Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Data Sheet 5.01 Issue C: Wet Alarm Valve Model B, D, E

Caricato da

pitigoiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Data Sheet 5.01 Issue C: Wet Alarm Valve Model B, D, E

Caricato da

pitigoiCopyright:

Formati disponibili

Data Sheet 5.

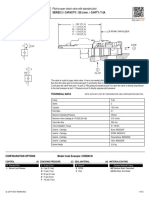

01 FM

Issue C Assessed to ISO 9001:2008

Cert/LPCB/ ref. 566b/01(B)

Cert/LPCB/ ref. 566b/02(D)

Wet Alarm Valve

Cert/LPCB/ ref. 566b/03(E)

Model B, D, E

General Description

Model B, D & E wet alarm valves are designed for use in wet

pipe sprinkler installations in buildings not subject to freezing

temperatures.

This type of wet alarm valve is designed to automatically initiate

electric or hydraulic alarm whenever there is a flow of water to one

or more sprinklers.

A variety of trim packages are available to suit the requirements

of the authority having jurisdiction and a number of accessories

can be supplied including straps and padlocks, pressure switches,

retard chamber and water motor alarm gong.

This valve must be installed vertically in the main supply to a wet

pipe sprinkler system.

Operation

In the case of a fire the sprinkler head operates and the pressure Models

on the system side of the clapper falls below the pressure on the

Face

supply side. The clapper lifts off the grooved seat and permits water

to Weight

flow from the supply to enter the system for distribution on the fire. Model Sizes Connection Type

Face (kg)

Water also flows through the clapper seat to the alarm device via (mm)

the optional retard chamber.

DN80/3” 273 23.0

A pressure surge or water hammer in the supply line may increase Model B

the pressure on the supply side of the clapper, causing it to lift DN100/4” 225 23.5 Flange*:

Flange - ANSI 125/150

intermittently which may result in a false alarm. – DN150/6” 267 35.5 - PN16 (hole drilling pattern)

Flange

The Wet alarm valve prevents such false alarms by two features:

DN200/8”** 298 60.0

• An external by-pass allows the pressure surge from the supply

DN100/4” 263 22.7 Flange*:

to bypass the alarm valve clapper. This creates an excess - PN16 (hole drilling pattern)

Model D

system pressure and thus steadies the clapper. DN150/6” 280 29.5

Groove:

• Should a heavy surge unseat the clapper and allow water to Flange

- DN100/4”: 114.3 OD

–

flow into the alarm line, the optional Model E retard chamber - DN150/6”: 165.1 OD (UK)

Groove DN200/8” 335 56.8

168.3 OD

comes into action, delaying the activation of the alarm. - DN200/8”: 219.1 OD

Specially designed inlet and drain orifices allow the chamber

Model E DN100/4” 286 19.1

to partially drain before filling and activating the alarm device. Groove:

- DN100/4”: 114.3 OD

The retard chamber is supplied with a strainer in the supply line to Groove

- DN150/6”: 165.1 OD (UK)

– DN150/6” 287 22.7

prevent foreign matter from clogging the inlet orifice. Groove

168.3 OD

*All valves with flange connections are supplied with flat face

Pressure Rating flanges.

Max. Working Pressure 12 Bar (175 PSI) **The PN16 drilling on the top flange of the DN200 size valve is

radially off set to the drilling in the bottom flange. This is required

Approvals to achieve bolt clearance of the body casting and must be taken

into consideration in the design of mating flanged pipe work.

UL, FM, LPCB, CE

DS: 5.01 Rapidrop Global Ltd

Issue C T: +44 (0) 1733 847 510 F: +44 (0) 1733 553 958

20/07/2017 e: rapidrop@rapidrop.com

© 2017 Rapidrop w: www.rapidrop.com Page 1 of 3

Rapidrop Global Ltd reserves the right to change the design, materials and specifications without notice to continue product development

Potrebbero piacerti anche

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDa EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNessuna valutazione finora

- 729 Double Interlock Preaction DDXDocumento22 pagine729 Double Interlock Preaction DDXfarshan296015Nessuna valutazione finora

- Framo PumpDocumento13 pagineFramo PumpHarbinder Singh100% (4)

- TFP1420 09 2004 PDFDocumento14 pagineTFP1420 09 2004 PDFPhuNguyenHoangNessuna valutazione finora

- Compressor WP81L - WP101L - Data - Leaflet - 2015Documento2 pagineCompressor WP81L - WP101L - Data - Leaflet - 2015RizzoRo1Nessuna valutazione finora

- TFP1421 06 2022Documento18 pagineTFP1421 06 2022Diego PinedaNessuna valutazione finora

- Alarm Valve: Model-H (Ductile Iron)Documento16 pagineAlarm Valve: Model-H (Ductile Iron)Karen IsananNessuna valutazione finora

- Deluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataDocumento16 pagineDeluge Valve Model-H2: HD Fire Protect Pvt. Ltd. (Cast Steel) Technical DataNethajiNessuna valutazione finora

- HD 247 Alarm Valve Model-HDocumento16 pagineHD 247 Alarm Valve Model-HChiranjeev NathNessuna valutazione finora

- Valves Deluge Valve Model h3-bkp-03-04-2018Documento16 pagineValves Deluge Valve Model h3-bkp-03-04-2018Benny Kurniawan LimNessuna valutazione finora

- HD 247 Alarm Valve Model-HDocumento16 pagineHD 247 Alarm Valve Model-HMinhthien NguyenNessuna valutazione finora

- Valves Deluge Valve Model h3Documento16 pagineValves Deluge Valve Model h3Pedro Caminos BolanosNessuna valutazione finora

- TFP1421 08 2023Documento21 pagineTFP1421 08 2023Vivekanand SonavaneNessuna valutazione finora

- Page48low ResSRI 2014 - Nov PDFDocumento1 paginaPage48low ResSRI 2014 - Nov PDFSk NgNessuna valutazione finora

- Operation Manual: Submerged Ballast PumpsDocumento13 pagineOperation Manual: Submerged Ballast PumpsNay LinNessuna valutazione finora

- Tyco Alarm Check Valve AV-1 300 PDFDocumento26 pagineTyco Alarm Check Valve AV-1 300 PDFRomyrNessuna valutazione finora

- CKEB Full en Metric LetterDocumento2 pagineCKEB Full en Metric LetterRafalNessuna valutazione finora

- 3 Way Sauter ValveDocumento8 pagine3 Way Sauter ValverkssNessuna valutazione finora

- Valves Deluge Valve Model h3Documento16 pagineValves Deluge Valve Model h3RaviNessuna valutazione finora

- VAV TerminalsDocumento18 pagineVAV TerminalsFaquruddinNessuna valutazione finora

- Ocv Series 129FC METRICDocumento2 pagineOcv Series 129FC METRICmuthuvelaa100% (1)

- Aqua Dosing Pump NewDocumento2 pagineAqua Dosing Pump NewSumit MishraNessuna valutazione finora

- 052115xyz Re18309-86Documento2 pagine052115xyz Re18309-86JavierNessuna valutazione finora

- 200-FPS 2378Documento2 pagine200-FPS 2378Green MichaelsNessuna valutazione finora

- D-050 D-050-C D-052: Combination Air ValveDocumento6 pagineD-050 D-050-C D-052: Combination Air Valve7erick7Nessuna valutazione finora

- PDF Actuator Datasheet - CompressDocumento1 paginaPDF Actuator Datasheet - Compresshellraizer1978Nessuna valutazione finora

- Datasheet Model C-EL Electrically Operated Control ValveDocumento2 pagineDatasheet Model C-EL Electrically Operated Control ValveRomulo Rodriguez VivasNessuna valutazione finora

- Resolution For HAZOP Action Point No 17Documento4 pagineResolution For HAZOP Action Point No 17vasudhaNessuna valutazione finora

- Series A, AHDocumento6 pagineSeries A, AHThu Hiền NguyễnNessuna valutazione finora

- Deluge Valve: Model-A (Cast Iron)Documento14 pagineDeluge Valve: Model-A (Cast Iron)Jaime RodriguezNessuna valutazione finora

- Yokogawa AS-Schneider 2601 Ed1.usDocumento2 pagineYokogawa AS-Schneider 2601 Ed1.usArash SepahvandNessuna valutazione finora

- Techniical DetailDocumento42 pagineTechniical DetailAhmed AbdelgawadNessuna valutazione finora

- Deluge Valve Modelh5Documento16 pagineDeluge Valve Modelh5Mariana HusainNessuna valutazione finora

- ZDM Series Automatic Recirculation Valve - Weilan Flow Control Equipment CoDocumento4 pagineZDM Series Automatic Recirculation Valve - Weilan Flow Control Equipment CoEsteban CastellanoNessuna valutazione finora

- Tyco - Mokri Sprinkler VentilDocumento20 pagineTyco - Mokri Sprinkler VentilMuhidin KozicaNessuna valutazione finora

- 3-Way Flow Control Valves: 1 DescriptionsDocumento6 pagine3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNessuna valutazione finora

- Deluge Valve ADocumento14 pagineDeluge Valve AKuldeep SinghNessuna valutazione finora

- Valves Deluge Valve Model h3Documento16 pagineValves Deluge Valve Model h3Jaime RodriguezNessuna valutazione finora

- Dorot 68-De - El - MRDocumento6 pagineDorot 68-De - El - MRJosé Daniel ArenasNessuna valutazione finora

- Valves Deluge Valve Model h2Documento16 pagineValves Deluge Valve Model h2peerlessNessuna valutazione finora

- Deluge Valve - SD-DVA PDFDocumento15 pagineDeluge Valve - SD-DVA PDFboxyfunNessuna valutazione finora

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Documento2 pagineModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNessuna valutazione finora

- 3 Delugevalve HDocumento14 pagine3 Delugevalve HHarishNessuna valutazione finora

- Small Enclosure Cylinder and Valve Assemblies: Part Number Cylinder VolumeDocumento6 pagineSmall Enclosure Cylinder and Valve Assemblies: Part Number Cylinder VolumeMar SolNessuna valutazione finora

- CVCV Full en Metric A4Documento2 pagineCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNessuna valutazione finora

- Valves Deluge Valve Model h3Documento16 pagineValves Deluge Valve Model h3Peter Keith Vela RuizNessuna valutazione finora

- VG221 - 2 Port Control ValveDocumento4 pagineVG221 - 2 Port Control ValveNoah MusundiNessuna valutazione finora

- Deluge Valve SystemDocumento16 pagineDeluge Valve SystemAob AprilNessuna valutazione finora

- Delugue Valve. Viking. 1.5 A 2pulg PDFDocumento8 pagineDelugue Valve. Viking. 1.5 A 2pulg PDFcmarinvzlaNessuna valutazione finora

- 422 Model E Alarm Check ValveDocumento6 pagine422 Model E Alarm Check ValveraneensysNessuna valutazione finora

- DBAFMCV924 Full en Metric LetterDocumento6 pagineDBAFMCV924 Full en Metric LetterMechanical2022Nessuna valutazione finora

- 100407Documento4 pagine100407ioan cristian cotorobaiNessuna valutazione finora

- Model 1260XL: Water Hammer ArresterDocumento2 pagineModel 1260XL: Water Hammer ArresterAbou Backar Sittique JNessuna valutazione finora

- Deluge Valve - SD-DVH5Documento16 pagineDeluge Valve - SD-DVH5boxyfunNessuna valutazione finora

- WFDEN Series Waterfl Ow DetectorDocumento4 pagineWFDEN Series Waterfl Ow Detectorioan cristian cotorobaiNessuna valutazione finora

- Model RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)Documento4 pagineModel RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)asimnaqvi2008Nessuna valutazione finora

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocumento2 pagineModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AAnurag JainNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- ABB Hospital 64Documento1 paginaABB Hospital 64pitigoiNessuna valutazione finora

- ABB Hospital 53Documento1 paginaABB Hospital 53pitigoiNessuna valutazione finora

- ABB Hospital 67Documento1 paginaABB Hospital 67pitigoiNessuna valutazione finora

- ABB Hospital 66Documento1 paginaABB Hospital 66pitigoiNessuna valutazione finora

- ABB Hospital 58Documento1 paginaABB Hospital 58pitigoiNessuna valutazione finora

- ABB Hospital 61Documento1 paginaABB Hospital 61pitigoiNessuna valutazione finora

- ABB Hospital 44Documento1 paginaABB Hospital 44pitigoiNessuna valutazione finora

- ABB Hospital 56Documento1 paginaABB Hospital 56pitigoiNessuna valutazione finora

- ABB Hospital 49Documento1 paginaABB Hospital 49pitigoiNessuna valutazione finora

- ABB Hospital 46Documento1 paginaABB Hospital 46pitigoiNessuna valutazione finora

- ABB Hospital 54Documento1 paginaABB Hospital 54pitigoiNessuna valutazione finora

- ABB Hospital 24Documento1 paginaABB Hospital 24pitigoiNessuna valutazione finora

- ABB Hospital 52Documento1 paginaABB Hospital 52pitigoiNessuna valutazione finora

- ABB Hospital 39Documento1 paginaABB Hospital 39pitigoiNessuna valutazione finora

- ABB Hospital 35Documento1 paginaABB Hospital 35pitigoiNessuna valutazione finora

- ABB Hospital 60Documento1 paginaABB Hospital 60pitigoiNessuna valutazione finora

- ABB Hospital 48Documento1 paginaABB Hospital 48pitigoiNessuna valutazione finora

- ABB Hospital 45Documento1 paginaABB Hospital 45pitigoiNessuna valutazione finora

- ABB Hospital 42Documento1 paginaABB Hospital 42pitigoiNessuna valutazione finora

- ABB Hospital 43Documento1 paginaABB Hospital 43pitigoiNessuna valutazione finora

- ABB Hospital 25Documento1 paginaABB Hospital 25pitigoiNessuna valutazione finora

- ABB Hospital 26Documento1 paginaABB Hospital 26pitigoiNessuna valutazione finora

- ABB Hospital 32Documento1 paginaABB Hospital 32pitigoiNessuna valutazione finora

- ABB Hospital 55Documento1 paginaABB Hospital 55pitigoiNessuna valutazione finora

- ABB Hospital 41Documento1 paginaABB Hospital 41pitigoiNessuna valutazione finora

- ABB Hospital 36Documento1 paginaABB Hospital 36pitigoiNessuna valutazione finora

- ABB Hospital 30Documento1 paginaABB Hospital 30pitigoiNessuna valutazione finora

- ABB Hospital 31Documento1 paginaABB Hospital 31pitigoiNessuna valutazione finora

- ABB Hospital 33Documento1 paginaABB Hospital 33pitigoiNessuna valutazione finora

- ABB Hospital 37Documento1 paginaABB Hospital 37pitigoiNessuna valutazione finora

- Software Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToDocumento30 pagineSoftware Testing Notes Prepared by Mrs. R. Swetha M.E Unit I - Introduction at The End of This Unit, The Student Will Be Able ToKabilan NarashimhanNessuna valutazione finora

- Technical Engineering PEEDocumento3 pagineTechnical Engineering PEEMariano Acosta Landicho Jr.Nessuna valutazione finora

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocumento45 pagineRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaNessuna valutazione finora

- R 18 Model B Installation of TC Auxiliary Lights and WingletsDocumento29 pagineR 18 Model B Installation of TC Auxiliary Lights and WingletsAlejandro RodríguezNessuna valutazione finora

- DevelopersDocumento88 pagineDevelopersdiegoesNessuna valutazione finora

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Documento3 pagineSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantNessuna valutazione finora

- How Can You Achieve Safety and Profitability ?Documento32 pagineHow Can You Achieve Safety and Profitability ?Mohamed OmarNessuna valutazione finora

- Safety Inspection Checklist Project: Location: Inspector: DateDocumento2 pagineSafety Inspection Checklist Project: Location: Inspector: Dateyono DaryonoNessuna valutazione finora

- 16 Easy Steps To Start PCB Circuit DesignDocumento10 pagine16 Easy Steps To Start PCB Circuit DesignjackNessuna valutazione finora

- 8524Documento8 pagine8524Ghulam MurtazaNessuna valutazione finora

- Manulife Health Flex Cancer Plus Benefit IllustrationDocumento2 pagineManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritNessuna valutazione finora

- Fast Binary Counters and Compressors Generated by Sorting NetworkDocumento11 pagineFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Nessuna valutazione finora

- Fire and Life Safety Assessment ReportDocumento5 pagineFire and Life Safety Assessment ReportJune CostalesNessuna valutazione finora

- 990-91356A ACRD300 CE-UL TechnicalSpecifications Part2Documento25 pagine990-91356A ACRD300 CE-UL TechnicalSpecifications Part2Marvin NerioNessuna valutazione finora

- Ground Vibration1Documento15 pagineGround Vibration1MezamMohammedCherifNessuna valutazione finora

- Vocabulary Practice Unit 8Documento4 pagineVocabulary Practice Unit 8José PizarroNessuna valutazione finora

- VRIODocumento3 pagineVRIOJane Apple BulanadiNessuna valutazione finora

- Revenue Management Session 1: Introduction To Pricing OptimizationDocumento55 pagineRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenNessuna valutazione finora

- Tecplot 360 2013 Scripting ManualDocumento306 pagineTecplot 360 2013 Scripting ManualThomas KinseyNessuna valutazione finora

- Sigma Valve 2-WayDocumento2 pagineSigma Valve 2-WayRahimNessuna valutazione finora

- Enumerator ResumeDocumento1 paginaEnumerator Resumesaid mohamudNessuna valutazione finora

- WPGPipingIndex Form 167 PDFDocumento201 pagineWPGPipingIndex Form 167 PDFRaj AryanNessuna valutazione finora

- 254 AssignmentDocumento3 pagine254 AssignmentSavera Mizan ShuptiNessuna valutazione finora

- Bondoc Vs PinedaDocumento3 pagineBondoc Vs PinedaMa Gabriellen Quijada-TabuñagNessuna valutazione finora

- Spare Parts ManagementDocumento21 pagineSpare Parts Managementdajit1100% (1)

- 14 CE Chapter 14 - Developing Pricing StrategiesDocumento34 pagine14 CE Chapter 14 - Developing Pricing StrategiesAsha JaylalNessuna valutazione finora

- Key Features of A Company 1. Artificial PersonDocumento19 pagineKey Features of A Company 1. Artificial PersonVijayaragavan MNessuna valutazione finora

- Chap 06 Ans Part 2Documento18 pagineChap 06 Ans Part 2Janelle Joyce MuhiNessuna valutazione finora

- Ril Competitive AdvantageDocumento7 pagineRil Competitive AdvantageMohitNessuna valutazione finora

- The Fundamentals of Investing PPT 2.4.4.G1Documento36 pagineThe Fundamentals of Investing PPT 2.4.4.G1Lùh HùñçhòNessuna valutazione finora