ = − = 19.738 − 17.514 = 2.224

= 0.338

= 0.172

= + ∆ = 21.440 + 0.338 × 2.224 = 22.192

= + ∆ = 14.974 + 0.172 × 2.224 = 15.357

Step 5 :- Check the depth for flexure

= 22.192 . , = 260.87 , = 0.019, b=1000mm

22.192 × 10

= = = 81.46 < 120 …. !

0.2952 0.2952 1000 11.33

Step 6 :- Reinforcement design for flexure

b=1000mm=1m, d1=120mm=0.12m, d=130mm=0.13m

The maximum spacing between main bars is

2 , ℎ ℎ 2 × 150 = 300

= = =300mm

350 350

Minimum area of steel

0.5 0.5 × 1000 × 130

≥ = = 216.67

300

0.5 0.5 × 1000 × 120

≥ = = 200

300

Surafel T. Date:-November 29, 2017 Page 16

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

By using design table

= → , =

To calculate spacing between bars, by selecting the diameter of the bar, as

1000 × 10

= , = = 78.54

4

d or

Moment As S Provided

Location d1 Km Ks 2

KN.m mm mm Spacing

m

Mxs 11.217 0.13 25.763 3.999 345.05 228 220

Mxf 9.980 0.13 24.301 3.985 305.925 256.73 250

Panel 1

Mys

Myf 10.080 0.12 26.458 4.008 336.69 233.27 230

Mxs

Mxf 16.7 0.13 31.435 4.064 522.07 150.44 150

Panel 2

Mys,R 9.85 0.13 24.142 3.984 301.86 260.18 260

Myf 7.279 0.12 22.483 3.973 241 325.9 320

Mxs,L 9.85 0.13 24.142 3.984 301.86 260.18 260

Mxf 10.56 0.13 24.997 3.990 324.11 242.32 240

Panel 3

Mys,R 17.13 0.13 31.837 4.068 536.04 146.52 140

Myf 7.739 0.12 23.183 3.978 256.55 306.14 300

Mxs

Mxf 21.837 0.13 35.946 4.109 690.22 113.79 110

Panel 4

Mys 17.13 0.13 31.837 4.068 536.04 146.52 140

Myf 15.11 0.12 32.393 4.074 512.98 153.1 150

Surafel T. Date:-November 29, 2017 Page 17

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Step 7 :- Reinforcement detail

Surafel T. Date:-November 29, 2017 Page 18

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Step 8 :- Load transfer to frames

=

=

Pd=13.6125kN/m2

Lx Vx Vy

Support

Panel Ly/Lx Discont

Condition m Cont. Discont. Cont. Discont. Cont. Cont. Discont.

.

1 7 1 4 0.45 0.30 - 0.30

24.503 16.335 0 16.335

0 21.780 21.780 0

2 6 1.5 4 - 0.40 0.40 -

26.408 17.424 21.780 14.157

3 4 1.25 4 0.485 0.32 0.40 0.26

0 24.503 30.628 20.419

4 8 1.2 5 - 0.36 0.45 0.30

Surafel T. Date:-November 29, 2017 Page 19

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Surafel T. Date:-November 29, 2017 Page 20

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Surafel T. Date:-November 29, 2017 Page 21

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Surafel T. Date:-November 29, 2017 Page 22

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Design of one way ribbed Slab

In one way ribbed slab, the supporting beams called joists or ribs are closely spaced. The ribbed

floor is formed using temporary or permanent shuttering (form work) while the hollow block floor

is generally constructed with block made of clay tiles or with concrete containing light weight

aggregate. This type of floor is economical for buildings where there are long spans and light or

moderate live loads such as in hospitals and apartment buildings.

General requirements:

Because joists are closely spaced, thickness of slab (topping), tslab ≥ 40 mm or 1/10 clear

distance between ribs.

The topping shall be provided with a reinforcement mesh providing in each direction a

cross sectional area not less than 0.001 of the section of the slab.

Unless calculation requires, minimum reinforcement to be provided for joists include two

bars, where one is bent near the support and the other is straight.

Rib width bw ≥ 70 mm, and overall depth Dj ≤ 4 bw,joist , excluding tslab

Rib spacing is generally less than 1m.

In case of rib spacing larger than 1m, the topping need to be designed as if supported on

ribs (i.e. as one way solid slab between the ribs).

If the span of the ribs exceeds 6m, transverse ribs may be provided.

When transverse ribs are provided, the center to center distance shall not exceed 20 times

the overall depth of the ribbed slab.

The transverse ribs shall be designed for at least half the values of maximum moments and

shear force in the longitudinal ribs.

The girder supporting the joist may be rectangular or T-beam, with the flange thickness

equal to the floor thickness.

Procedure for design of a floor system of ribbed slab:

1. Thickness of topping and ribs assumed based on minimum requirements.

2. Loads may be computed on the basis of center line of the spacing of joists.

3. The joists are analyzed as continuous T-beams supported by girders.

4. Determine flexural reinforcement and consider minimum provision in the final solution.

5. Provide the topping or slab with reinforcement as per temperature and shrinkage

requirement.

6. Design the girder as a beam.

EBCS 2 - provisions

Web-Flange Connections

Surafel T. Date:-November 29, 2017 Page 23

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Surafel T. Date:-November 29, 2017 Page 24

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Design Example of one way Ribbed Slab

Design the floor system shown below which is made of ribbed slab. Dead load from partition wall

plus floor finishing and HCB block =3.5kN/m2 and floor Live Load =2kN/m2. Column dimension

30x30cm and Use Materials C30, S300 class I works.

Step 1 Geometry

Effective depth of joist or rib

Here Le = span of the joist = 5.5 m

βa can be taken similar to flat slab = 24

. . ∗

= (0.4 + ) =(0.4 + ) =195mm

Using ϕ12, 15mm concrete cover, ϕ6 stirrups

Over all depth

D=195+15+6+12/2=222mm <260mm …………………Ok!

Note: - overall depth (D) of the rib from the ribbed slab section is 260mm and its width

bw=80mm.

Use D=260mm

Overall depth of the joist D= 260mm≤ 4 bw = 4(80) = 320 mm. D provided is OK!

40

Thickness of slab (topping), ≥ ∗( )

From the ribbed slab section, the clear distance between ribs=320mm and the thickness

of the topping slab=60mm

Surafel T. Date:-November 29, 2017 Page 25

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

40

= 60 ≥ 1 = 40 …….

∗ (320 ) = 32

10

Step 2 Loading

Dead Load

Form self-weight topping slab + self-weight of the rib

= (0.06m * 0.4m * 25kN/m3) + (0.08 * 0.2 * 25) = 1kN/m

From partitions, Finishing and Block =3.5KN/m2 * 0.4m = 1.4kN/m

------------------------------------------------------------------------------------

Total Dead Load (DL)=1+1.4=2.4KN/m

Live Load(LL) = 2 * 0.4 = 0.8 KN/m

Design load(Pd)=1.35DL+1.5LL=1.35(2.4)+1.5(0.8)= 4.44kN/m

Step 3 Analysis

Step 4 Design for flexure

Design constant

. . ( . )

= ϒ

= .

= 13.6 , = ϒ

= .

= 260.87

= = , = 0.0035 = 200,000

13.6 0.0035

= 0.8 = 0.8 = 0.0304

+ 260.87 260.87

+ 0.0035

200000

To assure ductility = . = .

Surafel T. Date:-November 29, 2017 Page 26

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Check the depth for maximum moment

Mmax= 16.78kN.m, b = 80mm

Check it by using the limiting depth d

16.78 × 10

= = = 228.57

0.2952 0.2952 × 80 × 13.6

= 260 − 15 − 6 − 6 = 233 > 228.57 …….. !

Design of the mid span Section as a T-beam

5500

+ = 80 + = 1180

= 5 5

ℎ = 400

= 400

Assuming the NA to fall in the flange,

Mu=9.44KN.m

Mu = 0.8 x be fcd (d – 0.4x)

9.44 * 106 = 0.8x (400)*(13.6)*(233 – 0.4x)

Or x2 – 582.5x + 5422.794 = 0

On solving the above quadratic equation,

x = 9.46mm

Therefore, NA falls within the flange

As = (0.8 x be fcd)/fyd

= (0.8 * 9.46 * 400 * 13.6)/260.87

= 157.87 mm2

Number of 12 mm diameter rods = 157.87 / (π * 122/4) = 1.4

Use 2ϕ12

Design of support section as a rectangular beam

Overall depth D = 260mm; d = 233 mm

Breadth b = 80mm; Mmax = 16.78KNm

Mumax = 0.2952 fcd bd = 0.2952 * 13.6 * 80 * 2332 * 10-6 = 17.44KNm > 16.78KNm the

2

section is single reinforced.

= 0.0304

= 0.61 = 0.0185

2∗ 2 ∗ 16.78 ∗ 10 13.6

= (1 − (1 − )) = (1 − (1 − )) = 0.0179

80 ∗ 233 ∗ 13.6 260.87

0.5 0.5

= = = 0.0017

300

>

As = ρbd=0.0179*80*233=333.184mm2

Number of 12 mm diameter rods = 333.184 / (π * 122/4) = 2.95

Use 3ϕ12

Surafel T. Date:-November 29, 2017 Page 27

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Transverse reinforcement at topping.

Cross-section area of the topping Ac = 60 * 1000 = 60000 mm2

Based on EBCS-2, Ast = 0.001 Ac, Ast = 0.001*60000 = 60 mm2

Reinforcement in a unit width (i.e. 1m)

. ×

Spacing using ϕ6 = = 471.17

Use Ф6mm @ c/c 400mm in both directions (since secondary reinforcements shall

not be greater than 400mm spacing)

Step 5 Design for Shear

The design shear at d distance from the face of the support; we do center to center

analysis so the distance will be=30/2 + 233mm=248mm=0.248m. The design is

done for the maxmuim shear.

Maximum shear force at the support = 15.26kN

Shear force at the critical section (Vsd) = 14.16kN

VRD = 0.25 fcdbwd

= 0.25* 13.6 * 80 * 233 * 10-3=63.38kN

= 63.38KN >>14.16kN → ok

. . ×

= .

= .

=1.165Mpa

k1 = 1+50p = 1+50*0.0179 = 1.895≤ 2.0

k2 = 1.6 –d = 1.6-0.233 = 1.37 > 1.0

Vc = 0.25 fctdk1k2bwd

= 0.25*1.165*1.895*1.367*80*233*10-3

= 14.06kN ≤ Vsd=14.16kN

Since Vsd > Vc→ provide shear reinforcements

V = , Vs=Vsd-Vc

Consider 6 mm diameter stirrups with 2 legs,

Av = 2 * 62 * π / 4 = 56.55 mm2

56.55 × 260.87 × 233

= = =∞

(14.16 − 14.06) × 10

2/3*VRD=42.25>Vsd so the maximum spacing will be

But Smax = 0.5d = 0.5*233 = 116.5 mm

Use Ф6mm stirrup @ c/c 110 mm

Surafel T. Date:-November 29, 2017 Page 28

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Longitudinal shear (page 45, article 4.5.5. EBCS 2)

Flange in compression

Compression under maximum span moment

Mmax =16.78kNm, Maximum transverse Shear, Vsd = 14.16kN

x = 0.45 * 233 = 104.85

& Z = d – 0.4x = 233 – 0.4(104.85) = 191.06 mm

be = 400mm , bw = 80mm

Longitudinal shear for flange in compression,

− 400 − 80 14.04 × 1000 /

= = = 29.39 /

2 2 × 400 191.06

vsd = 29.39 KN/m

VRd 1 = 0.25 fcd hf = 0.25* 13.6* 60 = 204 KN/m

VRd 1 = 204 KN/m > 29.39 KN/m

Safe against failure by crushing of concrete.

= 0.50 ℎ +

Sf = Spacing of reinforcement in the topping perpendicular to the web-flange interface

= 400mm

Asf = Area of reinforcement per unit length perpendicular to the web-flange interface

× 1000 28.27 × 1000

= = = 70.69 /

400

70.69 × 260.87

= 0.50 × 1.165 × 60 + = 34.95 + 46.1

400

= 81.05 > 29.39 … . .

Flange in tension

Tension under maximum support moment

Mmax = 16.78Nm

Maximum transverse shear = Vsd = 14.16kN

z = 191.06 mm

As = 3ф12 = 3*113.1 = 339.29mm2 Asw = 2ф12 = 2*113.1 =226.2mm2

Longitudinal shear for flange in tension

− 339.29 − 226.2 14.04 × 1000 /

= = = 12.25 /

2 2 × 339.29 191.06

= 204 > 12.25 KN/m ……..safe

70.96 × 260.87

= = = 46.1 /

400

= 46.1 > 12.25 ….

Surafel T. Date:-November 29, 2017 Page 29

Hawasssa University iOT, School of Civil Engineering

Reinforced concrete Structures I

Step 6 Reinforcement Detailing

Reference

Ethiopian building code of standard -EBCS 1 and 2 of 1995.

Surafel T. Date:-November 29, 2017 Page 30

Potrebbero piacerti anche

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Chapter 4, Design of SlabDocumento32 pagineChapter 4, Design of Slabzeru3261172100% (2)

- 3 Design of Rectangular Beams - Ed1Documento23 pagine3 Design of Rectangular Beams - Ed1ሽታ ዓለሜ100% (1)

- Chapter 3 ExamplesDocumento15 pagineChapter 3 Exampleszeru326117283% (6)

- Steel Structure Chapter-2 ExampleDocumento17 pagineSteel Structure Chapter-2 Examplebini1221Nessuna valutazione finora

- RC-1 Example NewDocumento23 pagineRC-1 Example NewAnonymous VUXxu1gT100% (1)

- Assignment 3 & 4 - AnswersDocumento23 pagineAssignment 3 & 4 - Answersአድሜ ልስልሱ100% (2)

- Chapter 1 DesignDocumento17 pagineChapter 1 DesignAbera Mamo100% (2)

- Lateral Force Resisting Systems PDFDocumento59 pagineLateral Force Resisting Systems PDFhanose100% (4)

- RCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabDocumento46 pagineRCI Hand Out Chapter 4 - PPT - 4.2 One Way Ribbed SlabNathnael Jia100% (3)

- RC-1 Example 3.1Documento7 pagineRC-1 Example 3.1rabia jemal100% (2)

- Chapter 3 Flat-SlabsDocumento14 pagineChapter 3 Flat-SlabsAbera MamoNessuna valutazione finora

- RC.1 Example 4.1&6.1Documento10 pagineRC.1 Example 4.1&6.1ሽታ ዓለሜNessuna valutazione finora

- Chapter 2 Tension MembersDocumento8 pagineChapter 2 Tension MembersGamtesa EjetaNessuna valutazione finora

- Problems (Beams)Documento15 pagineProblems (Beams)Haftom Gebreegziabiher100% (3)

- Chapter3 - Analysis Ofwind Loads Acting On StructuresDocumento6 pagineChapter3 - Analysis Ofwind Loads Acting On Structuresh0% (1)

- Chap. 1Documento27 pagineChap. 1Alemayehu DargeNessuna valutazione finora

- Chapter 2: Analysis and Design of RC Slabs Per EbcsDocumento45 pagineChapter 2: Analysis and Design of RC Slabs Per EbcsCaalaa Bashaa100% (5)

- Steel Structure Final 1 PDFDocumento50 pagineSteel Structure Final 1 PDFMesfinNessuna valutazione finora

- RC Example ES-EN Code-1Documento17 pagineRC Example ES-EN Code-1Firomsa EntertainmentNessuna valutazione finora

- Example For CH-2Documento25 pagineExample For CH-2antenehNessuna valutazione finora

- Chapter 1 Powerpoint - Steel StructuresDocumento47 pagineChapter 1 Powerpoint - Steel StructuresMubarek AbduljebarNessuna valutazione finora

- KIoT Civil Engineering Department - Model Exit ExamDocumento22 pagineKIoT Civil Engineering Department - Model Exit ExamBayisa Dagne100% (2)

- Hydraulic Structure II AssignmentDocumento6 pagineHydraulic Structure II Assignmentmasre1742100% (1)

- Chapter 2 - Design of Beam For Flexure and ShearDocumento43 pagineChapter 2 - Design of Beam For Flexure and ShearZemen JM100% (2)

- CH 01-ColumnsDocumento30 pagineCH 01-Columnsnvnrev100% (1)

- Soil Mechanics 2Documento13 pagineSoil Mechanics 2Negesa100% (1)

- Examples On Design of Flexural Members: M KN X X MDocumento9 pagineExamples On Design of Flexural Members: M KN X X MTesfa HunderaNessuna valutazione finora

- Example NR 2. CH 4Documento11 pagineExample NR 2. CH 4Tesfa Hundera100% (1)

- Ribbed Slab 1Documento20 pagineRibbed Slab 1ephrem100% (2)

- Part 2 - Roof Analysis and Design PDFDocumento40 paginePart 2 - Roof Analysis and Design PDFhanose100% (6)

- Highway Integraated Design ProjectDocumento92 pagineHighway Integraated Design ProjectDaniel100% (1)

- RCI Hand Out Chapter 4 - PPT - 4.3 Two Way Solid SlabDocumento70 pagineRCI Hand Out Chapter 4 - PPT - 4.3 Two Way Solid SlabNathnael Jia67% (3)

- RC Chapter 4 Edge Supported Two Way SlabsDocumento66 pagineRC Chapter 4 Edge Supported Two Way SlabsAshu NegnNessuna valutazione finora

- Foundation Engineering-I Design of ShallDocumento44 pagineFoundation Engineering-I Design of ShallFatima Al-Doski100% (1)

- Example 3.4 - Continuous One Way Slab-Updated 080812Documento12 pagineExample 3.4 - Continuous One Way Slab-Updated 080812Muhammad Farhan Gul86% (7)

- Example 3.4 - One Way Continuous SlabDocumento12 pagineExample 3.4 - One Way Continuous SlabFareez Sedaka50% (4)

- Lecture#1 Guide BankDocumento34 pagineLecture#1 Guide BankManamno Beza100% (1)

- Course Outline - CEng 3204 - Foundation Engineering I - 2020 PDFDocumento1 paginaCourse Outline - CEng 3204 - Foundation Engineering I - 2020 PDFNatty TesfayeNessuna valutazione finora

- Chapter 3 Inelastic Redistribution of MomentsDocumento6 pagineChapter 3 Inelastic Redistribution of MomentsMesfin DerbewNessuna valutazione finora

- RC III Ch-3 - Reinforced Concrete WallsDocumento11 pagineRC III Ch-3 - Reinforced Concrete WallsJo YohannesNessuna valutazione finora

- Flat SlabDocumento33 pagineFlat SlabHelen Negash100% (1)

- Examples On Chapter 1 (1) #1Documento17 pagineExamples On Chapter 1 (1) #1Boom OromiaNessuna valutazione finora

- Chapter 4 - COLUMNSDocumento21 pagineChapter 4 - COLUMNSHelen NegashNessuna valutazione finora

- Final Report ....Documento47 pagineFinal Report ....Sai Gowtham100% (1)

- #1 What Are The Typical Characterstics Black Cotton Soil?Documento16 pagine#1 What Are The Typical Characterstics Black Cotton Soil?yeshi janexoNessuna valutazione finora

- Water Supply and Urban Drainage PDFDocumento107 pagineWater Supply and Urban Drainage PDFManiko Maniko100% (1)

- Chapter 1 Design of Roof and Truss B G 4Documento34 pagineChapter 1 Design of Roof and Truss B G 4Eyoel Ashagre100% (5)

- Chapter-Ii Types of FoundationsDocumento61 pagineChapter-Ii Types of FoundationsVijaykumar Nagnaik100% (1)

- Bahirdar University Bahirdar Institute of Technology Faculty of Civil and Water Resources Engineering Structural Design Mini ProjectDocumento18 pagineBahirdar University Bahirdar Institute of Technology Faculty of Civil and Water Resources Engineering Structural Design Mini ProjectYONAS GOSANessuna valutazione finora

- Column-Design EthiopianDocumento8 pagineColumn-Design EthiopianMesfin100% (2)

- RCII Column Design Solved Examples: Example 2.1. (Classification of Columns)Documento18 pagineRCII Column Design Solved Examples: Example 2.1. (Classification of Columns)Dechas MohammedNessuna valutazione finora

- Substitute Frame AnalysisDocumento5 pagineSubstitute Frame Analysissiniann7100% (1)

- Irrigation Model Ques AnswerDocumento6 pagineIrrigation Model Ques AnswerBeza Getachew100% (3)

- One Way & 2way Slab Desi̇gnDocumento24 pagineOne Way & 2way Slab Desi̇gnObsii W Busha LaloNessuna valutazione finora

- Chapter 8Documento12 pagineChapter 8gilbert850507Nessuna valutazione finora

- Mod 3Documento59 pagineMod 3Eesha NairNessuna valutazione finora

- UNIT-3 NotesDocumento23 pagineUNIT-3 NotesKrishnakanth ChidreNessuna valutazione finora

- Analysis and Design of SlabsDocumento5 pagineAnalysis and Design of SlabsKulal SwapnilNessuna valutazione finora

- Chapter 2.1Documento101 pagineChapter 2.1zeru3261172Nessuna valutazione finora

- Chapter 5 Staircase Types, Analysis and DesignDocumento15 pagineChapter 5 Staircase Types, Analysis and Designzeru32611720% (1)

- Chapter 2.2Documento92 pagineChapter 2.2zeru3261172100% (2)

- Chapter Four: Design of Shallow Foundations Lecture OneDocumento27 pagineChapter Four: Design of Shallow Foundations Lecture Onezeru3261172Nessuna valutazione finora

- Chapter 3 Design of Beam For Flexure and ShearDocumento37 pagineChapter 3 Design of Beam For Flexure and Shearzeru3261172Nessuna valutazione finora

- Foundation HU Lec 1Documento20 pagineFoundation HU Lec 1zeru3261172Nessuna valutazione finora

- Foundation HU Lec 4Documento40 pagineFoundation HU Lec 4zeru3261172Nessuna valutazione finora

- Chapter 1 IntroductionDocumento10 pagineChapter 1 Introductionzeru3261172Nessuna valutazione finora

- CH 77Documento1 paginaCH 77zeru3261172Nessuna valutazione finora

- CH 44Documento7 pagineCH 44zeru3261172Nessuna valutazione finora

- Algorithms Pseudocode Flowcharts PDFDocumento20 pagineAlgorithms Pseudocode Flowcharts PDFzeru3261172Nessuna valutazione finora

- Section 2 Electrostatics: Superposition of ForcesDocumento10 pagineSection 2 Electrostatics: Superposition of Forceszeru3261172Nessuna valutazione finora

- Chapter 6-Traffic Control Devices and SystemsDocumento2 pagineChapter 6-Traffic Control Devices and Systemszeru3261172Nessuna valutazione finora

- Chapter 5-Fundamental Principles of Traffic FlowDocumento2 pagineChapter 5-Fundamental Principles of Traffic Flowzeru3261172Nessuna valutazione finora

- ch4 TPDocumento27 paginech4 TPzeru3261172Nessuna valutazione finora

- FlowchartsDocumento25 pagineFlowchartszeru3261172Nessuna valutazione finora

- Electrodynamics IIDocumento1 paginaElectrodynamics IIzeru32611720% (1)

- Car Section 2 Series (H) Part-IiDocumento6 pagineCar Section 2 Series (H) Part-Iipandurang nalawadeNessuna valutazione finora

- 103-Article Text-514-1-10-20190329Documento11 pagine103-Article Text-514-1-10-20190329Elok KurniaNessuna valutazione finora

- Din 48204Documento3 pagineDin 48204Thanh Dang100% (4)

- AURTTA104 - Assessment 2 Practical Demonstration Tasks - V3Documento16 pagineAURTTA104 - Assessment 2 Practical Demonstration Tasks - V3muhammaduzairNessuna valutazione finora

- Eea2a - HOLIDAY HOMEWORK XIIDocumento12 pagineEea2a - HOLIDAY HOMEWORK XIIDaksh YadavNessuna valutazione finora

- Contract 1 ProjectDocumento21 pagineContract 1 ProjectAditi BanerjeeNessuna valutazione finora

- CNNPX310R-6P: General SpecificationsDocumento5 pagineCNNPX310R-6P: General SpecificationsZoheir KacimiNessuna valutazione finora

- Smart Cockpit System Questions - FlattenedDocumento85 pagineSmart Cockpit System Questions - FlattenedBarut Brkk100% (4)

- TAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardDocumento5 pagineTAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardNguyenSongHaoNessuna valutazione finora

- Tripura 04092012Documento48 pagineTripura 04092012ARTHARSHI GARGNessuna valutazione finora

- Final Project Synopsis 1Documento90 pagineFinal Project Synopsis 1Shyam YadavNessuna valutazione finora

- Supply Chain Management 101Documento36 pagineSupply Chain Management 101Trần Viết ThanhNessuna valutazione finora

- Project BAGETS Wok Plan and Budget SIPDocumento4 pagineProject BAGETS Wok Plan and Budget SIPMaia AlvarezNessuna valutazione finora

- Pitch AnythingDocumento8 paginePitch AnythingDoland drumb100% (1)

- AAPG 2012 ICE Technical Program & Registration AnnouncementDocumento64 pagineAAPG 2012 ICE Technical Program & Registration AnnouncementAAPG_EventsNessuna valutazione finora

- Defenders of The Empire v1.4Documento13 pagineDefenders of The Empire v1.4Iker Antolín MedinaNessuna valutazione finora

- Day 2 - Evident's Official ComplaintDocumento18 pagineDay 2 - Evident's Official ComplaintChronicle Herald100% (1)

- PST SubjectDocumento2 paginePST SubjectCarol ElizagaNessuna valutazione finora

- A History of The Ecological Sciences, Part 1 - Early Greek OriginsDocumento6 pagineA History of The Ecological Sciences, Part 1 - Early Greek OriginskatzbandNessuna valutazione finora

- Revised PARA Element2 Radio LawsDocumento81 pagineRevised PARA Element2 Radio LawsAurora Pelagio Vallejos100% (4)

- Sample TRM All Series 2020v1 - ShortseDocumento40 pagineSample TRM All Series 2020v1 - ShortseSuhail AhmadNessuna valutazione finora

- LampiranDocumento26 pagineLampiranSekar BeningNessuna valutazione finora

- Slem Descriptive EssayDocumento2 pagineSlem Descriptive EssayMary Jane DingalNessuna valutazione finora

- L Rexx PDFDocumento9 pagineL Rexx PDFborisg3Nessuna valutazione finora

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Documento222 pagineMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesNessuna valutazione finora

- Ccie R&s Expanded-BlueprintDocumento12 pagineCcie R&s Expanded-BlueprintAftab AlamNessuna valutazione finora

- Dark Energy Survey DES CollaborationDocumento38 pagineDark Energy Survey DES CollaborationgeorgcantorNessuna valutazione finora

- Projected Costs of Generating Electricity (EGC) 2005Documento233 pagineProjected Costs of Generating Electricity (EGC) 2005susantojdNessuna valutazione finora

- Advocating For Appropriate Educational ServicesDocumento32 pagineAdvocating For Appropriate Educational ServicesTransverse Myelitis AssociationNessuna valutazione finora

- Solution Documentation For Custom DevelopmentDocumento52 pagineSolution Documentation For Custom DevelopmentbayatalirezaNessuna valutazione finora