Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5s Implementation Work1 PDF

Caricato da

Rama PrasetiaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5s Implementation Work1 PDF

Caricato da

Rama PrasetiaCopyright:

Formati disponibili

S5 – SUSTAIN

The purpose of S5-Sustain is to maintain the momentum generated during the initial event or project. A management

auditing process should be put into practice to ensure that employees understand that maintaining the level of

workplace organization is a top priority. Management audits should focus on ensuring that the routines and schedules

specified in S4 Standardize are being properly maintained. The audit also provides an excellent opportunity for asking

questions and providing suggestions that stimulate further improvements.

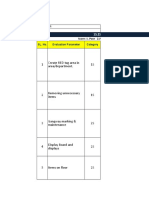

5S Housekeeping Score Sheet

Site Location Audited: Tech Support - Good Hope Facility

Date:___________ Auditor:____________________________

NA 0 1 2 3 4 Description of Area

Sort

1 No old or unnecessary materials in area.

2 Empty / unused ribbons/materias are out of the area.

3 Free of unnecessary equipment, furnitre and personal items.

Set In Order

4 Printers, batteries and adapters are properly identified and stoerd in designated area.

5 Portable and benchtop printer cabinets are clean and organized.

6 Movable pritner carts are in proper location.

7 Inventory neat, organized and identified.

Shine

8 Tops of machines, cabinets free of dust and debris.

9 Floors are clean around the work area.

10 Benchtop islands are orgaized and free of unnecessary items.

11 Work station neat, clean and organized.

Standard

12 Damaged or non-functional printers / equipment is removed from the area or marked for replacement.

13 Electrical Panel area unobstructed.

14 Furniture/chairs/desks are in good condition and clean.

Sub

0 0 0 0 0 0

Total

Next, the 5S effort needs to be expanded to other work areas. Use the 5S’ed work area as a model for emulation,

and invite the original 5S team to share their ideas and experiences with employees from other work areas. Be sure

to publicize success stories and provide appropriate recognition to team members. 5S newsletters, displays, and

awards are excellent ways to build employee morale and motivation.

Finally, it should be reinforced that 5S is an on-going journey. Workers should be encouraged to continue to make

improvements to their workplace on a regular basis. The same work area might even be scheduled for a follow-up

5S event six months or a year later. Continuous improvement must become part of the routine expectations and

activities of the work day. When improvement stops, the likelihood is that workplace organization will not just

stagnate, but will actually deteriorate. To avoid that, keep everyone continually looking for ways to improve their work

conditions.

Action steps for implementing S5 - Sustain

• Audit to ensure that processes established during S4– Standardization continue to be maintained.

• Use the phase 1 work area as a model for other areas to match, and have the original 5S team share their

insights and experiences with employees in other work areas.

• Use newsletters, displays and other communication tools to publicize successes and reward strong efforts with

recognition.

• Evaluate 5S effectiveness and continue to improve. Conduct regular review meetings to identify additional 5S

opportunities.

Potrebbero piacerti anche

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 5S - Excellence Assessment PDFDocumento2 pagine5S - Excellence Assessment PDFAshokNessuna valutazione finora

- 5 S Presentation Basic TrainingDocumento82 pagine5 S Presentation Basic TrainingEmman Bosito100% (1)

- ERPNext Basic ConceptsDocumento17 pagineERPNext Basic ConceptsLawes Chan100% (5)

- Introduction To Management by Stephen P. Robbins Chapter.7Documento16 pagineIntroduction To Management by Stephen P. Robbins Chapter.7Murtaza Moiz0% (1)

- Is-Retail Replenishment Vs Multi-Step ReplenishmentDocumento9 pagineIs-Retail Replenishment Vs Multi-Step ReplenishmentNoppawan BuangernNessuna valutazione finora

- 5S - Levels of ExcellenceDocumento2 pagine5S - Levels of ExcellenceRamanagiri BharathanNessuna valutazione finora

- Five SDocumento43 pagineFive SKavitha RamalingamNessuna valutazione finora

- Npa Bit 2Documento58 pagineNpa Bit 2gajendra2010Nessuna valutazione finora

- BF Area - 5S Check ListDocumento30 pagineBF Area - 5S Check ListVi KraNessuna valutazione finora

- NPA: Business Improvement Techniques: Contributing To The Application of Workplace Organisation TechniquesDocumento58 pagineNPA: Business Improvement Techniques: Contributing To The Application of Workplace Organisation TechniquesAman RizviNessuna valutazione finora

- Five SDocumento41 pagineFive Srolly curiaNessuna valutazione finora

- Five SDocumento44 pagineFive SPanch BNessuna valutazione finora

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Documento43 pagineSort Set-In-Order Shine Standardize Sustain: What Is 5-S?niratNessuna valutazione finora

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Documento44 pagineSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Angel David ChavezNessuna valutazione finora

- QA: 5S Improvement Techniques: Contributing To The Application of Workplace Organisation TechniquesDocumento58 pagineQA: 5S Improvement Techniques: Contributing To The Application of Workplace Organisation TechniquesRashid GhaniNessuna valutazione finora

- 5S Productivity ManagementDocumento28 pagine5S Productivity Managementloryn_dungca2031Nessuna valutazione finora

- Welcome: Workplace Organization & Housekeeping 101Documento70 pagineWelcome: Workplace Organization & Housekeeping 101Pedro SousaNessuna valutazione finora

- 5S Audit FormDocumento2 pagine5S Audit FormWaqar DarNessuna valutazione finora

- 5SDocumento50 pagine5Skashifbutty2kNessuna valutazione finora

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Documento40 pagineSort Set-In-Order Shine Standardize Sustain: What Is 5-S?blitzkrigNessuna valutazione finora

- 5'S ManualDocumento44 pagine5'S ManualSayan KonarNessuna valutazione finora

- Good HousekeepingDocumento12 pagineGood HousekeepingShane Anne Parcarey NambongNessuna valutazione finora

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Documento43 pagineSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Navnath TamhaneNessuna valutazione finora

- 5SDocumento56 pagine5SInderpreet Singh AhujaNessuna valutazione finora

- TQM Chapter 5Documento8 pagineTQM Chapter 5KENNETH IAN MADERANessuna valutazione finora

- 5S Good HousekeepingDocumento30 pagine5S Good HousekeepingChristopher BalbuenaNessuna valutazione finora

- Five SDocumento44 pagineFive SburritolocoNessuna valutazione finora

- 5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergDocumento24 pagine5-S Handbook For Operations Depot 105/NBE-AM: TNT Express Germany Road Hub and Depot NürnbergthomasarnosanderNessuna valutazione finora

- 5S - Levels of ExcellenceDocumento2 pagine5S - Levels of ExcellenceHartoyo SwiNessuna valutazione finora

- 5S Audit FormDocumento2 pagine5S Audit Formmounirs719883Nessuna valutazione finora

- 5S Audit FormDocumento2 pagine5S Audit FormNavnath Tamhane100% (2)

- Group 2 - Module 3-4Documento75 pagineGroup 2 - Module 3-4Neil Matthew Jarabelo DandanNessuna valutazione finora

- 5S and Workplace Productivity CLADocumento48 pagine5S and Workplace Productivity CLASteben MeuerteNessuna valutazione finora

- Module 5 - TQMDocumento8 pagineModule 5 - TQMRevenlie GalapinNessuna valutazione finora

- 5s ImplementationDocumento20 pagine5s ImplementationHerry Prakoso100% (1)

- Reported By: Ms. Laarni P. LacandazoDocumento36 pagineReported By: Ms. Laarni P. Lacandazolpl_0124Nessuna valutazione finora

- 02 HousekeepingDocumento21 pagine02 Housekeepingjome benicsNessuna valutazione finora

- 5S Japanese Ways To SuccessDocumento39 pagine5S Japanese Ways To SuccessNerizza SomeraNessuna valutazione finora

- 5S TrainingDocumento32 pagine5S TrainingQuest Certification B.KarthikeyanNessuna valutazione finora

- EXEC 5S ModuleDocumento34 pagineEXEC 5S ModulejaymuscatNessuna valutazione finora

- 5S ManualDocumento23 pagine5S ManualBittuNessuna valutazione finora

- G11 - LAS in ACP-Q1Wk5-6 Performing Housekeeping and Maintaining Nursery FacillityDocumento17 pagineG11 - LAS in ACP-Q1Wk5-6 Performing Housekeeping and Maintaining Nursery FacillityEMNessuna valutazione finora

- Module For Operations Management and TQM Part 5Documento7 pagineModule For Operations Management and TQM Part 5Karyll JustoNessuna valutazione finora

- Assignment On Achieving Quality With 5 S AQM M.F.Tech - II SemDocumento26 pagineAssignment On Achieving Quality With 5 S AQM M.F.Tech - II SempetcutpaulNessuna valutazione finora

- Welcomes All The Participants To The: Continuous Training & Development ProgramDocumento47 pagineWelcomes All The Participants To The: Continuous Training & Development Programselvarangam govindarajanNessuna valutazione finora

- 5s ImplementationDocumento22 pagine5s Implementationah antarNessuna valutazione finora

- Pre Read 5S Program GuideDocumento27 paginePre Read 5S Program GuideHerry Prakoso100% (1)

- Presentation 6 S STARTER TrainingDocumento96 paginePresentation 6 S STARTER Trainingm_ramas2001Nessuna valutazione finora

- Introduction To 5SDocumento27 pagineIntroduction To 5SArnab ChakrabortyNessuna valutazione finora

- The 5s of Ideal HousekeepingDocumento16 pagineThe 5s of Ideal HousekeepingKarenSantiago-VillanuevaNessuna valutazione finora

- Lean Chapter 6Documento46 pagineLean Chapter 6WinterMist11Nessuna valutazione finora

- 5'SDocumento13 pagine5'SSharny Lee BasarteNessuna valutazione finora

- Lean Production, Kaizen & 5SDocumento22 pagineLean Production, Kaizen & 5Sapi-26904714100% (2)

- BOSH Week 2Documento17 pagineBOSH Week 2Marion DominoNessuna valutazione finora

- Week 3 HandoutDocumento22 pagineWeek 3 HandoutMj Ong Pierson GarboNessuna valutazione finora

- New Note On Apply 5s ProcedureDocumento9 pagineNew Note On Apply 5s ProcedureTeamir LegeseNessuna valutazione finora

- Visual Management: Visual Management Is A Set of Techniques ThatDocumento28 pagineVisual Management: Visual Management Is A Set of Techniques ThatBangaru BharathNessuna valutazione finora

- Week 8 CARPENTRYDocumento19 pagineWeek 8 CARPENTRYFerdinand R. AlbertoNessuna valutazione finora

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsDa Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsValutazione: 5 su 5 stelle5/5 (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityDa Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityValutazione: 5 su 5 stelle5/5 (3)

- Summary of Michael L. George, John Maxey, David T. Rowlands & Mark Price's The Lean Six Sigma Pocket ToolbookDa EverandSummary of Michael L. George, John Maxey, David T. Rowlands & Mark Price's The Lean Six Sigma Pocket ToolbookNessuna valutazione finora

- S5 - Sustain: 5S Housekeeping Score SheetDocumento1 paginaS5 - Sustain: 5S Housekeeping Score SheetRama PrasetiaNessuna valutazione finora

- S4 - Standardize: Activity ResponsibilityDocumento1 paginaS4 - Standardize: Activity ResponsibilityRama PrasetiaNessuna valutazione finora

- 5s PerforrmDocumento1 pagina5s PerforrmRama PrasetiaNessuna valutazione finora

- Job Aid - Sustain: Definition - Sustain Target OutcomeDocumento1 paginaJob Aid - Sustain: Definition - Sustain Target OutcomeRama PrasetiaNessuna valutazione finora

- Taxation AmendmentsDocumento33 pagineTaxation AmendmentscawinnersofficialNessuna valutazione finora

- Tabish IT AdvisorDocumento4 pagineTabish IT AdvisortabishasifiNessuna valutazione finora

- Data Set - Project 2Documento64 pagineData Set - Project 2Sai Swaroop MandalNessuna valutazione finora

- VodafoneDocumento28 pagineVodafoneNavaneet Yadav100% (1)

- FRI AssignmentDocumento18 pagineFRI AssignmentHaider SaleemNessuna valutazione finora

- External RecruitmentDocumento15 pagineExternal RecruitmentSiti NurafiqahNessuna valutazione finora

- Important Steps To Implement Risk Management in QMS ProcessesDocumento2 pagineImportant Steps To Implement Risk Management in QMS ProcessesCentauri Business Group Inc.Nessuna valutazione finora

- Mis 001250165Documento312 pagineMis 001250165ashishsanandNessuna valutazione finora

- Speaker Series Write Up - Sridhar Chunduri - Aniruddha - 2408016Documento1 paginaSpeaker Series Write Up - Sridhar Chunduri - Aniruddha - 2408016Aniruddha Srinath100% (1)

- SodapdfDocumento1 paginaSodapdfMarcos WilkerNessuna valutazione finora

- FARAP 4404 Property Plant EquipmentDocumento11 pagineFARAP 4404 Property Plant EquipmentJohn Ray RonaNessuna valutazione finora

- Answer Sheet (Sagutang Papel) : ActivityDocumento2 pagineAnswer Sheet (Sagutang Papel) : ActivityAngelica ParasNessuna valutazione finora

- Bata AssignmentDocumento5 pagineBata AssignmentMumit Ahmed100% (1)

- CTM 201305Documento31 pagineCTM 201305ist0Nessuna valutazione finora

- NEF Application Form 28nov2022Documento9 pagineNEF Application Form 28nov2022NicolasNessuna valutazione finora

- Presentation On Reliance Trends: by Manya Gupta, Iv Sem, B.SC, F.DDocumento24 paginePresentation On Reliance Trends: by Manya Gupta, Iv Sem, B.SC, F.DdurgaraoNessuna valutazione finora

- R2. TAX (M.L) Solution CMA May-2023 ExamDocumento5 pagineR2. TAX (M.L) Solution CMA May-2023 ExamSharif MahmudNessuna valutazione finora

- MAS-Learning Assessment 2-For PostingDocumento7 pagineMAS-Learning Assessment 2-For PostingDarlene JacaNessuna valutazione finora

- Lagos State Government: Request For Proposal RFP No: /S/C/SS/003/21Documento76 pagineLagos State Government: Request For Proposal RFP No: /S/C/SS/003/21olumidewilliams0207Nessuna valutazione finora

- Wave 1 Toa AnswersDocumento7 pagineWave 1 Toa AnswerschelissamaerojasNessuna valutazione finora

- Ed 2Documento19 pagineEd 2CA Arena TumkurNessuna valutazione finora

- CHP 15 Fin 13Documento14 pagineCHP 15 Fin 13Player OneNessuna valutazione finora

- SAP MM Interview QuestionsDocumento8 pagineSAP MM Interview QuestionsTara Panda100% (2)

- This Study Resource Was: Page 1 of 5Documento5 pagineThis Study Resource Was: Page 1 of 5debate ddNessuna valutazione finora

- CQI-15 Special Processes Welding System Assessment 2ediciónDocumento46 pagineCQI-15 Special Processes Welding System Assessment 2ediciónCristhian Benitez100% (1)

- Assignment 1 Brief: ScenarioDocumento4 pagineAssignment 1 Brief: ScenarioChâu TrầnNessuna valutazione finora

- TOC Thinking Processes Workshop - June 2018 PDFDocumento4 pagineTOC Thinking Processes Workshop - June 2018 PDFSudhagar PNessuna valutazione finora