Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Motor-Operated Adjusting Carrier.1407

Caricato da

JR RZ0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni6 pagineMotor-operated Adjusting Carrier.1407

Titolo originale

Motor-operated Adjusting Carrier.1407

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMotor-operated Adjusting Carrier.1407

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni6 pagineMotor-Operated Adjusting Carrier.1407

Caricato da

JR RZMotor-operated Adjusting Carrier.1407

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 6

Belt Sway Detection and Correcting Equipment Matsu ma

Belt Sway Detection and Correcting Equipment

Motor-Operated Adjusting Carrier

‘Swaying of the conveyor belt causes loads to

fall and conveyor belt damage.

An adjustment of the conveyor belt is the only

way to correct this swaying.

Matsushima's Motor-Operated Adjusting

Carrier detects conveyor belt sway and

automatically corrects it, greatly reducing the

‘time and cost needed for operation

control and maintenance.

y

Ideal protection for your

Carrier side mounting type

materials, your products Model HAB-MC

and your conveyor belt

Falling loads and the resulting accidents

can be prevented.

‘As an additonal benefit, your conveyor belt ite

is extended because the breakage and damage

caused by swaying and twisting is prevented.

Return side mounting type

Model IAB MN

Easy installation

and maintenance

‘The Motor-Operated Adjusting Carrier requires:

no extra installation space, It can easily be

‘mounted on your conveyor, and is built to operate

even under severe environmental concitions, ———

The Motor-Operated Adjusting Carrier replaces ae ev

‘conventional manual adjustment and simplifies iain

‘convevor belt maintenance. (A: Qurtematic rasat tyne-

Operation Principles of Motor-Operated Adjusting Carri

Operation Principles

1

|- When the conveyor belt sways, the bet edge pushes the

touch pully it a slanted poston Then, the potentiometer

inthe detoctor rotates at an angen proportion to the ploy

slant angle, and the miroswitch in the detector operates to

sexi the direction for coestion at the same ie.

2, The positioner in the motor actuator compares the

‘potentiometer resistance value ofthe detector wit that ofthe

‘motor actuator, and operates the motor actuator to turn the

dusting cairn a crecton that sorees withthe potentiometer

resistance value of the motor actuator to conect the say.

Note The adusing cor me

tosonocar (rneton 50

eat he dvaon wher te

‘arveyer ae devas ay 9

Siracon shown nthe gue

ecg a wn th bh

hatecton

se itt

3. The adlusting carrier maintains the slant angle after the

‘conveyor bet positon has been corrected andthe bolt edge

{no longer in contact with the touch pulley ifthe conveyor

belt sways in the same direction again, the adjusting carer

wil automaticaly move to conect the belt sway.

4. If the conveyor sways in the opposite diraction, the

‘aciustina carer will tun in the reverse direction to adiust

the conveyor bolt, correcting the sway at the moment the

belt edge pushes against the touch pulley onthe other side

tosiantit

Arrangement of Motor-Operated

Adjusting Carrier Components

a

)

init stn

Application Exar

Constant Feed Weigher (CFW)

(Constant Feeder)

Initon and stee! plants or cement plans, a constant feeders

attached to the bottom of the hopper to remove a constant

‘amount of material fom the hopper. Tis feeder uses a fat

bell, ad flat belts cheracteiscally sway under certain

‘operation and maintenance condtons. Asa result, the belt

‘edge frequently suffers damage caused by rubbing against

‘the detection arm of the load cl. The oly way to soe this

hile the conveyer is sil running, This acustment must be

‘complotod quick, or humiy wil causo the materials to

‘tick tothe belt andthe conveyor fame wll wap.

‘The retum side mounting type Motor-Operaied Adlusting

Carer iS widely used in ron and steel plants as well as

‘cement plats to corect conveyor belt sway, and has proven,

results inthe reduction of maintenance cos, prevention of

problem is by the poston adjustment of tal puley bearings accidents, and reliable performance.

iso , \ Gempound hopper

Conveyor scale

Detector

4 Motor-onerated adjusting carrer for CFW

conveyor

Motor Actuator

TTiuanions

levis brackets

116mm fornenmal operation “no vou age on he runs

Speed | 197/298 main (0/60 He) Son Ro ee]

oes E001) witnomalabstad | Matern

2 | TBKN(IBO em Special

[Postion Lint Sich | Oneeochorforerdinit andbackwardimt | | Enclosure P67

Potentometr | Fr wos feedback (HO) | owacevmpaaue | ~ 107 t0 507%

Diving Motor | Reversible motor 400 W790 inating) | [Satna tch uly | 4° rae.

Posiioner Hevea pe wept sauna wrp | [Potentometer | Fresno age TT

‘Space Honler | 200.7 er pewrten feral condeste)| [Postion Lt Switch |Get ang

Thermal lay | With thormal vip contact signal | Gear Rao an ___|

200 (100 V) S060 He eam GW Cana vr

Power Consumption | 65W

“Thepotentiomster opt son fv Glan and canal bo wed wry

stad aie 125 an? «5m

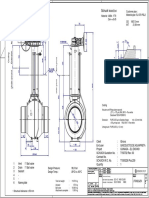

@ External Dimensions in mm

nce ae

type

‘Actuating Device

Sela out

retsea wate men)

Detecting Device

x e z

| \

coe aie:

I st | 1

a = | Mina

ssgatoctdnbaitetsamnmd |? pete eg me

Rectretamaanamaregsers — iatedoahanbauatadenead

EERIE vin oud le 20,

Blee)wla]alrl oo

500g, || 780 70 | Ho [so 08 | 5

oon ano) wo as row [as

sme "a ae es

tor es it oe | 0 son | 20 [as |

oo) | 1280 | 1990 | aT) eno | 227 | ats

it 150 | 25 | as,

| 98 10 30, an ams

io ea fe | [oer oe| [imeem Tet Bae

wo} [8 efct sas wr [ Ws aoa [aon [aie [ans

teeter _ fee 36 5 Fe Ps aT [bomen tee oe Po

insane | Tes | se fo een te || oo oo om wn) ase

Waa Ta (8a) gg [| et | Wat) | ote [to | Ses a5

toavcarat [eo | [at 20 | 0 Faen, vat a] [ao 0 emt noses

+The door of traci Sand Lando etre

Tadbamenonfevonh woh

Detecting Device

onvyertame

BREET ener) ype

19. 0 chalet if ae HE

: al 2 SST

ee Is Bo See oWatte 125 ans m

{40 fat wis: $200 ren max) tt

Cats WO TO :

Cable sie: B10 12 da. £2.16: eo hk wid 1260 men)

Tresbavedagam isle heen) 22232 ve hes Betws HOO em)

Shee eas

ee

En tet oe

wwlwlale[elelt ce

wwe aw) aon eo

1 | aa| 700] ial no-prsasot | S00

a Tae es Season | wo

100 0m Tineanorstsn | 0

sea i600 | 70 8109 | 210 75 || o-onenese | a0

tao 0 ose | 00

{300 sss | 0

HNO ano on a 89 Ta| 210 a0 an

rape |) eo em] em ee 0

HAO [on got] ro [as 20

Fase rn 2 [1500 | oz? an | 9 7a

Pasa co | [zm an it) lo “a0

(CHmg-wf-aonosan | 2000 Tza20 | 2400. soso | 2157 | 1 ‘2000

Matsushima

Matsushima Measure Tech

1B Model Designation

HaB-O0-000 OO

1 ta grating cna

© :canerude mot ype

ipatarside mount Ube

Bot wit bite

cHAB-104e

May. 2012

ad

e888

® Connaction Diagram (Hold Type Detectors) for Unidirectional Conveyor Application

+ neal wen yom. Nord to comes those ara

cri sete mong

ip No 8 eter

iE,

Distr

oH

Fete sie moirg

“a

Netes:1. auto ae! pe deuce ao aval.

2. es Beton mina ond A? ad

‘ve capar th rer el st rng to

‘nov theoto-Opeated Asting Crier

broth nial poston sare conayor

‘cation ial nee Oe.

NPE Howtng postions .

‘hen ah

ul

Plnea tobe cto comer Sek

epee to seu cance nd ste agpeton

| erate cf we gow etc

Sy hd oe ye te,

A

Matsushima Measure Tech Co.,Ltd.

[eRe mca mcmeens xranvens Same ee sams amen euro

heoeeenatnbinemacin na earaneins mince

Potrebbero piacerti anche

- 945 Cci 100dpc Drag Production Wellhead Choke New ConstructionDocumento4 pagine945 Cci 100dpc Drag Production Wellhead Choke New ConstructionAnderson SiqueiraNessuna valutazione finora

- en VEGAFLEX 81-4-20 MA HART Two Wire Rod and Cable ProbeDocumento2 pagineen VEGAFLEX 81-4-20 MA HART Two Wire Rod and Cable ProbeJR RZNessuna valutazione finora

- 5 - Empaques Metalicos Tipo Anillos R API PDFDocumento1 pagina5 - Empaques Metalicos Tipo Anillos R API PDFJR RZNessuna valutazione finora

- KHD G110 BrochureDocumento8 pagineKHD G110 BrochureMauricio Oropeza CabreraNessuna valutazione finora

- 315 - Isolation Valves For Coking Service - March 2019 - ReducedDocumento4 pagine315 - Isolation Valves For Coking Service - March 2019 - ReducedJR RZNessuna valutazione finora

- en Level and Interface Measurement in Liquids VEGAFLEX 81-83-86Documento28 pagineen Level and Interface Measurement in Liquids VEGAFLEX 81-83-86JR RZNessuna valutazione finora

- The Alloy Valve Stockist Catalogue PDFDocumento53 pagineThe Alloy Valve Stockist Catalogue PDFShan ShahNessuna valutazione finora

- Valvula de Bola GF-RF Nps30 Cl600 - Ag - GearDocumento1 paginaValvula de Bola GF-RF Nps30 Cl600 - Ag - GearJR RZNessuna valutazione finora

- GEN 2000 Electronics Radiation-Based Weigh Systems For ConveyorsDocumento2 pagineGEN 2000 Electronics Radiation-Based Weigh Systems For ConveyorsJR RZNessuna valutazione finora

- Rectiequipos SAS - Bogotá Colombia PDFDocumento5 pagineRectiequipos SAS - Bogotá Colombia PDFJR RZNessuna valutazione finora

- Safe Practices For The Preparation of Containers and Piping For Welding and CuttingDocumento4 pagineSafe Practices For The Preparation of Containers and Piping For Welding and Cuttingingrcl100% (1)

- Operation Manual Inno BlidDocumento10 pagineOperation Manual Inno BlidJR RZNessuna valutazione finora

- GB CL600 - UG - GearDocumento1 paginaGB CL600 - UG - GearJR RZNessuna valutazione finora

- Standard Drawing Adr PDFDocumento10 pagineStandard Drawing Adr PDFJR RZNessuna valutazione finora

- 2600 Series Catalog R3Documento96 pagine2600 Series Catalog R3Mrr Afrasiabi100% (1)

- Team Pipe RepairDocumento24 pagineTeam Pipe RepairDavid Rios CruzNessuna valutazione finora

- Certificate of Authorization: This Is To Certify ThatDocumento1 paginaCertificate of Authorization: This Is To Certify ThatJR RZNessuna valutazione finora

- Apc 2000Documento4 pagineApc 2000JR RZNessuna valutazione finora

- Apr 2000alwDocumento4 pagineApr 2000alwJR RZNessuna valutazione finora

- GS01C25B01 01enDocumento17 pagineGS01C25B01 01enJR RZNessuna valutazione finora

- Iso 5752Documento56 pagineIso 5752JR RZNessuna valutazione finora

- 210 Valve Wtfy PDFDocumento50 pagine210 Valve Wtfy PDFJR RZNessuna valutazione finora

- Tankdome®: Aluminum Geodesic Dome: General InformationDocumento3 pagineTankdome®: Aluminum Geodesic Dome: General InformationJR RZNessuna valutazione finora

- Rectiequipos SAS - Bogotá Colombia PDFDocumento5 pagineRectiequipos SAS - Bogotá Colombia PDFJR RZNessuna valutazione finora

- Slab GateDocumento14 pagineSlab GateJR RZNessuna valutazione finora

- FCCU Expansion Joints References 2017Documento28 pagineFCCU Expansion Joints References 2017JR RZ100% (1)

- DV BUD Brochure 2015v2-Secured PDFDocumento16 pagineDV BUD Brochure 2015v2-Secured PDFJR RZNessuna valutazione finora

- Product Data Sheet SP-2888 RGDocumento8 pagineProduct Data Sheet SP-2888 RGJR RZNessuna valutazione finora

- DV TUD Brochure 2015v2-SecuredDocumento16 pagineDV TUD Brochure 2015v2-SecuredJR RZNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Bazooka February 2023 - CompressedDocumento146 pagineBazooka February 2023 - Compressedsandeep kumarNessuna valutazione finora

- Dwnload Full Business Data Networks and Telecommunications 8th Edition Panko Test Bank PDFDocumento36 pagineDwnload Full Business Data Networks and Telecommunications 8th Edition Panko Test Bank PDFchebaccoeggnogoetw7100% (15)

- Catalogo JoinMasterDocumento64 pagineCatalogo JoinMasterAyubkhan2Nessuna valutazione finora

- Pavement MarkingDocumento3 paginePavement Markingsethu1091Nessuna valutazione finora

- What Does A Fishing Schooner Have To Do With STEM Education?Documento1 paginaWhat Does A Fishing Schooner Have To Do With STEM Education?Hartford CourantNessuna valutazione finora

- Chapter 6 - Public ProcurementDocumento39 pagineChapter 6 - Public ProcurementwawaNessuna valutazione finora

- THE Bicicle Effect: Juan Carlos KreimerDocumento5 pagineTHE Bicicle Effect: Juan Carlos KreimerPatriciaNessuna valutazione finora

- Personal ConveyanceDocumento2 paginePersonal ConveyanceMorris TruckingNessuna valutazione finora

- Berhanu's Final Internship Report AastuDocumento50 pagineBerhanu's Final Internship Report AastuphilipostamruNessuna valutazione finora

- Moveable Span Bridge Study Volume 2 Bascule and Swing Span Bridges Part 2 PDFDocumento54 pagineMoveable Span Bridge Study Volume 2 Bascule and Swing Span Bridges Part 2 PDFaqhammam100% (1)

- Malindo AirDocumento22 pagineMalindo AirKHAIRIL HAJAR BINTI AHMADNessuna valutazione finora

- Kompilasi Soal Paket BDocumento10 pagineKompilasi Soal Paket Babdul wahidNessuna valutazione finora

- 17 Special Tools-N900 Series JMCDocumento16 pagine17 Special Tools-N900 Series JMCRusonegroNessuna valutazione finora

- NHW 4e Upp-Int WB Answer KeyDocumento12 pagineNHW 4e Upp-Int WB Answer KeySophia KastrovskayaNessuna valutazione finora

- Final Thesis - Chapter 1-WPS OfficeDocumento36 pagineFinal Thesis - Chapter 1-WPS OfficeBai-Sandra Tabua Macarimbang100% (1)

- Westside Subway Final EIR ReleaseDocumento3 pagineWestside Subway Final EIR ReleaseMetro Los AngelesNessuna valutazione finora

- PC300 8M0 PDFDocumento12 paginePC300 8M0 PDFDin Udin0% (1)

- DPH Elring CrossDocumento87 pagineDPH Elring Crossj_hernandez_chNessuna valutazione finora

- Mechanical EngineeringDocumento42 pagineMechanical EngineeringNagendra NaiduNessuna valutazione finora

- Cokaliong Vs UcpbDocumento11 pagineCokaliong Vs UcpbRavenFoxNessuna valutazione finora

- Defenses of The Common CarrierDocumento6 pagineDefenses of The Common CarrierXian Alden67% (3)

- Construction Vibration AssessmentDocumento19 pagineConstruction Vibration AssessmentEric ArevaloNessuna valutazione finora

- 2018 - Clarity - Plug - in - Hybrid - BrochureDocumento8 pagine2018 - Clarity - Plug - in - Hybrid - BrochureChristian BatistaNessuna valutazione finora

- Disconnected Streets and The Effect On Walkability in LiverpoolDocumento59 pagineDisconnected Streets and The Effect On Walkability in LiverpoolJared AlvesNessuna valutazione finora

- DDL Nop Since 60 DaysDocumento200 pagineDDL Nop Since 60 DaysSO Savlaj 1 MSEDCLNessuna valutazione finora

- Vespa Vespa 946 Vespa 946 125 4T 3V Abs - 2013-2015Documento66 pagineVespa Vespa 946 Vespa 946 125 4T 3V Abs - 2013-2015Tara ChandNessuna valutazione finora

- EC 49StateCatalog08Documento347 pagineEC 49StateCatalog08Lee Prine0% (1)

- RFD 3-1-2017Documento24 pagineRFD 3-1-2017vinitNessuna valutazione finora

- New York Tourist Map PDFDocumento1 paginaNew York Tourist Map PDFRaquelNessuna valutazione finora

- Supply Chain Management - Future Trends. Prihor AdinaDocumento11 pagineSupply Chain Management - Future Trends. Prihor AdinaAdinaOanaPrihor100% (2)