Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2001 ICJ - Part2

Caricato da

AnoopBharathanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2001 ICJ - Part2

Caricato da

AnoopBharathanCopyright:

Formati disponibili

International standards for

durability of RC structures:

Part II Recommendations

for IS 456 : 2000

M.B. Anoop, K. Balaji Rao, T .V

T.V .S.R. Appa Rao,

.V.S.R.

S. Gopalakrishnan

The first part of this paper, published in September 2001 issue Recommendations for changes in

of this journal, contained a detailed review of the provisions IS 456: 2000

in various international codes and standards for ensuring

Durability of concrete structures was one of the major thrust

durability of reinforced concrete structures. The recently revised

area for changes in the recent revision of IS 456. In this revision,

IS 456 : 2000 identifies durability as a major criterion in the in order to introduce in-built protection from factors affecting

design of RC structures; however, the review of various a structure, the existing durability related clause in

international durability provisions indicates that there is a IS 456 : 1978 has been improved and elaborated, and a detailed

scope for improvement in the current provisions for durability. clause covering different aspects of design of durable

The part II of the paper* presents a list of recommendations for structure has been incorporated. For example, while IS 456 :

changes in the durability provisions of IS 456 : 2000. 1978 defines only three classes of exposure, IS 456 : 2000

defines five classes of exposure thus providing a more detailed

(Continued from pp. 559-569 of September 2001 issue)

classification. The maximum value of w-c ratio for mild

In 1996, CEB decided to accept a performance-based approach

exposure condition specified by IS 456 : 1978 was 0.65, which

with explicit attention for the design life, limit states and

is very high compared to most of other codes of practice and

reliability. The Western Scheldt tunnel (in Netherlands) is the

has been reduced to 0.55 in IS 456 : 2000. While IS 456 : 1978

first concrete structure that has been designed completely on

specified a minimum grade of concrete to be used for all RC

the basis of service life, performance and reliability concepts1.

constructions irrespective of the exposure classes,

Attempts are being made internationally to incorporate the

IS 456 : 2000 specifies explicitly the minimum grade of concrete

concept of service life in the codes of practices. This change in

to be used in different exposure zones. While these changes

trend world over has been reflected in the recently-revised

will help in integrating the service life design with limit state

Indian standard code of practice for plain and reinforced concrete,

design, there is a scope for improvement over the current

IS 456 : 2000, in which durability is identified as a major criteria

in the design of RC structures and due emphasis is given to

the specifications of durability requirements2.

November 2001 * The Indian Concrete Journal 693

Table 1: Proposed exposure classification for IS 456 : 2000

Exposure Definition of exposure conditions as stated in IS 456 : 2000 Modified definition of exposure conditions suggested

class

Mild Concrete surfaces protected against weather or Concrete surfaces in inland zone protected against weather

aggressive conditions, except those situated in coastal area or not exposed to aggressive conditions

Moderate Concrete surfaces sheltered severe rain or freezing whilst wet Concrete members in inland zone with low temperature and low rainfall

Concrete exposed to condensation and rain Concrete members in inland or near-coastal zone with medium temperature and low

Concrete continuously under water to medium rainfall

Concrete in contact or buried under non-aggressive soil/ground water Concrete members in near-coastal zone protected against weather or not exposed to

Concrete surfaces in coastal zone sheltered from salt air aggressive conditions

Concrete surfaces sheltered from saturated salt air in coastal areas Concrete members submerged in fresh water

Concrete in contact with or buried under non-aggressive sub-soil or ground water

Severe Concrete surfaces exposed to severe rain, alternate wetting and drying, Concrete members in inland or near-coastal zone with high temperature

or occasional freezing whilst wet or severe condensation Concrete members in inland or near-coastal zone with medium temperature and heavy

Concrete completely immersed in sea water rainfall

Concrete exposed to coastal environment Concrete members in coastal zone with medium temperature

Concrete members submerged in seawater

Concrete members in contact with slightly aggressive chemical environments*

Very severe Concrete surfaces exposed to sea water spray, corrosive fumes Concrete members in coastal zone with high temperature

or severe freezing conditions whilst wet Concrete members in inland zone with very low temperature (annual average

Concrete in contact with or buried under aggressive temperature less than 10oC) and medium to heavy rainfall

sub-soil/ground water Concrete members in tidal zone

Concrete members in contact with moderately aggressive chemical environments*

Extreme Surface of members in tidal zone Concrete members exposed to seawater spray

Members in direct contact with liquid/solid aggressive chemicals Concrete members in contact with highly aggressive chemical environments*

Note: * the classification specified in Eurocode 2 is used for the classification of chemical environment; for details refer Table. 5.8-3 of reference 39

provisions for durability. The following recommendations

are proposed for consideration in the future revision of on many of the deterioration processes. The average

IS 456 : 2000. These recommendations are based on the review annual rainfall available in different parts of the

presented in this paper, and the information available in the country as shown in Fig 2. Broadly, three different

public domain on temperature, rainfall and corrosion rainfall regions can be identified in India; heavy rainfall

aggressivity of environment. regions (regions with annual rainfall greater than 200

cm), medium rainfall regions (regions with annual

(i) IS 456 : 2000 defines five classes of exposure, as against rainfall between 40 cm and 200 cm), and low rainfall

three classes of exposure defined in IS 456 : 1978, to regions (regions with annual rainfall less than 40 cm).

cater for different environments encountered in The concentration of chloride and carbon dioxide

practice. These definitions of exposure conditions are define the corrosivity of the environment. It can be

general and are qualitative. A more rational

classification of the exposure conditions can be made

based on the available information on the

environmental parameters influencing the durability

of reinforced concrete. The major environmental

parameters that influence the different deterioration

mechanisms in reinforced concrete are temperature,

rainfall, and concentration of chlorides and carbon

dioxide3,4. For instance, it is known that an increase in

temperature accelerates the chemical reactions leading

to the deterioration of reinforced concrete. A simple

rule-of-thumb is that an increase in temperature of

10oC causes a doubling of the rate of reaction5. The

annual average temperatures for different parts of

the country are shown in Fig 1. Based on the annual

average temperature, India can be broadly divided

into three regions, namely, high temperature regions

(regions with average annual temperature greater

than 27.5oC), medium temperature regions (regions

with average annual temperature between 20.0oC and

27.5oC), and low temperature regions (regions with

average annual temperature less than 20.0oC).

The amount of rainfall influences the moisture

conditions within the cover zone of the concrete4. The source: www.mapsofindia.com

moisture conditions in concrete have significant effect Fig 1 The average annual temperature in India

694 The Indian Concrete Journal * November 2001

Table 2: Values of diffusion coefficients for OPC concrete and concrete Thus, the time to initiation of reinforcement

with PFA as cement replacement material based on experiments carried corrosion increases.

out at SERC, Chennai 43

No Cement Water- Cement Superpl- Compressive Diffusion SERC, Chennai has been conducting

replacement binder content, asticiser, strength at coefficient, experiments for characterising the durability

90 days × 10 , m /s

3 3 -12 2

material, percent ratio kg/m l/m 28 days

properties of ordinary portland cement concrete

1 - 0.3 520 13 83.5 93.7 0.204

(OPC) and high performance cement concrete

2 25 percent flyash 0.3 390 13 85.2 94.0 0.102

(HPC) mixes. Some of the results of these

3 50 percent flyash 0.4 240 2.4 40.0 45.0 0.047

experiments for concrete with pulverised fly ash

Note: The values of diffusion coefficient reported here are based on the results obtained from rapid

chloride penetration test (RCPT) of 6 hours duration performed according to AASHTO specifications 11 (PFA) as cement replacement material are given

in Table 2. From this table, it is noted that as the

amount of cement replacement material

increases, the value of diffusion coefficient of concrete

observed from the corrosivity map of India, Fig 3,

for chlorides decreases. For instance, value of diffusion

that the corrosivity of the environment depends upon

coefficient of concrete with 25 percent PFA as cement

the distance from the sea. The Australian code,

replacement material is about half of that of OPC

AS 3600, classifies the exposure in accordance with the 6

concrete . This is attributed to the improvement in

distance of the structure from the coastline. Following

microstructure of concrete due to the addition of PFA.

the exposure classification specified in AS 3600, three

The durability based service life design of structures

zones can be identified for classifying the

involves the determination of the time to corrosion

environmental aggressivity in India, namely :

initiation. The time to corrosion initiation can be

inland zone (greater than 50 km from the coastline), determined using Ficks second law of diffusion. This

requires the values of diffusion coefficient, surface

near-coastal zone (1 to 50 km rom the coastline), and chloride content, and critical chloride content.

coastal zone (less than1km from the coastline). Experiments by Thomas and Takagi et al have shown

that for reinforcement embedded in concrete with

Also, the aggressive chemical environment, which has mineral admixtures, the value of critical chloride

been classified as extreme exposure in IS 456 : 2000, can be content is smaller compared to reinforcement

divided into three sub-classes as defined in Eurocode 2 as 7,8

embedded in OPC concrete . For instance, Thomas

slightly aggressive chemical environment, moderately has reported a critical chloride content of 0.50 percent

aggressive chemical environment, and highly aggressive by weight of cementitious material for concrete with

chemical environment. In IS 456 : 2000, tidal zone is classified 30 percent PFA as cement replacement material while

as extreme exposure while sea water spray is considered to the critical chloride content for OPC concrete is 0.70

be very severe exposure. It is noted from literature that sea percent by weight of cement7.

4

water spray conditions are more severe than tidal condition .

Based on the above discussion, it is proposed to redefine the The time to corrosion initiation determined using

environmental exposure conditions. The proposed exposure values of diffusion coefficient (diffusion coefficient

classification is given in Table 1. values based on field tests and laboratory tests)

(ii) IS 456 : 2000 specifies limits on total

amount of chloride content in the

Table 3: Computed values of time to initiation of corrosion of reinforcement

concrete at the time of placing. While this

embedded in OPC concrete (Mix-1) and concrete with 25 percent PFA as

reduces the risk of corrosion of cement replacement material (Mix-2)

reinforcement due to chlorides already

Exposure Concrete Cover, Surface chloride Critical chloride Diffusion Time for

present in the concrete, the risk due to class type mm iii content percent by content percent by coefficient, corrosion

ingress of chlorides from the weight of concrete

iv

weight of concrete

2

cm /s initiation,

environment is not considered. years

Specification of a critical chloride content Severe

i

Mix-1 45 0.25 0.125 5.0 x 10

-8

14.1

(the chloride content at which the steel Mix-2 45 0.33 0.100 1.0 x 10-8 30.3

depassivates and corrosion is initiated) Extreme

ii

Mix-1 75 0.40 0.125 5.0 x 10

-8

17.5

as given by BS 8110 and CEB Design Mix-2 75 0.53 0.100 1.0 x 10

-8

51.6

Guide will be useful in the durability- Note: * Values of diffusion coefficient reported in literature based on field tests (tests on concrete

based service life design for determining specimens in natural exposure conditions and on existing concrete structures

the service life of new structures and (i) RC member exposed to coastal environment with medium temperature

residual service life of existing structures. (ii) RC member exposed to splashing of seawater

Also, IS 456 : 2000 permits the use of (iii) Minimum cover thickness as per IS 456 : 2000

mineral admixtures in concrete to render (iv) Values of surface chloride content are based on the values reported in literature

concrete eco-friendly. The use of mineral If the cover to reinforcement provided is 35 mm instead of 45 mm for members exposed to severe

environmental conditions, the time to corrosion initiation reduces to 8.5 and 18.3 years for

admixtures in concrete reduces the rate mix-1 and mix-2, respectively. This shows the importance of quality of workmanship in

of diffusion of chlorides from the maintaining the cover thickness. The nominal cover specified by IS 456 : 2000 should be

environment into the cover concrete. strictly adhered to.

November 2001 * The Indian Concrete Journal 695

source: www.mapsofindia.com

Fig 2 The average annual rainfall in India

source: http://www.corrosion-doctors.org/AtmCorros/mapIndia.htm

reported in literature for OPC concrete and concrete

Fig 3 The corrosivity map of India

with 30 percent PFA as cement replacement material

are presented in Table 3. From this table, it is noted

that though the critical chloride content for PFA

materials such as PFA in reinforced concrete to enhance

concrete is lesser than that of OPC concrete, the time

the durability properties.

to corrosion initiation increases by 2 to 3 times for

concrete with PFA as compared to OPC concrete. This From the above discussion, it is clear that for

indicates the benefit of using cement replacement durability-based service life design of structures, there

is a need to specify the values of critical chloride content

Table 4: Requirements for durability (Eurocode 2)

Requirement Type of concrete Class of exposure

1 2a 2b 3 4a 4b 5a 5b 5c

Grade of concrete CE 32.5 cement C25 C30 C35 C30 C35 C30 C35 C40

CE 42.5 cement C30 C35 C40 C35 C40 C35 C40 C45

Maximum Plain - 0.70

water-cement ratio Reinforced 0.65 0.60 0.55 0.50 0.55 0.50 0.55 0.50 0.45

Prestressed 0.60 0.60

Minimum cement Plain 150 200 200 200

3

content, kg/m Reinforced 260 280 280 300 300 300 280 300 300

Prestressed 300 300 300 300

Minimum cover thicknes, mm

Concrete grade < C40/50

Slabs Reinforced 15 15 20 35 35 35 20 25 35

Prestressed 25 25 30 45 45 45 30 35 45

Other members Reinforced 15 20 25 40 40 40 25 30 40

Prestressed 25 30 25 50 50 50 25 40 50

Stronger concrete

Slabs Reinforced 15 15 15 30 30 30 15 20 35

Prestressed 25 25 25 40 40 40 25 30 45

Other members Reinforced 15 15 20 35 35 35 20 25 40

Prestressed 25 25 30 45 45 45 30 35 50

Minimum air content for maximum

size of aggregate, percent

32 mm 4 4 4

16 mm - - 5 5 - 5 - - -

8 mm 6 6 6

Frost-resistant aggregate - - Yes Yes - Yes - - -

Low permeability - - Yes Yes Yes Yes Yes Yes Yes

696 The Indian Concrete Journal * November 2001

Table 5: Recommended values of minimum cover thickness for Table 6: Recommendations for changes in IS 456 : 2000

RC slabs

Parameter IS 456 : 2000 Recommendations

Exposure Minimum cover thickness* Recommended values of concrete

Exposure Five classes of exposure are A revised classification based

condition specified in IS 456 : 2000 cover thickness for slabs, mm

classification defined as in BS 8110, that is, on the major environmental

Mild 20** 15 mild, moderate, severe, very parameters influencing the

severe, extreme different deterioration

Moderate 30 25

mechanisms related to durability

Severe 45+ 35+ of reinforced concrete is

Very severe 50+ 45+ suggested in Table 22

Extreme 75 60 Permissible The specified permissible In addition, the specification of a

Note: * for a longitudinal reinforcing bar in a column, nominal cover shall not be less level of chloride total amount of acid soluble critical chloride content value, to

than 40 mm, nor less than the diameter of such bar content chlorides at the time of account for the risk of corrosion of

** for reinforcement upto 12 mm diameter. bar for mild exposure, the nominal placing for reinforced reinforcement due to the ingress of

cover may be reduced by 5 mm concrete is 0.60 kg/m3 per chlorides from the environment, is

+ for exposure conditions severe and very severe, reduction of 5mm may be cubic meter of concrete. suggested.

made, where concrete grade is M 35 and above

Cover to Minimum cover to reinforce- It is recommended to specify the mini-

reinforcement ment is specified for different mum cover thickness for slabs sepa-

exposure conditions.. rately. The recommended values are

for concrete with mineral admixtures. Experiments given in Table 25.

on corrosion of reinforcement in concrete with mineral

For concrete grade ≥ M 35, It is suggested to expand the

admixtures commonly available in India are being provision is given for 5 mm provision for trade-off between

carried out at SERC, Chennai, and other research reduction in cover cover and concrete quality for

laboratories/institutions. The results of these thickness if the exposure better grades of concrete as in BS

class is severe or very 8110 and AS 3600.

experiments will be useful while incorporating the severe

specifications for durability of concrete with

Service life The service life of the It is recommended to specify the

admixtures. structure/structural member service life for structures in lieu

is not explicitly mentioned with specifications in BS 7543.

(iii) IS 456 : 2000 permits a reduction in cover thickness for

severe and very severe classes of exposure if the grade

of concrete used is greater than equal to M 35.

However, it can be noted that values of minimum in lieu with BS 7543 will be useful for durability-based

cover thickness specified by IS 456 : 2000 for aggressive service life design.

environments are high when compared with values

The recommendations along with the provisions for

specified in EC2, BS 8110 and AS 3600 for similar

durability in IS 456 : 2000 are given in Table 6.

environments (especially for higher grades of

concrete). Hence, the current provisions for trade-off

between concrete cover and grade of concrete can be

Conclusions

expanded for higher grades of concrete (as in BS 8110 Worldwide, efforts are being made to rationally integrate

and AS 3600). the durability-based design clauses with the existing limit

state design clauses. This trend has been reflected in the recent

(iv) IS 456 : 2000 specifies the minimum values of nominal revision of IS 456. Based on the studies reported in this paper

cover thickness for reinforced oncrete for all types of and information collected on Indian environmental

structural members. Beams and columns are the main conditions, recommendations on exposure classification and

load bearing members of a structure. Hence, any minimum cover thickness have been made which may be

damage/distress to any of these members will have considered in the future revision of IS 456.

severe consequence(s) including partial or complete

collapse of the structure. But, the consequence(s) of Acknowledgements

damage/distress of slabs is less severe compared to

This paper is being published with the kind permission of the

those of beams and columns. Hence, a lower value of

director, Structural Engineering Research Centre, Chennai.

minimum cover thickness can be specified separately

The authors are thankful to the referee for the comments,

for slabs as in Eurocode 2, Table 4. The recommended

which have been helpful.

values are given in Table 5.

References

(v) The review presented in this paper brings out the

1. SIEMES, T. History of service life design of structures, Workshop on Design

importance of designing the structure/structural

durability of concrete,15-16 June 1999, Berlin.

element for specified target service life. The guidelines

available in literature can be used for specifying the 2. _______ Indian Standard code of practice for plain and reinforced concrete,

IS 456 : 2000, Indian Standards Institution, New Delhi.

target service life9,10. However, it is noted that to put

service life design into practice in Indian conditions, a 3. LINDVALL , A. Environmental actions and response - Survey, inspection and

measurements, The European Committee Brite EuRam Project BE95-1347

holistic approach involving concerted efforts from Working Report, March 1999.

researchers, designers, contractors and builders, is

4. ALLEN, R. T. L. (ED.) Concrete in coastal structures, Thomas Telford, London,

required. The explicit specification of expected service

1998.

lives for structures/structural elements in IS 456 : 2000,

November 2001 * The Indian Concrete Journal 697

5. _______ Durable concrete structures - Design guide, CEB, Second Edition, Dr K. Balaji Rao obtained his masters and doctorate

Thomas Telford, London, 1989. degrees in civil engineering from Indian Institute of

6. GOPALAKRISHNAN, S. Durable concretes using mineral waste materials - An Science, Bangalore in 1984 and 1990, respectively.

overview of SERCs Experience, Conference on Waste and byproducts as Since then he has been working as a scientist at SERC,

secondary resources for alternate building materials, New Delhi, April 14-15, Chennai. His research interests include analysis and

1999, pp. 283-296. design of reinforced concrete and ferrocement

7. THOMAS, M. Chloride thresholds in marine concrete, Cement and Concrete structures/structural members, uncertainty

Research, 1996, vol. 26, pp. 513-519. handling, reliability analysis and reliability-based design of

8. TAKAGI, N., MIYAGAWA, T., AMASAKI, S., and KOJIMA, T. Chloride corrosion of structures, risk analysis for decision-making.

reinforcing steel in silica fume concrete exposed to marine environment,

Dr T.V.S.R. Appa Rao is an emeritus scientist in

Durability of concrete 126,Vol. I, SP Malhotra, V. (Ed.), American Concrete

Institute, Detroit, 1991, pp. 479-497.

SERC, Chennai and was its former director. His

research interests include computer-aided analysis

9. BALAJI RAO, K. and APPA RAO, T.V.S.R. Chloride induced corrosion of reinforcement and design of complex structures, risk and reliability-

in reinforced concrete members - Brief review of literature and results of preliminary

based design of structures and computer software

studies on reliability analyses, Project Report No. SS-OLP 07741-RR-99-1, SERC

Madras, May 1999.

development. He has been guiding a number of

scientists in the development of the finite element

10. _______ Structural Concrete: Textbook on behaviour, design and performance method for advanced structural analysis and also in the

Updated knowledge of the CEB/FIP Model Code 1990 - Volume 3, International

development of integrated software packages for design of

Federation for Structural Concrete, December 1999.

structures. He has authored a number of technical papers

11. _______ Standard method of test for rapid determination of chloride permeability published in national/international journals.

of concrete, AASHTO Designation T277-83, American Association of State

Highway and Transportation Officials, Washington D.C., 1983. Mr S. Gopalkrishnan is deputy director and head

of concrete composites laboratory and advisor

Mr M.B. Anoop obtained his Masters degree in management, SERC, Chennai. He is currently vice-

structural engineering from Indian Institute of president of International Centre for Fibre Reinforced

Science, Bangalore, in 1998. Since then he has been Concrete, Chennai. His research interests include

working as a scientist at Structural Engineering inelastic analysis of RC shells and concrete

Research Centre (SERC), Chennai. His research composites, high performance concrete and

interests include analysis and design of structures, assessments of distress and repair of concrete structures.

computational mechanics, uncertainty handling, and

risk and reliability of structures.

698 The Indian Concrete Journal * November 2001

Potrebbero piacerti anche

- Corrosion: Corrosion ControlDa EverandCorrosion: Corrosion ControlL L ShreirValutazione: 5 su 5 stelle5/5 (1)

- Newton BS 8102 2022 Technical Paper Apr22Documento19 pagineNewton BS 8102 2022 Technical Paper Apr22nandanaNessuna valutazione finora

- G 020 Classifying Environments v2 Sept 2017Documento8 pagineG 020 Classifying Environments v2 Sept 2017Nuno FerreiraNessuna valutazione finora

- CT CT: Concrete Structures For Storage of Liquids Ode of PracticeDocumento13 pagineCT CT: Concrete Structures For Storage of Liquids Ode of PracticeakhilashNessuna valutazione finora

- IS3370 (Part - I) 2009Documento20 pagineIS3370 (Part - I) 2009amithcivil100% (1)

- IS 3370 Part 2 - 2009-Readable PDFDocumento14 pagineIS 3370 Part 2 - 2009-Readable PDFpradip ghodeswarNessuna valutazione finora

- IJCRT2107046Documento5 pagineIJCRT2107046المهندس: محمد محمود السوائيNessuna valutazione finora

- IS 456 Comparison of 1978 Vs 2000Documento9 pagineIS 456 Comparison of 1978 Vs 2000man.drakeNessuna valutazione finora

- Irjet V4i6461 PDFDocumento6 pagineIrjet V4i6461 PDFANKESH SHRIVASTAVANessuna valutazione finora

- Is 3370 2 2009Documento13 pagineIs 3370 2 2009Abh AbhNessuna valutazione finora

- IS 3370 (Part2) 2009Documento15 pagineIS 3370 (Part2) 2009AMAR HEBBAR V.PNessuna valutazione finora

- ASD Unit 3 Code BookDocumento15 pagineASD Unit 3 Code BookGurram AmarsaiNessuna valutazione finora

- RC Lecture1Documento15 pagineRC Lecture1Sara ZavariNessuna valutazione finora

- Atmospheric Corrosion Resistance of HDG CoatingsDocumento9 pagineAtmospheric Corrosion Resistance of HDG CoatingsPepo MihovNessuna valutazione finora

- IS 3370 Part 2 - 2009Documento14 pagineIS 3370 Part 2 - 2009Nagamani Venkataramana100% (1)

- RS Concrete Brochure 6 PDFDocumento2 pagineRS Concrete Brochure 6 PDFbenni_amir3945Nessuna valutazione finora

- How To Use BS8500 With BS8110Documento8 pagineHow To Use BS8500 With BS8110Marty AndersonNessuna valutazione finora

- IS 3370 (Part 1) - 2021Documento28 pagineIS 3370 (Part 1) - 2021Praveen Agarwal95% (20)

- Codal Practices For RCC Design Part A General by VKMehtaDocumento22 pagineCodal Practices For RCC Design Part A General by VKMehtavijaymehta3450% (1)

- Paper OPNandsidhantagarwalDocumento5 paginePaper OPNandsidhantagarwalArmash MominNessuna valutazione finora

- Hot Dip Galvanizing Coatings Provide Predictable Atmospheric Corrosion ResistanceDocumento9 pagineHot Dip Galvanizing Coatings Provide Predictable Atmospheric Corrosion Resistanceskmanglik123Nessuna valutazione finora

- Code of Practice For Waterproofing of Underground WaterreservoirsandswimmingpoolsDocumento9 pagineCode of Practice For Waterproofing of Underground WaterreservoirsandswimmingpoolsAnvit GadkarNessuna valutazione finora

- Standard Civil Design Basis - GeneralDocumento4 pagineStandard Civil Design Basis - Generalnirmal sutharNessuna valutazione finora

- Design of Liquid Retaining Concrete StructuresDocumento6 pagineDesign of Liquid Retaining Concrete StructuresmoorhouseNessuna valutazione finora

- 78-8126-6169-8 Rev CDocumento14 pagine78-8126-6169-8 Rev CDarwin CampoverdeNessuna valutazione finora

- How To Specify Concrete For Civil Engineering Structures Using BS 8500Documento8 pagineHow To Specify Concrete For Civil Engineering Structures Using BS 8500simonralphNessuna valutazione finora

- FormConEC2Documento23 pagineFormConEC2Afendi AriffNessuna valutazione finora

- Design Formula For EC2 Version 04 UTMDocumento23 pagineDesign Formula For EC2 Version 04 UTMJackieSimNessuna valutazione finora

- IS 3370.2009 Part-1 PDFDocumento20 pagineIS 3370.2009 Part-1 PDFnalla maheshNessuna valutazione finora

- Seismic Design of Elevated TanksDocumento59 pagineSeismic Design of Elevated Tankstuky10Nessuna valutazione finora

- CVS 416 Notes - 2016-17Documento70 pagineCVS 416 Notes - 2016-17Victor KemeiNessuna valutazione finora

- BS 1521-1972Documento11 pagineBS 1521-1972nazgul85Nessuna valutazione finora

- High Performance Protective CoatingsDocumento9 pagineHigh Performance Protective CoatingsgangadevimgmNessuna valutazione finora

- 3M™ Cold Shrink QT-III Silicone Rubber Termination Kits,: 7620-S, 7680-S and 7690-S Series 5, 8, 15, 25/28 and 35 KVDocumento14 pagine3M™ Cold Shrink QT-III Silicone Rubber Termination Kits,: 7620-S, 7680-S and 7690-S Series 5, 8, 15, 25/28 and 35 KVSup ProyNessuna valutazione finora

- Watyl Equivalent To NZS 2312Documento52 pagineWatyl Equivalent To NZS 2312Oh No PotatoNessuna valutazione finora

- Basement Waterproofing New ConstructionDocumento19 pagineBasement Waterproofing New ConstructionDevinder ChawlaNessuna valutazione finora

- Standardising The Durability Figures of Metallic and Paint CoatingsDocumento9 pagineStandardising The Durability Figures of Metallic and Paint CoatingsDavid RodriguesNessuna valutazione finora

- Galvanize 83Documento13 pagineGalvanize 83accountsNessuna valutazione finora

- ISO 12944 2022 MasterDocumento22 pagineISO 12944 2022 MasterJosé Román MenaNessuna valutazione finora

- BS 8500 For Building Structures: Concrete Design InformationDocumento8 pagineBS 8500 For Building Structures: Concrete Design Informationroyal_eagle04Nessuna valutazione finora

- Thioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocumento5 pagineThioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureAhmad AfeeqNessuna valutazione finora

- Guide To The LEED Green AssociateDocumento8 pagineGuide To The LEED Green AssociateMahmoud Abd El MonemNessuna valutazione finora

- Corrosion Protection For Cold-Formed Structural STDocumento8 pagineCorrosion Protection For Cold-Formed Structural STethiwaNessuna valutazione finora

- TDS Renderoc LAXtra India3Documento2 pagineTDS Renderoc LAXtra India3ARCHANA GUPTANessuna valutazione finora

- 1-500612836746976-Main - MÓDULO ARGAMASSASDocumento15 pagine1-500612836746976-Main - MÓDULO ARGAMASSASaz1993Nessuna valutazione finora

- SSPC PS Guide 12 PDFDocumento6 pagineSSPC PS Guide 12 PDFNuzul Furqony100% (2)

- Is 3370 - 1Documento20 pagineIs 3370 - 1Umesh ChikhlikarNessuna valutazione finora

- Lectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1Documento6 pagineLectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1William PinzonNessuna valutazione finora

- New Design Procedure for Seismically Isolated Buildings Based on Worldwide CodesDocumento9 pagineNew Design Procedure for Seismically Isolated Buildings Based on Worldwide CodesabdulghafrNessuna valutazione finora

- Catalogo RCP - Resin - Busbar - 2021Documento24 pagineCatalogo RCP - Resin - Busbar - 2021carlos william zapata sernaNessuna valutazione finora

- N 490 Terms Definitions and SymbolsDocumento40 pagineN 490 Terms Definitions and SymbolsJason Jiahui WuNessuna valutazione finora

- Dhavalkuma Rami (190101101910) - 1. INDIAN STANDARDS ON EARTHQUAKE ZONE BUILDINGDocumento7 pagineDhavalkuma Rami (190101101910) - 1. INDIAN STANDARDS ON EARTHQUAKE ZONE BUILDINGDHAVALKUMAR RAMINessuna valutazione finora

- ISO 12944 - tcm279-213128Documento16 pagineISO 12944 - tcm279-213128rodrigogomez87100% (1)

- Substation Composite Insulator Solutions and ApplicationDocumento67 pagineSubstation Composite Insulator Solutions and Applicationvenkatesh bharadwajNessuna valutazione finora

- IS 3370 (Part 2) - 2021Documento22 pagineIS 3370 (Part 2) - 2021Praveen Agarwal93% (15)

- Basis of Design 25000 ReservoirDocumento3 pagineBasis of Design 25000 ReservoirAnonymous D1h2pKNessuna valutazione finora

- U.S. Army Explosives and Demolitions HandbookDa EverandU.S. Army Explosives and Demolitions HandbookNessuna valutazione finora

- Marine and Offshore Corrosion: Marine Engineering SeriesDa EverandMarine and Offshore Corrosion: Marine Engineering SeriesNessuna valutazione finora

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionDa EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNessuna valutazione finora

- Creep Behavior of C-S-H Under Different Drying Relative HumiditiesDocumento13 pagineCreep Behavior of C-S-H Under Different Drying Relative HumiditiesAnoopBharathanNessuna valutazione finora

- Staad Pro TutorialDocumento9 pagineStaad Pro Tutorialsaisssms9116100% (12)

- 2018 MCRDocumento17 pagine2018 MCRAnoopBharathanNessuna valutazione finora

- 2001 NBM&CWDocumento11 pagine2001 NBM&CWAnoopBharathanNessuna valutazione finora

- 2006 JoseDocumento7 pagine2006 JoseAnoopBharathanNessuna valutazione finora

- 2004 JoseDocumento15 pagine2004 JoseAnoopBharathanNessuna valutazione finora

- 2001 ICJ - Part1Documento11 pagine2001 ICJ - Part1AnoopBharathanNessuna valutazione finora

- Purpose and Justification For New Design Standards Regarding The Use of Fibre-Reinforced Polymer Composites in Civil EngineeringDocumento31 paginePurpose and Justification For New Design Standards Regarding The Use of Fibre-Reinforced Polymer Composites in Civil EngineeringAnoopBharathanNessuna valutazione finora

- ACADEMY OF SCIENTIFIC AND INNOVATIVE RESEARCH THESIS SUBMISSION CHECKLISTDocumento1 paginaACADEMY OF SCIENTIFIC AND INNOVATIVE RESEARCH THESIS SUBMISSION CHECKLISTAnoopBharathanNessuna valutazione finora

- Culinary Nutrition BasicsDocumento28 pagineCulinary Nutrition BasicsLIDYANessuna valutazione finora

- Sceduling and Maintenance MTP ShutdownDocumento18 pagineSceduling and Maintenance MTP ShutdownAnonymous yODS5VNessuna valutazione finora

- What Is Inventory Management?Documento31 pagineWhat Is Inventory Management?Naina SobtiNessuna valutazione finora

- Lending Tree PDFDocumento14 pagineLending Tree PDFAlex OanonoNessuna valutazione finora

- After EffectsDocumento56 pagineAfter EffectsRodrigo ArgentoNessuna valutazione finora

- 1 s2.0 S0959652619316804 MainDocumento11 pagine1 s2.0 S0959652619316804 MainEmma RouyreNessuna valutazione finora

- Carbapenamses in Antibiotic ResistanceDocumento53 pagineCarbapenamses in Antibiotic Resistancetummalapalli venkateswara raoNessuna valutazione finora

- 1 Univalent Functions The Elementary Theory 2018Documento12 pagine1 Univalent Functions The Elementary Theory 2018smpopadeNessuna valutazione finora

- Technical CommunicationDocumento35 pagineTechnical CommunicationPrecious Tinashe NyakabauNessuna valutazione finora

- Developmen of Chick EmbryoDocumento20 pagineDevelopmen of Chick Embryoabd6486733Nessuna valutazione finora

- Benefits of Eating OkraDocumento4 pagineBenefits of Eating Okraama931Nessuna valutazione finora

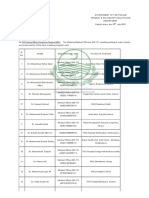

- Government of The Punjab Primary & Secondary Healthcare DepartmentDocumento3 pagineGovernment of The Punjab Primary & Secondary Healthcare DepartmentYasir GhafoorNessuna valutazione finora

- Fuather, That Smid Govern-: Such Time As It May Deem Proper: TeDocumento18 pagineFuather, That Smid Govern-: Such Time As It May Deem Proper: Tencwazzy100% (1)

- Issue 189Documento38 pagineIssue 189Oncampus.net100% (1)

- Solution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Documento54 pagineSolution of Introduction To Many-Body Quantum Theory in Condensed Matter Physics (H.Bruus & K. Flensberg)Calamanciuc Mihai MadalinNessuna valutazione finora

- p2 - Guerrero Ch13Documento40 paginep2 - Guerrero Ch13JerichoPedragosa88% (17)

- Case 1 1 Starbucks Going Global FastDocumento2 pagineCase 1 1 Starbucks Going Global FastBoycie TarcaNessuna valutazione finora

- Veolia Moray Outfalls Repair WorksDocumento8 pagineVeolia Moray Outfalls Repair WorksGalih PutraNessuna valutazione finora

- SCIENCE 5 PERFORMANCE TASKs 1-4 4th QuarterDocumento3 pagineSCIENCE 5 PERFORMANCE TASKs 1-4 4th QuarterBALETE100% (1)

- Outstanding 12m Bus DrivelineDocumento2 pagineOutstanding 12m Bus DrivelineArshad ShaikhNessuna valutazione finora

- Value Chain AnalysisDocumento4 pagineValue Chain AnalysisnidamahNessuna valutazione finora

- Case Study - Help DocumentDocumento2 pagineCase Study - Help DocumentRahNessuna valutazione finora

- CM Template For Flora and FaunaDocumento3 pagineCM Template For Flora and FaunaJonathan Renier Verzosa0% (1)

- Research of William Wells at HarvardDocumento10 pagineResearch of William Wells at HarvardARGHA MANNANessuna valutazione finora

- KS4 Higher Book 1 ContentsDocumento2 pagineKS4 Higher Book 1 ContentsSonam KhuranaNessuna valutazione finora

- PLJ-8LED Manual Translation enDocumento13 paginePLJ-8LED Manual Translation enandrey100% (2)

- SWOT AnalysisDocumento6 pagineSWOT Analysishananshahid96Nessuna valutazione finora

- 8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamDocumento129 pagine8086 Microprocessor: J Srinivasa Rao Govt Polytechnic Kothagudem KhammamAnonymous J32rzNf6ONessuna valutazione finora

- Country Profile - NigerDocumento1 paginaCountry Profile - Nigernana kayNessuna valutazione finora

- Primary Homework Help Food ChainsDocumento7 paginePrimary Homework Help Food Chainsafnaxdxtloexll100% (1)