Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Charlie Durfee, Nathan Ouellette, Kurt Wiessmeyer: Functional Requirements

Caricato da

KurtTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Charlie Durfee, Nathan Ouellette, Kurt Wiessmeyer: Functional Requirements

Caricato da

KurtCopyright:

Formati disponibili

Bartender’s Buddy

Charlie Durfee, Nathan Ouellette, Kurt Wiessmeyer

Professor Bo Tao

Wentworth Institute of Technology

Abstract Functional Requirements Parts Results

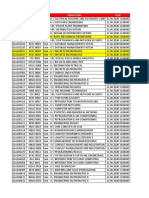

The purpose of our project is to design and The final product conforms to the following Chart 1: Test Times, 6 oz. drink

create a machine that can automatically Board: 1 x Arduino Mega, chosen due to

specifications: memory usage and connections needed for

create a beverage at the press of a button. By Drink

● Operates at the push of a button to the system

providing an automated drink service, the 2 Part 3 Part 4 Part 5 Part

create a drink of pre-specified parts Pumps: 6 x 12V Peristaltic Pumps, chosen Type

machine is able to help relieve bartenders at

● Capable of pouring 4 drinks at a time due to their ability to pump accurate and

rush times as they prepare drinks for many

● Drinks have the proper percentage of Pour

different customers. This could reduce wait consistent volumes of fluid per revolution 9.4 5.7 4.3 3.5

each part, within 5% of the full scale. Time (s)

times while increasing sales and customer Motor Drivers: 4 x L298 motor drivers,

satisfaction. This product could also be used ● Capable of creating drinks from 6 chosen due to their ease of use with Arduino

different bottles at once Note:

at home as a consumer product to serve Boards ● Since pumps run simultaneously, the time

drinks for guests at parties. ● All drink options are automatically Stepper Motor: 1 x Nema 17, chosen to

determined from the bottles connected to to pour is dependent on the largest

accurately rotate the drinks tray due to its component of drink

Problem Definition the machine consistency and ease of use with Arduino

● Drinks are made in equal or less time

● Wait times at bars can be upwards of 15 than what a bartender is capable of

User Interface: 1 x 16x2 LCD display with

click encoder, chosen due to the simplicity of

Conclusions

minutes for a drink that can be made in doing. ● Drink times are far better than expected -

the system for the user and easier coding

30 seconds ● All materials that are in contact with fluids max drink time is ~35% faster than initial

integration

● Waiting can cause patrons to order less, are FDA approved testing

Power Supply: 1 x 20V Lenovo Charger,

leave smaller tips, or even find a different ● The machine can successfully output up to

chosen due to cost and performance

bar due to frustration 4 separate drinks that a user can select

benefits. Motors will run at higher RPMs at

● Having a machine to quickly produce from a generated menu based off of

20V

multiple drinks at once would massively available bottles

shorten such wait times ● Initial designs called for full device to be

● We decided to create an automated 3D printed, this was adjusted with the

drink-dispensing device that can work back half being made out of wood.

alongside a bartender

● Reduce waiting times at bars by Future Improvements:

alleviating the bartenders’ workload ● Noise reduction through smoother direct

during peak business hours drive motors and better motor mounts

● Insulated area for temperature sensitive

mixers/alcohols

● More space for bottles in the back of the

device (Ability for full handles)

Acknowledgements

Some final notes:

Figure 1: Arduino Mega Figure 2: Rendering of Bartender’s Buddy Figure 3: Peristaltic Pump Diagrams • Special thanks to Professor Tao and

Alexander Cate

www.postersession.com

Potrebbero piacerti anche

- Flange Design & Analysis (Final Project, Simulation Based Design)Documento23 pagineFlange Design & Analysis (Final Project, Simulation Based Design)KurtNessuna valutazione finora

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocumento8 pagineAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- HP Printer Diagnostics v19Documento72 pagineHP Printer Diagnostics v19Jean LordNessuna valutazione finora

- en InstructionsDocumento28 pagineen Instructionsfesevi4355Nessuna valutazione finora

- HP Printer Diagnostics - v18 PDFDocumento68 pagineHP Printer Diagnostics - v18 PDFTariq MajeedNessuna valutazione finora

- New Brunswick Scientific: 1.6 L - 14.0L BIOFLO 310 Fermentation SystemDocumento4 pagineNew Brunswick Scientific: 1.6 L - 14.0L BIOFLO 310 Fermentation SystemJOSE LUIS ARTETA ALEGRÍANessuna valutazione finora

- Dell Active Pen Pn579x User's Guide en UsDocumento23 pagineDell Active Pen Pn579x User's Guide en UsJan PaneriNessuna valutazione finora

- Content: Topic Page NoDocumento52 pagineContent: Topic Page NoHedayatul KNessuna valutazione finora

- Kafemat CM450102Documento2 pagineKafemat CM450102office.tik90Nessuna valutazione finora

- Maintain Your Online Sensor Condition in Harsh Environment-10 Jun 2021Documento34 pagineMaintain Your Online Sensor Condition in Harsh Environment-10 Jun 2021Dhenis Imam FaujiNessuna valutazione finora

- 4aa7 7079enucDocumento4 pagine4aa7 7079enucJack BravoNessuna valutazione finora

- SB 25Documento2 pagineSB 25Andres MoralesNessuna valutazione finora

- SAE Net Horsepower: 177 HP (132 KW) Operating Weight: 61,950 Lbs. (28 100 KG) Digging Depth: 47 Ft. 9 In. (14.56 M)Documento12 pagineSAE Net Horsepower: 177 HP (132 KW) Operating Weight: 61,950 Lbs. (28 100 KG) Digging Depth: 47 Ft. 9 In. (14.56 M)Bart JohnNessuna valutazione finora

- 15352, Flex BrochureDocumento2 pagine15352, Flex BrochureshadhafNessuna valutazione finora

- Link Belt 210 X3Documento12 pagineLink Belt 210 X3Yew Lim100% (1)

- B Dispensing Us 01Documento12 pagineB Dispensing Us 01Vruno Velasquez LNessuna valutazione finora

- Datasheet - Rozum Cafe - Eng - 2023Documento12 pagineDatasheet - Rozum Cafe - Eng - 2023Yasser SayedNessuna valutazione finora

- HP Notebook PCs - Improving Battery Performance (Windows) - HP® Customer SupportDocumento5 pagineHP Notebook PCs - Improving Battery Performance (Windows) - HP® Customer SupportbrianNessuna valutazione finora

- Spear Ink CatalogDocumento11 pagineSpear Ink CatalogMohamed Ali RabeeNessuna valutazione finora

- Cafeseries ManualDocumento8 pagineCafeseries Manualmarkisasatu4Nessuna valutazione finora

- HP Ink Tank Wireless 415 All-in-One: Wireless, Print, Scan andDocumento2 pagineHP Ink Tank Wireless 415 All-in-One: Wireless, Print, Scan andJonah Marie Therese BurlazaNessuna valutazione finora

- RPI007 User ManualDocumento14 pagineRPI007 User ManualJorgeGirónNessuna valutazione finora

- Hot Beverage Dispenser ManualDocumento36 pagineHot Beverage Dispenser ManualRadha EnterprisesNessuna valutazione finora

- Dell Active Pen User's Guide: 5000 SeriesDocumento24 pagineDell Active Pen User's Guide: 5000 Seriesashokj1984Nessuna valutazione finora

- Fa 13Documento441 pagineFa 13Mohd Iqbal HaziqNessuna valutazione finora

- 4aa7 9533eeinDocumento2 pagine4aa7 9533eeinArunangshu BiswasNessuna valutazione finora

- LG Ldf6920 Dishwasher Service ManualDocumento43 pagineLG Ldf6920 Dishwasher Service ManualTomNessuna valutazione finora

- HP 10000 MantenimientoDocumento28 pagineHP 10000 MantenimientoAlex DurandNessuna valutazione finora

- A4 Manual BookDocumento22 pagineA4 Manual Bookbowmandave67% (3)

- HP Laserjet Managed E60155 SeriesDocumento4 pagineHP Laserjet Managed E60155 Seriesmolik1Nessuna valutazione finora

- Dishmaid 5Documento20 pagineDishmaid 5Llewellyn OliverNessuna valutazione finora

- Máy Phân Tích Hàm Lư NG Nư CDocumento2 pagineMáy Phân Tích Hàm Lư NG Nư CfreescalerNessuna valutazione finora

- Milli-Q IQ 7000 Purification System: An Ultrapure Water Solution Designed With YOU in MindDocumento24 pagineMilli-Q IQ 7000 Purification System: An Ultrapure Water Solution Designed With YOU in MindĐoàn HạnhNessuna valutazione finora

- For Household Use Only Usage Domestique SeulementDocumento39 pagineFor Household Use Only Usage Domestique SeulementMichael FelipeNessuna valutazione finora

- 6645B-ND 50Hz It0450 SpecDocumento2 pagine6645B-ND 50Hz It0450 SpecNikolaNessuna valutazione finora

- HP Designjet L25500Documento3 pagineHP Designjet L25500vitprint22Nessuna valutazione finora

- Manitowoc Iyt 1900aDocumento2 pagineManitowoc Iyt 1900aDragos DumitrascuNessuna valutazione finora

- HP Smart Tank 615 Wireless All-in-One: The Ultimate in Printing FreedomDocumento2 pagineHP Smart Tank 615 Wireless All-in-One: The Ultimate in Printing FreedomAtika FridausNessuna valutazione finora

- Simply A Smarter Investment: Product Coding - Small Character Inkjet - 9028Documento4 pagineSimply A Smarter Investment: Product Coding - Small Character Inkjet - 9028Aditya C. DesaiNessuna valutazione finora

- HJ-1604 ManualDocumento26 pagineHJ-1604 ManualErkan KabakçıNessuna valutazione finora

- G20 Titrator Potentiometer 30265057C V04.21 G20S Titrator DS en LRDocumento2 pagineG20 Titrator Potentiometer 30265057C V04.21 G20S Titrator DS en LRSales - Khushboo ScientificNessuna valutazione finora

- Laserjet Pro P1102WDocumento36 pagineLaserjet Pro P1102WDanNessuna valutazione finora

- DNX4150BT DNX4150BTM DNX4150DAB: Instruction ManualDocumento123 pagineDNX4150BT DNX4150BTM DNX4150DAB: Instruction ManualGlobaltrip BrasovNessuna valutazione finora

- Contador - Particulas - 200.053 MP LPA2 User Guide ENDocumento72 pagineContador - Particulas - 200.053 MP LPA2 User Guide ENJoaoNessuna valutazione finora

- 200.053 MP LPA2 User Guide EN PDFDocumento72 pagine200.053 MP LPA2 User Guide EN PDFafnanNessuna valutazione finora

- Refractometer RA 620 600Documento8 pagineRefractometer RA 620 600tefovNessuna valutazione finora

- f4480 ManualDocumento113 paginef4480 ManualTimothy A. LaCroixNessuna valutazione finora

- User Manual 4501195Documento17 pagineUser Manual 4501195Eduin BustosNessuna valutazione finora

- 58MM MINI Portable Thermal Printer Instruction Manual-20170214Documento16 pagine58MM MINI Portable Thermal Printer Instruction Manual-20170214Abdul Maghfir Zakir100% (1)

- HP Scitex Lx600 PrinterDocumento3 pagineHP Scitex Lx600 PrinterCarlos SanchezNessuna valutazione finora

- Chapter 5Documento1 paginaChapter 5ayesandar4394Nessuna valutazione finora

- Essential Pro: Basic and FunctionalDocumento1 paginaEssential Pro: Basic and FunctionalEduardo MattosNessuna valutazione finora

- 1620 Ultra High Speed: Continuous Ink Jet PrinterDocumento8 pagine1620 Ultra High Speed: Continuous Ink Jet PrinterRudiNessuna valutazione finora

- HP Smart Tank 670 All-in-One: Data SheetDocumento2 pagineHP Smart Tank 670 All-in-One: Data Sheetmaf.save02Nessuna valutazione finora

- HP Printer Diagnostics v14Documento50 pagineHP Printer Diagnostics v14Escoffier0% (1)

- 4 Troubleshooting M4080 EngDocumento112 pagine4 Troubleshooting M4080 EngadolfoNessuna valutazione finora

- Ra 620 600Documento8 pagineRa 620 600taufik ismullahNessuna valutazione finora

- MM Brochure - IQ7000 - MERCK - InaDocumento12 pagineMM Brochure - IQ7000 - MERCK - InaArdian Rizki SetiawanNessuna valutazione finora

- B2B RO Systm 310134 Rev2-1Documento4 pagineB2B RO Systm 310134 Rev2-1IanNessuna valutazione finora

- How To Speed Up Computer: Your Step-By-Step Guide To Speeding Up ComputerDa EverandHow To Speed Up Computer: Your Step-By-Step Guide To Speeding Up ComputerNessuna valutazione finora

- Bartenders BuddyDocumento1 paginaBartenders BuddyKurtNessuna valutazione finora

- RC Buggy ProjectDocumento2 pagineRC Buggy ProjectKurtNessuna valutazione finora

- 3D Printed Trebuchet FinalDocumento8 pagine3D Printed Trebuchet FinalKurtNessuna valutazione finora

- Vapor Compression Refrigeration System LabDocumento7 pagineVapor Compression Refrigeration System LabKurtNessuna valutazione finora

- Kurt Wiessmeyer, CMFGT: EducationDocumento1 paginaKurt Wiessmeyer, CMFGT: EducationKurtNessuna valutazione finora

- Figure 1: DFMA Table Using The Parts in The Given AssemblyDocumento2 pagineFigure 1: DFMA Table Using The Parts in The Given AssemblyKurtNessuna valutazione finora

- Cantilever Beam VibrationDocumento8 pagineCantilever Beam VibrationKurtNessuna valutazione finora

- Quality Engineering Report IDocumento6 pagineQuality Engineering Report IKurtNessuna valutazione finora

- Quality Engineering Report IIDocumento2 pagineQuality Engineering Report IIKurtNessuna valutazione finora

- Quality Engineering Report IIIDocumento3 pagineQuality Engineering Report IIIKurtNessuna valutazione finora

- Grouped Data Lab: Table 1: Metrics of DatasetDocumento1 paginaGrouped Data Lab: Table 1: Metrics of DatasetKurtNessuna valutazione finora

- Bolted Joint Member StiffnessDocumento15 pagineBolted Joint Member StiffnessKurtNessuna valutazione finora

- How To Build A GreenhouseDocumento67 pagineHow To Build A GreenhouseBolarinwaNessuna valutazione finora

- Part 66 B1 - MODULE 4 3 SERVOMECHANISMSDocumento26 paginePart 66 B1 - MODULE 4 3 SERVOMECHANISMSyaman91100% (1)

- Pahlavi PoemDocumento9 paginePahlavi PoemBatsuren BarangasNessuna valutazione finora

- Recipes G.garvin Copy1 Scribd 5Documento7 pagineRecipes G.garvin Copy1 Scribd 5Peggy Bracken StagnoNessuna valutazione finora

- Power - Distribution Transformers @2020V2Documento34 paginePower - Distribution Transformers @2020V2Musfiqul AzadNessuna valutazione finora

- Substation Battery ChargerDocumento2 pagineSubstation Battery Chargercadtil0% (1)

- Samuelson and Nordhaus ch22 PDFDocumento30 pagineSamuelson and Nordhaus ch22 PDFVictor ManatadNessuna valutazione finora

- Model A SOLUTIONSDocumento8 pagineModel A SOLUTIONSasdfNessuna valutazione finora

- Ansi/Isa - 75.08.04-2001 (R2013) Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Class 4500)Documento16 pagineAnsi/Isa - 75.08.04-2001 (R2013) Face-to-Face Dimensions For Buttweld-End Globe-Style Control Valves (Class 4500)Horas CanmanNessuna valutazione finora

- Gastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDDocumento82 pagineGastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDAvi Themessy100% (1)

- An Overview of The IEEE Color BooksDocumento6 pagineAn Overview of The IEEE Color BooksOhm666Nessuna valutazione finora

- 34 Plaza Newsletter 101317 FINALDocumento4 pagine34 Plaza Newsletter 101317 FINALJosef SzendeNessuna valutazione finora

- 2014-2015+M70 Retro+Manual+Documento93 pagine2014-2015+M70 Retro+Manual+Bass is heavyNessuna valutazione finora

- Eurolite Led TMH 7 PDFDocumento2 pagineEurolite Led TMH 7 PDFSarahNessuna valutazione finora

- BFE II ScenariosDocumento25 pagineBFE II Scenarioselmitxel100% (1)

- Seminar1final ReviewDocumento19 pagineSeminar1final ReviewMounika ChNessuna valutazione finora

- Despiesse de Las Guallas D6H SERIE 3ZF06342Documento4 pagineDespiesse de Las Guallas D6H SERIE 3ZF06342David manjarresNessuna valutazione finora

- Manual Elspec SPG 4420Documento303 pagineManual Elspec SPG 4420Bairon Alvira ManiosNessuna valutazione finora

- Mensuration Practice SheetDocumento1 paginaMensuration Practice SheetSonia SabuNessuna valutazione finora

- Chapter 13 Managerial AccountingDocumento168 pagineChapter 13 Managerial AccountingChandler Schleifs100% (4)

- Staff Code Subject Code Subject Data FromDocumento36 pagineStaff Code Subject Code Subject Data FromPooja PathakNessuna valutazione finora

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorDocumento34 pagineStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezNessuna valutazione finora

- Lesson 24 - Laminate Modeling - Rev C PDFDocumento20 pagineLesson 24 - Laminate Modeling - Rev C PDFraduga_fbNessuna valutazione finora

- Quiz - Ionic EquilibriumDocumento2 pagineQuiz - Ionic EquilibriumSiddNessuna valutazione finora

- Tools, Equipment, and ParaphernaliaDocumento35 pagineTools, Equipment, and Paraphernaliajahnis lopez100% (1)

- CJR Fisika Umum IDocumento17 pagineCJR Fisika Umum IveronikaNessuna valutazione finora

- EASL 2021 Version 4 NewDocumento691 pagineEASL 2021 Version 4 NewGupse Köroğlu AdalıNessuna valutazione finora

- DysphagiaDocumento4 pagineDysphagiaMicaNessuna valutazione finora

- Parker Valve Safety CrownDocumento11 pagineParker Valve Safety Crownayman akrabNessuna valutazione finora