Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lecture 24 25 - Robot Programming and Work Cell Concepts

Caricato da

AJENACopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lecture 24 25 - Robot Programming and Work Cell Concepts

Caricato da

AJENACopyright:

Formati disponibili

Lecture 24 & 25

Robot Programming and

Work Cell concepts

Dr. D. Saravanakumar,

Assistant Professor, SMBS,

VIT - Chennai Campus.

Email: saravanakumar.d@vit.ac.in

22 & 25-Oct-18 MEE1030 – Robotics 1

Programming

• Three Programming Methods:

• Manual teaching

• Lead through teaching

• Programming languages

22 & 25-Oct-18 MEE1030 – Robotics 2

Programming

•Manual Teaching:

•Point to Point applications

•Lead Through Teaching:

•Continuous Path Programming

•Robot Simulator

•Advantage is direct programming but also

have disadvantages

22 & 25-Oct-18 MEE1030 – Robotics 3

Programming

•Disadvantages:

•Every motion is recorded and played back

in the same manner. So unintentional

motions also be played.

•Impossible to achieve exact required

velocity

•Memory size is required to store the data.

•Investment in a simulator is required.

22 & 25-Oct-18 MEE1030 – Robotics 4

Programming

•Programming Languages:

•AL

•VAL

•AML

•RPL

22 & 25-Oct-18 MEE1030 – Robotics 5

Classification of Robotics Languages

•First Generation Language

•Off-Line Programming used in combination

with teach pendant.

•VAL is an example of this kind.

•Second Generation Language

•World modelling and task oriented object

level language

22 & 25-Oct-18 MEE1030 – Robotics 6

Classification of Robotics Languages

•Second Generation Language:

•AML,VAL II etc…

•Structural Programming language

performing complex tasks.

•Apart from straight line interpolation

performs complex motions.

•Uses force, torque and other sensors.

•Data processing, file management and

keeping all records is done.

22 & 25-Oct-18 MEE1030 – Robotics 7

Classification of Robotics Languages

•World modelling and task oriented object

level language

•More advanced language is WORLD

modelling.

•Intelligence is required.

22 & 25-Oct-18 MEE1030 – Robotics 8

Modes

• In a robot, there are 3 basic modes of operation:

• Monitor mode

• Programmer define locations, load a particular

information in a register, save transfer programs

from storage.

• Move back and forth into edit or run mode

• Edit mode

• Programmer can edit or change set of instructions.

• Run or Execute mode

• Pre defined task can be executed in run mode.

• Debugging.

22 & 25-Oct-18 MEE1030 – Robotics 9

VAL System and Language

INTRODUCTION TO VAL:

• Programming language and operating system which

controls a robotic system.

• VAL programs also include subroutines, which are

separate programs.

LOCATIONS:

• Represents the position and orientation of robot tool.

• Two ways of representing robot locations

* Precision point.

* Cartesian coordinates and orientation angles.

• These are called transformations.

22 & 25-Oct-18 MEE1030 – Robotics 10

VAL System and Language

TRAJECTORY CONTROL:

Two methods to control the path of the robot.

• Interpolate between initial and final position, producing tool

tip curve in space.

• Move the robot tip in straight line path.

• For the first case, called JOINT INTERPOLATED

MOTION, the total time required is that of the longest joint

in the robot.

• In the second case, the motion speed of the robot tool tip can

be accurately controlled.

22 & 25-Oct-18 MEE1030 – Robotics 11

VAL System and Language

MONITOR COMMANDS:

To enter and execute a program, we have to

use monitor commands.

• Defining and Determining Locations.

• Editing Programs.

• Listing Program and Location Data.

• Storing, Retrieving and Location Data.

• Program control

22 & 25-Oct-18 MEE1030 – Robotics 12

VAL System and Language

Determining and Defining Locations:

• HERE and POINT command.

• WHERE command is used to display the current location.

• TEACH command is used for recording locations when

RECORD button is pressed.

22 & 25-Oct-18 MEE1030 – Robotics 13

VAL System and Language

Editing Programs:

• EDIT command.

Listing Program and Location Data:

• LISTL & LISTP commands.

Storing, Retrieving and Location Data:

• LISTF command.

• STOREP, STOREL and STORE commands.

• LOADP, LOADL and LOAD commands.

22 & 25-Oct-18 MEE1030 – Robotics 14

VAL System and Language

Storing, Retrieving and Location Data:

• In VAL II, an additional command is FLIST.

• Besides VAL and VAL II can accept commands.

COPY

RENAME

DELETE

22 & 25-Oct-18 MEE1030 – Robotics 15

VAL System and Language

Program control:

• SPEED command.

• EXECUTE command.

• ABORT command.

• DRIVE command.

• DO ALIGN command.

22 & 25-Oct-18 MEE1030 – Robotics 16

VAL System and Language

PROGRAM INSTRUCTIONS:

Describes some important instructions

included in the program.

• Robot Configuration Control.

• Motion Control.

• Hand Control.

• Location, Assignment and Modification.

• Program Control.

22 & 25-Oct-18 MEE1030 – Robotics 17

VAL System and Language

Robot Configuration Control:

• Execution of next motion of instruction other than a

straight line.

• RIGHTY or LEFTY command.

• ABOVE or BELOW command.

22 & 25-Oct-18 MEE1030 – Robotics 18

VAL System and Language

Motion Control:

• MOVE command.

• MOVES command.

• DRAW command.

• APPRO command.

• DEPART command.

• APPROS or DEPARTS commands.

• CIRCLE command.

22 & 25-Oct-18 MEE1030 – Robotics 19

VAL System and Language

Hand Control:

• OPEN and CLOSE commands.

• OPENI and CLOSEI commands.

• CLOSEI 75 in VAL II, if a servo-controlled gripper

is used, then this command causes the gripper to

close immediately to 75 mm.

• A gripper closing command is also given by

GRASP 20, 15

22 & 25-Oct-18 MEE1030 – Robotics 20

VAL System and Language

Hand Control:

• MOVEST PART, 30

Indicates the servo controlled end effector causes a

straight line motion to a point defined by the PART

and the gripper opening is changed to 30 mm.

• MOVET PART, 30

Causes the gripper to move to position, PART with

an opening of 30 mm by Joint Interpolated Motion.

22 & 25-Oct-18 MEE1030 – Robotics 21

VAL System and Language

Location, Assignment and Modification:

The instructions that do the same as

the corresponding monitor commands

• SET and HERE commands.

22 & 25-Oct-18 MEE1030 – Robotics 22

VAL System and Language

Program Control:

• SETI command sets the value of an integer variable

to the result of an expression

• TYPEI displays the name and value of an integer

variable.

• GOTO20

• GOSUB and RETURN

• PAUSE

22 & 25-Oct-18 MEE1030 – Robotics 23

VAL System and Language

Program Control:

• PROCEED

• SIGNAL

• IFSIG and WAIT

• RESET

22 & 25-Oct-18 MEE1030 – Robotics 24

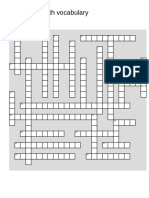

A Sample Robot Program

22 & 25-Oct-18 MEE1030 – Robotics 25

Work cell

• Robot + associated equipment.

• Workstation

• Workcell with single robot

• One work location along production line

consisting of several robot, including human

worker

• Problems:

• Physical design of the workcell

• Design of the control system which will

coordinate the activities, various components

22 & 25-Oct-18 MEE1030 – Robotics 26

Robot Workcell Layouts

•Robot-centered cell

•In-line robot cell

•Mobile robot cell

22 & 25-Oct-18 MEE1030 – Robotics 27

Robot-centered cell

• Single robot

• Located at the approximate

center.

• Partial circle

• Servicing a single

production machine

• Performing a single

production operation

• Disadvantage

• Delivery methods to be

provided

• More idle time

• Large cycle time

22 & 25-Oct-18 MEE1030 – Robotics 28

Robot-centered cell

•Application

•Die casting

•Loading and unloading

•Machining

•Plastic molding

•Welding

22 & 25-Oct-18 MEE1030 – Robotics 29

In-line Robot Cell

• Robot is located along a moving conveyor or other handling

system

• Perform task when product travels pass.

• Involve more than a single robot placed along the moving line

• E.g. Car body assembly, spot welding

• Categories of transfer

• Intermittent transfer

• Continuous transfer

• Nonsynchronous transfer

22 & 25-Oct-18 MEE1030 – Robotics 30

In-line Robot Cell

• Intermittent

• System moves the parts with start and stop motion

• Synchronous

• Parts moved simultaneously

• Registered at their next stop

• Fixed location and orientation

• Idle time

22 & 25-Oct-18 MEE1030 – Robotics 31

In-line Robot Cell

• Continuous

• Workparts are moved continuously along line at constant speed

• Position and orientation changes which can be fixed using -

• Moving baseline tracking system- additional DOF (mounting

robot on cart)

• Floor space, collision, interference

• Stationary baseline tracking system- tracking moving parts

• Sufficient computational and control

• Tracking window (Net work volume)

• Non synchronous

• ‘power and free’ part moves independently along the conveyor

in a stop-and-go fashion.- sensor

22 & 25-Oct-18 MEE1030 – Robotics 32

Mobile Robot Cells

• Capable of moving to the

various pieces of

equipment with in the

cell.

• Mounting robot on a

mobile base

• Floor or overhead rail

• Increased cost

• Application for Long

processing cycles

(enough time for

others)

• Optimum number of

machines

22 & 25-Oct-18 MEE1030 – Robotics 33

Work Cell Control

• Coordinating various activities that occur in work cell

• Coordination is accomplished by work cell controller.

• Workcell controller

• Performing computations

• Dealing with exceptional events such as equipment

breakdown

• perform irregular cycles- tool changing

• The functions performed are

• Sequence control

• Operator interface

• Safety monitoring

22 & 25-Oct-18 MEE1030 – Robotics 34

Work Cell Control - Sequence control

• Control of the sequence of activities in the workcell.

• Control of simultaneous activities

• Making decisions to proceed with the work cycle based

on events that occur in the cell

• Making decisions to stop or delay the work cycle based

on events that occur in the cell

22 & 25-Oct-18 MEE1030 – Robotics 35

Work Cell Control - Operator interface and

Safety monitoring

• Safety monitoring

• Monitor its own operation for unsafe or

potentially unsafe conditions in cell.

• Operator interface

• The human is an integral part of the workcell

• Emergency stop conditions

• Program editing or data input by operator

22 & 25-Oct-18 MEE1030 – Robotics 36

Interlocks

• To make sure that a raw workpart was at the pickup

location on the conveyor before the robot tried to

grasp the part

• To determine when the machining cycle was

completed before the robot attempts to load the part

into the fixture.

• To indicate that the part has been successfully

loaded so that the automatic machining cycle can

begin

22 & 25-Oct-18 MEE1030 – Robotics 37

Interlocks

• Regulating the sequence in which various elements

of the cycle are carried out

• Output Interlocks- signal from workstation. Eg work

part have been safely loaded

• Input Interlocks – Wait signal (Properly loaded to

the fixture of machine tool. Limit switches can be

used)

22 & 25-Oct-18 MEE1030 – Robotics 38

Potrebbero piacerti anche

- Lecture 16, 17 & 18 Robot Kinematics: Dr. D. Saravanakumar, Assistant Professor, SMBS, VIT - Chennai Campus. EmailDocumento55 pagineLecture 16, 17 & 18 Robot Kinematics: Dr. D. Saravanakumar, Assistant Professor, SMBS, VIT - Chennai Campus. EmailAJENANessuna valutazione finora

- Lecture 5 6 - Actuators For Robots PDFDocumento26 pagineLecture 5 6 - Actuators For Robots PDFAJENANessuna valutazione finora

- Lecture 10, 11 12 - Sensors For Robots PDFDocumento65 pagineLecture 10, 11 12 - Sensors For Robots PDFAJENANessuna valutazione finora

- Challenging TaskDocumento22 pagineChallenging TaskAJENANessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 9th Grade Math Vocabulary 1683069284Documento2 pagine9th Grade Math Vocabulary 1683069284BABY MARIE APASNessuna valutazione finora

- Questions About GenerosityDocumento7 pagineQuestions About GenerosityEmmylouNessuna valutazione finora

- Ghalib and His PoetryDocumento14 pagineGhalib and His PoetryAreef OustaadNessuna valutazione finora

- The Heart of Oracle How The Core Architecture Works Martin Widlake PDFDocumento45 pagineThe Heart of Oracle How The Core Architecture Works Martin Widlake PDFronrodriNessuna valutazione finora

- Interview Questions and AnswerDocumento3 pagineInterview Questions and AnswerDitha CastillonNessuna valutazione finora

- Fire Safety Ws4Documento1 paginaFire Safety Ws4Donnette DavisNessuna valutazione finora

- K80S & K120S Wiring DiagramDocumento2 pagineK80S & K120S Wiring DiagramrawsteelNessuna valutazione finora

- Matlab Lecture 6Documento70 pagineMatlab Lecture 6Ub UsoroNessuna valutazione finora

- Grammar Tick ( ) A, B, or C To Complete The SentencesDocumento3 pagineGrammar Tick ( ) A, B, or C To Complete The SentencesAndre SilvaNessuna valutazione finora

- Non Receipt of Arrears of Terminal Benefits As Per 7 CPC: TH THDocumento5 pagineNon Receipt of Arrears of Terminal Benefits As Per 7 CPC: TH THJaswinder SinghNessuna valutazione finora

- Calculus (Rate of Change)Documento5 pagineCalculus (Rate of Change)landscapesinthemistNessuna valutazione finora

- Writing Analytically 8Th Edition David Rosenwasser All ChapterDocumento67 pagineWriting Analytically 8Th Edition David Rosenwasser All Chapterallison.nunez856100% (4)

- Tito Puente-Extention FormDocumento2 pagineTito Puente-Extention Formapi-550368270Nessuna valutazione finora

- Longchenpa Rabjam - Commentary On The Precious Treasury of DharmadhaatuDocumento462 pagineLongchenpa Rabjam - Commentary On The Precious Treasury of Dharmadhaatulanrover100% (12)

- PragmatismDocumento36 paginePragmatismtasneemNessuna valutazione finora

- 1Documento27 pagine1Cosmin VulpeNessuna valutazione finora

- ErroresDocumento6 pagineErroresBernard Surita PlacenciaNessuna valutazione finora

- Vam Shi ResumeDocumento2 pagineVam Shi ResumeDharmapuri Shri lekhaNessuna valutazione finora

- EF3e Preint Endtest B PDFDocumento6 pagineEF3e Preint Endtest B PDFData BaseNessuna valutazione finora

- QuotationDocumento12 pagineQuotationRaghav RamamurthyNessuna valutazione finora

- Mini ProjectDocumento12 pagineMini ProjectTamizh KdzNessuna valutazione finora

- TP V Needs Analysis 8-20Documento13 pagineTP V Needs Analysis 8-20Anonymous 1nE8IBPFLsNessuna valutazione finora

- John Fraser Jan 5th 2020 Rev3 PDFDocumento2 pagineJohn Fraser Jan 5th 2020 Rev3 PDFapi-300781429Nessuna valutazione finora

- PoemDocumento3 paginePoemTAI SOH MOI KPM-GuruNessuna valutazione finora

- Sparx EA-User InterfaceDocumento694 pagineSparx EA-User Interfacesarma5153Nessuna valutazione finora

- Semana 4 - Ingles 7 - First ConditionalDocumento2 pagineSemana 4 - Ingles 7 - First ConditionalAntonio DelgadoNessuna valutazione finora

- FE Project StructureDocumento2 pagineFE Project StructureTuan TruongNessuna valutazione finora

- Church History (By Watchman Nee)Documento76 pagineChurch History (By Watchman Nee)Yohannes BushoNessuna valutazione finora

- 2.1basic Assemblers FunctionsDocumento15 pagine2.1basic Assemblers FunctionsChanchal Rawat100% (1)

- Tenaga D. Silat ArticleDocumento185 pagineTenaga D. Silat Articlebrendan lanza100% (1)