Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Caricato da

alDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Caricato da

alCopyright:

Formati disponibili

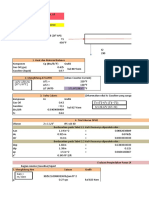

REAKTOR (R-01)

I. Fungsi : Tempat terjadikan reaksi hidrodealkilasi pembentukan benzen

Laju alir massa : 31137.238 kg/jam 𝑗𝑢𝑚𝑙𝑎ℎ 𝑡𝑢𝑏𝑒 (𝑁

Q pendingin :

Tekanan : 25 atm

Temperatur : 600 °C

(Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C.,

Baile and Friend)

𝜌�=(𝐵𝑀� 𝑥 𝑃)/(𝑅 𝑥

Densitas Campuran : 𝜌𝑐𝑎𝑚𝑝𝑢𝑟𝑎�=ρi .Xi 𝑇)

P = 25 atm

T = 873 K

R = 0.0821 L.atm/mol.K

Komponen ni fraksi mol i BM ρi ρcamp.

(Berdasarkan laju alir masuk (i) (mol/jam) (Xi) (g/mol) (gr/dm3) (gr/dm3)

Reaktor) Benzena 718.8 0.0003873128 78 27.207 0.01053754

Toluena 304096.8 0.1638572389 92 32.09 5.25818749

Hidrogen 1550893.6 0.8356718754 2 0.6976 0.58297293

Metana 155.1 8.35729207E-05 16 5.5809 0.00046641

Total 1855864.3 1 5.85216437

Densitas Campuran : 5.85216437 gr/dm3 𝜌=𝑚/� �=𝑚/ρ

Volumetrik Rate (V) : 5320636.27 dm3/jam

II. Spesifikasi Katalis

Jenis Katalis : Chromia Alumina (Al2O3-Cr2O3)

Diameter Katalis : 3.1 mm

Panjang : 3 mm (US Patent 378388)

GHSV : 815 /jam

Bentuk : Pellet

Porositas : 0.8

III. Volume Katalis

𝐺𝐻𝑆�= (�𝑜𝑙𝑢𝑚𝑒𝑡𝑟�𝑘 𝑟𝑎𝑡𝑒 𝑔𝑎𝑠)/(�𝑜𝑙𝑢𝑚𝑒 𝑘𝑎𝑡𝑎𝑙�𝑠 (𝑣𝑜𝑙𝑢𝑚𝑒�𝑜𝑙𝑢𝑚𝑒

𝑟𝑒𝑎𝑘𝑡𝑜𝑟))

𝐾𝑎𝑡𝑎𝑙�𝑠= (�𝑜𝑙𝑢𝑚𝑒𝑡𝑟�𝑘 𝑟𝑎𝑡𝑒 𝑔𝑎𝑠)/𝐺𝐻𝑆�

Volumetrik rate gas = 5320636.27 dm3/jam

GHSV = 815 /jam

Volume katalis = 6528.38806 dm3

Faktor keamanan 20% = 7834.06567 dm3

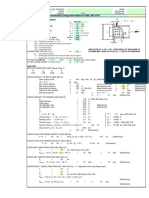

REAKTOR (R-01)

P design = 30.017252059 atm 441.430177

r tube = Tube OD(in)/2 = 0.375 in

f = 8500 psia = 578 1 psia = 0,068 atm

effisiensi = 0.8 atm

penyambungan

C (faktor = 0,0125 in/tahun= 0.125 in

korosi)

𝑡𝑒𝑏𝑎𝑙 𝑡𝑢𝑏𝑒=(𝑃𝑑𝑒𝑠�𝑔� 𝑥 (𝑟 𝑡𝑢𝑏𝑒 (𝑂�)))/(𝑓 𝑥 𝑒 − (0,6𝑃𝑑𝑒𝑠�𝑔�))+�

tebal tube = 0.1503301794 in

= 0.1875 in (mengikuti standar tabel 5.6 brownell young)

ID tube = OD - 2 (tebal tube) = 0.375 in

ID tube = 0,375 in

V. Diameter Shell

ID shel= 39 in = 0.9906 m

VI. Tebal Shell

tebal shell = 1.44216933 in

= 1.5 in (mengikuti standar tabel 5.6

brownell young)

OD shell = ID shell + 2 (tebal shell)

= 39 + 3

OD shell = 42 in

VII. Tebal Head

Tebal Head = (Pdesign x radius of crown x W)/((2 x f x e)-(0,2 x P design))

r = 42

icr = 3.75 3 3/4 (Tabel 5.7 Brownell young)

W = 1/4 x ((3+(r/icr))^0,5) Torispherical head (Flanged and dishead head)

= 0.94207218

f = 578 atm

e = 0.8

P desig= 25.0143767 atm

Tebal Head = 1.07604667 in

Tebal Head standar = 1.125 in (Tabel 5.6 Brownell Young)

1 1/8

REAKTOR (R-01)

VIII. Tinggi head dan volume head

Thickness (in) = 1,125 in

Sf dipilih = 1.5 1 1/2 in

icr = 2.375 3 3/8 in

r = 42 in

Dengan demikian direncanakan reaktor fixed bed dengan spesifikasi :

Shell :

ID = 39 in = 0.9906 m

OD = 42 in = 1.0668 m

Tebal shell = 1.5 in = 0.0381 m

Tube :

ID = 0,375 in = 0.009525 m

OD = 0,75 in = 0.01905 m

Jumlah tube dengan 2-P = 1330 tube

Pitch = 15/16 in triangular pitch = 0.0238125 m

Panjang tube = 1000 in = 25.4 m

Tebal tube = 0.1875 in = 0.0047625 m

Tebal head = 1.125 in = 0.028575 m

Tinggi head = 8.8916122513 in = 0.2258469512 m

Volume head = 0.0001477538 m3 = 0.0001477538 m3

Tinggi reaktor= 25.851693902 m = 25.8516939024 m

Volume total = 0.0128087648 m3 = 0.0128087648 m3

reaktor

Bahan yang digunakan adalah stainless steel SA-167 grade 11 tipe 316

Bentuk head Torispherical head (Flanged and dishead head)

REAKTOR (R-01)

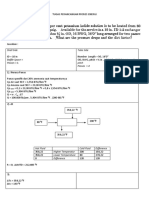

III. Jumlah Tube (Nt) 1 in = 0,0254 m

𝑗𝑢𝑚𝑙𝑎ℎ 𝑡𝑢𝑏𝑒 (𝑁𝑡)= (�𝑜𝑙𝑢𝑚𝑒 𝑘𝑎𝑡𝑎𝑙�𝑠)/((1−𝑋)𝑥(0,25� 〖��〗 ^2 𝐿)) 1 ft = 0,305 m

Spesifikasi tube : (Tabel 10. Kern)

(pendekatan) OD (in) = 1.5

BWG = 18

ID (in) = 1.4 0.03556 m

Flow area = 1.54

per tube

(in2)

Surface = 0.3925

per lin

(ft2/ft)

Volume Katalis = 6528.388 dm3 = 6.528388 m3

X = 0.8

ID = 0.03556 m

L (panjang tube) = 1000 in = 25.4 m

Nt = 1294.64

Nt = 1330 (mengikuti standar Tabel 9. Kern)

Shell ID (in) = 39

2-P = 1330 tube

Tube OD (in) = 0.75 (3/4) (Tabel 9 Kern)

15/16 in Triangular pitch

L (in) = 1000

Laju alir umpan dalam tube = Feed masuk / jumlah tube

= 4000.478 dm3/jam

IV. Tebal Tube

𝑡𝑒𝑏𝑎𝑙 𝑡𝑢𝑏𝑒=(𝑃𝑑𝑒𝑠�𝑔� 𝑥 (𝑟 𝑡𝑢𝑏𝑒))/(𝑓 𝑥 𝑒 − (0,6𝑃𝑑𝑒𝑠�𝑔�))+�

P design = P operasi + P hidrostatik psi

P operasi = 25 atm

P hidrostat= ρ.g.tinggi cairan tinggi cair = 1000 in

= 1456720.755 gr/m.s2 = 25.4 m

= 1456.720755 kg/m.s2 ρcampuran= 5.852164 gr/dm3

= 1456.720755 Pa = 5852.164 gr/m3

= 0.014376716 atm g = 9.8 m/s

P design = 25.01437672 atm 1 atm = 101325 Pa

Faktor = 30.01725206 atm

Keamanan

20%

REAKTOR (R-01)

Bahan yang digunakan adalah stainless steel SA-167 grade 11 tipe 316

Allowable stress (f) = 8500 psia 1112 F 600 °C

(item 4, allowable stress p.342)

Dari Figure 5.8 Process Equipment Design by Brownell and Young

a = ID/2 = 19.5 in

AB = a-icr = 17.125 in

BC = r-icr = 39.625 in

AC = (BC2-AB2)^0,5 = 35.73339 in

b = r-AC = 6.266612 in

OA = Tinggi hea= th + b + Sf

= 1.125 + 6.266612 + 1.5

Tinggi hea= 8.891612 in

Tinggi hea= 0.225847 m

1 in = 0,0254 m

Volume head = 2 x 0,000076 x ID3 1 ft = 0,305 m

= 0.000147754 m3

IX. Tinggi reaktor dan volume reaktor

- Tinggi reaktor = Tinggi shell+ 2xTinggi Head

= 25.4 + 0.451694

Tinggi reaktor = 25.85169 m

- Volume total reaktor

x P design)) Vt = Vsilinder + Vhead + 2Vsf

V silinder = 1/4 x π x IDshell2 x L

= 0.012623142 m3

V head = 0.000147754 m3

Vsf = 1/4 x π x IDshell2 x sf

= 1.89347E-05 m3

2Vsf = 3.78694E-05 m3

Vt = 0.012808765 m3

Potrebbero piacerti anche

- Vital Judo Throwing TechniquesDocumento193 pagineVital Judo Throwing TechniquesJuan Jose Opazo Carvajal100% (1)

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Documento4 pagineMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNessuna valutazione finora

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Documento64 pagineBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoNessuna valutazione finora

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocumento3 pagineDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNessuna valutazione finora

- IbnTaymiyyah Theological EthicsDocumento361 pagineIbnTaymiyyah Theological EthicsDado Daki100% (1)

- Stratigraphy MCQs With AnswerDocumento10 pagineStratigraphy MCQs With Answerkumar Harsh67% (3)

- ScantlingDocumento39 pagineScantlingSky R100% (1)

- Yehuda Berg Satan PDFDocumento77 pagineYehuda Berg Satan PDFOswaldo Archundia100% (7)

- Planetary Characteristics: © Sarajit Poddar, SJC AsiaDocumento11 paginePlanetary Characteristics: © Sarajit Poddar, SJC AsiaVaraha Mihira100% (11)

- Bolt Connection Design Based On NDS 2018: Input Data & Design SummaryDocumento2 pagineBolt Connection Design Based On NDS 2018: Input Data & Design Summaryalejahrojas96Nessuna valutazione finora

- KRC1 Start-Up PDFDocumento29 pagineKRC1 Start-Up PDFRafael50% (2)

- Elements, Compounds, MixturesDocumento35 pagineElements, Compounds, MixturesNorvieNessuna valutazione finora

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Documento12 pagineLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNessuna valutazione finora

- TubesheetDocumento8 pagineTubesheetVaibhavNessuna valutazione finora

- Die CalculationsDocumento13 pagineDie CalculationsDhinakaran R100% (1)

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Documento42 pagine8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- Div 2 THK CalcDocumento10 pagineDiv 2 THK CalcelleNessuna valutazione finora

- Shell CalculationsDocumento3 pagineShell CalculationsBaher Elsheikh100% (7)

- Boiler Stack Height Calculation From DLDocumento2 pagineBoiler Stack Height Calculation From DLNasrul HazimNessuna valutazione finora

- Bracket Design For ReactorDocumento32 pagineBracket Design For ReactorbrencejunNessuna valutazione finora

- Concrete ON MALDIVESDocumento55 pagineConcrete ON MALDIVESKãrthìçk JkrNessuna valutazione finora

- L15 - Parallel Magnetic CircuitsDocumento6 pagineL15 - Parallel Magnetic CircuitsParikshit MishraNessuna valutazione finora

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocumento37 pagineSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Line Sizing Calculation 1Documento9 pagineLine Sizing Calculation 1SAMUEL UDOHNessuna valutazione finora

- Boil-Off Gas CalculationsDocumento14 pagineBoil-Off Gas CalculationsAlberto100% (1)

- 11.3 KernDocumento78 pagine11.3 KernChou ChouNessuna valutazione finora

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocumento13 pagineProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (1)

- Reactor 20Documento1 paginaReactor 20Kriengsak RuangdechNessuna valutazione finora

- Chap 8. CondenserDocumento9 pagineChap 8. CondenserAli Ahsan100% (1)

- 5.3 Design of Waste Heat Boiler: (13) : DataDocumento7 pagine5.3 Design of Waste Heat Boiler: (13) : Datamoni beeNessuna valutazione finora

- Boiler CalcDocumento92 pagineBoiler CalcPrasanta Kumar BeheraNessuna valutazione finora

- Perancangan Alat CekDocumento19 paginePerancangan Alat CekLilyNessuna valutazione finora

- JAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1Documento21 pagineJAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1jawad khalidNessuna valutazione finora

- Submarine ReportDocumento10 pagineSubmarine ReportShahzeb Bin TariqNessuna valutazione finora

- Problem 1 Dphe Kusnaryo Hal 19 NFDDocumento7 pagineProblem 1 Dphe Kusnaryo Hal 19 NFDLDK UISINessuna valutazione finora

- API 650 Calculation ThicknessDocumento20 pagineAPI 650 Calculation ThicknessHsein WangNessuna valutazione finora

- Heat Balannce:: Fluid AllocationDocumento16 pagineHeat Balannce:: Fluid AllocationUsama AkramNessuna valutazione finora

- Mixer - 01: A. Menentukan Volum Tangki (V)Documento13 pagineMixer - 01: A. Menentukan Volum Tangki (V)kurniawanNessuna valutazione finora

- Vessel Heat LossDocumento2 pagineVessel Heat LossakisdassasNessuna valutazione finora

- Pompa Util SulsulDocumento90 paginePompa Util SulsulMaRhaenia TheresaNessuna valutazione finora

- Example 3Documento2 pagineExample 3RindangNessuna valutazione finora

- 100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)Documento10 pagine100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)MuhammadTanzeeLUsmanNessuna valutazione finora

- 11.mixing TankDocumento16 pagine11.mixing TankZaidatu ImtinanNessuna valutazione finora

- External Forced Convection: Pipe 90 °CDocumento16 pagineExternal Forced Convection: Pipe 90 °CiosuarizNessuna valutazione finora

- Inner Vessel Check Shell Thickness For Internal PressureDocumento6 pagineInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANNessuna valutazione finora

- Calculation For Steel Lift Pit at Concourse LevelDocumento5 pagineCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNessuna valutazione finora

- Perhitungan Tugas 1 Perancangan HEDocumento3 paginePerhitungan Tugas 1 Perancangan HELuthfanNessuna valutazione finora

- Beam Connection of Conventional Configuration Based On AISC 360-10/16Documento1 paginaBeam Connection of Conventional Configuration Based On AISC 360-10/16Karen Esther Acuña VelasquezNessuna valutazione finora

- Tangki BufferDocumento6 pagineTangki BufferdwirustantoNessuna valutazione finora

- Final GP2 Process Plantfor Aromatic ExtractionDocumento81 pagineFinal GP2 Process Plantfor Aromatic ExtractionLuxainne Tremont EchegarayNessuna valutazione finora

- Kristalizer (Cr-01)Documento5 pagineKristalizer (Cr-01)Winda Nirmala DewiNessuna valutazione finora

- Cantelever Retaining WallsDocumento7 pagineCantelever Retaining WallsChristina Daoud BarmoNessuna valutazione finora

- Appendix - Flash and Storage TK-101,102,103Documento14 pagineAppendix - Flash and Storage TK-101,102,103Kudo ShinichiNessuna valutazione finora

- Lampiran Perhitungan DesainDocumento13 pagineLampiran Perhitungan DesainPuspita PuspitaNessuna valutazione finora

- Calc WT - Lbm-Tanara - Z2Documento6 pagineCalc WT - Lbm-Tanara - Z2bertaNessuna valutazione finora

- Calculation D44Documento6 pagineCalculation D44hilal permanaNessuna valutazione finora

- Monteron Jaji C4 5Documento3 pagineMonteron Jaji C4 5John Lloyd TulopNessuna valutazione finora

- Machine Design of Stepper MotorsDocumento12 pagineMachine Design of Stepper Motorsabhrajit ghoshNessuna valutazione finora

- HEATER (H-01) : LMTD (-T) - (T - T) LN - T - TDocumento8 pagineHEATER (H-01) : LMTD (-T) - (T - T) LN - T - TJofanny Ferdian RahmansyahNessuna valutazione finora

- Chapter 6 eDocumento22 pagineChapter 6 eVoora GowthamNessuna valutazione finora

- 2.TankSurge Plate FOundationDocumento2 pagine2.TankSurge Plate FOundationdanjidNessuna valutazione finora

- RW Condenser V1.1Documento9 pagineRW Condenser V1.1Steve WanNessuna valutazione finora

- Chapter 8aDocumento157 pagineChapter 8aSolehah OmarNessuna valutazione finora

- Appendiks C Spesifikasi PeralatanDocumento2 pagineAppendiks C Spesifikasi PeralatanridanormaNessuna valutazione finora

- SBC CalculationDocumento3 pagineSBC CalculationStandardtec EngineersNessuna valutazione finora

- LAMPIRAN B RiskaDocumento32 pagineLAMPIRAN B RiskaIkhsan FoldismeNessuna valutazione finora

- Ion Beams for Materials AnalysisDa EverandIon Beams for Materials AnalysisR. Curtis BirdNessuna valutazione finora

- Speaker 0Documento12 pagineSpeaker 0alNessuna valutazione finora

- Simple Amine System V1.0Documento7 pagineSimple Amine System V1.0alNessuna valutazione finora

- Neraca MassaDocumento2 pagineNeraca MassaalNessuna valutazione finora

- English Language Education Department: Application For Field Study in AustraliaDocumento11 pagineEnglish Language Education Department: Application For Field Study in AustraliaalNessuna valutazione finora

- Indian Standard: Methods of Chemical Testing of LeatherDocumento75 pagineIndian Standard: Methods of Chemical Testing of LeatherAshish DixitNessuna valutazione finora

- HellforgedDocumento89 pagineHellforgedBrian Rae100% (1)

- Dumel James Melchor DuayDocumento3 pagineDumel James Melchor DuayBle DuayNessuna valutazione finora

- IPC 4552 Cuprins - ENIG PDFDocumento3 pagineIPC 4552 Cuprins - ENIG PDFMarlon CornejoNessuna valutazione finora

- Volume 2 Part 1 - Civil & Arch SpecificationsDocumento173 pagineVolume 2 Part 1 - Civil & Arch Specificationsanish100% (1)

- Miltel - Case Study, Steven Age, UKDocumento2 pagineMiltel - Case Study, Steven Age, UKAnit SahuNessuna valutazione finora

- LC Magna Leaflet 2019Documento2 pagineLC Magna Leaflet 2019saemiNessuna valutazione finora

- An Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageDocumento10 pagineAn Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageChristian EmenikeNessuna valutazione finora

- SMA - Core 1 - IEC62109-2 - 0 Test ReportDocumento6 pagineSMA - Core 1 - IEC62109-2 - 0 Test ReportFurqan HamidNessuna valutazione finora

- Linear Predictor: Nature of Linear PredictionDocumento9 pagineLinear Predictor: Nature of Linear PredictionkvNessuna valutazione finora

- Question Paper - GIAN - 19 - ModifiedDocumento4 pagineQuestion Paper - GIAN - 19 - Modifiedsayan mukherjeeNessuna valutazione finora

- Correlation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingDocumento101 pagineCorrelation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingpritamNessuna valutazione finora

- Cigarettes and AlcoholDocumento1 paginaCigarettes and AlcoholHye Jin KimNessuna valutazione finora

- Evaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CDocumento10 pagineEvaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CAliNessuna valutazione finora

- Static CMOS and Dynamic CircuitsDocumento19 pagineStatic CMOS and Dynamic CircuitsAbhijna MaiyaNessuna valutazione finora

- BSO 04cDocumento267 pagineBSO 04cSamikshya BNessuna valutazione finora

- Aoc f22sDocumento43 pagineAoc f22sJoao Jose Santos NetoNessuna valutazione finora

- EclipseDocumento6 pagineEclipsetoncipNessuna valutazione finora

- Bài 1: Fill in The Blank With Present Simple, Present Continuous or Past SimpleDocumento6 pagineBài 1: Fill in The Blank With Present Simple, Present Continuous or Past SimplePhương Anh Đỗ NgọcNessuna valutazione finora

- Aluminum Alloy 6351 T6 Sheet SuppliersDocumento10 pagineAluminum Alloy 6351 T6 Sheet Supplierssanghvi overseas incNessuna valutazione finora