Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FMC PDF

Caricato da

Anggi SujiwoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FMC PDF

Caricato da

Anggi SujiwoCopyright:

Formati disponibili

HOUSTON OILFIELD EQUIPMENT, INC.

PRODUCT CATALOG 2003

FLOW

CONTROL

EQUIPMENT

LICENSE

6A-0487

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

HOUSTON OILFIELD EQUIPMENT, INC.

TABLE OF CONTENTS

Choke Selection Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Positive and Adjustable Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Threaded Choke Assemblies - FMC Profile . . . . . . . . . . . . . . . . . . . . . Page 3

Flanged Choke Assemblies - FMC Profile . . . . . . . . . . . . . . . . . . . . . . Page 4

Flanged Choke Assemblies - FMC Profile . . . . . . . . . . . . . . . . . . . . . . Page 5

Positive Flow Beans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

Parts for Adjustable Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Parts for Adjustable Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Heater Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Positive and Adjustable Chokes w/Removable Hammer Wing . . . . . . Page 10

Type H-H2 Positive and Adjustable Chokes . . . . . . . . . . . . . . . . . . . Page 11

Type H-H2 Adjustable Chokes - Max 2” Orifice . . . . . . . . . . . . . . . . . Page 12

Type H-H2 Positive Chokes - Max 2” Orifice . . . . . . . . . . . . . . . . . . . Page 13

Type H-H2 Adjustable Chokes - Max 1” Orifice . . . . . . . . . . . . . . . . . Page 14

Steam Choke Assembly - 3000 Lbs. CWP . . . . . . . . . . . . . . . . . . . . . Page 15

Indicator & Packing Detail/Procedures FMC - H2 Adjustable Chokes . . Page 16

❖

MANUFACTURING CAPABILITIES

Houston Oilfield Equipment, Inc.’s objective is to manufacture quality products

at competitive prices. The company offers chokes of actual OEM dimensional

standards as well as those of custom dimensions. All manufacturing is

accomplished with the use of modern CNC equipment and tooling. In addition

to choke assemblies, parts for many types of chokes are also manufactured here.

The company employs a quality system which is approved by the American

Petroleum Institute under License #6A-0487. Products with ABS and DNV

certification may also be provided upon request.

Houston Oilfield Equipment, Inc. has full capabilities of satisfying all of your

manufacturing needs.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

1 1

HOUSTON OILFIELD EQUIPMENT, INC.

CHOKE SELECTION INFORMATION

SPECIFICATIONS FEATURES AND BENEFITS

Type: Positive and Adjustable • Hammerlug bonnet & cap connections

Body Design: Angle Type • Forged Steel bodies - Alloy and 410 SS

End Connections: 1” LPT, 2” LPT • Choice of end connections

Flanged RTJ and RF • Available H2S Service (NACE MR-01-75)

Union Ends • Easily converted in field

• Choice of trim materials

Design Pressure: 2000 PSI CWP • Choice of orifice sizes

3000 PSI CWP • Grease fittings on Adj. Model Bonnets

5000 PSI CWP • Thumb screw for “locking” stem

10,000 PSI CWP • 1/2” NPT test port on flanged models

15,000 PSI CWP • FMC and H2 profile centerline

Trim Sizes: 1/2”, 3/4”, 1”, 2” dimensions

Trim Materials: Alloy Steel, Stellite • Easy to read indicator in 64ths inch

Stainless Steel, Inconel • Readily available parts

Stainless Steel Tungsten Carbide • Low Maintenance

With so many choices, selection of the proper choke for the job does not have

to be difficult. Turn to Houston Oilfield Equipment, Inc. for prompt customer

service and a quality manufactured product.

Houston Oilfield Equipment, Inc. is which facilitates the quick changing of

recognized throughout the oil and gas flow beans and trims. In addition, each

industry as a manufacturer of quality choke is easily converted from positive to

choke products. Our company produces adjustable or adjustable to positive while

choke assemblies of the FMC and H2 type the choke body remains installed in the

profiles which are fully interchangeable line. This means more time working and

with those of other manufacturers of the less time waiting as replacement parts are

same. This design is a time proven one readily available from your local supply

which has been employed in many types store.

of service within the industry.

Your selection of materials for choke

Our line of chokes is ideally suited for a bodies include alloy steel and 410

broad range of applications. These include stainless steel. All FMC profile flanged

wellheads, production manifolds, well models employ bodies of forged steel

testing, choke and kill manifolds, and well construction with integral flanges while

clean-up operations. fabricated versions are also available. The

standard materials used for our threaded

Chokes may be ordered in both positive

bodies are forged alloy steel with carbon

and adjustable models. Each model

steel also available upon request.

utilizes a hammerlug type connection

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

2 2

HOUSTON OILFIELD EQUIPMENT, INC.

POSITIVE AND ADJUSTABLE CHOKES

TYPICAL THREADED TYPICAL FLANGED

ADJUSTABLE CHOKE POSITIVE CHOKE

RETAINING

RING

WING

NUT

HEX NUT

STEM

WASHER

HANDWHEEL BLANKING

CAP

Ref: MODELS Ref: MODELS “O” RING

H0-60 INDICATOR

HFT-116

HN-60 SET SCREW HT-1

HFT-116 SEAT BONNET

HPC

BEAN

WING NUT

“O” RING

BONNET

NYLON BALL BODY

FLOW TEE

THUMB

SCREW

GREASE

FITTING

PACKING

CAGE NIPPLE

JUNK RING

SPIROLOX

RING

HOW TO ORDER CHOKES

1. Type of Choke - Positive or Adjustable.

2. Specify Working Pressure.

3. Type of Inlet and Outlet Connections; Size and Pressure Rating.

4. Specify Trim Size (Orifice Required).

5. Trim Material - Alloy Steel, Tungsten Carbide, Inconel, Stellite, SS.

6. Specify Heater Choke if applicable.

NOTE: Beans for Positive Chokes are not furnished with assemblies and

must be ordered separately.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

3 3

HOUSTON OILFIELD EQUIPMENT, INC.

THREADED CHOKE ASSEMBLIES

FMC PROFILE

TYPE H-29 TYPE

H-FT-108 INLET

16.41” 12.75”

2,000 PSI CWP INLET 3,000 PSI CWP

Adjustable Choke 5,000 PSI CWP

with 2” LP Inlet Positive Choke 9.00”

and 2” LP Outlet with 2” LP Inlet

5.41” and 2” LP Outlet

2.75”

OUTLET 2.38” OUTLET

TYPE HO-60 TYPE

H-N-60

23.25” 23.25”

3,000 PSI CWP INLET 3,000 PSI CWP INLET

Adjustable Choke 5,000 PSI CWP

with 2” LP Inlet Adjustable Choke

and 2” LP Outlet with 2” LP Inlet

9.00” and 2” LP Outlet 9.00”

OUTLET 2.75” OUTLET 2.75”

H-29 and H-O-60 not acceptable for H2S service H-FT-108 & H-N-60 also available with 1” LP connections and 3/4” or 1” trim

NOTE: Positive Chokes not furnished with flow beans, must order separately.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

4 4

HOUSTON OILFIELD EQUIPMENT, INC.

FLANGED CHOKE ASSEMBLIES

TYPE H-PC INLET TYPE H-JWA

INLET

POSITIVE C ADJUSTABLE C

CHOKE A CHOKE A

OUTLET B B OUTLET

SIZE CWP A” B” C”

2” 5,000 9.38 7.50 14.13 SIZE CWP A” B” C”

2 9/16” 5,000 9.38 9.38 15.56 2” 5,000 9.38 7.50 20.81

9

1 13/16” 10,000 9.38 7.50 14.13 2 /16” 5,000 9.38 9.38 20.81

13

2 1/16” 10,000 9.38 7.50 16.31 1 /16” 10,000 9.38 7.50 21.06

2 9/16” 10,000 9.38 9.38 15.56 2 1/16” 10,000 9.38 7.50 21.38

1 13/16” 10,000 9.38 7.50 14.00 2 9/16” 10,000 9.38 9.38 20.81

TYPE H-T-1 INLET TYPE H-N-62

POSITIVE C ADJUSTABLE C

CHOKE A CHOKE INLET

OUTLET B OUTLET B

SIZE CWP A” B” C” SIZE CWP A” B” C”

2” 2,000 9.38 7.50 14.50 2” 2,000 9.38 7.50 24.38

2” 5,000 9.38 7.50 13.88 2” 5,000 9.38 7.50 24.38

2” 150 ANSI 9.38 7.50 14.13 2” 150 ANSI 9.38 7.50 24.38

2” 300 ANSI 9.38 7.50 16.31 2” 300 ANSI 9.38 7.50 24.38

2” 600 ANSI 9.38 7.50 14.13 2” 600 ANSI 9.38 7.50 24.38

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

5 5

HOUSTON OILFIELD EQUIPMENT, INC.

FLANGED CHOKE ASSEMBLIES

FMC PROFILE

TYPE H-FT-116-F CAGE NIPPLES

POSITIVE CHOKE POSITIVE AND

C

ADJUSTABLE CHOKES

A

OUTLET

TYPE TYPE

OCT FC -140 TC-1018

PART NO. PART NO.

1041 1121

7-5/16

7-1/8

B

2-3/8 2-3/8

INLET

SIZE CWP A” B” C”

TYPE TYPE

2” 3,000 And 5,000 8.75 6.63 13.25 McEVOY R GULFCO RB

(NO. 10530) (NO. RB-2,

TYPE H-FT-116-F PART NO.

RB-3)

ADJUSTABLE CHOKE 1095 PART NO.

7

7

1098

OUTLET 2-3/8 2-3/8

A B

TYPE

A. GRAY-60

B. GRAY-80

B

PART NO.

1096

8

1097

INLET

A

SIZE CWP A” B” C” 2-3/8 2-3/8

2” 3,000 And 5,000 8.75 6.63 23.25

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

6 6

HOUSTON OILFIELD EQUIPMENT, INC.

POSITIVE FLOW BEANS

Oil 1-1/32 Thornhill - Craver Cameron Iron Works

HEX

Center A

Tool 7-9/32

6-1/8

6-1/8

6-1/8

1-3/16

A B

1-3/16

Alloy / Steel PN-1SIZE 1-3/32

Alloy / Ceramic PN-2SIZE Alloy / Steel PN-25 SIZE Alloy / Steel PN-23 SIZE

SSTC (PL) PN-3SIZE Alloy / Ceramic PN-27 SIZE Alloy / Ceramic PN-20 SIZE

SSTC (FL) PN-4SIZE SSTC (FL) PN-26 SIZE SSTC (FL) PN-34 SIZE

McEvoy & Gray Tool Gulfco National Supply

Hughs Atlas 1-1/32 Type 60 Type 80 1-1/2 1-1/32

HEX 1-7/16 HEX HEX

1-1/32 HEX B

A

HEX

Style RB

6-26/32

6-3/8

6-7/8

6-7/8

6-7/8

1-3/8 1-5/16

1-3/8 1-5/8 1-1/2 1-3/8 1-9/16

Alloy / Ceramic A. Alloy / Ceramic PN-16 SIZE Alloy / Steel PN-1098 Alloy / Steel PN-35 SIZE

PN-24 SIZE B. Alloy / Ceramic PN-18 SIZE Alloy / Ceramic PN-9 SIZE Alloy / Ceramic PN-36 SIZE

MISCELLANEOUS PARTS Master Bean:

CHOKE BEAN WRENCHES Oil Center Tool

For standard flow beans

12.75” 12”

EXTERNAL

EXTERNAL

EXTERNAL

1.03

7.25”

1.75”

For use with type

HEX

HEX

HEX

50”

INTERNAL

1”

1”

FC-140 cage nipple HEX

Type FC-140 Type FC-143 and FC-142 flow inserts.

Bean & Seat Wrench Flow Bean Wrench Also fits similar profile

Part No. 1050 Part No. 1122

chokes supplied by

1.78” other manufacturers.

All orifice sizes expressed in increments

81”

of 1/64” fractional sizes of 1/2 of 1/64”

available from 2/64” 1.53”

to 20/64” hardened steel, ss. PN: 1419

Specify Orifice Size: PN 39 SIZE TYPE FC-141

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

7 7

HOUSTON OILFIELD EQUIPMENT, INC.

PARTS FOR ADJUSTABLE CHOKES

A

GRAY TOOL CO.

31/32

Equivalent Hardened Tungsten

15-1/2

Part Alloy Carbide

6-1/32 Description No. Steel Stainless

B 1-5/16 A - Stem 8711, 8727 Adj. Choke 20-353/30702 1432 1433

B - Seat Type 80 91022/30716 1434 1435

18-5/8

A

McEVOY

5/8

21-13/16

Equivalent Hardened Tungsten

Part Alloy Carbide

Description No. Steel Stainless

2-1/8 B

A - Stem for Type A, B, and Dual 14715 1436 1437

B - Seat for A, B, and Dual 14288 1438 1439

15/16

12-3/32

A (12-3/32)

B (16)

NATIONAL SUPPLY

Equivalent Hardened Tungsten

2-7/8 C Part Alloy Carbide

Description No. Steel Stainless

1-5/8

A- Stem for 2” Type F, G and GR Chokes 522114 1440 1441

7-3/4 B- Stem for 2” Type F 2900 Series 522164 1442 1443

D

C- Seat for Type F, GR 522105 1444 1445

2-3/8

D- Choke Nipple Seat Type G 522113 1446 N/A

13-29/32 A

GULFCO

Equivalent Hardened Tungsten

Part Alloy Carbide

Description No. Steel Stainless

B

13-29/32 A- Stem for AB - 75 Choke AB - 2 1447 1448

6-25/32 C B- Stem for for AB - 100 Choke AB - 2A 1449 1221

C- Seat for AB - 75 Choke AB - 3 1450 1451

1-3/8

D- Seat for AB - Choke AB - 3A 1452 1210

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

8 8

HOUSTON OILFIELD EQUIPMENT, INC.

PARTS FOR ADJUSTABLE CHOKES

A

THORNHILL-CRAVER TYPE

19-5/8”

Hardened Tungsten

Alloy Carbide

B

24-1/2” Description Steel Stainless

4-1/2” 1-23/32” C A- Stem - Adjustable Wing Valve Choke 1100 1099

1.81 D B- Stem - Long Nose Heater Choke 1102 1101

EXTERNAL E C- Seat - 3,000 & 5,000 PSI CWP Chokes, 1/2” Orifice 1106 1103

HEX D- Seat - 3,000 & 5,000 PSI CWP Chokes 3/4” Orifice 1107 1104

6-1/32” E- Seat - 3,000 & 5,000 PSI CWP Chokes 1” Orifice 1108 1105

1-23/32”

1.81 F- Seat - 10,000 PSI CWP Choke, 1/2” Orifice 1125 1112

EXTERNAL G- Seat - 10,000 PSI CWP Choke, 3/4” Orifice 1116 1113

HEX H- Seat - 10,000 PSI CWP Choke, 1” Orifice 1117 1114

A

OIL CENTER TOOL TYPE

B

C THREADED & FLANGED BODY CHOKES

D Over Hardened Tungsten

E All Orifice Alloy Carbide

Description Length Size Steel Stainless

A- Stem HO-60, HN-60, HT-116-F 3-5,000 CWP 16 3/4” 3/4” 1018 1028

F

G B- Stem H-N-62, 2-5,000 CWP 18” 3/4” 1059 1061

C- Stem H-29 2,000 CWP 14 3/32” 3/4” 1002 N/A

D- Stem H-JWA 5-10,000 CWP 14 15/32” 3/4” 1068 1070

H E- Stem H-JWA 15,000 CWP 19 1/8” 3/4” 1455 1456

I

F- Stem H-O-60, HN-60, HFT-116F 3-5,000 CWP 16 3/4” 1” 1027 1029

J G- Stem H-N-62 2-5,000 CWP 18” 1” 1060 1062

K

H- Stem H-JWA 5-10,000 CWP 14 15/16” 1” 1068 1070

I - Stem H-JWA 15,000 CWP 19 1/8” 1” 1457 1458

J- Seat Type N & H-JWA 8 1/4” 3/4” 1030 1032

L

M K- Seat Type N & H-JWA 8 1/4” 1” 1031 1033

L- Seat Nipple H-O-60 6” 3/4” 1025 N/A

M- Seat Nipple H-29 4” 3/4” 1014 N/A

H2 CAMERON TYPE

Tungsten

A Stainless Carbide

21 3/4”

Description Steel Stainless

B

A - Stem - 1” f/3” H2 2034 1460

23 1/8”” B - Stem - 2” F/3” H2 1509 1427

C - Seat - 1” F/3” H2 Long 2035 1459

D

2.75 *D - Seat - 1” F/2” H2 1655 1203

1.69

EXTERNAL EXTERNAL Seat - 2” F/3” H2 Long 2028 1594

HEX HEX

Seat 2” F/3” H2 Short (3.30” Length) 1514 1429

6” C 6” *Requires adapter for use in 3” & 4” H2

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

9 9

HOUSTON OILFIELD EQUIPMENT, INC.

HEATER CHOKE

The low cost HEATER CHOKE with quality and a time proven design.

SPECIFICATIONS FEATURES AND BENEFITS

End Connections: 2” threaded • Threaded bonnet with O-ring

Socket Weld • Available in NACE (MR-01-75)

Butt-Weld

• Safety pressure relief vent in body

Trim Sizes: 1/2”, 3/4”, 1”

• Choice of end connections

Body Design: Angle Type, Long Nose

• Body A-487-4A with high tensile and

Trim Materials: Alloy Steel

SS Tungsten Carbide yield strengths

Design Pressure: 6500 psi cwp • Interchangeable with Thornhill Craver

7800 psi cwp Economy Heater Choke

10,000 psi cwp • Upgradeable to 7800 psi cwp

NOTE: STEM SEATS AVAILABLE W/.500, .750,

1.00 DIAMETER BORES MARK NAME OF PART PART NO

1 BODY 2” LPT (TC-4373) 1163

.500 DIAMETER - PART NO. 1106

.750 DIAMETER - PART NO. 1107 2 SEAT, 3/4 HS 1107

1.00 DIAMETER - PART NO. 1108 3 SEAT GASKET (TC-1016) 1165

4 STEM, HS (TC-899) 1102

• When you select a 6500 psi ECONOMY HEATER CHOKE from Houston 5 RETAINER RING (TC-959) 1161

Oilfield Equipment, Inc. you can be assured of high quality at a very 6 O-RING, BUNA 1160

competitive price. Our long nose Heater Choke is manufactured to the 7 JUNK RING (TC-895) 1144

most rigid specifications with special emphasis on safety and reliability. It 8 STEM PACKING (TC-896) 1143

is built upon a time proven design that has been employed by both end 9 BONNET, ALLOY STEEL 1158

users and fabricators in countless trouble-free installations. 10 NYLON BALL 1004

• The function of a Heater Choke is to expand the high pressure gas 11 THUMB SCREW (TC-529) 1162

within the tubing coils of an indirect fired heater. The coil attaches to the 12 INDICATOR 3/4” (TC-530) 1417

choke at its outlet end which is immersed in the water bath of the heater. 13 SET SCREW F/INDICATOR 1007

The resultant generation of heat minimizes the extreme refrigerating 14 HANDWHEEL 9000

action which will occur as the high pressure gas expands.

15 WASHER, FLAT 5/8” 1023

• Get more value for your dollar when you specify the 6500 psi ECONOMY 16 HEX NUT 5/8” 1043

HEATER CHOKE from Houston Oilfield Equipment, Inc.

14

6 7 11

9

3 5 8 15

1 2 4 12

10 13

16

3.25

12.25

28.44 MIN REMOVAL CLEARANCE

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

10 10

HOUSTON OILFIELD EQUIPMENT, INC.

POSITIVE AND ADJUSTABLE CHOKES

WITH REMOVABLE HAMMER WING

UNION CAGE NIPPLE ASSEMBLY

HOE, Inc. is pleased to announce the arrival of its removable wing union cage

nipple assembly. This assembly may be fitted to any existing HN-60 adjustable

choke or HFT-108 positive choke assembly. It employs the same time proven

hammer nut design which is used extensively throughout the oil and gas indus-

try. In fact, the hammer nut is interchangeable with the ones currently being

used to secure the bonnet and blanking cap. On the removable wing union

assembly the hammer nut secures the cage nipple to the body outlet end. This

allows the cage nipple to be changed in a minimal amount of time with only the

use of a simple shop hammer.

Say farewell to the often

tedious job of removing a

threaded type cage nipple

and re-installing with a new

one. Choke beans and seats

can now be changed much

quicker which means less

down time and increased

production. Consider this on

your next requirement for an

HN-60 adjustable choke or

HFT-108 positive choke

assembly. You will be glad

you did.

SPECIFICATIONS FEATURES AND BENEFITS

Type: Positive and Adjustable • Uses standard HN-60 Hammer Nut

Forged Steel

End Connections: Threaded, Butt Weld • Minimal down time for change-out

Design Pressure: 5M CWP • Simple conversion from conventional

assembly

Service Type: H2S or Standard • No special tools needed

• Field weldable materials

Materials: Alloy, Stainless Steel

• Readily available spare parts

Trim Sizes: 3/4”, 1” • Forged steel tee body

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

11 11

HOUSTON OILFIELD EQUIPMENT, INC.

TYPE H-H2 POSITIVE AND ADJUSTABLE CHOKES

The type H H2 Choke from Houston SPECIFICATIONS

Oilfield Equipment features the

Type: Positive and Adjustable

needle and seat design to allow fully

adjustable flow. The adjustable choke Body Design: Angle Type

is operated by rotating the hand- End Connections: Flanged RTJ and RF

Threaded

wheel in order to obtain a desired Union Ends

flow rate, or a specified downstream Design Pressure: 2000 PSI CWP

pressure. The H H2 is also available in 3000 PSI CWP

a positive or fixed orifice design. In 5000 PSI CWP

10,000 PSI CWP

this model a flow bean is installed in 15,000 PSI CWP

the choke to achieve the desired TRIM SIZES: 3/4”, 1, 1 1/2”, 2”

flowing conditions.

TRIM MATERIALS: Alloy Steel, Stellite

Stainless Steel, Inconel

Stainless Steel Tungsten Carbide

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

12 12

HOUSTON OILFIELD EQUIPMENT, INC.

TYPE H-H2 ADJUSTABLE CHOKES

MAX 2” ORIFICE

2

1 TYPE H-H2

4 3

ADJUSTABLE CHOKES

5 MAX 2” ORIFICE

6

7 FLANGE SIZE CWP A” B” C”

8

10

3” 3,000 API 11.38 8.88 30.00

3” 5,000 API 11.38 8.88 30.00

9 11

12 3 1/16” 10,000 API 11.75 10.38 30.25

13 4 1/16” 10,000 API 11.50 9.94 30.12

13A 3” 600 ANSI RTJ 11.38 8.88 30.00

13B

14

16

PARTS H-H2

15

ADJUSTABLE CHOKES

MAX 2” ORIFICE

PART

ITEM DESCRIPTION QTY. NUMBER

1 Hex Nut 1 1024

STEM 2” ORIFICE 2 Flat Washer 1 1023

3 Handwheel 1 1521

4 Stem HS 2” 1 1530

Stem SS 2” 1 1590

23 1/8” Stem SSTC 2” 1 1427

5 Set Screw 1 1535

6 Indicator 2” 1 1483

7 Bonnet 1 1510

8 Thumbscrew 1 1529

9 Nylon Ball 1 1004

10 Grease Fitting 1 1013

11 Hammer Nut 5M 1 1511

Hammer Nut 10M 1 1512

C” 12 O-Ring 1 1528

2.75 13 Packing 1 1505

EXTERNAL 13A Junk Ring 1 1614

HEX

13B Retaining Ring 1 1484

14 Seat HS 2” 1 1513

6” Seat SS 2” 1 1514

Seat SSTC 2” 1 1429

A” SEAT 2” ORIFICE 15 Seat Gasket 1 1464

16 Body, Flanged 3” 5M 1 1516

Body, Flanged 3” 10M 1 1517

*17 Seat Wrench 1 1474

B” *Sold Separately – Not Pictured

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

13 13

HOUSTON OILFIELD EQUIPMENT, INC.

TYPE H-H2 POSITIVE CHOKES

MAX 2” ORIFICE

DIMENSIONS

1 EXTERNAL BIG JOHN FLOW BEAN

HEX

AVAILABLE

2 LENGTHS

6”, 3.30”

3 A. B.

1” MAX 6.13” 2” MAX

4

ORIFICE ORIFICE

5

6 TYPE H-H2

POSITIVE CHOKES

7

MAX 2” ORIFICE

FLANGE SIZE CWP A” B” C”

3” 3,000 API 11.38 8.88 18.50

3” 5,000 API 11.38 8.88 18.50

3 1/16” 10,000 API 11.75 10.38 18.75

4 1/16” 10,000 API 11.50 9.94 18.69

3” 600 ANSI RTJ 10.00 7.50 17.12

PARTS H-H2

POSITIVE CHOKES

MAX 2” ORIFICE

PART

ITEM DESCRIPTION QTY. NUMBER

INLET

1 Blanking Cap 1 1475

2 Retaining Ring 1 1562

C”

3 Hammer Nut 5M 1 1511

Hammer Nut 10M 1 1512

4 O-Ring, Nitrile 1 1462

A” 5 Body, Flanged 3” 5M 1 1516

Body, Flanged 3” 10M 1 1517

6 Seat Gasket 1 1464

*7 Flow Bean HS 1 41 SIZE

Flow Bean SSTC 1 40 SIZE

*8 Bean Wrench 1 1474

OUTLET B”

*Items 7 and 8 are sold separately.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

14 14

HOUSTON OILFIELD EQUIPMENT, INC.

TYPE H-H2 ADJUSTABLE CHOKES

MAX 1” ORIFICE

TYPICAL 2000 PARTS H-H2

THROUGH 10,000 PSI ADJUSTABLE CHOKES

MAX 1” ORIFICE

ADJUSTABLE CHOKES

ITEM NO. DESCRIPTION 1” MAXIMUM ORIFICE

2 1 5M CWP 10M CWP

1 Hex Bolt 1542 1542

3 2 Washer 1011 1011

3 Handwheel 1522 1522

4 4 Set Screw 1007 1007

5 5 Indicator 1” 1207 1207

6 Wing Nut 1536 1536

7 Bonnet 1538 1538

6 8 Nylon Ball (Plug) 1004 1004

9 Thumb Screw 1003 1003

8 10 O-Ring 1205 1205

11 Junk Ring 1206 1206

7 12 Packing w/BU 1202 1202

13 Retainer Ring 1590 1590

9 14 Stem HS 1208 1208

Stem HSS 1656 1656

10 Stem SSTC 1209 1209

15 Seat HS 1415 1415

12 Seat HSS 1655 1655

11 Seat SSTC 1204 1204

16 Gasket 1541 1541

13 17 Body, Flanged 1539 1539

*18 Wrench 1465 1465

* Wrench sold separately – Not Pictured

14 MISCELLANEOUS PARTS

FOR H-H2 POSITIVE AND

15 ADJUSTABLE CHOKES

16

• Indicator 3 x 1 PVC PN1550

17 • Ditto Aluminum PN1715

• Ditto 3 x 1 1/2 PVC PN1864

• Ditto 3 x 2 Aluminum PN2088

• Ditto 2 x 3/4 PVC PN1916

• Adapter Bean/Seat 3 x 1 H2 Alloy PN1525

• Ditto SS PN2089

• Adapter 3 x 1 H2 F/FC-140 Alloy PN1593

• Ditto SS PN1790

• Stem H2 15M 1” SSTC PN1543

• Seat 3 x 1 SSTC Short FL PN1899

• Ditto 3 x 1 1/2 PN1863

• Ditto 3 x 2 SSTC Short FL PN1745

1.69

EXTERNAL HEX • Ditto 3 x 2 SSTC 6” Long PL PN1925

• Ditto 3 x 2 SSTC 10” OAL FL PN1624

• Ditto 2 x 1 SSTC 12” OAL FL PN1985

6”

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

15 15

HOUSTON OILFIELD EQUIPMENT, INC.

STEAM CHOKE ASSEMBLY

3000 LBS. CWP

HANDWHEEL

THUMB SCREW

PACKING BOX

LOWER STEM

BUSHING

STEM BEARING STEM CLAMP

BONNET

STEM SEAT ASSEMBLY

WING NUT

CHOKE BODY ADAPTER UPPER STEM

WASHER

STEM LOCK HEX NUT

SHOE

PACKING OPERATOR BONNET

BONNET SEAL RING

OPERATOR YOKE

PACKING GLAND

LOCK NUT

The Houston Oilfield Equipment, Inc. Steam Choke uses a non rotating stem

with linear motion that won’t grab the packing and pull it out of place. When

packing needs adjustment simply tighten the choke packing gland as required.

The gland is easily accessible as it is externally located. This means minimal time

and simple maintenance.

SPECIFICATIONS FEATURES AND BENEFITS

• 3000 LBS. CWP • Uses FMC Type Standard JWA Body

• Max 1” Orifice • Aluminum Indicator

• Alloy or SS Body

• Flanged, Butt Weld, Socket Weld or • External Packing Adjustment

Threaded End Connections • Field Repairable

• Manual Type or Actuated Operation • Metal to Metal Taper Seal

• Temperature Range -32oF to 850oF

• Angle Body with Vent Port • Parts Interchangability

• Trim Stainless Steel • No Special Tools Required

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

16 16

HOUSTON OILFIELD EQUIPMENT, INC.

INDICATOR DETAIL/PROCEDURES FMC

H2 ADJUSTABLE CHOKES

PROCEDURE: NOTCH FOR READING BONNET

ORIFICE SIZE

With choke in fully closed

position align mark (64ths

increments) on indicator

with notch on bonnet.

Tighten set screw. Indicator

is now set in proper

calibration.

NOTE:

Remember to open choke INDICATOR SET SCREW

prior to shipment or final STEM SET SCREW

disposition. (FULLY SEATED/CLOSED) ACCESS HOLE

PACKING TYPE U PACKING CHEVRON TYPE

W/BACK-UP RING PN: 1505 TYPICAL FOR

H2S/CO2 SERVICE H2/FMC ADJUSTABLE CHOKES

LOWER JUNK RING

SOLID BACK-UP RING

U-PACKING UPPER

JUNK RING

RETAINING

RING

TO CHOKE SEAT

INSTRUCTIONS 1. Slide lower junk ring to bottom of packing gland.

2. Install packing rings into bonnet with flat

1. Slide back-up ring to bottom of packing gland. adapter first. NOTE: V shape of packing rings

2. Install packing into bonnet with radius end up must be positioned with open (lip end) toward

and flat against junk ring. pressure.

3. Place upper junk ring on top of packing. 3. Place upper junk ring on top of packing and

4. Install retaining ring in groove. install retaining ring.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

HOUSTON OILFIELD EQUIPMENT, INC.

TERMS AND CONDITIONS

Standard terms are net 30 days, unless otherwise agreed by Houston Oilfield Equipment, Inc. in writing. Boxing,

freight, cartage and like charges, where applicable, are net. All weights are approximate.

All sales are F.O.B. Factory, unless otherwise expressly stipulated. Our responsibility ceases upon delivery of goods

and bill of lading or dock receipt, invoice and supplementary documents to the customer or his agent, or upon delivery

of the shipment to the carrier.

All price quotations are F.O.B. Factory, are subject to change without notice, and are for immediate acceptance

unless otherwise specified. Delivery dates promised will be kept to the best of our ability, but cannot be guaranteed, and

Houston Oilfield Equipment, Inc., (hereafter referred to as HOE, Inc.), will assume no liability for damages

arising out of failure to keep delivery date, irrespective of the delay. Purchase orders placed and accepted may be

cancelled with HOE, Inc.’s consent and upon terms which will indemnify HOE, Inc. against loss. All invoices are due and

payable at our offices, located in Houston, Harris County Texas.

PRODUCT WARRANTY

We warrant products of our manufacture one year from date of shipment to the extent that HOE, Inc. will repair

or replace any products of defective workmanship proven under normal use and service. No other warranty is expressed

or implied. We specifically are not responsible for damages or injury, direct or indirect, or for damages or failures caused

by improper installation, operation or misuse.

Goods or parts thereof, not manufactured by us are guaranteed only in accordance with the manufacturer’s

guarantee and only to the extent that we are able to enforce it.

All claims for in-transit shortages, damages or erroneous charges must be made within thirty (30) days from receipt

of shipment and must be accompanied by the packing lists covering shipment.

We strive to pack and prepare all shipments so that they will not break, rust or deteriorate in transit, but do not

guarantee against such damage.

Upon request, HOE, Inc. will provide engineering and/or technical information regarding its products and their uses

and, if feasible, will provide personnel to assist purchasers in effecting field installations and/or field service. Any such

information, service, advice or assistance when provided, whether with or without charge, shall be advisory only. It is

expressly understood that HOE, Inc. assumes no liability for damage or loss arising out of, resulting from, or caused in

whole or in part by such information, service, advice or assistance so provided.

We reserve the right to change or modify the design and/or construction of any HOE, Inc. product in due course of

manufacturing procedure without notice, and without incurring any obligation to furnish or install such changes or

modifications on products previously or subsequently sold. Any other representations, warranties or conditions, expressed

or implied, relating to material, equipment or services provided by HOE, Inc. are excluded, unless specifically agreed in

writing, by HOE, Inc.

All sales made by us, unless otherwise agreed to in writing by an executive officer of the Company, are made

subject to each and all of the foregoing conditions and the placing of an order, or the acceptance by the customer of the

above said conditions.

UNUSED PRODUCT RETURN POLICY

New, unused products of our current manufacture may be returned for credit, provided written request is received

within eighteen (18) months after the purchase date. Special or discontinued and/or obsolete products are not returnable

for credit. Restocking charges may apply and will be determined at time of request.

Requests for the return of material should show original purchase order number, invoice number, description of

material and date of purchase. All requests should be mailed to: HOUSTON OILFIELD EQUIPMENT, INC., 11320 FM 529,

BUILDING D, HOUSTON, TEXAS 77041.

Material returned for credit shall be shipped via prepaid freight to our specified destination.

The credit allowed on returned goods is a merchandise credit and applicable only against purchases of our products.

Credit will be allowed under the above conditions at the original price, or at a subsequently adjusted price.

24 HOUR ANSWER/ORDER NUMBERS ❖ TEL: 1-800-882-3717 ❖ FAX: 713-466-3189

HOUSTON OILFIELD EQUIPMENT, INC.

COMPANY HISTORY

ouston Oilfield Equipment, Inc. (HOE, Inc.) is recognized throughout the world

as a manufacturer of quality choke products. Our company was formed in 1993

and is headquartered in Houston, Texas, which is considered to be a major hub

within the oil and gas industry. Houston was a natural choice, as this location

ideally serves both domestic and international markets. The president and

founder of HOUSTON OILFIELD is Tom Bowers. Mr. Bowers has 30 years

experience in the oil and gas industry, has attained a vast knowledge of chokes and related

products and possesses an impeccable reputation with customers, colleagues and

competitors alike.

OE, Inc. markets its products through a network of distributors and sales

representatives, both domestic and foreign. Our company takes pride in being

able to respond to its customers in minimal time, whether the task be

providing a quote, shipping a product or assisting in customer service. We have

maintained excellent customer relationships by providing unsurpassed service.

This everyday challenge is the basis of operation by which our

company operates. HOE, Inc. specializes in chokes of the FMC and Cameron type H2 and

Thornhill-Craver profile, which are fully interchangeable with those manufacturers of the

same product style. These designs are time proven and have been employed in many

different types of service. In addition to the choke assemblies, parts for the above

mentioned and various other types of chokes are also available.

OE, Inc.’s line of chokes is ideally suited for a broad range of applications. These

include well heads, production manifold, well testing, steam injection, choke

and kill manifolds, indirect fired heaters and well clean up operations. Should

your choke require the API 6A monogram, Houston Oilfield is a current license

holder of API 6A certificate 6A-0487. We welcome the opportunity to address

your choke needs. As our reputation has shown for the past 10 years, we will

make every effort to provide timely and professional service to your organization. Providing

a quality product with outstanding customer service has and will continue to be, our

benchmark in the oil and gas industry.

HOUSTON OILFIELD EQUIPMENT, INC.

11320 FM 529, Building D & E

Houston, Texas 77041

Tel: 713-466-3797 ❖ Fax: 713-466-3189

Website: www.hoeinc.com HOEIPC62003

Potrebbero piacerti anche

- Houston Oilfield Catalog Adjustable ChokeDocumento20 pagineHouston Oilfield Catalog Adjustable ChokeelvagojpNessuna valutazione finora

- Cameron ChokeDocumento20 pagineCameron ChokeMichael Haise0% (1)

- HoustonOE Catalog FINALDocumento32 pagineHoustonOE Catalog FINALclaudio godinezNessuna valutazione finora

- Pioneer Castor Catalogue 2008Documento24 paginePioneer Castor Catalogue 2008SunnySinghNessuna valutazione finora

- Series 2700 Maintenance ManualDocumento12 pagineSeries 2700 Maintenance ManualLuciusNessuna valutazione finora

- Catalogue CNA 50Hz Rev.1 Update 6-1Documento6 pagineCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNessuna valutazione finora

- Bohmer Subsea #U2013 50 MM Offshore Pipeline ValvesDocumento14 pagineBohmer Subsea #U2013 50 MM Offshore Pipeline ValvesBilly KurniawanNessuna valutazione finora

- OPR - EZ-118032 - I-Jar Wireline and Accelerators - 5406176 - 01Documento33 pagineOPR - EZ-118032 - I-Jar Wireline and Accelerators - 5406176 - 01Yermi ParabangNessuna valutazione finora

- Mobile Cylinder Div. Standard Build Series: Catalog HY18-0014/US Rev CDocumento58 pagineMobile Cylinder Div. Standard Build Series: Catalog HY18-0014/US Rev CDiego PacheNessuna valutazione finora

- Farris Valve CatalogueDocumento20 pagineFarris Valve CatalogueSamuelBartoMuntheNessuna valutazione finora

- Hyd Inc Swivel JointsDocumento28 pagineHyd Inc Swivel Jointsfrancis_15inNessuna valutazione finora

- Catalog Mud Pump 25864Documento24 pagineCatalog Mud Pump 25864agus100% (1)

- Catalog ParkerDocumento230 pagineCatalog Parkeringerash_mic9067% (3)

- Mac Tools Catalog No 14 1947Documento40 pagineMac Tools Catalog No 14 1947OSEAS GOMEZNessuna valutazione finora

- Cilindros Mobile IIDocumento52 pagineCilindros Mobile IIBernardo Orozco LariosNessuna valutazione finora

- 05.2. - Valvula de Bola Montada Sobre Muñon PDFDocumento24 pagine05.2. - Valvula de Bola Montada Sobre Muñon PDFalquimista203Nessuna valutazione finora

- HP Fishing Tools Catalog (1712)Documento9 pagineHP Fishing Tools Catalog (1712)Mohammad Reza NajafiNessuna valutazione finora

- CT WKM Ball Dynaseal 310Documento1 paginaCT WKM Ball Dynaseal 310JonathanNessuna valutazione finora

- Panam Needle Valves - SB SeriesDocumento16 paginePanam Needle Valves - SB SeriesCarlos WotchoskiNessuna valutazione finora

- Catálogo Mariposas PRATT USADocumento12 pagineCatálogo Mariposas PRATT USAAlex Javier Garzon OrduñaNessuna valutazione finora

- Bomba Myres I2ci-15rDocumento5 pagineBomba Myres I2ci-15rJemka RodriguezNessuna valutazione finora

- AllAir Catalog SchraderBellows NC9SeriesCylindersDocumento41 pagineAllAir Catalog SchraderBellows NC9SeriesCylindersAlexsandro Cavalcanti de SouzaNessuna valutazione finora

- Nozzle Holders Clemco Industries Corp. Parts List 2005Documento1 paginaNozzle Holders Clemco Industries Corp. Parts List 2005Fredy SierraNessuna valutazione finora

- Jensen. A Swagelok Company. Jenflo Series Pumps Sanitary Centrifugal PumpsDocumento24 pagineJensen. A Swagelok Company. Jenflo Series Pumps Sanitary Centrifugal PumpsAgustin CesanNessuna valutazione finora

- YG Tooling System New CatalogueDocumento260 pagineYG Tooling System New CatalogueUthaya AbiNessuna valutazione finora

- Wellhead Fittings & Valve Components - PGI-WFDocumento28 pagineWellhead Fittings & Valve Components - PGI-WFIan KevinNessuna valutazione finora

- Manual de BombasDocumento10 pagineManual de BombasCalcetinNessuna valutazione finora

- Coromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaDocumento4 pagineCoromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaazharzebNessuna valutazione finora

- Crown-Fusion ASME B16.34 Threaded Ball Valves Brochure 2Documento20 pagineCrown-Fusion ASME B16.34 Threaded Ball Valves Brochure 2claudio godinezNessuna valutazione finora

- Crown-Fusion ASME B16.34 Threaded Ball Valves Brochure 2 CompressedDocumento20 pagineCrown-Fusion ASME B16.34 Threaded Ball Valves Brochure 2 Compressedclaudio godinezNessuna valutazione finora

- Rotary Feeder 1Documento6 pagineRotary Feeder 1elangorengaNessuna valutazione finora

- Bombas CUTESDocumento6 pagineBombas CUTESCarlos Andres Gonzales VerasteguiNessuna valutazione finora

- Manual Book Pompa 104G5Documento7 pagineManual Book Pompa 104G5Ardi 4791Nessuna valutazione finora

- KF Threaded Ball Valve Catalog PDFDocumento24 pagineKF Threaded Ball Valve Catalog PDFAnonymous qhVGVpNessuna valutazione finora

- 11 - Forged Gate Valves RPC Procedure PDFDocumento52 pagine11 - Forged Gate Valves RPC Procedure PDFtilakthakar1Nessuna valutazione finora

- BOP Quad 3.06 10KDocumento33 pagineBOP Quad 3.06 10KWill CastellanosNessuna valutazione finora

- Thornhill Craver Chokes and CouplingsDocumento32 pagineThornhill Craver Chokes and CouplingsJorge Hanna AkouriNessuna valutazione finora

- ThreadedGrooved CatalogDocumento24 pagineThreadedGrooved Catalogprihartono_diasNessuna valutazione finora

- HoustonOE Catalog Final 08-02-2022 CompressedDocumento17 pagineHoustonOE Catalog Final 08-02-2022 Compressedclaudio godinezNessuna valutazione finora

- Soportes EricoDocumento12 pagineSoportes EricoJulian RiverosNessuna valutazione finora

- Wet Cutting-Off GrinderDocumento2 pagineWet Cutting-Off GrinderMiguel RomanNessuna valutazione finora

- Viking Q4195 1Documento14 pagineViking Q4195 1arbiNessuna valutazione finora

- Robo Catalog US LIT.9075Documento40 pagineRobo Catalog US LIT.9075Oscar SermeñoNessuna valutazione finora

- Mercer Valve 9100 Relief Valve Flanged AEDocumento16 pagineMercer Valve 9100 Relief Valve Flanged AEChristopher Kenneth ChoaNessuna valutazione finora

- Manual Valves Datasheet. Rev 1Documento7 pagineManual Valves Datasheet. Rev 1eke23Nessuna valutazione finora

- D Series Installation&Maintenance PDFDocumento56 pagineD Series Installation&Maintenance PDFPablo GarcíaNessuna valutazione finora

- HPT NozzleDocumento19 pagineHPT Nozzlekien Duy PhanNessuna valutazione finora

- M60eh54 Z549xy Man 001Documento22 pagineM60eh54 Z549xy Man 001Riski KurniawanNessuna valutazione finora

- Premier Valves Product SelectorDocumento8 paginePremier Valves Product SelectortcsNessuna valutazione finora

- Premier ValvesDocumento12 paginePremier Valvesneelkant sharmaNessuna valutazione finora

- Taco 0011 Circulator PumpDocumento2 pagineTaco 0011 Circulator Pumpsonali boranaNessuna valutazione finora

- Tri Cone BitsDocumento16 pagineTri Cone BitsPeter ForrestNessuna valutazione finora

- 6400 Series Horizontal Loading Valves: BenefitsDocumento12 pagine6400 Series Horizontal Loading Valves: Benefitsvalter mNessuna valutazione finora

- Valvula Convencional de BNDocumento4 pagineValvula Convencional de BNdanielNessuna valutazione finora

- Mercer Valve 9100 Relief Valve Threaded AEDocumento16 pagineMercer Valve 9100 Relief Valve Threaded AEdoens JKTNessuna valutazione finora

- M60eh44 Man 001Documento40 pagineM60eh44 Man 001Riski KurniawanNessuna valutazione finora

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Handloader's Digest: The World's Greatest Handloading BookDa EverandHandloader's Digest: The World's Greatest Handloading BookValutazione: 2 su 5 stelle2/5 (1)

- Warning: Installation, Operating, & Maintenance InstructionsDocumento9 pagineWarning: Installation, Operating, & Maintenance InstructionsAnggi SujiwoNessuna valutazione finora

- Proquip Dual Plate Check Valves: ASME Classes: 150-2500 API: 2000-5000 Sizes: 2-60" (50-1500 MM)Documento28 pagineProquip Dual Plate Check Valves: ASME Classes: 150-2500 API: 2000-5000 Sizes: 2-60" (50-1500 MM)Anggi SujiwoNessuna valutazione finora

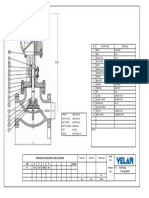

- Dimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateDocumento1 paginaDimensions in Millimetres and Kilograms: Prepered by Checked by Costomer Appd Drawn DateAnggi SujiwoNessuna valutazione finora

- CAT CSV 02 13.unlockedDocumento36 pagineCAT CSV 02 13.unlockedAnggi SujiwoNessuna valutazione finora

- ABV Side Entry Ball Valves PDFDocumento22 pagineABV Side Entry Ball Valves PDFAnggi SujiwoNessuna valutazione finora

- C-BS2. Bellows Seal ValvesDocumento52 pagineC-BS2. Bellows Seal ValvesAnggi SujiwoNessuna valutazione finora

- Ball Valve FCTDocumento16 pagineBall Valve FCTAnggi SujiwoNessuna valutazione finora

- Forged Cast Trunnion Ball Valves PDFDocumento24 pagineForged Cast Trunnion Ball Valves PDFAnggi SujiwoNessuna valutazione finora

- Flanged Floating Ball Valves PDFDocumento16 pagineFlanged Floating Ball Valves PDFAnggi SujiwoNessuna valutazione finora

- Star LaneDocumento12 pagineStar LaneAnggi SujiwoNessuna valutazione finora

- A49-12 Standard Specification For Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint BarsDocumento4 pagineA49-12 Standard Specification For Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint BarsDiego Egoávil MéndezNessuna valutazione finora

- BS EN12079-1999 (Inspection and Testing of Offshore ContainerDocumento32 pagineBS EN12079-1999 (Inspection and Testing of Offshore Containerjohnsonpinto100% (3)

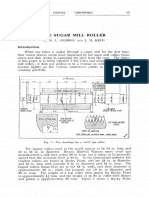

- The Sugar Mill Roller: BV R. I,. Geokge MDocumento9 pagineThe Sugar Mill Roller: BV R. I,. Geokge MuksrajNessuna valutazione finora

- Astm A 564Documento7 pagineAstm A 564GeorgeAzmirNessuna valutazione finora

- Cpe Saunders HC4 - Overview Bu en A4 2019 - 08 - 29Documento16 pagineCpe Saunders HC4 - Overview Bu en A4 2019 - 08 - 29DeRjOx1709Nessuna valutazione finora

- Quality ControlDocumento6 pagineQuality ControlEileen WongNessuna valutazione finora

- Forged Carbon and Alloy Steel Flanges For Low-Temperature ServiceDocumento6 pagineForged Carbon and Alloy Steel Flanges For Low-Temperature ServiceShahul Hameed RazikNessuna valutazione finora

- AFA CHAPTER: Engine ValvesDocumento26 pagineAFA CHAPTER: Engine ValvesMohamed HamdallahNessuna valutazione finora

- Datasheet 316 316L Imperial Hpsa Outokumpu en Americas PDFDocumento3 pagineDatasheet 316 316L Imperial Hpsa Outokumpu en Americas PDFgauravme1983Nessuna valutazione finora

- Nupla 2007 CatalogDocumento60 pagineNupla 2007 Catalogdonnal47Nessuna valutazione finora

- Forging: Workshop Practice ME-105Documento21 pagineForging: Workshop Practice ME-105Mazahir habibNessuna valutazione finora

- Runout Mecanico y ElectricoDocumento6 pagineRunout Mecanico y ElectricoJuan Pablo Chumba LaraNessuna valutazione finora

- MF4202 Additive ManufacturingDocumento159 pagineMF4202 Additive ManufacturingOptimMart InternationaleNessuna valutazione finora

- Corrosion Resistance Table of Metal MaterialsDocumento6 pagineCorrosion Resistance Table of Metal Materialsbehrooz rajabshehniNessuna valutazione finora

- Is 2004 PDFDocumento7 pagineIs 2004 PDFAshutosh Pandey100% (1)

- Manufacturing Process Paper 2Documento5 pagineManufacturing Process Paper 2elisabetbertaniaNessuna valutazione finora

- Copper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification ForDocumento8 pagineCopper and Copper Alloy Forging Rod, Bar, and Shapes: Standard Specification Formarjan banooNessuna valutazione finora

- Gunnebo Lifting Shackle Catalogue 2010Documento16 pagineGunnebo Lifting Shackle Catalogue 2010ofitec787Nessuna valutazione finora

- Comparative Study of Wheel Rim Materials Ijariie1437Documento4 pagineComparative Study of Wheel Rim Materials Ijariie1437simalaraviNessuna valutazione finora

- Module 2Documento79 pagineModule 2uditNessuna valutazione finora

- A503.2001 Ultrasonic Examination of Forged CrankshaftsDocumento3 pagineA503.2001 Ultrasonic Examination of Forged CrankshaftsEHT pipeNessuna valutazione finora

- Asme Section II A Sa-372 Sa-372mDocumento6 pagineAsme Section II A Sa-372 Sa-372mAnonymous GhPzn1xNessuna valutazione finora

- Supplier Evaluation Checklist F-PU-05 - FILLEDDocumento2 pagineSupplier Evaluation Checklist F-PU-05 - FILLEDNav Talukdar100% (1)

- Smithy & Forging ShopDocumento24 pagineSmithy & Forging Shopashok junapudiNessuna valutazione finora

- Fonte PROMEXDocumento34 pagineFonte PROMEXMass GiovaniNessuna valutazione finora

- Dynemech Visco DampersDocumento4 pagineDynemech Visco DampersYogesh BansalNessuna valutazione finora

- Crankshaft ConstructionDocumento24 pagineCrankshaft ConstructionBharatiyulam100% (2)

- Understanding API SIRE Reading-1 Part 2 of 2Documento358 pagineUnderstanding API SIRE Reading-1 Part 2 of 2Charlie Chong83% (6)

- Chapter 5 Die DesignDocumento129 pagineChapter 5 Die Designkb89% (9)

- PROJECT PPT 3rd SemDocumento19 paginePROJECT PPT 3rd SemanimeshNessuna valutazione finora