Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Recommended Frame Shoring Erection Procedures

Caricato da

Dak Kaiz0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni2 pagineSSFI

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSSFI

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni2 pagineRecommended Frame Shoring Erection Procedures

Caricato da

Dak KaizSSFI

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

INTRODUCTION INSPECTION OF SHORING

Guides to contractors, architects, engineers, EQUIPMENT

dealers, etc., for the proper use of this equipment PRIOR TO ERECTION

are deemed necessary, and for this reason the The three main areas of inspection are for rust,

Scaffolding, Shoring & Forming Institute has straightness of members and welds. This applies

RECOMMENDED prepared this bulletin. Consult Safe Practices for to all components of a shoring system.

FRAME SHORING Erection and Dismantling of Frame Shoring,

Single Post Shore Safety Rules, Flying Deck 1. Rust - Rusted shoring equipment may

ERECTION PROCEDURE Form Safety Rules, and Horizontal Shoring Beam indicate abuse, neglect, or corrosion and, if

Safety Rules prepared by the Institute. severe, should not be used.

2. Straightness of members - Mishandling,

NOMENCLATURE trucking and storing may cause damage to

1. Adjustment Screw - device composed of a shoring equipment. All members or parts of

threaded screw and an adjusting handle all shoring components should be straight

used for the vertical adjustment of the and free from bends, kinks or dents.

shoring and formwork. 3. Welds - Equipment should be checked

2. Base Plate - a device used to distribute the before use for damaged welds and any piece

leg load. of equipment showing damaged welds or

3. Coupling Pin- an insert device used to rewelding beyond the original factory weld

align lifts or tiers vertically. should not be used. The factory weld

4. Cross-bracing - system of members reference pertains to location and quality of

connecting frames to make a tower rewelds.

structure.

5. Extension Device - any device used to While rust, straightness and welds are of primary

obtain vertical adjustment of shoring towers concern, other component parts should be

other than an adjustment screw. checked.

6. Factor of Safety - the ratio of ultimate load

to the allowable load. 4. Locking devices on frames and braces shall

7. Formwork - the material used to give the be in good working order, and if not, must

required shape and support of poured be repaired or replaced prior to use.

concrete, consisting primarily of: 5. Coupling pins must effectively align the

frame legs.

Sheathing - material which is in direct contact 6. Pivoted cross braces must have the center

with the concrete. pivot securely in place.

Joists - members which directly support

SCAFFOLDING, SHORING & sheathing. SAFE BEARING LOADS FOR SOILS

FORMING INSTITUTE, INC. Stringers or ledgers - members which directly Considering that the allowable loads (bearing) on

support the joists. various soils and rock range from less than 1000

1300 SUMNER AVE.

p.s.f. (47.9 kN/m2 ) to more than 50,000 p.s.f.

CLEVELAND, OHIO 44115 8. Frame - the principal prefabricated (2393.7 kN/m2 ) care should be exercised in

structural unit in a tower. determining the capacity of the soil for every

9. Lifts or Tiers* - the number of frames shoring job, realizing that weather conditions can

stacked one above each other in a vertical turn an otherwise suitable ground condition into a

direction. hazardous situation. As an example, dry clay

10. Locking Device - a device used to secure with an allowable bearing capacity of 8,000 p.s.f.

the cross brace to the frame. (383.0 kN/m2 ) could become very plastic after a

11. Safe Leg Load - that load which can safely rainfall and drop to less than 2,000 p.s.f. (95.8

Copyright 1994, 1961 by: be directly imposed on the frame leg. kN/m2).

Scaffolding, Shoring & Forming Institute, Inc. 12. Shoring Layout - an engineered drawing

1300 Sumner Ave., Cleveland, Ohio 44115 prepared prior to erection showing Care should also be taken not to excessively

arrangement of equipment for proper disturb the soil. If fill is required in shored areas,

shoring. a qualified engineer should be consulted as to

13. Sill or Mud Sill - a footing, usually wood, materials and compaction.

SH304 which distributes the vertical shoring loads

4/00 to the ground or slab below.

14. Towers - a composite structure of frames,

braces and accessories.

15. Ultimate Load - the maximum load which

may be placed on a structure causing failure

by buckling of column members or failure

of some other component.

* These terms can be used synonymously

FOUNDATIONS FINAL INSPECTION OF properly tightened. If devices for holding

The purpose of good foundation or mud sill is to timber require nails, check to see that

ERECTED SHORING

distribute the shoring load over a suitable ground sufficient nails have been used to hold the

area. The size of the footing or sill is determined

EQUIPMENT bracing securely to the frame legs.

The following is a list of check points to be

by the total shoring load carried over a particular

covered when making a final inspection of

ground area, and by the nature of the soil DISMANTLING OF SHORING

shoring equipment prior to the placing of

supporting these sills.

concrete on the form. All points should be EQUIPMENT

carefully checked to insure a safe and accident- Premature releasing or stripping of shoring can

The total shoring load should be computed and

free job. be a cause of failure. A qualified engineer must

the sills designed accordingly.

decide when and how stripping is to proceed.

1. Check to see that there is a sound footing, Variables which enter into this phase include

Suitable sills should be used on a pan or grid

or sill, under every leg of every frame on the load transfer, weather conditions, variations in

dome, floor, or any other floor system involving

job. Check also for possible washout due to different parts of the structure and the setting

voids, where a frame leg could concentrate an

rain. qualities of the concrete.

undesirable load on a thin concrete section.

2. Check to make certain that all base plates or

adjustment screws are in firm contact with After approval of a qualified engineer is obtained,

When shoring from earth or fill, the area should

the footing or sill. All adjustment screws follow approved dismantling procedure. Screw

be leveled and the sills spaced in a pattern

should be snug against the legs of the jacks should be released only far enough to

assuring adequate stability for all shoring legs.

frame. remove forming member. The dismantling of the

3. Obtain a copy of the shoring layout that was equipment can then be performed in the reverse

ERECTION OF FRAMES prepared for this specific job. Make sure that method used in erection and moved to the next

The work of erecting the shoring should be under the spacings between towers and the cross location for reuse. It is often more desirable to

the supervision of a person with proper brace spacing of the towers do not exceed the merely release the adjusting screws to such a

experience and aptitude for securing a safe spacings shown on the layout. If any point that the forming members can be pulled

installation. deviation is necessary because of field away from the underside of the concrete and

condition consult with the qualified shoring allowed to rest in certain modules on top of the

Shoring layouts made by a qualified shoring designer who prepared the layout for his frame shoring equipment and the entire unit

designer must be strictly adhered to when approval of the actual field setup. moved to the next location. Formwork and

locating frame legs. Layouts may be obtained 4. Frames should be checked for plumbness in shoring of varying sizes are frequently moved

from your shoring supplier in most instances. both directions. The maximum allowable from one pour to other pours without dismantling

tolerance for a frame which is out of plumb or removing formwork.

Advance planning will help the erection of is (1/8 inch in 3 feet). If the frames exceed

frames to progress smoothly. The material this tolerance the base should be adjusted Lower shoring components in a safe manner. Do

should be unloaded as close to the area to be until the frames are within the tolerance. not drop or throw components as this could result

shored as possible and should be arranged in the 5. If there is a gap between the lower end of in injury to personnel or damage to equipment.

order it is to be used. Adjustment screws should one frame and the upper end of another

be set to their approximate final adjustment frame, it indicates that one adjustment

before setting up the shoring units. At this time, THE RESHORING OPERATION

screw must be adjusted to bring the frames Reshoring is one of the most critical operations in

a person should check to see that all frames in contact. If this does not help, it indicates

which require coupling pins have them, and that formwork; consequently, reshoring procedure

the frame is out of square and should be must be designed by a qualified person and

all frames which require accessories at the top do removed.

not have coupling pins. Consult safety rules as approved by the architect/engineer of record.

6. When two or more tiers of frames are used,

recommended by the Institute. each shall be braced to at least one adjacent Extreme care must be taken to release the

frame. adjustment screws to a point where the slab takes

To expedite erection of the shoring and to be sure 7. While checking the cross braces also check

the loading is distributed the way the shoring is its actual permanent deflection. The adjustment

the locking devices to assure that they are screws should then be tightened until contact is

designed, the location of each tower should be all in their closed position or that they are

marked on the floor by use of chalk line or some again made with the underside of the slab. In this

all tight. manner, the frame reshoring below will not be

other simple method. If required, sills should be 8. Check the upper adjustment screw or shore

placed first. After the location of the shoring carrying the load of the slab that it had previously

head to assure that it is in full contact with shored.

towers has been marked, the adjustment screws the formwork. If it is not in contact, it

or base plates, whichever is to be used, along should be adjusted or shimmed until it is.

with the necessary braces, should be distributed Reshoring is usually done to facilitate maximum

9. Check to see that the obvious mistakes of reuse of framework and may utilize the strength

to each set of marks indicating the location of the omitting joists, using the wrong size ledger

tower. of the completed construction below when such

or incorrectly orienting members have not construction is fully cured and capable of

been made. Check the print to see that the supporting the loads to be imposed by the

After assembling the basic unit it should be lumber used is equal to that specified on the

leveled so that no matter how high the final tower additional construction above.

shoring layout. Check the general

is to be, the additional frames will be level and formwork scheme to make sure that it

plumb as they are installed. When the basic unit While reshoring is being placed, no construction

follows good standard practice for loads should be permitted on the new

is leveled, it is ready to receive the next tier of formwork.

frames. For higher lifts, a work platform is easily construction.

10. If the shoring layout shows exterior bracing

formed for erecting the shoring by using planks for lateral stability, check to see that this

on the top horizontal member of the frames. Tie Extra care should be taken during a reshoring

bracing is in place in the locations specified operation where an upper slab being poured is

towers of shoring frames together with sufficient on the drawing. Check to make sure that

bracing to make a rigid, solid unit. heavier than the slab being reshored.

the devices which attach this bracing to the

equipment are securely fastened to the legs

of the shoring equipment. If tubing clamps

are used, make sure that they have been

Potrebbero piacerti anche

- Jha Swing Stage Scaffold PDFDocumento2 pagineJha Swing Stage Scaffold PDFkaruna60% (5)

- JSA For Chimney Works 17.09.2021Documento2 pagineJSA For Chimney Works 17.09.2021Brenden PalanithangamNessuna valutazione finora

- Safe Work Procedure in Cold SawDocumento1 paginaSafe Work Procedure in Cold SawCyril AngkiNessuna valutazione finora

- Method Statement ST100Documento6 pagineMethod Statement ST100tarekNessuna valutazione finora

- Caretaker Risk Assessment - Working at HeightDocumento8 pagineCaretaker Risk Assessment - Working at HeightLina MarcelaNessuna valutazione finora

- Temporary StructuresDocumento65 pagineTemporary StructuresyzzaNessuna valutazione finora

- Steel Erection JSADocumento5 pagineSteel Erection JSASalah Abd Eldayem100% (1)

- Tekla Structural Designer 2022 Engineers HandbooksDocumento416 pagineTekla Structural Designer 2022 Engineers Handbooksrajendra50% (2)

- Plate GirderDocumento25 paginePlate GirderVarun ShastryNessuna valutazione finora

- All JsaDocumento88 pagineAll JsaPankaj BhattNessuna valutazione finora

- The Stability of Elastic Systems: Pergamon Unified Engineering SeriesDa EverandThe Stability of Elastic Systems: Pergamon Unified Engineering SeriesValutazione: 5 su 5 stelle5/5 (1)

- EN1997 5 Simpson Opt PDFDocumento95 pagineEN1997 5 Simpson Opt PDFshykojcrsaNessuna valutazione finora

- Manual Reductor Dodge Tep PDFDocumento232 pagineManual Reductor Dodge Tep PDFraulNessuna valutazione finora

- Bar Bending MachineDocumento1 paginaBar Bending Machinesaurav royNessuna valutazione finora

- Service and Parts Manual: Orbital Motors Omt FX, Omt FL and Omt FHDocumento20 pagineService and Parts Manual: Orbital Motors Omt FX, Omt FL and Omt FHjose manuel barroso pantojaNessuna valutazione finora

- JSA For Hydro Test Activites GenericDocumento4 pagineJSA For Hydro Test Activites GenericMajdiSahnounNessuna valutazione finora

- Safload™ Shoring SystemDocumento2 pagineSafload™ Shoring SystemJohn Paulsy100% (1)

- Risk Assessment of Height WorkDocumento1 paginaRisk Assessment of Height WorkM.Usama MustafaNessuna valutazione finora

- EN - AuV - UniBreit P2Documento17 pagineEN - AuV - UniBreit P2Maguin Bolaños AriasNessuna valutazione finora

- Recommended Scaffolding Erection Procedure: Page 1 of 4Documento16 pagineRecommended Scaffolding Erection Procedure: Page 1 of 4pisalNessuna valutazione finora

- Recommended Scaffolding Erection Procedure: Page 1 of 4Documento4 pagineRecommended Scaffolding Erection Procedure: Page 1 of 4Etibar AliyevNessuna valutazione finora

- 1-Frame Scaffolds GuidelinesDocumento2 pagine1-Frame Scaffolds GuidelinesToni hawkNessuna valutazione finora

- Safety Guidelines: Suspended ScaffoldDocumento2 pagineSafety Guidelines: Suspended ScaffoldPahala PardedeNessuna valutazione finora

- Installing Machine Tools: Here's What To ConsiderDocumento1 paginaInstalling Machine Tools: Here's What To ConsiderMobile SunNessuna valutazione finora

- Sunmow Jha 001Documento3 pagineSunmow Jha 001Douglas DellyNessuna valutazione finora

- Manual Installation Operation Maintenance: e-AHUDocumento8 pagineManual Installation Operation Maintenance: e-AHUFrancisNessuna valutazione finora

- 7 ReductorDocumento9 pagine7 ReductorArielNessuna valutazione finora

- SOP Material InstructionsDocumento1 paginaSOP Material Instructionspankajbhatt376100% (1)

- Dodge 268700 Instruction SheetDocumento20 pagineDodge 268700 Instruction SheetJOSE LOPEZNessuna valutazione finora

- 6 Temporary StructuresDocumento65 pagine6 Temporary StructuresEl LlacunaNessuna valutazione finora

- Daikin Refrigeration Malaysia AHU IOMDocumento27 pagineDaikin Refrigeration Malaysia AHU IOMwayhoong lamNessuna valutazione finora

- GeoconDocumento1 paginaGeoconhugoq21hugoNessuna valutazione finora

- Daikin - Refrigeration - Malaysia - AHU - File gốcDocumento26 pagineDaikin - Refrigeration - Malaysia - AHU - File gốcPhuNguyenHoangNessuna valutazione finora

- DM AhuDocumento21 pagineDM AhuThe dingdamNessuna valutazione finora

- Installation Operation Maintenance: ManualDocumento21 pagineInstallation Operation Maintenance: ManualFrancisNessuna valutazione finora

- Instruction Manual: WarningDocumento4 pagineInstruction Manual: WarningKang Kawe Waone SetiaoneNessuna valutazione finora

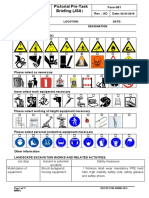

- Landscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalDocumento17 pagineLandscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalJohn Vincent Macatangay Cleofe100% (1)

- General Safety Rules: Minifold & Klikfold Mobile Aluminium Folding Tower Systems Instruction ManualDocumento6 pagineGeneral Safety Rules: Minifold & Klikfold Mobile Aluminium Folding Tower Systems Instruction ManualHari HaranNessuna valutazione finora

- Jha For SMP 2Documento7 pagineJha For SMP 2Rohit TharseNessuna valutazione finora

- Waler Units of Trench Support SystemsDocumento1 paginaWaler Units of Trench Support SystemsNorhazerahYussopNessuna valutazione finora

- Precast ConcreteDocumento3 paginePrecast ConcreteSage UniversityNessuna valutazione finora

- Whitepaper - AlignmentDocumento20 pagineWhitepaper - Alignmentafif atmajaNessuna valutazione finora

- Ficha Técnica ANSI Z359.11 - 2014Documento7 pagineFicha Técnica ANSI Z359.11 - 2014CEFSA Centro de Formación de Seguridad y Alturas SASNessuna valutazione finora

- Concrete Construction Article PDF - Shore Concrete Formwork SafelyDocumento2 pagineConcrete Construction Article PDF - Shore Concrete Formwork Safelynattanai kuangmiaNessuna valutazione finora

- MF Prensa Tuberia Ridgid Tristand 460-6Documento36 pagineMF Prensa Tuberia Ridgid Tristand 460-6Edwin Restrepo SalazarNessuna valutazione finora

- Img - 0030 Psme Code 2008 19aDocumento1 paginaImg - 0030 Psme Code 2008 19aArwyn BermasNessuna valutazione finora

- Jsa For - SRPDocumento3 pagineJsa For - SRPVijay chauhanNessuna valutazione finora

- Occupational Safety and Health Admin., Labor 1926.251: Housekeeping. Storage Areas ShallDocumento13 pagineOccupational Safety and Health Admin., Labor 1926.251: Housekeeping. Storage Areas ShallhferrebusNessuna valutazione finora

- Annexure On Safety RequirementsDocumento8 pagineAnnexure On Safety RequirementsPatel KuldeepNessuna valutazione finora

- Automatic Magnetic DrillDocumento12 pagineAutomatic Magnetic DrillAli AbdallahNessuna valutazione finora

- Jsa For Hydro Test Activites GenericDocumento4 pagineJsa For Hydro Test Activites GenericShahid RazaNessuna valutazione finora

- 02-Scaffold InspectionDocumento1 pagina02-Scaffold InspectionVarunendra TiwariNessuna valutazione finora

- Techniques For Tapered Roller BearingsDocumento20 pagineTechniques For Tapered Roller BearingsJackson PhinniNessuna valutazione finora

- Receiving and Inspection: Installation, Operation and Maintenance ManualDocumento8 pagineReceiving and Inspection: Installation, Operation and Maintenance ManualMustafa ShamimNessuna valutazione finora

- ASS70FD InstallationGuideDocumento12 pagineASS70FD InstallationGuideDanilo ConceiçãoNessuna valutazione finora

- Temporary AnchorDocumento4 pagineTemporary Anchordey6686Nessuna valutazione finora

- Aea 1305 WC El MS 0001Documento12 pagineAea 1305 WC El MS 0001Adil HasanovNessuna valutazione finora

- Installation, Operation and Maintenance ManualDocumento12 pagineInstallation, Operation and Maintenance Manualsergio catañoNessuna valutazione finora

- Shuttering in Foundation HSE ProfessionalsDocumento1 paginaShuttering in Foundation HSE Professionalsalaa_2305Nessuna valutazione finora

- Health: & Safety AdvisoryDocumento2 pagineHealth: & Safety AdvisorykrissregionNessuna valutazione finora

- Electrical Work Gecmal SDN BHD Job Hazard Analysis: Activity Hazards Control MeasuresDocumento5 pagineElectrical Work Gecmal SDN BHD Job Hazard Analysis: Activity Hazards Control MeasuresliveaneshNessuna valutazione finora

- CalOSHA Ladder Fall Protection PlanDocumento4 pagineCalOSHA Ladder Fall Protection PlanRandy100% (6)

- 04 - WindpostsDocumento1 pagina04 - WindpostsNiemNessuna valutazione finora

- 02 - Freyssinet Webinar2 - Reinforced Earth Indonesia - Dewi Zuhari - 250620 PDFDocumento76 pagine02 - Freyssinet Webinar2 - Reinforced Earth Indonesia - Dewi Zuhari - 250620 PDFDak KaizNessuna valutazione finora

- Notes Design Process PDFDocumento11 pagineNotes Design Process PDFDak KaizNessuna valutazione finora

- The Falcon, From Stolt Comex Seaway To GSP - Multi-LayDocumento6 pagineThe Falcon, From Stolt Comex Seaway To GSP - Multi-LayDak KaizNessuna valutazione finora

- SSFI Tech Bulletin - Standards That Apply To ShoringDocumento1 paginaSSFI Tech Bulletin - Standards That Apply To ShoringDak KaizNessuna valutazione finora

- CV Yohana Felicia Candra PDFDocumento1 paginaCV Yohana Felicia Candra PDFDak KaizNessuna valutazione finora

- External Training Calendar 2020 PDFDocumento1 paginaExternal Training Calendar 2020 PDFDak KaizNessuna valutazione finora

- Kestrel A Reel-Lay VesselDocumento6 pagineKestrel A Reel-Lay VesselDak KaizNessuna valutazione finora

- Lampiran IDocumento95 pagineLampiran IDak KaizNessuna valutazione finora

- Indonesian fib-YMG Webinar Series-III PDFDocumento3 pagineIndonesian fib-YMG Webinar Series-III PDFDak KaizNessuna valutazione finora

- Marine & Offshore Rules, Rule Notes and Guidance NotesDocumento6 pagineMarine & Offshore Rules, Rule Notes and Guidance NotesDak KaizNessuna valutazione finora

- 13.122 Ship Structural Design and Analysis: Station Combined Cargo & Machinery (LBS) Total Weight Per Station (LBS)Documento2 pagine13.122 Ship Structural Design and Analysis: Station Combined Cargo & Machinery (LBS) Total Weight Per Station (LBS)Dak KaizNessuna valutazione finora

- LEEA Foundation Certificate - Refresher DaysDocumento1 paginaLEEA Foundation Certificate - Refresher DaysDak KaizNessuna valutazione finora

- Career Objective:: Ahmed Mohammed Ibrahim Mosa - El-Qanater, Qalyubiamob: 01140644111Documento2 pagineCareer Objective:: Ahmed Mohammed Ibrahim Mosa - El-Qanater, Qalyubiamob: 01140644111Dak KaizNessuna valutazione finora

- Design Manual Fixed PDFDocumento7 pagineDesign Manual Fixed PDFDak KaizNessuna valutazione finora

- Ps5instructions PDFDocumento1 paginaPs5instructions PDFDak KaizNessuna valutazione finora

- Problem Set 1: Part B Solutions: Stiffener Catalog (T Bar)Documento10 pagineProblem Set 1: Part B Solutions: Stiffener Catalog (T Bar)Dak KaizNessuna valutazione finora

- PS2 Classuse DVB SolnDocumento25 paginePS2 Classuse DVB SolnDak KaizNessuna valutazione finora

- Torsion ST V Multi Ce PDFDocumento3 pagineTorsion ST V Multi Ce PDFDak KaizNessuna valutazione finora

- Problem Set 8: 13.122 Ship Structural Design and AnalysisDocumento2 pagineProblem Set 8: 13.122 Ship Structural Design and AnalysisDak KaizNessuna valutazione finora

- Problem ... : W Cos 2Documento5 pagineProblem ... : W Cos 2Dak KaizNessuna valutazione finora

- Ps 1 2003 1 PDFDocumento3 paginePs 1 2003 1 PDFDak KaizNessuna valutazione finora

- Y 10K 100 K-FT 1 K/FT: 13.122 Ship Structural Design and AnalysisDocumento3 pagineY 10K 100 K-FT 1 K/FT: 13.122 Ship Structural Design and AnalysisDak KaizNessuna valutazione finora

- GEOMETRY Channel Made Up of 2-Inch SegmentsDocumento4 pagineGEOMETRY Channel Made Up of 2-Inch SegmentsDak KaizNessuna valutazione finora

- IEEE STD C57.00 2010 IEEE Standard For General Requirements For Liquid Immersed DistributionPowerand Regulating TransfDocumento6 pagineIEEE STD C57.00 2010 IEEE Standard For General Requirements For Liquid Immersed DistributionPowerand Regulating TransfFendi R MndzNessuna valutazione finora

- VF730 & VF733 - AGA ApprovedDocumento8 pagineVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNessuna valutazione finora

- Local Government Engineering Department: Design UnitDocumento2 pagineLocal Government Engineering Department: Design UnitSaadNessuna valutazione finora

- Scheerer Bearing Oil Industry PDFDocumento8 pagineScheerer Bearing Oil Industry PDFcristinelbNessuna valutazione finora

- Pomi Brakup SheetDocumento138 paginePomi Brakup SheetNicholas SmithNessuna valutazione finora

- Datasheet Polystone P CubX ENDocumento1 paginaDatasheet Polystone P CubX ENjavierNessuna valutazione finora

- Lecture-Trenches GEN IDocumento20 pagineLecture-Trenches GEN IjashndeepNessuna valutazione finora

- Approx Vertical ModifiedDocumento25 pagineApprox Vertical ModifiedShafkat SaminNessuna valutazione finora

- 31) Method Statement For Shaft WorksDocumento3 pagine31) Method Statement For Shaft WorksNikhil Manjrekar0% (1)

- Pt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiDocumento6 paginePt. Adiprotek Envirodunia Pt. Pdpde Gas: Epcc Usm Metering Station at Simpang Abadi JambiAdhya RazanNessuna valutazione finora

- Effects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear TestsDocumento7 pagineEffects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear TestsJavier MtNessuna valutazione finora

- ITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Documento23 pagineITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Destra Dwi Falah SetyamaNessuna valutazione finora

- 2 Post Lifter - ManualDocumento24 pagine2 Post Lifter - ManualRyan EncomiendaNessuna valutazione finora

- cw274jws SpecDocumento1 paginacw274jws Speccivilengineer.nklNessuna valutazione finora

- Atlas 65 RozdzielaczDocumento23 pagineAtlas 65 RozdzielaczPawel TomwidlakNessuna valutazione finora

- Lecturer Name: Section: 1 Date of Submission: 5: November 2020Documento3 pagineLecturer Name: Section: 1 Date of Submission: 5: November 2020little projectNessuna valutazione finora

- Membrane StructuresDocumento22 pagineMembrane StructuresRyana Rose CristobalNessuna valutazione finora

- Taguibo Const. ExpensesDocumento31 pagineTaguibo Const. ExpensesEvangeline CasccaraNessuna valutazione finora

- Certificado Brida 3Documento1 paginaCertificado Brida 3juan aguilarNessuna valutazione finora

- KR - MV IV - R410A - 5060Hz - HR - EU - MFL67474006 - 0CVY0-01A - July.2013Documento349 pagineKR - MV IV - R410A - 5060Hz - HR - EU - MFL67474006 - 0CVY0-01A - July.2013diegoescalona1985Nessuna valutazione finora

- Lines GP - Boom Float: 330D Excavator Hydraulic System - AttachmentDocumento2 pagineLines GP - Boom Float: 330D Excavator Hydraulic System - AttachmentKJDNKJZEFNessuna valutazione finora

- DO 005 s2017Documento195 pagineDO 005 s2017Tina Rosales0% (1)

- Microsoft PowerPoint - Fondasi I - Pertemuan 12 (2023)Documento9 pagineMicrosoft PowerPoint - Fondasi I - Pertemuan 12 (2023)Gifara DzikryNessuna valutazione finora

- Apartment Hunting ChecklistDocumento1 paginaApartment Hunting ChecklistTime Warner Cable NewsNessuna valutazione finora

- ConPave 01Documento5 pagineConPave 01Dhen UlesNessuna valutazione finora

- Scroll Enclosure Air Compressor 15-60 HP: DescriptionDocumento28 pagineScroll Enclosure Air Compressor 15-60 HP: DescriptionAlain ManceraNessuna valutazione finora