Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UTP 3545 NB PDF

Caricato da

NTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UTP 3545 NB PDF

Caricato da

NCopyright:

Formati disponibili

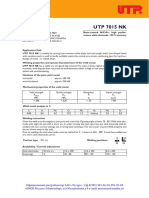

Standards : UTP 3545 Nb

EN 1600 : EZ 35 45 Nb B 6 2

Basic coated special stick electrode

EN ISO 14172 : E Ni Z

with high carbon content for high tem-

(NiCr35 Fe15Nb 0,8)

perature cast materials

Application field

UTP 3545 Nb is suitable for joining and surfacing high alloyed 35/45 CrNi high temperature cast materi-

als of identical or similar nature.

Main applications are reformer tubes in petrochemical installations with a service temperature up to

1175° C.

Welding properties and special properties of the weld metal

UTP 3545 Nb has a smooth and stable arc, good slag removal and a fine-rippled seam structure.The weld

metal is high temperature resistant with very good creep strength.

Mechanical properties of the weld metal

Yield strength Tensile strength Elongation

Rp0,2 Rm A

MPa MPa %

450 600 8

Weld metal analysis in %

C Si Mn Cr Ni Nb Fe

0,45 1,0 0,8 35,0 45,0 0,9 balance

Welding instructions

Clean welding area. Hold stick electrode as vertically as possible, keep a short arc. Use string bead welding

technique with little weaving. The stick electrode is weldable with low amperage settings. Interpass tem-

perature max. 150° C. Re-dry stick electrodes for 2 – 3 h / 120 – 200° C.

Current type DC (+) Welding positions

PA PB PC PF

Current adjustment

Stick electrodes Ø mm x L 2,5 x 300 3,2 x 350 4,0 x 350 4,0 x 350

Amperage A 70 – 90 90 – 110 100 – 140 100 – 140

All data on our products are based upon careful investigation and intensive © UTP Schweissmaterial

research. However, we do not assume any liability for their correctness. Zweigniederlassung der Böhler Schweisstechnik Deutschland GmbH

www.utp-welding.com Edition: 08/2010 Rev.: 1

Potrebbero piacerti anche

- UTP A 3545 NB PDFDocumento1 paginaUTP A 3545 NB PDFNNessuna valutazione finora

- UTP A 3545 NBDocumento1 paginaUTP A 3545 NBNapol HengbumrungNessuna valutazione finora

- UTP A 3545 NB PDFDocumento1 paginaUTP A 3545 NB PDFNNessuna valutazione finora

- UTP 6222 MoDocumento1 paginaUTP 6222 ModantegimenezNessuna valutazione finora

- Utp 068 HHDocumento1 paginaUtp 068 HHRoberto_PrrNessuna valutazione finora

- Utp 7015 NKDocumento1 paginaUtp 7015 NKsergey.pu4kaNessuna valutazione finora

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Documento1 paginaОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNessuna valutazione finora

- Utp 7015Documento1 paginaUtp 7015cesarlopezpolysiusNessuna valutazione finora

- Utp 34 NDocumento1 paginaUtp 34 NbrayanNessuna valutazione finora

- 11062016000000utp A 068 HHDocumento1 pagina11062016000000utp A 068 HHtqtatqawNessuna valutazione finora

- Utp A 3444Documento1 paginaUtp A 3444Sun SunNessuna valutazione finora

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Documento1 paginaL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNessuna valutazione finora

- Carbocast 1 - eDocumento1 paginaCarbocast 1 - eali torabiNessuna valutazione finora

- A389 CuNiDocumento1 paginaA389 CuNiPrathamesh OmtechNessuna valutazione finora

- UTP Cladding en 2017Documento12 pagineUTP Cladding en 2017Gourav SharmaNessuna valutazione finora

- UTP A 6222 MoDocumento1 paginaUTP A 6222 MoKara WhiteNessuna valutazione finora

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Documento1 paginaFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNessuna valutazione finora

- ESABDocumento1 paginaESABXQNessuna valutazione finora

- Utp 63Documento1 paginaUtp 63brayanNessuna valutazione finora

- Barrettetig Catalogo Oerlikon 35035Documento44 pagineBarrettetig Catalogo Oerlikon 35035mp303Nessuna valutazione finora

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocumento1 paginaThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNessuna valutazione finora

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocumento1 paginaSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNessuna valutazione finora

- مكونات نقط اللحام شامل بنط اللحامDocumento2 pagineمكونات نقط اللحام شامل بنط اللحامdaha333Nessuna valutazione finora

- Böhler Cat 409 Cb-Ig: Classifi CationsDocumento1 paginaBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNessuna valutazione finora

- Utp A 068 HH: ClassificationsDocumento1 paginaUtp A 068 HH: ClassificationsErickNessuna valutazione finora

- Utp 630Documento1 paginaUtp 630brayanNessuna valutazione finora

- 1 - UTP 614 KBDocumento1 pagina1 - UTP 614 KBKrishna VachaNessuna valutazione finora

- Boehler SKWAM-IG de en 5Documento2 pagineBoehler SKWAM-IG de en 5Ivica MikolajNessuna valutazione finora

- MIP Bohler Welding Austria 364Documento1 paginaMIP Bohler Welding Austria 364c131508Nessuna valutazione finora

- 1.06 Introduction To GSAW Process IWE May2019Documento157 pagine1.06 Introduction To GSAW Process IWE May2019rohit mathankerNessuna valutazione finora

- Utp A 3444 - 2Documento1 paginaUtp A 3444 - 2Sun SunNessuna valutazione finora

- Böhler 7018-1 h4r enDocumento1 paginaBöhler 7018-1 h4r enValentin Hernández TrianoNessuna valutazione finora

- UTP Raiilways BrochureDocumento8 pagineUTP Raiilways Brochurekamals55Nessuna valutazione finora

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocumento1 paginaOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedNessuna valutazione finora

- 02112015000000B - Boehler FOX EV 65 - CeDocumento1 pagina02112015000000B - Boehler FOX EV 65 - CeMohamed AdelNessuna valutazione finora

- 570 950mpa High Tensile Strength SteelDocumento32 pagine570 950mpa High Tensile Strength SteelAde Aidil SyuhadaNessuna valutazione finora

- Utp 86 FNDocumento1 paginaUtp 86 FNc131508Nessuna valutazione finora

- Datasheet Sanicro 69Documento1 paginaDatasheet Sanicro 69Agustin CesanNessuna valutazione finora

- B Boehler Ni 1-Ig Ss en 5Documento1 paginaB Boehler Ni 1-Ig Ss en 5Andrei UrsacheNessuna valutazione finora

- L1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Documento2 pagineL1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Απόστολος ΣτεργιάδηςNessuna valutazione finora

- OK Tigrod NiCrMo-3 (OK 19.84) - ENDocumento1 paginaOK Tigrod NiCrMo-3 (OK 19.84) - ENbaladiroyaNessuna valutazione finora

- Thermanit P24Documento1 paginaThermanit P24Branko FerenčakNessuna valutazione finora

- 11062016000000utp 86 FNDocumento1 pagina11062016000000utp 86 FNbrayanNessuna valutazione finora

- T - Thermanit 25 - 09 CuT - de - en - 5Documento1 paginaT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINessuna valutazione finora

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocumento2 pagineThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNessuna valutazione finora

- BÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28Documento1 paginaBÖHLER Alform® 960-IG: Standard Designations EN ISO 16834-A AWS A5.28JORAMNessuna valutazione finora

- TriMark Metalloy 80N1Documento2 pagineTriMark Metalloy 80N1Claudia MmsNessuna valutazione finora

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocumento1 paginaB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNessuna valutazione finora

- Flux Shielded Welding ProcessesDocumento42 pagineFlux Shielded Welding ProcessesjoehodohNessuna valutazione finora

- Electrode Booklet F Web 24Documento1 paginaElectrode Booklet F Web 24satnamNessuna valutazione finora

- L1 34264 en T Thermanit MTS 3 Se en v2Documento1 paginaL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNessuna valutazione finora

- Kobel NicroDocumento1 paginaKobel NicroBHARAT KNessuna valutazione finora

- Classifications: Approvals:: Typical Tensile PropertiesDocumento1 paginaClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNessuna valutazione finora

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocumento1 paginaExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNessuna valutazione finora

- 02112015000000B - Boehler FOX EV 70 - CeDocumento1 pagina02112015000000B - Boehler FOX EV 70 - CeOPAZOSCNessuna valutazione finora

- Welding Stal 20 PDFDocumento20 pagineWelding Stal 20 PDFFaraj KhalikovNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesDa EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesValutazione: 4.5 su 5 stelle4.5/5 (7)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Da EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363Nessuna valutazione finora

- 2 SinteringDocumento70 pagine2 SinteringMohammed Bilal100% (1)

- BT Reviewer PrelimsDocumento3 pagineBT Reviewer PrelimsDianalen RosalesNessuna valutazione finora

- Item Changes and Transfer/deletion Scripts With Dark Legacy: EquipmentDocumento14 pagineItem Changes and Transfer/deletion Scripts With Dark Legacy: Equipmentalo KusaNessuna valutazione finora

- Ion Exchange Resins Selectivity - 45-D01458-EnDocumento4 pagineIon Exchange Resins Selectivity - 45-D01458-EnDFMNessuna valutazione finora

- GB 8163-2008Documento14 pagineGB 8163-2008hungNessuna valutazione finora

- Tectyl-Houghton-Macron-EDM-110 (By MAD)Documento1 paginaTectyl-Houghton-Macron-EDM-110 (By MAD)HDSC ChemicalsNessuna valutazione finora

- Effect of Pasture Improvement Managements On Physical Properties and Water Content Dynamics of A Volcanic Ash Soil in Southern ChileDocumento10 pagineEffect of Pasture Improvement Managements On Physical Properties and Water Content Dynamics of A Volcanic Ash Soil in Southern ChileJose CuevasNessuna valutazione finora

- Metalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspDocumento1 paginaMetalworking Woodworking Tool Cut Hand Tool Steel Case Hardened Tang RaspQamar ZamansNessuna valutazione finora

- T.Y.Yeh Professor Department of Civil and Environmental EngineeringDocumento14 pagineT.Y.Yeh Professor Department of Civil and Environmental EngineeringAlberto Acabal IINessuna valutazione finora

- Determination of Molar Volume and Universal Gas ConstantDocumento4 pagineDetermination of Molar Volume and Universal Gas ConstantChester James PeñarubiaNessuna valutazione finora

- 15 - Mangla Joshi PDFDocumento22 pagine15 - Mangla Joshi PDFSHIKHA SINGHNessuna valutazione finora

- Checkered PlateDocumento1 paginaCheckered PlateMark A FainaNessuna valutazione finora

- Data Sheet: Experiment 1: Chemical ReactionsDocumento17 pagineData Sheet: Experiment 1: Chemical ReactionsLinh NguyễnNessuna valutazione finora

- Material Take-Off List: Rev. CodeDocumento6 pagineMaterial Take-Off List: Rev. CodeSIVANessuna valutazione finora

- Plastic InjectionDocumento39 paginePlastic InjectionRishav KumarNessuna valutazione finora

- Metamorphic Rocks PracticalDocumento27 pagineMetamorphic Rocks PracticalMr Gk meenaNessuna valutazione finora

- Diaphragm Design GuideDocumento29 pagineDiaphragm Design GuideJaher Wasim100% (1)

- Compressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmDocumento6 pagineCompressive Strength Modelling of Concrete Mixed With Fly Ash and Waste Ceramics Using K-Nearest Neighbor AlgorithmNewton GalileoNessuna valutazione finora

- Hydro Power NEW - FinalDocumento84 pagineHydro Power NEW - FinalPablo ThomassetNessuna valutazione finora

- Assignment Neutralisation ReactionDocumento1 paginaAssignment Neutralisation ReactionMaridjan WiwahaNessuna valutazione finora

- Sika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcreteDocumento2 pagineSika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcretepouyaNessuna valutazione finora

- SECTION 05530 Gratings Rev 1Documento17 pagineSECTION 05530 Gratings Rev 1Mohsin ShaikhNessuna valutazione finora

- Metallurgy Theory PDFDocumento13 pagineMetallurgy Theory PDFUtkarsh RaiNessuna valutazione finora

- Paper 2 Paper With Solution ChemistryDocumento14 paginePaper 2 Paper With Solution ChemistryddssdsfsNessuna valutazione finora

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocumento13 pagineCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaNessuna valutazione finora

- PDS Petrygo Heavy AntifreezeDocumento2 paginePDS Petrygo Heavy AntifreezemostafaNessuna valutazione finora

- Candidate's Name: Gender Class: Monday: 6 August, 2017. DurationDocumento7 pagineCandidate's Name: Gender Class: Monday: 6 August, 2017. DurationSimon SimuntalaNessuna valutazione finora

- Painting Specification PDFDocumento17 paginePainting Specification PDFGaurav TripathiNessuna valutazione finora

- HVAC Gold Case Thermometer: Description & FeaturesDocumento7 pagineHVAC Gold Case Thermometer: Description & FeaturesFAIYAZ AHMEDNessuna valutazione finora